Are you tired of your laser cutter breaking down every time you need it the most? Do you find yourself spending countless hours and dollars on repairs and maintenance? Well, fear not! We have the ultimate solution for you. Introducing the 10 essential laser cutter maintenance features for safety and efficiency.

This groundbreaking article will provide you with the knowledge and expertise you need to keep your laser cutter running smoothly and efficiently. From ventilation and exhaust systems to regular cleaning and lubrication, we have got you covered. Say goodbye to costly repairs and hello to uninterrupted production.

With our detailed guide, you will learn how to properly calibrate and align your laser cutter, ensuring accurate and precise cuts every time. We will also explore emergency stop and safety interlock systems, monitoring and maintenance of laser power and cooling systems, and the importance of training and education for operators on maintenance procedures.

So, get ready to revolutionize your laser cutter maintenance routine and take your productivity to new heights. Let’s dive in!

Key Takeaways

- Regular cleaning and lubrication are essential for maintaining a laser cutter’s efficiency and preventing damage.

- Proper ventilation and exhaust systems are necessary for controlling air quality and ensuring the safety of operators.

- Calibration and alignment checks are crucial for achieving precise cutting and avoiding the negative effects of misalignment.

- Training and education for operators on maintenance procedures and safety guidelines are vital for enhancing safety and efficiency in laser cutter maintenance.

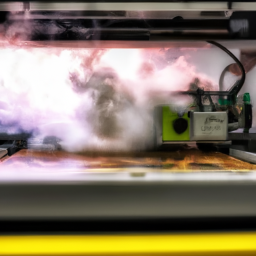

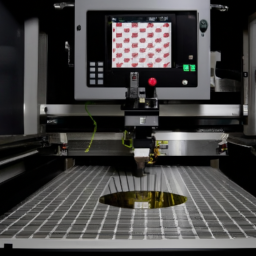

Ventilation and Exhaust Systems

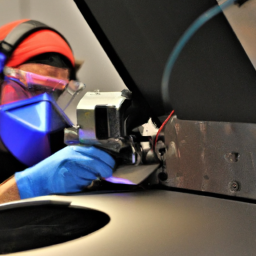

You need to ensure your laser cutter is equipped with proper ventilation and exhaust systems to maintain a safe and efficient working environment. Air quality control is crucial in a laser cutting facility due to the potential release of harmful fumes and particles during the cutting process.

An effective ventilation system will remove these pollutants and maintain a clean atmosphere. The ductwork design plays a significant role in this process, as it should efficiently capture and transport the emissions away from the cutting area. It is essential to consider factors such as airflow rate, duct size, and placement to ensure optimal ventilation.

By incorporating these features, you can effectively control air quality and minimize the risk of exposure to hazardous materials.

Now let’s move on to the next section about regular cleaning and lubrication to maintain the laser cutter’s longevity and performance.

Regular Cleaning and Lubrication

Regular cleaning and lubrication are key for keeping the laser cutter in optimal condition and ensuring smooth operation. To maintain the laser cutter’s efficiency and safety, follow these maintenance guidelines:

-

Maintenance schedule: Create a regular cleaning and lubrication schedule to prevent build-up of debris and ensure all components are functioning properly. This will help extend the lifespan of the laser cutter and minimize downtime.

-

Proper storage: When not in use, store the laser cutter in a clean and dry environment to avoid dust accumulation and potential damage. Cover the machine with a protective cover to prevent dust and debris from settling on sensitive parts.

-

Thorough cleaning: Use a soft brush and compressed air to remove dust and debris from the laser cutter’s exterior and interior components. Clean the lenses and mirrors with a lens cleaning solution to maintain optimal cutting performance.

By following these maintenance practices, you can keep your laser cutter running smoothly. Once you’ve completed regular cleaning and lubrication, it’s essential to move on to calibration and alignment checks for precise laser cutting.

