Are you tired of your laser cutter breaking down at the most inconvenient times? Do you find yourself constantly spending money on repairs and replacements? Well, fear not! We have the solution for you.

In this article, we will discuss the 10 essential features that will not only extend the lifespan of your laser cutter but also save you time and money in the long run. It’s ironic, isn’t it? The very tool that is meant to cut and shape with precision needs its own set of maintenance techniques to ensure its longevity. But trust us, it’s worth it.

From regular cleaning and maintenance to proper ventilation and air filtration, we will cover all the bases. So, put on your technical hat and get ready to dive into the world of laser cutter care. Your machine will thank you.

Key Takeaways

- Regular cleaning and maintenance are necessary for the longevity and optimal performance of a laser cutter.

- Proper ventilation and air filtration are crucial to protect the machine and operator from harmful fumes and particles.

- Lubrication and calibration help minimize wear and tear and ensure accurate cuts.

- Regular software updates enhance the efficiency and performance of a laser cutter.

Regular Cleaning and Maintenance

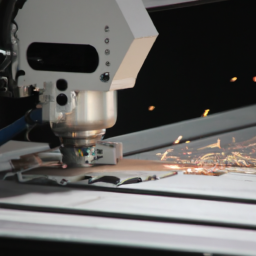

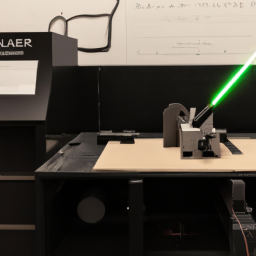

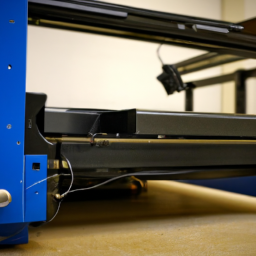

Regular cleaning and maintenance are essential to ensure the longevity and optimal performance of your laser cutter. By implementing regular maintenance, you can prevent the buildup of debris and dust that can hinder the machine’s functionality.

Start by inspecting the laser cutter for any signs of wear or damage, such as loose wires or belts. Clean the machine using appropriate cleaning techniques, such as using compressed air to remove dust from the lenses and mirrors.

Additionally, regularly check and clean the exhaust fan and filters to maintain proper ventilation and prevent overheating. Proper ventilation and air filtration are crucial to protect both the machine and the operator from harmful fumes and particles.

By following these cleaning and maintenance practices, you can extend the lifespan of your laser cutter and ensure its continued efficiency.

Proper Ventilation and Air Filtration

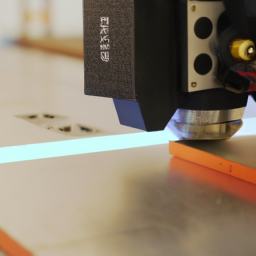

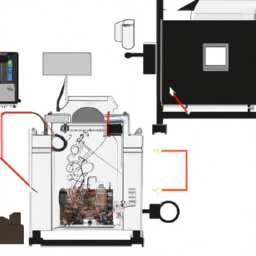

To ensure the proper ventilation and air filtration in your laser cutting workspace, it’s essential to install a ventilation system. This system will help remove the smoke, fumes, and particulate matter generated during the laser cutting process.

Additionally, using an air filtration unit will further enhance the air quality by capturing and filtering out any remaining contaminants.

Lastly, it’s crucial to ensure proper airflow in the workspace to maintain a safe and healthy environment for both the operator and the laser cutter.

Install a ventilation system

When it’s time to get your laser cutter up and running, it’s essential to install a ventilation system. This will keep it cool and ensure a smooth operation. A well-designed ventilation system is crucial for maintaining the optimal performance and longevity of your laser cutter.

The design of the ventilation system should take into consideration the specific requirements of your laser cutter, such as the size and power of the machine. It should also be equipped with an efficient exhaust fan to effectively remove the fumes and debris generated during the cutting process.

