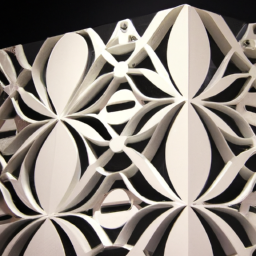

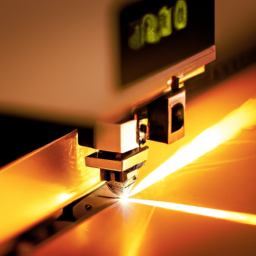

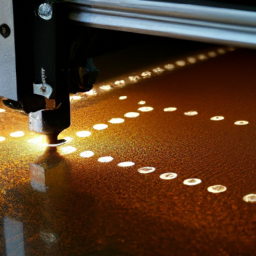

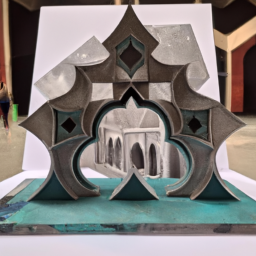

Did you know that laser cutting has become one of the most popular techniques for creating intricate models? With its precision and versatility, laser cutting allows you to bring your creative ideas to life with ease.

However, to achieve the best results, you need the right tools by your side. In this article, we will explore the 10 essential tools that every model maker should have for laser cutting projects.

From cutting mats to tweezers, rulers to adhesive applicators, and sanding tools to storage solutions, these tools will not only enhance your precision and efficiency but also make the entire process more enjoyable.

So, whether you’re a beginner or an experienced model maker, join us as we dive into the world of laser cutting and discover the must-have tools that will take your projects to the next level.

Key Takeaways

- Laser cutting requires the right tools for best results.

- Cutting mats and tweezers are essential tools for laser cutting projects.

- Rulers and measuring tools aid in accurate measurements and dimensions.

- Adhesive applicators help with precise glue application and minimizing mess.

Cutting Mats

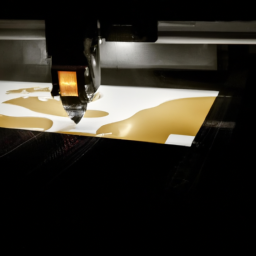

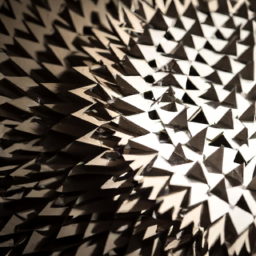

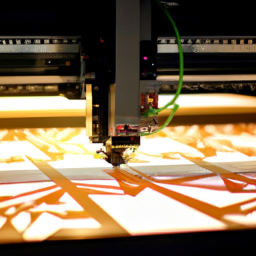

If you want to protect your work surface and ensure clean cuts, you’ll need to invest in a high-quality cutting mat. Cutting mats are essential tools for laser cutting models as they provide a stable and non-slip surface for your materials.

They are made from a self-healing material that prevents the blade from leaving permanent marks and helps prolong the life of your cutting tools. To maintain your cutting mat, it’s important to clean it regularly with mild soap and water, avoiding any harsh chemicals that can damage the surface.

When choosing the right cutting mat, consider the size, thickness, and grip of the mat to ensure it fits your specific needs.

Now, let’s move on to the next tool you’ll need – tweezers.

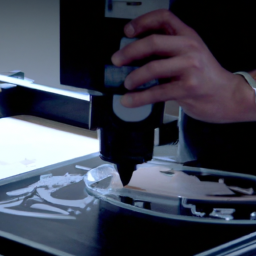

Tweezers

Tweezers are handy for precise manipulation and delicate details during the fabrication process. They allow for precision handling of small components and intricate parts with their fine tips.

When it comes to model assembly, tweezers are indispensable. They ensure that parts fit together snugly, avoiding any misalignment or gaps. Additionally, tweezers are useful for picking up and positioning delicate materials that may be too fragile to handle with bare hands.

Whether it’s adjusting tiny screws or placing tiny decals, tweezers provide the necessary dexterity and control.

Moving on to rulers and measuring tools, these essential instruments aid in accurate measurements and ensure the precise dimensions of your laser-cut models.

Rulers and Measuring Tools

Measuring accurately is key to creating precise and detailed models, and rulers provide the necessary guidance to ensure your dimensions are on point. These essential tools for laser cutting models play a crucial role in achieving measuring accuracy, which is vital for successful laser cutting techniques. Rulers come in various shapes and sizes, allowing you to choose the one that best suits your needs. They are typically made of durable materials such as stainless steel or acrylic, ensuring their longevity and accuracy over time. With clear markings and precise measurements, rulers help you accurately measure and align your materials before the laser cutting process. By incorporating rulers and measuring tools into your workflow, you can ensure that your models turn out exactly as intended, with every detail in its rightful place. Transitioning into the next section about adhesive applicators, precision is also crucial when it comes to securing the parts of your model together.

Adhesive Applicators

When it comes to applying glue or adhesive with precision, minimizing mess and excess is key. You want to ensure that the glue is applied exactly where it needs to be, without any drips or smudges. Using adhesive applicators can help you achieve this level of precision, allowing you to control the amount of glue and apply it precisely to your desired area.

By using these tools, you can minimize mess and excess, resulting in clean and professional-looking projects.

Apply Glue or Adhesive with Precision

To achieve impeccable precision, it’s crucial to master the art of applying glue or adhesive in laser cutting models. Here are some techniques to ensure precision glue application and strong adhesion:

-

Use a precision applicator: Opt for applicators with fine tips or needles that allow for precise control of the glue flow. This ensures that the adhesive is applied exactly where it’s needed, minimizing the risk of errors.