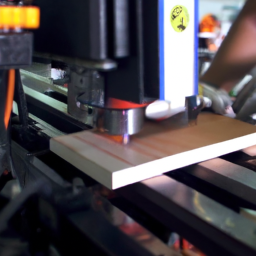

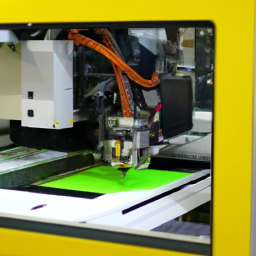

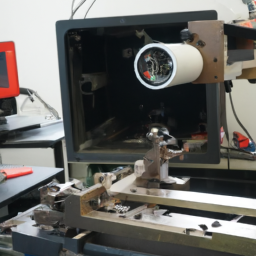

Calibration and Alignment Checks

After completing the regular cleaning and lubrication, it’s time to ensure precise laser cutting through calibration and alignment checks. Calibration accuracy is crucial for maintaining the efficiency and safety of a laser cutter. To achieve optimal results, it is essential to follow proper alignment procedures. This involves checking and adjusting the laser beam’s position, ensuring it is aligned with the cutting bed and cutting head. Misalignment can lead to inaccurate cuts and potential hazards.

To help you understand the importance of calibration and alignment, let’s look at the following table:

| Issue | Effect |

|---|---|

| Beam misalignment | Inaccurate cuts and reduced cutting speed |

| Cutting head misalignment | Uneven cuts and potential damage to the material |

| Bed misalignment | Uneven cuts and potential damage to the laser cutter |

| Inconsistent focus | Inaccurate cuts and reduced cutting quality |

By regularly performing calibration and alignment checks, you can maintain the laser cutter’s efficiency and ensure the safety of the operator and equipment. Now, let’s move on to the next section about the emergency stop and safety interlock systems.

Emergency Stop and Safety Interlock Systems

To ensure the highest level of operator protection and prevent potential accidents, it’s crucial to understand the functionality and importance of the emergency stop and safety interlock systems in a laser cutting machine. These systems play a vital role in laser cutter troubleshooting and emergency shutdown procedures. Here are five key features of these systems:

-

Emergency Stop Button: Easily accessible and instantly shuts down the laser cutter in case of an emergency.

-

Safety Interlock Switches: Ensure that the machine can only operate when all doors and panels are securely closed.

-

Laser Enclosure Sensors: Detect any breach in the laser enclosure and automatically stop the laser beam.

-

Emergency Power Loss Protection: Prevents the laser cutter from restarting unexpectedly after a power failure.

-

Fault Detection Alarms: Alert operators if there is a malfunction in the system, allowing for timely intervention.

By understanding and utilizing these features, operators can ensure the safety and efficiency of the laser cutting machine.

Moving forward, let’s discuss the monitoring and maintenance of laser power and cooling systems.

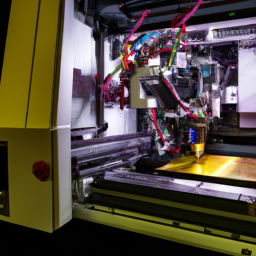

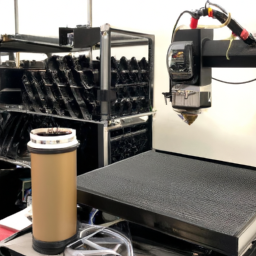

Monitoring and Maintenance of Laser Power and Cooling Systems

Keep a close eye on the monitoring and maintenance of your laser power and cooling systems to ensure optimal performance and avoid any potential breakdowns or disruptions. Proper power and cooling system troubleshooting is essential for the safe and efficient operation of your laser cutter. Regular preventive maintenance can help identify and address any issues before they escalate, saving you time and money in the long run. Here are some tips to keep your power and cooling systems in top shape:

| Power System | Cooling System | Troubleshooting |

|---|---|---|

| Check power supply | Monitor coolant levels | Inspect for leaks |

| Verify laser voltage | Clean cooling filters | Ensure proper airflow |

| Calibrate power settings | Maintain temperature | Monitor cooling pump |

By following these maintenance guidelines, you can ensure that your laser cutter stays in peak condition. Next, we will discuss the importance of training and education for operators on maintenance procedures without skipping a beat.