Regular maintenance of the ventilation system is necessary to prevent clogs and ensure continuous airflow. This includes cleaning or replacing filters, checking the fan for any issues, and monitoring the overall system performance.

Properly installing and maintaining a ventilation system will create a healthy working environment for your laser cutter and help prolong its lifespan.

Next, let’s discuss the importance of using an air filtration unit.

Use an air filtration unit

Breathe in fresh, clean air with the help of an air filtration unit, ensuring a healthier working environment for you and your laser cutting projects. Using an air filtration system offers several benefits for both your health and the lifespan of your laser cutter. Here are some advantages of using an air filtration unit:

- Removes harmful fumes and particles generated during laser cutting.

- Reduces the risk of respiratory issues caused by inhaling hazardous pollutants.

- Prevents the accumulation of dust and debris on the laser cutter’s components, improving its performance and longevity.

- Maintains the quality of the laser beam by eliminating contaminants that could affect the precision of cuts.

- Creates a more comfortable and pleasant workspace by eliminating odors and improving air quality.

Choosing the right air filtration unit for your laser cutter depends on factors such as the size of your workspace, the type of laser cutter you have, and the specific pollutants you need to filter. To ensure proper airflow in the workspace, consider implementing additional measures such as installing ductwork and using exhaust fans.

Ensure proper airflow in the workspace

Make sure the air in your workspace is flowing smoothly like a gentle breeze, allowing for proper ventilation and preventing the buildup of harmful pollutants.

To improve airflow, start by organizing your workspace in a way that promotes efficient air circulation. Keep the laser cutter away from walls or other objects that could obstruct the flow of air. Position it in a central location so that air can circulate evenly around the machine.

Additionally, remove any clutter or debris that may impede the airflow. Consider using fans or air purifiers to further enhance the ventilation in your workspace.

By ensuring proper airflow, you can maintain a clean and healthy environment for your laser cutter to operate in.

Now, let’s move on to the next section about lubrication and calibration.

Lubrication and Calibration

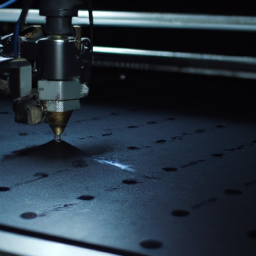

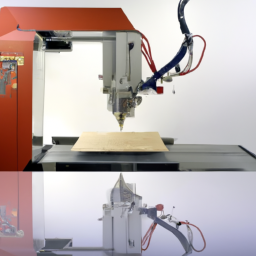

In order to maximize the longevity of your laser cutter, it’s imperative to ensure proper lubrication and calibration are regularly maintained.

Without adequate lubrication techniques, the moving parts of the laser cutter may experience excessive wear and tear, leading to reduced performance and potential breakdowns. Regularly applying lubricants to the necessary components such as the rails, bearings, and drive systems will help minimize friction and prolong the lifespan of your laser cutter.

Additionally, calibration tools play a crucial role in ensuring the accuracy and precision of the laser cutter’s movements. Regularly calibrating the machine to align the optics, mirrors, and focus will guarantee consistent and high-quality cuts.

Neglecting lubrication and calibration can result in costly repairs and downtime.

Moving forward, let’s explore the importance of software updates and maintenance to further enhance the performance of your laser cutter.

Software Updates and Maintenance

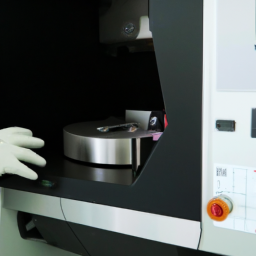

Don’t overlook the importance of keeping up with software updates and maintenance to maximize the performance and longevity of your laser cutting machine.

Regular software updates ensure that your machine is running on the latest features and improvements, enhancing its overall efficiency. Additionally, software troubleshooting plays a crucial role in identifying and resolving any issues that may arise during operation. Remote support services are available to provide prompt assistance and guidance in case of software-related problems.

