You know that proper ventilation is essential for maintaining the efficiency and safety of your laser cutter.

But did you know that it also offers a multitude of benefits that can greatly enhance your overall cutting experience?

By ensuring that harmful fumes and smoke are effectively removed, proper ventilation minimizes the risk of fires and protects you from inhaling hazardous chemicals.

Additionally, it improves cutting precision by preventing heat build-up and maintaining optimal operating conditions.

With a well-ventilated workspace, you can also reduce material waste, as the smoke and debris are efficiently extracted, leaving clean and precise cuts.

Moreover, proper ventilation extends the lifespan of your laser cutter by preventing the accumulation of harmful contaminants.

Not only does it keep your equipment in prime condition, but it also maintains a safe and healthy working environment for you and your team.

Lastly, by complying with safety regulations and standards, proper ventilation ensures that you are operating within legal requirements and mitigating potential risks.

So, don’t overlook the importance of proper ventilation for your laser cutter – it’s not just about safety, but also about maximizing efficiency and performance.

Key Takeaways

- Proper ventilation improves cutting precision and reduces material waste

- It extends the lifespan of a laser cutter by preventing accumulation of harmful contaminants

- Proper ventilation creates a safe and healthy working environment for the operator and team

- Compliance with safety regulations and standards is crucial for a safe working environment

Minimize the Risk of Fires and Harmful Fumes

To minimize the risk of fires and harmful fumes, you’ve got to make sure proper ventilation is in place and let the smoke go up in smoke.

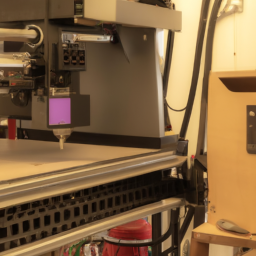

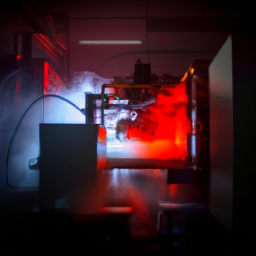

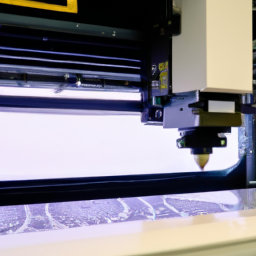

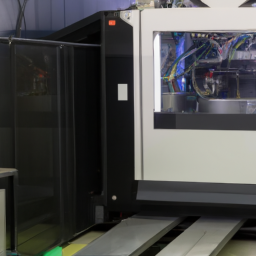

Proper ventilation is crucial in laser cutters to increase productivity and enhance overall efficiency. Laser cutting produces a significant amount of smoke and toxic fumes that can be hazardous to both the machine and the operator. Without adequate ventilation, the smoke can accumulate inside the machine, leading to potential fire hazards and health risks.

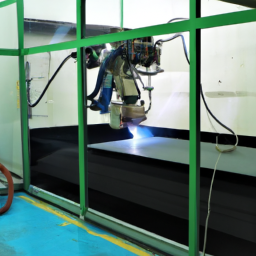

By implementing proper ventilation systems, the smoke and fumes are efficiently extracted, reducing the risk of fires and ensuring operator safety. In addition, proper ventilation helps maintain a clean and clear working environment, improving cutting precision and ensuring accurate results.

With proper ventilation in place, you can take the next step in improving cutting precision.

Improve Cutting Precision

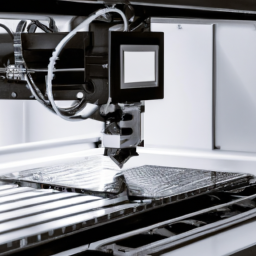

Enhancing cutting precision can be achieved by ensuring adequate airflow in the vicinity of the laser cutting machine. Proper ventilation helps to increase efficiency and enhance productivity by maintaining a stable temperature and removing any excess heat generated during the cutting process. This prevents the material from warping or distorting, resulting in more accurate and precise cuts.