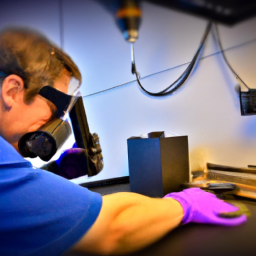

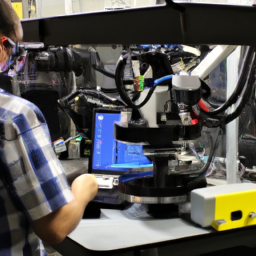

Training and Education for Operators on Maintenance Procedures

Now that we’ve discussed the importance of monitoring and maintaining laser power and cooling systems, let’s move on to the next crucial aspect of laser cutter maintenance: training and education for operators on maintenance procedures.

Ensuring operator safety and equipment maintenance is paramount in any laser cutting environment. Proper training equips operators with the knowledge and skills to perform routine maintenance tasks effectively and safely. This includes understanding the correct procedures for cleaning, lubricating, and inspecting various components of the laser cutter.

Operators should also be educated on the potential hazards associated with laser cutter maintenance and how to mitigate them. Regular training sessions should be conducted to keep operators up-to-date with the latest maintenance protocols and safety guidelines.

By investing in operator training and education, we can enhance both safety and efficiency in laser cutter maintenance.

Frequently Asked Questions

How often should the laser cutter’s ventilation and exhaust systems be inspected for any potential blockages or malfunctions?

To ensure optimal safety and efficiency, it’s crucial to regularly inspect the ventilation and exhaust systems of your laser cutter. These systems should be checked for potential blockages or malfunctions at least once a month. By doing so, you can proactively troubleshoot common ventilation issues, such as clogged filters or damaged ductwork. This frequency of ventilation inspection will help maintain a clean and properly functioning laser cutter environment.

Is it necessary to use a specific type of cleaning solution for regular cleaning and lubrication of the laser cutter?

When it comes to regular cleaning and lubrication of your laser cutter, it’s essential to use the right cleaning solution types and lubrication options. Using the wrong cleaning solution can damage the delicate components of the machine. Opt for a non-abrasive, non-flammable cleaning solution recommended by the manufacturer.

For lubrication, choose a high-quality lubricant specifically designed for laser cutters. Regular cleaning and lubrication will ensure optimal performance and extend the lifespan of your laser cutter.

How frequently should calibration and alignment checks be performed to ensure the laser cutter’s accuracy and precision?

How frequently should you perform calibration and alignment checks to ensure the laser cutter’s accuracy and precision? Achieving optimal results requires meticulous attention to detail. Regular calibration frequency is essential to maintain accuracy.

Alignment checks should be conducted at least once a month to ensure precise cutting. Neglecting these crucial steps can lead to subpar results and potential safety hazards. Remember, precision is the key to unlocking the laser cutter’s full potential.

What safety measures are in place to prevent the laser cutter from operating in case of an emergency or malfunction?

In order to prevent any potential accidents or damage, laser cutters are equipped with emergency shutdown systems and malfunction prevention measures. These safety features are designed to quickly and effectively halt the operation of the laser cutter in case of an emergency or malfunction.

The emergency shutdown system can be triggered manually or automatically, ensuring that the laser cutter stops functioning immediately to minimize risks. Additionally, malfunction prevention measures are in place to detect any abnormalities and prevent the laser cutter from operating until the issue is resolved.

Are there any recommended guidelines or standards for monitoring and maintaining the laser power and cooling systems to ensure optimal performance?

To ensure optimal performance of the laser power and cooling systems, it’s important to follow recommended guidelines and standards.

Regular monitoring is necessary to maintain laser power at the desired levels and prevent any fluctuations. This can be achieved by conducting power calibration tests periodically.

Additionally, the cooling systems should be regularly inspected to ensure proper functioning and prevent overheating.

By adhering to these guidelines, you can ensure the laser cutter operates at its highest efficiency and delivers consistent results.

Conclusion

So there you have it, the 10 essential laser cutter maintenance features that will ensure both safety and efficiency.

It’s ironic, isn’t it? The very technology designed to make our lives easier and more convenient requires so much maintenance and attention to detail. But hey, that’s the price we pay for precision and accuracy.

So, remember to keep those ventilation and exhaust systems in top shape, regularly clean and lubricate, and always stay on top of calibration and alignment checks.

Safety and efficiency are worth it, right?