It is essential to schedule regular maintenance checks to ensure that your machine is in optimal condition. This includes inspecting and cleaning the laser optics, checking the alignment, and verifying the functionality of key components.

By staying proactive with software updates and maintenance, you can ensure the smooth operation of your laser cutter and minimize downtime.

Now let’s move on to discussing the necessary safety measures to protect yourself and the machine.

Safety Measures

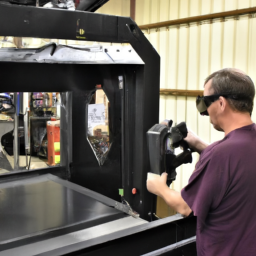

To ensure your safety while operating a laser cutter, it’s crucial to use safety goggles and other protective gear to protect your eyes and body from potential harm.

Additionally, make sure to follow proper laser cutter operation protocols to minimize the risk of accidents and injuries.

Lastly, implement emergency stop measures to quickly halt the laser cutter in case of any emergencies or malfunctions.

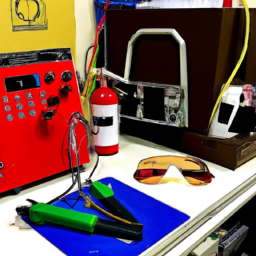

Use safety goggles and protective gear

Ensure you’re wearing safety goggles and protective gear when operating the laser cutter to emphasize the importance of personal safety. Safety regulations are crucial in any laser cutting operation to prevent potential injuries. By using protective gear, such as safety goggles, gloves, and aprons, you create a barrier between your body and the laser’s harmful effects.

Safety goggles shield your eyes from the intense laser light, preventing eye damage, while gloves and aprons protect your skin from burns and sparks. Additionally, wearing protective gear reduces the risk of inhaling harmful fumes or dust generated during the cutting process. By adhering to safety regulations and using protective gear, you significantly minimize the chances of accidents and injuries.

Moving forward, it’s essential to follow proper laser cutter operation protocols to ensure optimal performance and longevity.

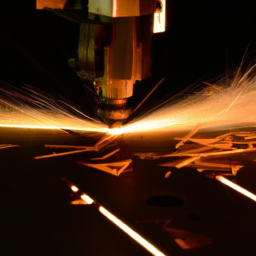

Follow proper laser cutter operation protocols

Mastering the art of laser cutter operation is like dancing with precision, where each carefully executed move determines the outcome of your creation. To ensure the longevity of your laser cutter and the safety of its users, it is crucial to follow proper laser cutter operation protocols. Adhering to laser cutter safety guidelines and receiving adequate laser cutter training are essential steps in preventing accidents and maintaining the machine’s functionality.

| Laser Cutter Safety Guidelines | Importance of Laser Cutter Training |

|---|---|

| Always wear appropriate safety goggles and protective gear. | Proper training ensures understanding of laser cutter operation and safety procedures. |

| Regularly inspect the machine for any signs of wear or damage. | Laser cutter training enhances knowledge of emergency procedures and troubleshooting techniques. |

| Maintain a clean and clutter-free workspace. | Trained operators can identify potential hazards and take necessary precautions. |

| Follow manufacturer’s guidelines for laser power and cutting materials. | Training reduces the risk of human error and improper usage. |

By following these laser cutter operation protocols, you can extend the lifespan of your laser cutter and minimize safety risks. In the next section, we will discuss how to implement emergency stop measures to further enhance the safety of your laser cutter.

Implement emergency stop measures

Implementing emergency stop measures enhances the safety of your laser cutter and adds an extra layer of protection. To ensure a swift response in case of emergencies, make sure your laser cutter is equipped with a prominent emergency stop button that’s easily accessible.

Familiarize yourself with the emergency shutdown procedures provided by the manufacturer and display them prominently near the machine. In the event of an emergency, press the emergency stop button immediately to halt all laser cutter operations.

Additionally, train all operators on how to effectively use the emergency stop button and conduct regular drills to ensure everyone’s prepared. By implementing these emergency stop measures, you can minimize the risk of accidents and protect both your equipment and personnel.

