Do you believe that laser cutters are extremely dangerous and should be avoided at all costs? Think again! Contrary to popular belief, laser cutters can actually be safe to use when proper safety precautions are followed.

In fact, many common myths surrounding laser cutter safety have been debunked, and it’s time to set the record straight.

One prevalent myth is that laser cutters always produce toxic fumes that are harmful to breathe. While it’s true that laser cutters can produce fumes, the reality is that with the right ventilation systems in place, any potential health risks can be minimized.

Another misconception is that laser cutters are only for professionals and cannot be used by amateurs. The truth is, laser cutters can be operated by anyone with the right knowledge and training.

In this article, we will explore and debunk ten common laser cutter safety myths. From the materials laser cutters can work with to their maintenance requirements, we will provide you with the facts you need to know.

So, let’s dive in and separate fact from fiction when it comes to laser cutter safety.

Key Takeaways

- Laser cutters can be safe to use when proper safety precautions are followed

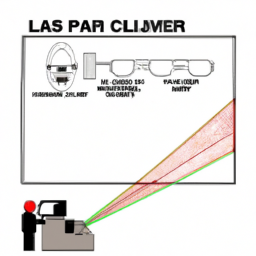

- Laser cutters emit a powerful beam of light that can cause harm

- Precautions include wearing protective eyewear, ensuring proper ventilation, and keeping a safe distance

- Proper training and material selection can further reduce health risks

Myth: Laser cutters are extremely dangerous and should be avoided at all costs.

Don’t believe the hype – laser cutters aren’t as dangerous as they’re made out to be and can actually be used safely with proper precautions. While it’s true that laser cutters emit a powerful beam of light that can cause harm, they can be safely operated by following laser cutter safety precautions.

These precautions include wearing protective eyewear to shield your eyes from the laser beam, ensuring proper ventilation in the workspace to prevent the accumulation of harmful fumes, and keeping a safe distance from the laser cutter while it’s in operation.

Additionally, laser cutters offer numerous benefits that make them worth using. They provide precise and accurate cuts, reduce the risk of injury compared to traditional cutting methods, and allow for intricate designs and patterns.

Fact: laser cutters can be safe to use when proper safety precautions are followed.

Fact: Laser cutters can be safe to use when proper safety precautions are followed.

Remember, when you follow the necessary safety measures, laser cutters can be as safe as a walk in the park. To ensure your safety while using a laser cutter, it is crucial to understand and implement the recommended safety guidelines. Here are some key benefits of laser cutters for small businesses:

| Benefits of Laser Cutters for Small Businesses | Safety Guidelines for Using Laser Cutters at Home |

|---|---|

| Increased precision and accuracy | Wear appropriate personal protective equipment |

| Versatility in cutting various materials | Ensure proper ventilation in the workspace |

| Faster production time | Keep a fire extinguisher nearby |

By adhering to these guidelines, you can minimize the risk of accidents and injuries. It is important to note that laser cutters can be safe as long as you take the necessary precautions. With that in mind, let’s move on to debunking the myth that laser cutters always produce toxic fumes that are harmful to breathe.

Myth: Laser cutters always produce toxic fumes that are harmful to breathe.

Ensure your health and well-being by understanding the truth about the fumes produced by laser cutters. Contrary to popular belief, laser cutters don’t always produce toxic fumes that are harmful to breathe. Here are some important facts to consider:

-

Laser Cutter Ventilation: Laser cutters are equipped with ventilation systems that effectively remove fumes from the cutting area, minimizing the risk of exposure. These systems ensure that the air is constantly circulated and filtered, maintaining a safe working environment.

-

Proper Training: It’s crucial to receive proper training on how to operate a laser cutter safely. This includes understanding the ventilation system, knowing how to use it correctly, and being aware of any potential risks associated with the materials being used.

-

Material Selection: Different materials can produce varying levels of fumes when cut with a laser. By carefully selecting materials that are known to be safe and low in toxicity, you can further reduce any potential health risks.