-

Practice controlled pressure: Apply gentle, consistent pressure when dispensing the glue. This helps in achieving a uniform application and prevents excessive glue from seeping out.

-

Test adhesion before assembly: Before joining the pieces together, perform a test to ensure that the glue has fully cured and provides sufficient adhesion. This step helps to avoid any weak spots in the final model.

By mastering these precision glue application techniques, you can minimize mess and excess, creating clean and professional laser cutting models.

Minimize Mess and Excess

By mastering the techniques for precise glue application, you can achieve clean and professional results while minimizing any mess or excess. To ensure efficient material usage, it is important to apply just the right amount of glue. Use a small brush or a toothpick to apply the glue precisely, focusing on the areas that require bonding. Avoid applying too much glue, as it can lead to messy and uneven results. After gluing the pieces together, gently wipe off any excess glue using a damp cloth or a cotton swab. Regularly clean and maintain your glue applicator to prevent clogging and ensure smooth application. By following these tips, you can create laser-cut models with precision and cleanliness. Now, let’s move on to the next section about sanding tools.

Sanding Tools

One of the must-have tools for laser cutting models is a good sanding tool. It’s essential for adding those finishing touches and smoothing surfaces to achieve a professional-looking result.

Here are five sanding tools that will help you achieve the desired outcome:

-

Sanding blocks: These provide a stable surface and allow for precise control over the sanding process.

-

Sanding sticks: Perfect for reaching tight corners and intricate details.

-

Sandpaper sheets: Use different grits to gradually refine the surface, starting with a coarse grit and moving to a finer one.

-

Sanding sponges: These flexible and versatile tools are great for contouring and shaping.

-

Sanding twigs: Ideal for getting into hard-to-reach areas and fine-tuning small details.

With these sanding tools, you can ensure that your laser cut models are smooth and free of imperfections.

Now, let’s move on to the next section about storage and organization solutions.

Storage and Organization Solutions

Are you tired of searching for your supplies and tools every time you want to work on your projects? If so, investing in storage and organization solutions can greatly improve your laser cutting experience.

One essential tool in this area is a labeling system. By labeling your materials and tools, you can easily locate them when needed, saving you time and frustration.

Additionally, compact storage solutions are crucial for keeping your workspace tidy and efficient. Consider using stackable bins or small drawers to store your materials and tools in an organized manner. These compact storage options not only save space but also make it easier to access your supplies.

With the right storage and organization solutions, you can streamline your laser cutting process and focus more on your creative projects.

Frequently Asked Questions

How do I properly clean and maintain my cutting mat to ensure its longevity?

To properly clean and maintain your cutting mat and ensure its longevity, imagine it as a delicate garden that needs tender care. Start by removing any loose debris with a soft brush or air compressor.

Then, dampen a cloth with mild soap and water, gently wiping the surface. Avoid using harsh chemicals or abrasive materials that could damage the mat.

Finally, let it air dry completely before using it again. Remember, proper cleaning and selecting the right tools are vital for your cutting mat’s longevity.

Are there any specific types of tweezers that are best for handling delicate materials during laser cutting?

To handle delicate materials during laser cutting, it’s recommended to use precision tweezers. These tweezers are designed with fine, pointed tips that allow for careful manipulation of the materials.

When choosing tweezers, consider the material you’ll be working with. For example, if you’re cutting paper or fabrics, tweezers with a non-slip coating can provide better grip.

Additionally, be sure to handle and store laser cutting blades properly to prevent any damage or accidents.

What are some key features to look for when selecting rulers and measuring tools for precise laser cutting?

When selecting rulers and measuring tools for precision laser cutting, it’s important to consider their accuracy. Did you know that a study found that using high-quality precision measuring tools can improve laser cutting accuracy by up to 20%?

Look for rulers with clear, easy-to-read markings and a non-slip grip. Consider using digital calipers for precise measurements. These tools will ensure that your laser cutting projects are executed with exceptional precision and accuracy.

Can adhesive applicators be used with different types of adhesives, or are they specific to certain kinds?

Yes, adhesive applicators can be used with different types of adhesives. These versatile tools are designed to work with various adhesives such as glue sticks, liquid glue, and even adhesive tapes. They provide a precise and controlled application, making them suitable for a wide range of projects. Whether you need to apply adhesive to paper, fabric, or other materials, adhesive applicators are a valuable tool that can handle different types of adhesives with ease.

Are there any safety precautions or techniques to keep in mind when using sanding tools in laser cutting projects?

When it comes to sanding in laser cutting projects, safety precautions and techniques are essential to ensure successful results.

It’s interesting to note that, according to a study by the Occupational Safety and Health Administration, improper use of sanding tools can lead to serious injuries.

To prevent accidents, always wear protective goggles, gloves, and a dust mask.

Additionally, use gentle and controlled movements when sanding delicate materials to avoid damaging them.

Remember, safety should always be the top priority in any project.

Conclusion

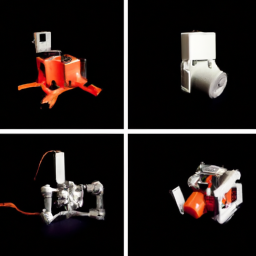

Now that you’ve learned about the 10 essential tools for laser cutting models, you’re well-equipped to take your crafting skills to the next level.

With cutting mats, tweezers, rulers, adhesive applicators, sanding tools, and storage solutions, you have everything you need to create intricate and precise designs.

But remember, the true magic happens when you combine these tools with your creativity and passion. So go ahead, dive into the world of laser cutting, and let your imagination soar.

The possibilities are endless, and the results will leave you in awe. Get ready to amaze yourself and others with your stunning laser-cut creations!