As the saying goes, ‘An ounce of prevention is worth a pound of cure.’ When it comes to maintaining your laser cutter, this adage couldn’t be more accurate. Laser cutters are intricate machines that require regular care and attention to ensure optimal performance and longevity.

In this article, we will explore the top 10 maintenance mistakes to avoid, providing you with the knowledge and guidance to keep your laser cutter running smoothly.

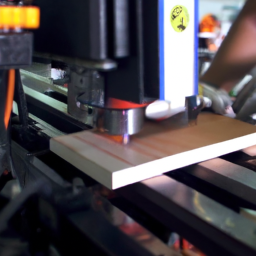

First and foremost, it’s crucial to regularly clean and clear the cutting area. Any debris or residue can hinder the laser’s precision and potentially damage the machine. Additionally, proper lubrication of moving parts is essential to minimize friction and prevent wear and tear.

Monitoring and replacing worn-out components is another critical aspect of laser cutter maintenance. Over time, certain parts will deteriorate and need to be replaced to maintain optimal performance. Furthermore, calibrating the laser beam alignment ensures accurate and precise cutting.

Avoid overworking the machine by adhering to recommended usage limits. Pushing the machine beyond its capabilities can lead to overheating and other issues.

Finally, staying up-to-date with the manufacturer’s maintenance guidelines is essential for a well-maintained laser cutter. By following these guidelines and avoiding common mistakes, you can extend the lifespan of your laser cutter and maximize its productivity.

Key Takeaways

- Regular maintenance is crucial for optimal performance and longevity of laser cutters.

- Cleaning and clearing the cutting area regularly prevents debris and damage.

- Proper lubrication of moving parts minimizes friction and wear.

- Monitoring and replacing worn-out components is essential for the machine’s efficiency and safety.

Regularly Clean and Clear the Cutting Area

Make sure you regularly clean and clear the cutting area to prevent any debris or obstructions from interfering with the laser cutter’s performance. This is crucial for maintaining the machine’s efficiency and prolonging its lifespan.

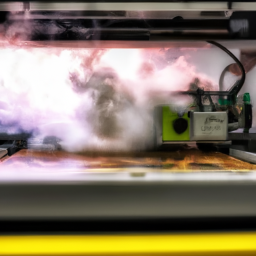

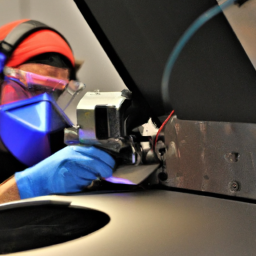

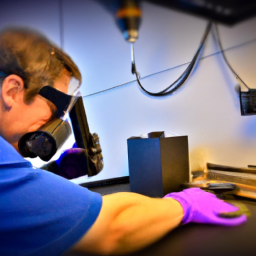

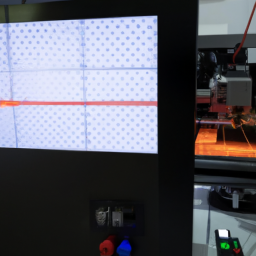

Proper ventilation is of utmost importance when operating a laser cutter, as it helps remove smoke, fumes, and toxic gases generated during the cutting process. It’s recommended to have a ventilation system in place to ensure a safe working environment.

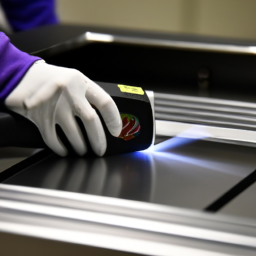

Additionally, wearing protective eyewear is essential to shield your eyes from the intense laser beam and potential debris. By taking these precautions, you not only protect yourself but also ensure the laser cutter operates at its best.

Now, let’s move on to the next section about properly lubricating the machine’s moving parts.

Properly Lubricate Moving Parts

To keep things running smoothly, it’s crucial to ensure that all the moving parts are well-oiled and in good working order. Here are three key points to consider when it comes to lubricating the laser cutter:

-

Importance of using high-quality lubricants: Using the right lubricants is vital for the longevity and performance of the machine. High-quality lubricants are designed to withstand the high temperatures and pressures generated during the laser cutting process, ensuring optimal functionality.

-

Common signs of inadequate lubrication: Insufficient lubrication can lead to various issues, including increased friction, excessive wear and tear, and potential damage to the moving components. Look out for signs such as unusual noises, decreased cutting precision, or increased resistance while moving the parts.