-

Regular Maintenance: Regular maintenance and inspection of the ventilation system is essential to ensure its effectiveness. By keeping the system clean and well-maintained, you can ensure that it’s working optimally to remove any fumes generated during the cutting process.

Understanding these facts about laser cutter ventilation and the importance of proper training and maintenance will help you make informed decisions and minimize any potential health risks. Fact: Laser cutters can produce fumes, but proper ventilation systems can minimize any potential health risks.

Fact: Laser cutters can produce fumes, but proper ventilation systems can minimize any potential health risks.

You’ll be surprised to learn that proper ventilation systems can significantly reduce any potential health risks associated with fumes produced by laser cutters. In fact, studies have shown that a well-maintained ventilation system can decrease the concentration of harmful fumes by up to 90%.

Ventilation systems are crucial in removing and filtering the fumes generated during laser cutting processes. These systems work by capturing the fumes at the source and directing them outside or through filters that remove harmful particles. By effectively removing or minimizing the fumes, ventilation systems help create a safer working environment, reducing the risk of respiratory issues and other health problems.

It is important to note that ventilation systems should be regularly maintained and inspected to ensure their optimal functioning. With proper ventilation systems in place, the potential health risks associated with laser cutters can be significantly minimized.

This brings us to the next myth: laser cutters are only for professionals and cannot be used by amateurs.

Myth: Laser cutters are only for professionals and cannot be used by amateurs.

Don’t believe the myth that laser cutters are off-limits to amateurs – they can be used by anyone with proper training and guidance. Laser cutter safety training ensures that individuals understand the potential risks and how to handle them effectively. By receiving the necessary training, hobbyists can safely utilize laser cutters and enjoy the numerous benefits they offer. Laser cutting provides precision and accuracy, allowing amateurs to create intricate designs with ease. Additionally, laser cutters can work with a wide range of materials, from wood and acrylic to fabric and leather, expanding the creative possibilities for hobbyists. However, it is crucial for amateurs to remember that laser cutters can be dangerous if not used correctly. Therefore, it is essential to receive proper training and follow safety guidelines to ensure a safe and enjoyable experience. Fact: laser cutters can be used by anyone, as long as they receive proper training and follow safety guidelines.

Fact: Laser cutters can be used by anyone, as long as they receive proper training and follow safety guidelines.

Contrary to popular belief, laser cutters are not solely reserved for professionals. In fact, laser cutters can be used by anyone, as long as they receive proper training and adhere to safety guidelines.

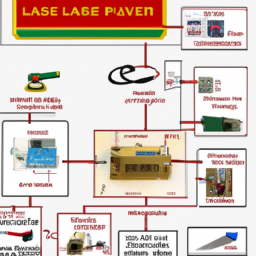

Laser cutter training is crucial to ensure that users understand how to operate the machine safely and effectively. It covers topics such as machine setup, material selection, and maintenance. By receiving this training, individuals can confidently utilize laser cutters and unleash their creativity.

Following safety guidelines is of utmost importance when using laser cutters. These guidelines outline the necessary precautions to prevent accidents and injuries. They include wearing appropriate protective gear, maintaining a clean workspace, and understanding the limitations of the machine. By following these guidelines, users can mitigate risks and ensure a safe working environment.

In the next section, we will address the myth that laser cutters are expensive and not worth the investment. But before we delve into that, let’s explore the financial aspect of laser cutting and how it can be advantageous for both professionals and amateurs.

Myth: Laser cutters are expensive and not worth the investment.

If you’re on the fence about investing in a laser cutter, let me shed some light on why it’s more bang for your buck than you might think. Laser cutters may seem expensive at first, but when you consider their affordability in the long run and the potential return on investment, they become a worthwhile purchase. To help you understand the cost-effectiveness of laser cutters, let’s take a look at a comparison table:

| Factor | Traditional Cutting Methods | Laser Cutter |

|---|---|---|

| Material Waste | High | Low |

| Precision | Moderate | High |

| Speed | Slow | Fast |

As you can see, laser cutters offer significant advantages over traditional cutting methods. While laser cutters can be costly, they offer numerous benefits and can be a worthwhile investment for many businesses and individuals. Transitioning into the subsequent section, it’s important to separate myth from fact when it comes to laser cutter safety.