Transitioning into the subsequent section about ‘training and education’, it’s crucial to provide comprehensive training to all laser cutter operators.

Training and Education

Get hands-on training and learn the ins and outs of operating your laser cutter to maximize its lifespan and efficiency. Training programs are essential for ensuring proper skill development and understanding of the machine’s capabilities. These programs should cover all aspects of laser cutter operation, including safety protocols, maintenance procedures, and troubleshooting techniques.

Through comprehensive training, operators can learn how to effectively utilize the laser cutter’s features and settings, reducing the risk of damage or misuse. Additionally, training programs should provide opportunities for practical application, allowing operators to practice their skills in a controlled environment. This practical experience will enhance their proficiency and confidence in using the machine, ultimately extending its lifespan and optimizing its performance.

Remember, investing in proper training and education is a wise decision that will benefit both the operator and the laser cutter in the long run.

Frequently Asked Questions

How often should I clean my laser cutter and what cleaning products should I use?

To ensure optimal performance and longevity of your laser cutter, it’s crucial to clean it regularly. The cleaning frequency depends on the intensity of usage, but a general rule of thumb is to clean it after every 8-10 hours of operation.

For cleaning, use non-abrasive cleaning products specifically designed for laser cutters. Avoid using harsh chemicals or solvents as they may damage the delicate components.

Regular cleaning will help maintain the machine’s efficiency and prevent issues caused by dirt and debris buildup.

Can I use my laser cutter in a small, enclosed space without proper ventilation?

Like a fish out of water, using a laser cutter in a small, enclosed space without proper ventilation is a risky move. While it may seem convenient, it can cause serious safety hazards due to the release of harmful fumes and gases.

However, there are alternatives to ensure safety. Implementing a ventilation system or using an air purifier can effectively filter the air and protect you from potential harm.

Always prioritize safety precautions in small spaces to extend the lifespan of your laser cutter.

How often should I lubricate and calibrate my laser cutter, and what are the signs that it needs to be done?

To ensure optimal performance and longevity of your laser cutter, it’s crucial to regularly lubricate and calibrate it. The laser cutter lubrication frequency depends on the manufacturer’s recommendations, but typically, it’s advised to lubricate the moving parts every 100-150 hours of operation.

Signs that indicate the need for calibration include inconsistent cutting or engraving results, irregular beam alignment, or unusual noises during operation.

Regular maintenance and timely calibration will keep your laser cutter in top-notch condition.

Are software updates and maintenance necessary for the proper functioning of a laser cutter?

To ensure the proper functioning of your laser cutter, regular software updates and maintenance are essential.

Software updates provide bug fixes, security enhancements, and new features that can optimize the machine’s performance.

Maintenance tasks include cleaning the machine, inspecting and replacing worn-out parts, and calibrating the laser.

Neglecting software updates and maintenance can lead to decreased accuracy, reduced efficiency, and potentially costly breakdowns.

Stay proactive by scheduling regular updates and maintenance to maximize the lifespan of your laser cutter.

Is there any specific safety gear or precautions I should take while operating a laser cutter?

To operate a laser cutter safely, proper training is crucial. Imagine driving a car without knowing how to use the brakes or turn the steering wheel. It’s like walking on a tightrope without a safety net.

Inadequate training can lead to disastrous mistakes, such as incorrect material settings or failing to secure the workpiece. Avoid these errors by following safety protocols, wearing protective gear like goggles and gloves, and always staying vigilant during operation.

Conclusion

In conclusion, maintaining your laser cutter is crucial for its longevity and optimal performance. By regularly cleaning and maintaining it, ensuring proper ventilation and air filtration, lubricating and calibrating its components, and keeping up with software updates, you can extend the lifespan of your machine.

Additionally, implementing safety measures is essential. A well-maintained laser cutter is like a well-tuned instrument, producing precise and beautiful cuts with ease. It allows you to unleash your creativity without any hindrance. So, invest time in its care and enjoy the endless possibilities it offers.