-

Regular lubrication schedule: Establish a regular maintenance routine that includes lubricating the moving parts of the laser cutter. Follow the manufacturer’s guidelines regarding the type and frequency of lubrication to ensure optimal performance and prevent any potential problems.

By properly lubricating the moving parts, you can minimize the risk of breakdowns and extend the lifespan of your laser cutter.

In the next section, we’ll discuss how to monitor and replace worn-out components.

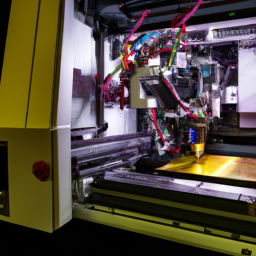

Monitor and Replace Worn-out Components

Keep an eye on the moving parts and replace any worn-out components in order to ensure smooth operation and prevent potential issues. Checking the power supply regularly is crucial to avoid any power-related problems that may affect the laser cutter’s performance. Additionally, it is important to monitor the ventilation system to prevent overheating and ensure proper air circulation. Failure to do so can lead to damage to the machine and potential safety hazards. To help you stay on top of these maintenance tasks, refer to the table below for a quick overview of the recommended frequency for checking and replacing key components:

| Component | Check Frequency | Replace Frequency |

|---|---|---|

| Power Supply | Monthly | As needed |

| Ventilation System | Weekly | As needed |

| Other Moving Parts | Monthly | As needed |

By following these maintenance practices, you can ensure the laser cutter operates at its optimal level. Now, let’s transition into the next section about calibrating the laser beam alignment.

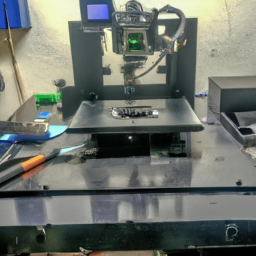

Calibrate the Laser Beam Alignment

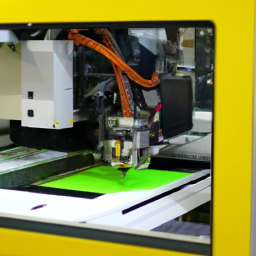

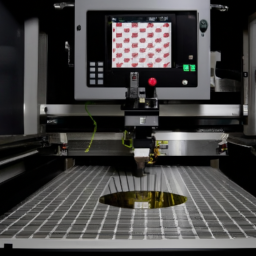

Ensure that you regularly calibrate the laser beam alignment to guarantee precise and accurate cutting, leaving you feeling confident in the quality of your work. Proper calibration of the laser beam alignment is crucial for maintaining the desired laser beam intensity and focus.

To ensure accurate alignment, follow these steps:

- Start by checking the laser beam focus to ensure it’s at the desired level.

- Use a laser beam alignment tool to adjust the beam alignment, ensuring it’s perfectly aligned with the cutting path.

- Regularly monitor the laser beam intensity to ensure it remains consistent throughout the cutting process.

By regularly calibrating the laser beam alignment, you can avoid issues such as uneven cuts or inaccurate designs. This’ll save you time and materials, allowing you to work efficiently and produce high-quality results.

Now, let’s move on to how to avoid overworking the machine.

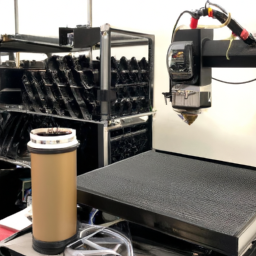

Avoid Overworking the Machine

Make sure you don’t push the machine beyond its limits and risk damaging it by avoiding overworking it. Laser cutters are powerful tools, but they have their limits. Overworking the machine can lead to overheating, decreased performance, and potential damage to the internal components. To avoid this, it is important to have proper ventilation in the workspace. This will help dissipate the heat generated by the machine and prevent it from overheating. Additionally, using appropriate materials is crucial. Some materials may produce toxic fumes or release harmful particles when cut with a laser. By using the right materials, you can prevent damage to the machine and ensure the safety of yourself and others. Remember to always follow the manufacturer’s guidelines for proper maintenance to keep your laser cutter in optimal condition. This includes regular cleaning, lubrication, and inspection of the machine. By staying up-to-date with the manufacturer’s maintenance guidelines, you can prolong the lifespan of your laser cutter and prevent costly repairs.