Fact: While laser cutters can be costly, they offer numerous benefits and can be a worthwhile investment for many businesses and individuals.

Now that we’ve dispelled the myth that laser cutters are expensive and not worth the investment, let’s delve into the benefits and cost-effectiveness of laser cutters.

Laser cutters provide numerous advantages that make them a worthwhile investment for both businesses and individuals. Firstly, laser cutters offer unmatched precision and accuracy, ensuring clean and precise cuts every time.

Additionally, they can cut a wide range of materials, including wood, acrylic, metal, and fabric, making them incredibly versatile. Moreover, laser cutters are highly efficient and can significantly reduce production time compared to traditional cutting methods. They also eliminate the need for complex setups and multiple tool changes, saving both time and resources.

Lastly, laser cutters have a high level of automation and can be easily integrated into existing production processes.

Transitioning into the next section, let’s address the myth that laser cutters can only cut certain materials.

Myth: Laser cutters can only cut certain materials.

However, it’s important to note that laser cutters have the ability to cut a wide variety of materials, including metals, plastics, glass, and even certain types of stone. Contrary to popular belief, laser cutters aren’t limited to specific materials.

Here are some common misconceptions about laser cutter materials:

-

Laser cutters can only cut thin materials: Laser cutters can effectively cut materials of varying thicknesses, ranging from thin sheets to thicker blocks.

-

Laser cutters can only cut flat materials: Laser cutters are capable of cutting both flat and curved surfaces, allowing for intricate designs and shapes.

-

Laser cutters can only cut certain types of materials: Laser cutters can work with a diverse range of materials, from organic substances like wood and fabric to synthetic materials like acrylic and rubber.

In fact, laser cutters are highly versatile and can cut a wide range of materials, including wood, acrylic, metal, fabric, and more.

Fact: Laser cutters can cut a wide range of materials, including wood, acrylic, metal, fabric, and more.

Laser cutters possess remarkable versatility, effortlessly slicing through a diverse array of materials such as wood, acrylic, metal, fabric, and more. With their precise beam of focused light, laser cutters are capable of handling intricate designs and producing clean, accurate cuts.

From crafting intricate patterns on wood and acrylic to fabricating precise metal parts, laser cutters have a wide range of applications in various industries. However, it’s crucial to ensure laser cutter safety guidelines are followed to prevent accidents and injuries. Regular maintenance and periodic inspections are essential to keep the machine in optimal condition and minimize the need for constant repairs. By adhering to these safety measures, you can avoid potential hazards and create a safe working environment.

Transitioning to the next section, let’s debunk the myth that laser cutters are difficult to maintain and require constant repairs.

Myth: Laser cutters are difficult to maintain and require constant repairs.

Contrary to popular belief, laser cutters aren’t as challenging to maintain as many may think, and they don’t require constant repairs. When properly maintained, laser cutters can be reliable and long-lasting machines. Here are four reasons why laser cutters aren’t difficult to maintain:

-

Regular cleaning: Laser cutters require routine cleaning to remove debris and residue that can affect performance. This can be done using a soft cloth and a mild cleaning solution.

-

Calibration checks: Periodically checking and calibrating the laser cutter ensures accurate and precise cutting. This process involves adjusting the laser beam focus, alignment, and power settings.

-

Cooling system maintenance: Laser cutters use a cooling system to prevent overheating. This system requires regular maintenance, such as checking coolant levels and cleaning filters to ensure optimal performance.

-

Preventive maintenance: Following manufacturer guidelines for preventive maintenance can help identify and address potential issues before they escalate, reducing the need for extensive repairs.

