Are you ready to take your home decor game to the next level?

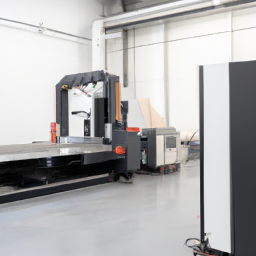

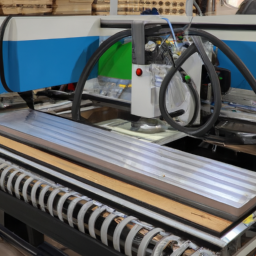

Laser cutting is an incredibly versatile and precise technique that can help you create stunning and unique pieces for your living space.

However, before you dive in, it’s important to be aware of the potential pitfalls that could derail your laser cutting projects.

In this article, we will discuss the top 10 mistakes to avoid when laser cutting home decor.

From choosing the wrong materials to neglecting proper design preparation, we will guide you through the do’s and don’ts of laser cutting.

By following our expert advice, you can ensure that your home decor projects are successful, safe, and visually striking.

So, grab your safety goggles and let’s get started on this laser cutting journey together!

Key Takeaways

- Proper design preparation is crucial for accurate and successful laser cutting of home decor.

- Safety measures, such as wearing protective equipment and maintaining a safe distance, should always be prioritized during laser cutting.

- Regular maintenance and calibration of the laser cutting machine are necessary to prevent breakdowns and ensure optimal performance.

- Conducting test cuts and adjusting settings for different materials are essential to avoid errors, wasted resources, and subpar results in laser cutting home decor.

Choosing the Wrong Materials

Don’t make the mistake of choosing the wrong materials for your laser-cut home decor, or you’ll end up with a jumbled mess of splintered wood and melted plastic. When it comes to laser cutting, it’s crucial to select materials that are of appropriate thickness and have suitable finishes.

Using materials that are too thin may result in the piece being fragile and prone to breakage. On the other hand, materials that are too thick can lead to incomplete cuts or even damage to the laser machine. Additionally, choosing materials with unsuitable finishes can affect the final appearance of your decor, leaving it looking rough or unfinished.

So, ensure you carefully consider the characteristics of the materials you choose, as they play a vital role in achieving the desired outcome.

Now let’s move on to the next section, where we’ll discuss the importance of not neglecting proper design preparation.

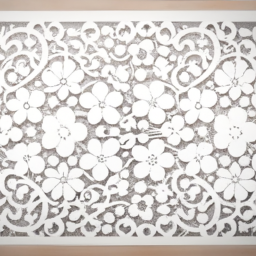

Neglecting Proper Design Preparation

Ensure you take the time to adequately plan and prepare your design to guarantee a flawless outcome when working with your laser cutter for your personal embellishments.

Before you even start cutting, it’s crucial to use design software that’s compatible with your laser cutter. This will ensure that your design is accurately translated into instructions for the laser cutter to follow.

Familiarize yourself with the software’s features and capabilities to maximize efficiency and precision. Additionally, pay attention to laser cutting techniques such as kerf width and power settings, as these can greatly affect the final result.

By neglecting proper design preparation, you risk wasting time, materials, and potential damage to your laser cutter.

Transitioning into the subsequent section about ‘ignoring safety measures,’ it’s important to remember that design preparation is just one aspect of laser cutting. Safety measures must also be prioritized.

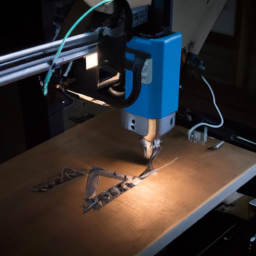

Ignoring Safety Measures

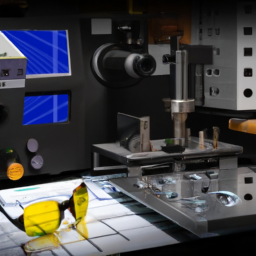

When laser cutting home decor, it’s crucial to always prioritize safety measures. To ensure your safety, make sure to wear appropriate protective equipment such as safety goggles and gloves.

Additionally, it’s important to maintain a safe distance from the laser to avoid any potential accidents or injuries.

Using protective equipment

Make sure you’ve got your safety goggles on before you start laser cutting because your eyes are just as important as the beautiful home decor you’re creating.