Additionally, proper ventilation helps to remove any debris or particles that may accumulate on the lens or interfere with the laser beam, further improving the cutting precision. By optimizing the airflow, you can ensure that the laser cutter operates at its best, producing high-quality cuts consistently.

This, in turn, reduces material waste and maximizes the utilization of the materials being cut. With improved cutting precision, you can proceed to the subsequent section about reducing material waste seamlessly.

Reduce Material Waste

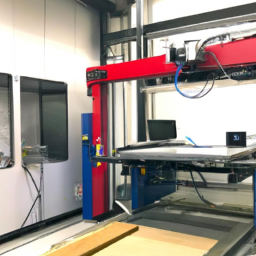

By minimizing material waste, companies can save costs and increase sustainability. One way to achieve this is by using nesting software, which optimizes the layout of parts on a sheet of metal. This reduces scrap and maximizes material utilization, improving energy efficiency and enhancing productivity.

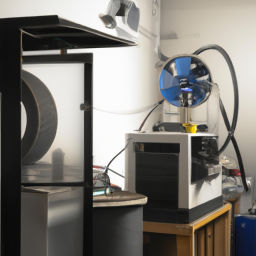

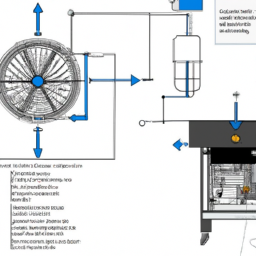

With proper ventilation, such as an efficient exhaust system, the laser cutter can operate at its optimum level, preventing overheating and minimizing downtime due to maintenance issues. By reducing material waste, companies not only save money but also contribute to a more sustainable manufacturing process.

Moreover, efficient ventilation helps extend the lifespan of the laser cutter by preventing the accumulation of debris and harmful fumes. This ensures a longer operational life, minimizing the need for costly repairs or replacements.

Extend the Lifespan of the Laser Cutter

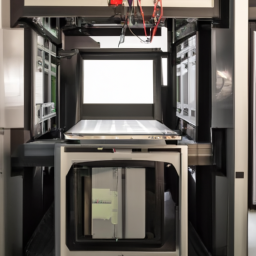

With efficient exhaust systems in place, companies can ensure the laser cutter keeps cutting for the long haul, giving them bang for their buck. Proper ventilation not only extends the lifespan of the laser cutter but also increases efficiency and improves productivity. By removing smoke, fumes, and dust from the cutting area, ventilation systems prevent these particles from accumulating on the laser lens, which can degrade its performance and require frequent cleaning or replacement. Moreover, a well-ventilated environment maintains a consistent temperature, preventing overheating and reducing the risk of mechanical failures. This translates into less downtime and increased productivity. Investing in proper ventilation is a smart move for any company looking to maximize the lifespan of their laser cutter while increasing efficiency. By doing so, they can maintain a safe and healthy working environment for their employees.

Maintain a Safe and Healthy Working Environment

Creating and maintaining a safe, healthy work environment is crucial for the well-being and satisfaction of employees. Proper ventilation for laser cutters is an essential aspect of this effort. By providing adequate ventilation, you can increase productivity and prevent equipment malfunction.

Laser cutting produces fumes and smoke that can be harmful if inhaled, leading to respiratory issues and reduced productivity. Proper ventilation systems remove these harmful particles from the air, ensuring a safe and healthy working environment.

In addition, efficient ventilation helps prevent equipment malfunction by reducing the buildup of dust and debris that can clog the laser cutter’s components. This not only extends the lifespan of the machine but also ensures consistent and accurate cutting results.

By maintaining a safe and healthy working environment through proper ventilation, you can comply with safety regulations and standards, protecting both your employees and your business.