Transition: Now that you understand the importance of avoiding overworking the machine, let’s move on to the next step: staying up-to-date with the manufacturer’s maintenance guidelines.

Stay Up-to-date with Manufacturer’s Maintenance Guidelines

Stay on top of the manufacturer’s maintenance guidelines to keep your laser cutter running smoothly, like a well-oiled machine. Regular maintenance checks are of utmost importance to ensure optimal performance and longevity of your laser cutter.

Following the manufacturer’s guidelines will help you avoid common misconceptions about laser cutter maintenance. These guidelines provide detailed instructions on tasks such as cleaning the lens, checking the mirrors, and inspecting the machine for any signs of wear or damage. By adhering to these guidelines, you can prevent issues such as decreased cutting quality, misalignment, or even costly repairs.

It’s crucial to understand that neglecting regular maintenance can lead to decreased efficiency, increased downtime, and potential safety hazards. So, make it a priority to stay up-to-date with the manufacturer’s maintenance guidelines and keep your laser cutter in top-notch condition.

Frequently Asked Questions

How often should I clean and clear the cutting area of the laser cutter?

To properly clean the laser cutter’s cutting area, you should perform regular maintenance. Start by turning off the machine and unplugging it. Remove any debris or dust using a clean, dry cloth or brush. Avoid using liquid cleaners as they can damage the machine. Be careful not to scratch the surface while cleaning.

Additionally, avoid using compressed air as it can blow debris into sensitive areas. Always follow the manufacturer’s guidelines for cleaning to prevent any mistakes.

What type of lubricant should I use for the moving parts of the laser cutter?

To properly lubricate the moving parts of a laser cutter, you should use a high-quality lubricant specifically designed for this purpose. There are different types of lubricants available, such as silicone-based or oil-based lubricants.

Before applying the lubricant, make sure to clean the parts thoroughly to remove any debris or dust. Apply a small amount of lubricant to the designated areas, ensuring even coverage.

Regularly check and reapply lubricant as needed to maintain smooth and efficient operation of the laser cutter.

How can I determine if a component in the laser cutter needs to be replaced?

To determine if a component in the laser cutter needs to be replaced, you should first troubleshoot any issues you’re experiencing. Start by thoroughly inspecting the component for any visible damage or signs of wear and tear.

Next, test the component to see if it’s functioning properly. If it isn’t, consult the laser cutter’s manual or contact the manufacturer for guidance on how to replace the specific component.

It’s important to regularly check and maintain all components to ensure optimal performance and prevent any potential damage.

Is it possible to calibrate the laser beam alignment myself or should I hire a professional?

To ensure precise laser beam alignment, it’s highly recommended to hire a professional for calibration. Laser beam alignment techniques require technical expertise and specialized tools.

A professional can accurately align the laser beam, ensuring optimal performance and avoiding potential damage to the laser cutter. Additionally, professional calibration offers the benefit of thorough inspection and adjustment of other critical components, ensuring the overall efficiency and longevity of the laser cutter.

What are the consequences of overworking the laser cutter machine?

Overworking the laser cutter machine can have serious consequences. The machine may experience increased wear and tear, leading to breakdowns and decreased performance.

The laser tube, which is a crucial component, may deteriorate faster, resulting in reduced cutting quality. Regular maintenance is of utmost importance to prevent these issues. It allows for early detection of problems, ensures optimal performance, and prolongs the lifespan of the machine.

Neglecting maintenance can result in costly repairs and downtime.

Conclusion

In conclusion, maintaining your laser cutter is essential for its longevity and optimal performance. By regularly cleaning and lubricating the machine, monitoring and replacing worn-out components, and calibrating the laser beam alignment, you can ensure smooth operations.

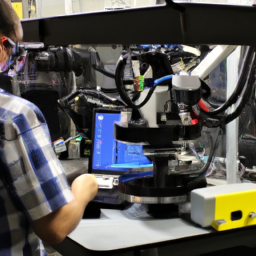

Additionally, it’s crucial to avoid overworking the machine and to stay updated with the manufacturer’s maintenance guidelines. While some may argue that maintenance can be time-consuming and tedious, the visual representation of these ideas, such as a before and after image of a well-maintained laser cutter, can showcase the benefits and motivate users to prioritize maintenance.