Using proper ventilation is essential when laser cutting home decor. It helps to remove harmful fumes and particles that may be produced during the process.

Additionally, it’s crucial to protect your eyes from potential damage caused by the laser beam. Laser cutting generates intense light that can harm your eyesight if not shielded properly. Wearing protective eyewear, such as safety goggles specifically designed for laser cutting, is a must. These goggles have the ability to filter out the harmful wavelengths of light.

By using protective equipment, you’re ensuring the safety of your eyes while creating stunning home decor.

Remember, keeping a safe distance from the laser is equally important, which will be discussed in the next section.

Keeping a safe distance from the laser

To fully appreciate your laser cutting experience, it’s important to maintain a safe distance from the mesmerizing glow of the laser beam. This not only ensures your personal safety but also helps in achieving precise and accurate cuts.

When working with a laser cutter, it’s crucial to maintain a clean and organized workspace. Clutter can obstruct your vision and increase the risk of accidents. Additionally, understanding laser safety protocols is essential. Familiarize yourself with the necessary precautions, such as wearing protective eyewear and clothing, to minimize potential hazards. Remember, the laser beam can cause severe burns and eye damage if proper precautions aren’t taken.

By following these guidelines, you can ensure a safe and successful laser cutting experience.

Moving on to the next section, it’s important not to overlook maintenance and calibration to maximize the efficiency of your laser cutter.

Overlooking Maintenance and Calibration

Don’t overlook the importance of regular maintenance and calibration to ensure optimal performance of your laser cutting machine. Following a maintenance schedule is crucial to prevent breakdowns and extend the lifespan of your equipment. This includes cleaning the machine regularly to remove dust and debris that can affect its performance.

Additionally, calibration techniques should be implemented to ensure that the laser is cutting accurately and efficiently. This involves adjusting the focus, power, and speed settings to match the requirements of your project. Neglecting maintenance and calibration can lead to inaccurate cuts, wasted materials, and potential safety hazards.

So, before moving on to the next section about not adjusting settings for different materials, make sure you prioritize maintenance and calibration to keep your laser cutting machine running smoothly.

Not Adjusting Settings for Different Materials

Neglecting to tailor the settings for various materials can result in subpar results and wasted resources. Laser cutting techniques require careful consideration of material compatibility to ensure optimal outcomes. Different materials have unique characteristics that affect how they interact with the laser beam. For instance, acrylic requires high power and low speed settings to avoid melting or charring, while wood may require lower power and higher speed to prevent burning. To avoid mistakes, it is crucial to adjust the laser cutter’s settings according to the material being used. The table below illustrates the recommended settings for commonly used materials in laser cutting:

| Material | Power Setting | Speed Setting |

|---|---|---|

| Acrylic | High | Low |

| Wood | Low | High |

| Leather | Medium | Medium |

| Cardboard | Medium | Medium |

By understanding and implementing the appropriate settings, you can achieve precise and clean cuts. However, overlooking this crucial step can lead to ruined materials and wasted efforts. Transitioning into the subsequent section, lack of planning and test cuts can exacerbate these issues.

Lack of Planning and Test Cuts

Before laser cutting your home decor, it’s crucial to create a design plan. This will help you visualize the final product and ensure that you have all the necessary materials and measurements.

Additionally, conducting test cuts is essential to ensure that the desired outcome is achieved and to avoid wasting materials. By carefully planning and testing your cuts, you can ensure a successful and efficient laser cutting process for your home decor projects.

Creating a design plan before cutting

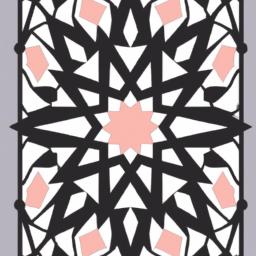

One way to ensure the success of your laser cutting project is by creating a design plan beforehand, which can significantly improve the final outcome. When starting a laser cutting project for home decor, it’s important to have a clear vision of the design you want to create.

Here are three key elements to consider when creating your design plan:

-

Design Inspiration: Gather inspiration from various sources such as magazines, websites, or even nature. This’ll help you come up with unique and creative ideas for your home decor.

