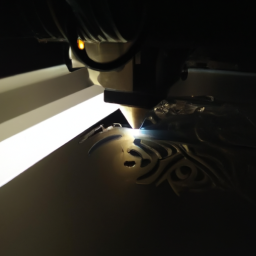

Hey there, jewelry makers! Are you tired of making costly mistakes when laser cutting your precious pieces? Well, fear not! We’re here to help you avoid those blunders and ensure a smooth and successful laser cutting process.

In this article, we’ll guide you through the top 10 mistakes to steer clear of when laser cutting jewelry. Whether you’re a seasoned pro or just starting out, these tips will save you time, money, and headaches.

From choosing the wrong materials to neglecting safety precautions, we’ll cover it all. By the end of this read, you’ll be equipped with the knowledge and expertise to produce flawless laser-cut jewelry every time.

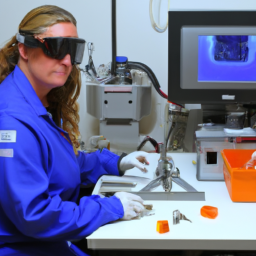

So, grab your goggles and let’s dive in to discover the secrets of successful laser cutting!

Key Takeaways

- Choosing the right material is crucial for successful laser cutting of jewelry.

- Follow proper design guidelines and dimensions to ensure quality.

- Conduct test cuts and engravings to determine optimal settings and achieve precision.

- Take necessary safety precautions and avoid rushing to prevent mistakes and compromised quality.

Choosing the Wrong Material

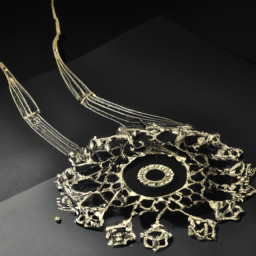

Don’t make the mistake of choosing the wrong material for your jewelry, as it could result in a disappointing outcome and wasted time and effort. When laser cutting jewelry, it’s crucial to evaluate material compatibility to ensure a successful outcome.

Different materials have varying properties and react differently to laser cutting. Some materials may not be suitable for intricate designs or may release toxic fumes when cut. It’s important to consider factors such as thickness, density, and heat resistance when selecting the material for your jewelry.

Conduct thorough research and consult with experts to determine the best material that suits your design and desired outcome. By choosing the right material, you can avoid potential complications and achieve the desired precision and quality in your laser-cut jewelry.

Now, let’s dive into the next section and learn about the importance of not ignoring proper design guidelines.

Ignoring Proper Design Guidelines

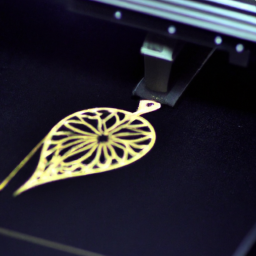

Neglecting to follow proper design guidelines can lead to a haphazard creation, like a house without a sturdy foundation. When laser cutting jewelry, it’s crucial to pay attention to design inspiration and ensure that your designs are suitable for laser cutting.

Consider the intricacy and complexity of your design, as well as the limitations of the laser cutting machine. It’s important to avoid designs with small, fragile parts that may easily break during the cutting process. Additionally, make sure to adhere to the recommended minimum and maximum dimensions for your materials.

Troubleshooting tips can include adjusting the spacing between elements, simplifying complex designs, and avoiding overlapping lines. By following proper design guidelines, you can ensure the success and quality of your laser-cut jewelry.

Transitioning into the next section, it’s also essential to not forget to test settings and parameters before proceeding.

Not Testing Settings and Parameters

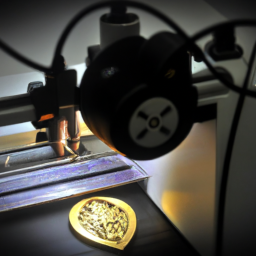

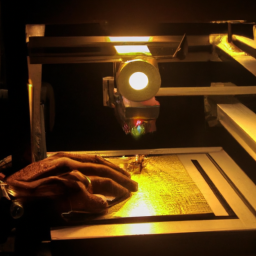

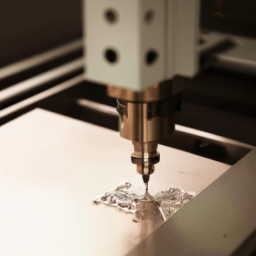

When laser cutting jewelry, it’s crucial to conduct test cuts and engravings on scrap materials before working on the final piece.

By doing so, you can determine the optimal settings and parameters for the specific material you’re using. Adjusting the power, speed, and frequency based on the material properties will ensure precise and accurate cuts, avoiding any potential damage or errors.

Conduct Test Cuts and Engravings on Scrap Materials

Ensure you try out test cuts and engravings on scrap materials to avoid any mishaps when laser cutting jewelry. By testing different designs and optimizing cutting and engraving speed, you can determine the ideal settings for your specific materials. Here are five reasons why conducting test cuts and engravings is crucial:

-

It helps you assess the quality and precision of the laser cuts and engravings.