With proper maintenance, laser cutters can operate smoothly and efficiently, providing reliable cutting capabilities for a wide range of materials.

Fact: With regular maintenance and proper care, laser cutters can be reliable and long-lasting machines

If you take good care of your laser cutter and maintain it regularly, you’ll be amazed at how reliable and long-lasting this machine can be. Owning a laser cutter comes with its pros and cons. On the positive side, laser cutters offer precise and intricate cutting capabilities, making them ideal for a variety of applications. However, they do require proper maintenance to ensure optimal performance. Here are some tips for maintaining a laser cutter safely:

-

Clean the lens regularly: The lens is a critical component that can affect the quality of the laser cutting. Use a lens cleaning solution and a lint-free cloth to remove any dust or debris.

-

Check and clean the exhaust system: Laser cutting produces fumes and particles that need to be properly vented. Regularly inspect the exhaust system and clean it to prevent clogs and ensure proper ventilation.

-

Perform routine maintenance: Regularly inspect and clean the laser tube, mirrors, and other components. Check for any signs of wear or damage and replace as necessary.

By following these maintenance tips, you can extend the lifespan of your laser cutter and enjoy its benefits for years to come.

Frequently Asked Questions

Are there any safety precautions that need to be taken when using a laser cutter?

When using a laser cutter, it’s crucial to follow proper safety precautions. Laser cutter safety precautions include wearing appropriate protective gear, such as safety goggles and gloves, to shield yourself from potential harm.

It’s also important to ensure proper ventilation in the workspace to prevent the buildup of fumes and smoke. Additionally, always operate the laser cutter in a well-lit area and keep a fire extinguisher nearby.

Remember, laser cutter safety is of utmost importance to prevent accidents and ensure a safe working environment.

What types of materials can be cut using a laser cutter?

Laser cutters are highly versatile machines capable of cutting a wide range of materials. They can cut wood and acrylic, as well as metal and fabric. Laser cutter applications are vast, and their precision capabilities allow for intricate designs and precise cutting. This makes them ideal for industries such as architecture, fashion, and manufacturing. Laser cutters have become an essential tool in many industries due to their ability to cut through various materials with accuracy.

Are there any health risks associated with the fumes produced by laser cutters?

Are there any health risks associated with the fumes produced by laser cutters? Yes, there are. When materials such as plastics, wood, or certain metals are cut using a laser cutter, fumes are released. These fumes can contain harmful substances like volatile organic compounds (VOCs) and particulate matter. Breathing in these fumes can lead to respiratory issues and other health problems. To mitigate these risks, proper ventilation systems should be in place to ensure the fumes are effectively removed from the workspace.

How much does a laser cutter typically cost?

The cost of a laser cutter can vary depending on several factors. Laser cutter maintenance cost is one of the key considerations. Regular maintenance is necessary to keep the machine functioning properly and can add to the overall cost.

Additionally, the price of a laser cutter is influenced by factors such as the power and size of the machine, the type of laser used, and any additional features or accessories. It’s important to research and compare different options to find the best laser cutter for your needs and budget.

How often does a laser cutter require maintenance and repairs?

Laser cutter maintenance frequency varies depending on usage, but regular upkeep is important to prevent common repair issues. It is recommended to schedule maintenance every 6-12 months to ensure optimal performance. During these check-ups, technicians will inspect and clean the laser cutter, replace worn-out parts, and calibrate the machine.

Common repair issues include problems with the laser tube, mirrors, or power supply. Timely maintenance can help avoid costly repairs and keep your laser cutter running smoothly.

Conclusion

In conclusion, laser cutters aren’t as dangerous as they’re often portrayed. When proper safety precautions are followed, they can be used safely by both professionals and amateurs.

Contrary to popular belief, laser cutters can cut a wide range of materials, making them versatile tools. Additionally, with regular maintenance and care, these machines can be reliable and long-lasting.

Think of a laser cutter as a precision instrument, like a surgeon’s scalpel, that requires skill and attention to operate effectively.