-

Troubleshooting Tips: Anticipate any potential issues that may arise during the laser cutting process. Consider factors like material thickness, intricate details, and optimal cutting settings to avoid any mistakes or setbacks.

-

Material Selection: Choose the right material for your project based on its properties and suitability for laser cutting. Factors such as durability, flexibility, and the desired aesthetic should be taken into account.

By creating a comprehensive design plan, you can ensure a smooth laser cutting process and achieve the desired outcome.

Next, we’ll discuss the importance of conducting test cuts to ensure the desired outcome without any errors.

Conducting test cuts to ensure desired outcome

To truly achieve the desired outcome, it’s crucial to conduct test cuts and ensure everything is on track.

When laser cutting home decor, optimizing cutting speed and understanding laser power levels are essential. Start by optimizing cutting speed, which determines the rate at which the laser moves along the material. Adjusting the speed can prevent burning or incomplete cuts. A slower speed may be suitable for intricate designs, while a faster speed may be necessary for larger patterns.

Additionally, understanding laser power levels is crucial. Higher power levels result in deeper cuts, while lower levels are ideal for delicate materials. Testing different power levels on scraps will help determine the appropriate setting for your specific project.

By conducting test cuts, you can fine-tune the process and ensure the best possible outcome for your home decor project.

Frequently Asked Questions

Can I use any type of material for laser cutting home decor?

To ensure successful laser cutting of home decor, it’s crucial to select the appropriate material. Numerous types of materials can be used for this purpose, including wood, acrylic, leather, and fabric.

When choosing the ideal material, consider factors such as its thickness, density, and heat resistance. Additionally, take into account the design and desired finish of the decor.

By carefully evaluating these aspects, you can make an informed decision and achieve optimal results in laser cutting home decor.

How can I ensure that my design is properly prepared for laser cutting?

To ensure your design is properly prepared for laser cutting, follow these steps.

First, use design optimization techniques to simplify and streamline your design. This will ensure faster cutting and minimize errors.

Next, ensure your design is in a file format compatible with the laser cutting software, such as SVG or DXF.

Properly preparing your design will result in precise and accurate cutting, saving you time and materials.

What are some important safety measures to take when laser cutting home decor?

When laser cutting home decor, it’s crucial to prioritize safety. Proper ventilation is of utmost importance to ensure the removal of potentially harmful fumes and particles. Additionally, wearing the necessary personal protective equipment (PPE) is essential to safeguard yourself from any potential injuries. These precautions help minimize the risks associated with laser cutting, ensuring a safe and secure environment for creating your home decor pieces.

How often should I maintain and calibrate my laser cutting machine?

To ensure optimal performance, it’s crucial to maintain and calibrate your laser cutting machine regularly. The maintenance frequency and calibration process depend on several factors, such as the machine’s usage and manufacturer’s recommendations.

Typically, it’s advised to perform routine maintenance every 100-150 hours of operation. Calibration should be done at least once a year, or whenever you notice any inconsistencies in the cutting quality or accuracy.

Following these guidelines will help maximize the lifespan and efficiency of your laser cutting machine.

What settings should I adjust when working with different materials?

To achieve optimal results when laser cutting different materials for home decor, you need to make precise adjustments. Think of it like driving a car on a winding road. Adjusting power and speed is like finding the perfect balance between acceleration and control. Too much power can burn through delicate materials, while too little can leave uneven cuts.

Choosing the right focal length is like adjusting your seat position for better visibility. It ensures that the laser beam is focused accurately, resulting in clean and precise cuts.

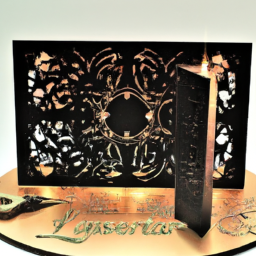

Conclusion

In conclusion, laser cutting home decor requires precision and expertise to avoid common mistakes. By choosing the right materials, preparing designs thoroughly, and following safety measures, you can ensure a successful outcome.

Remember to regularly maintain and calibrate your laser cutter for optimal performance. Adjusting settings for different materials is crucial to achieve desired results. Lastly, meticulous planning and conducting test cuts will save you time and resources.

Just like a skilled craftsman wielding a sharp blade, mastering the art of laser cutting will carve out beautiful creations that will leave a lasting impression.