-

You can check if the design details are accurately translated onto the jewelry.

-

It allows you to identify the optimal cutting and engraving speed for different materials.

-

You can avoid costly mistakes by identifying any potential issues or errors before working on the final piece.

-

It gives you the opportunity to experiment with different techniques and settings, ensuring you achieve the desired result.

By conducting test cuts and engravings, you can fine-tune your laser cutting process and make necessary adjustments to power, speed, and frequency based on the material properties. This ensures a smooth transition into the subsequent section about adjusting these parameters.

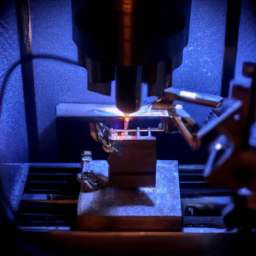

Adjust Power, Speed, and Frequency Based on Material Properties

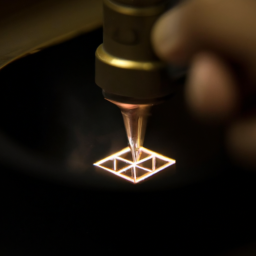

Fine-tune your laser cutting process by adjusting the power, speed, and frequency of your machine based on the unique properties of the materials you’re working with. This will allow your creativity to shine like a polished gem.

Adjusting laser settings is crucial for achieving precise cuts and engravings on different types of jewelry materials. To determine the appropriate settings, it’s important to understand material properties such as density, thickness, and composition.

For example, harder and denser materials like metal may require higher power levels and slower speeds to ensure clean cuts. On the other hand, softer materials like acrylic may need lower power and faster speeds to prevent melting or burning.

Additionally, the frequency setting can affect the level of detail and smoothness of the cut. By carefully adjusting these settings, you can achieve the desired results and avoid costly mistakes.

Now, let’s move on to the next section about neglecting safety precautions.

Neglecting Safety Precautions

Don’t ignore safety precautions – you’re risking serious injury or damage to your jewelry. When laser cutting jewelry, it is essential to prioritize safety by following workplace hazard protocols and using appropriate protective equipment. Take a look at the table below for a quick overview of common safety precautions to keep in mind.

| Safety Precautions | Description |

|---|---|

| Wear protective eyewear | Shield your eyes from potential laser beam reflections or particles. |

| Use proper ventilation | Ensure adequate air circulation to minimize fumes and prevent respiratory issues. |

| Keep a fire extinguisher nearby | Be prepared to handle any unexpected fires that may occur. |

| Avoid loose clothing or jewelry | Prevent any items from getting caught in the laser machine, which can cause accidents. |

By neglecting safety precautions, you not only put yourself at risk but also jeopardize the quality and integrity of your jewelry. In the next section, we will discuss the importance of not overlooking maintenance and calibration.

Overlooking Maintenance and Calibration

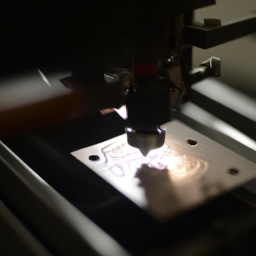

To ensure precise and accurate cuts and engravings, it’s crucial that you regularly clean your laser cutter to prevent debris build-up. This will help maintain the machine’s performance and prevent any potential damage.

Additionally, it’s important to calibrate the machine to ensure that it’s properly aligned and functioning correctly, guaranteeing the highest level of precision in your jewelry designs.

Clean the Laser Cutter Regularly to Prevent Debris Build-up

Make sure you regularly clean the laser cutter to avoid any debris build-up that could potentially interfere with the precision of your jewelry cuts. Cleaning the laser cutter is an essential part of laser cutter maintenance, as it helps prevent debris buildup that can affect the performance of the machine. Here are two important steps you should follow when cleaning the laser cutter:

-

Remove any loose debris: Start by removing any loose debris from the machine, such as dust, metal shavings, or small scraps of material. Use a soft brush or compressed air to gently clean the laser cutter, ensuring that all debris is removed from the surface and inside the machine.

-

Wipe down the machine: After removing the loose debris, wipe down the laser cutter with a clean, lint-free cloth. Make sure to clean all parts of the machine, including the lens, mirrors, and cutting bed. This will help maintain the cleanliness of the laser cutter and prevent debris from accumulating.

Regularly cleaning the laser cutter is just one aspect of maintenance. Additionally, it’s important to calibrate the machine to ensure accurate cuts and engravings.