Comply with Safety Regulations and Standards

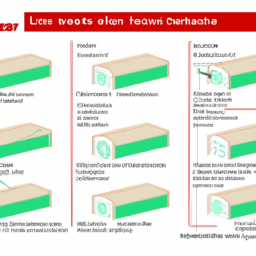

Ensure a safe and healthy work environment by following safety regulations and standards. This allows you to focus on your tasks without worrying about potential hazards. Compliance with workplace guidelines is crucial to ensure worker well-being and prevent accidents when operating laser cutters.

Proper ventilation is a key aspect of these guidelines. It helps to remove harmful fumes and dust generated during the cutting process. Laser cutters produce toxic gases, such as nitrogen oxide and carbon monoxide, which can have detrimental effects on health if inhaled. By implementing a ventilation system, you can effectively control the release of these hazardous substances, reducing the risk of respiratory problems and other health issues.

Additionally, proper ventilation helps maintain optimal air quality. It prevents the buildup of potentially flammable particles and ensures a safe working environment. By prioritizing compliance with safety regulations and standards, you can safeguard your workers’ well-being and create a productive workspace.

Frequently Asked Questions

How does proper ventilation reduce the risk of fires in laser cutters?

Proper ventilation reduces the risk of fires in laser cutters by minimizing smoke exposure and improving air quality. When laser cutters operate, they produce smoke, fumes, and potentially harmful particles. Without adequate ventilation, these substances can accumulate and increase the risk of fire.

However, with proper ventilation systems in place, the smoke is efficiently removed, reducing the chances of fires and ensuring a safer working environment. Additionally, proper ventilation helps protect operators from respiratory issues and maintains the longevity of the laser cutter by improving air quality.

What are the harmful fumes that can be emitted during laser cutting?

Harmful fumes emitted during laser cutting can pose significant health risks. These fumes consist of volatile organic compounds (VOCs), such as formaldehyde and benzene, as well as particulate matter. Breathing in these fumes can lead to respiratory irritation, eye and throat irritation, and even long-term health issues.

Proper ventilation is crucial to remove these harmful fumes from the laser cutter’s workspace, ensuring a safe and healthy environment for operators and preventing potential health hazards.

Can proper ventilation improve the precision of laser cutting?

Proper ventilation, oh what a wonder! It not only saves your lungs from the toxic fumes of laser cutting, but it also enhances precision. Ventilation techniques for laser cutting can greatly impact the performance of your cutter.

By removing smoke, dust, and debris, ventilation ensures a clean and clear cutting path. This allows for accurate and precise cuts, making your laser cutter a precision beast.

So, embrace the power of ventilation and elevate your laser cutting game!

How does ventilation help in reducing material waste during laser cutting?

Ventilation plays a crucial role in reducing material waste during laser cutting. By removing fumes and particles generated during the process, proper ventilation ensures a cleaner work environment, reducing the chances of debris interfering with the laser beam and compromising the precision of the cut.

Additionally, efficient ventilation systems enable enhanced cutting speed by preventing the accumulation of heat and maintaining optimal operating conditions. This results in reduced environmental impact and increased productivity.

What are the safety regulations and standards that laser cutter operators need to comply with?

To ensure safe operation, laser cutter operators must adhere to strict safety regulations and compliance requirements. These regulations establish guidelines for the safe handling of laser equipment, including proper training, protective measures, and regular maintenance. Compliance with these standards helps prevent accidents, such as fires or chemical exposures, and ensures the protection of both operators and the environment. Failure to comply with these regulations can result in fines, penalties, or even the shutdown of operations.

Conclusion

In conclusion, it’s absolutely imperative that you take proper ventilation for your laser cutter seriously. Not only will it minimize the risk of fiery disasters and those pesky harmful fumes, but it will also enhance the precision of your cuts and reduce material waste.

Additionally, it’ll extend the lifespan of your beloved laser cutter, ensuring it serves you faithfully for years to come. Let’s not forget the cherry on top: maintaining a safe and healthy working environment while complying with safety regulations.

So, don’t be a ventilation skeptic, embrace it for the sake of your cutter and your well-being!