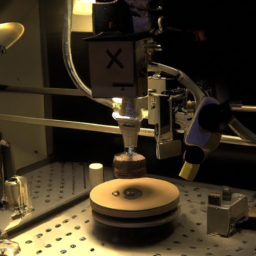

Calibrate the Machine to Ensure Accurate Cuts and Engravings

Ensuring precise and flawless craftsmanship in your jewelry creations requires careful calibration of the laser cutter machine. Proper calibration guarantees accurate cuts and engravings, avoiding costly mistakes and wasted materials. To maintain the machine’s performance and achieve optimal results, regular machine maintenance is vital. This includes cleaning the lenses, mirrors, and cutting bed, as well as checking and replacing any worn-out parts. Troubleshooting common issues like misalignment or power fluctuations should also be addressed promptly to prevent compromised outcomes.

To help you understand the calibration process better, refer to the table below:

| Calibration Step | Description |

|---|---|

| Lens Alignment | Adjusting the position of the lens to ensure the laser beam hits the target accurately. |

| Power Calibration | Fine-tuning the laser power settings to achieve desired cutting or engraving results. |

| Focus Adjustment | Setting the correct focal length for optimal precision and clarity. |

| Speed and Feed Rate | Adjusting the machine’s speed and feed settings to control the cutting or engraving speed. |

| Test Cuts and Engravings | Performing trial runs to verify the accuracy of the machine’s settings. |

By following these calibration steps and maintaining your laser cutter machine, you will be able to produce high-quality jewelry with confidence. Now, let’s delve into the next section about ‘rushing the process’ to further enhance your laser cutting skills.

Rushing the Process

Don’t rush through the laser cutting process or you’ll end up with jagged edges and uneven designs on your jewelry. It’s important to take your time and ensure that each cut and engraving is done with precision. Rushing the process can lead to mistakes and compromised quality.

Additionally, improper ventilation and inadequate training can contribute to rushed work. Without proper ventilation, the laser cutter may not function optimally, resulting in inaccurate cuts and engravings. Similarly, if you haven’t received adequate training on how to operate the machine, you may be tempted to rush through the process to save time. However, this can lead to costly errors and wasted materials.

So, take your time, follow proper procedures, and avoid rushing the laser cutting process to achieve the best results for your jewelry.

Frequently Asked Questions

What are the typical design guidelines to follow when laser cutting jewelry?

To ensure successful laser cutting of jewelry, there are typical laser cutting techniques and popular jewelry designs that you should follow.

When it comes to laser cutting techniques, it’s important to consider factors such as material thickness, laser power, and cutting speed.

As for popular jewelry designs, intricate patterns, delicate filigree work, and personalized engravings are often favored.

By adhering to these design guidelines, you can achieve precise and beautiful laser-cut jewelry pieces.

How can I ensure the safety of myself and others while laser cutting jewelry?

To ensure safety while laser cutting jewelry, it’s crucial to take protective measures. Start by wearing appropriate personal protective equipment, such as safety glasses and gloves, to shield yourself from potential hazards.

Clear the work area of any flammable materials and ensure there are no obstructions that could cause accidents. Regularly inspect the laser cutter for any issues and follow the manufacturer’s guidelines for safe operation.

By implementing these precautions, you can ensure a safe environment for yourself and others.

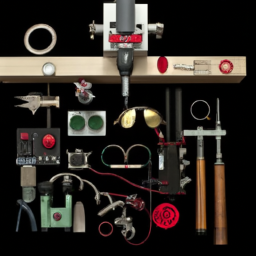

What are the most common maintenance and calibration tasks required for a laser cutting machine used in jewelry making?

To maintain and calibrate a laser cutting machine used in jewelry making, there are several important tasks to consider.

Regular maintenance tasks include cleaning the machine’s optics, checking the alignment of the laser beam, and ensuring proper ventilation.

Calibration procedures involve adjusting the power and speed settings for different materials and thicknesses, as well as testing and adjusting the focal length.

These tasks are crucial for ensuring precise and accurate laser cutting results in jewelry production.

Are there any specific settings and parameters that should be tested before starting a laser cutting project for jewelry?

Before starting a laser cutting project for jewelry, it’s crucial to test specific settings and parameters to ensure optimal results. Juxtaposing different settings allows you to visually compare and select the most suitable ones.

Begin by testing power levels to achieve the desired cutting depth and speed. Next, experiment with different focal lengths and beam sizes for precision. Additionally, examine the material’s thickness and adjust the cutting speed accordingly.

Thoroughly testing these settings will ensure a successful laser cutting project for jewelry.

How can rushing the laser cutting process affect the quality and outcome of the jewelry pieces?

Rushing the laser cutting process can have a detrimental impact on the quality of your jewelry pieces. When you rush, you may overlook important details like checking the laser settings and parameters, resulting in inaccurate cuts or even damage to the material.

Additionally, rushing can lead to uneven heat distribution, causing the jewelry to warp or melt. Taking the time to properly set up and execute the laser cutting process ensures a higher-quality outcome for your jewelry pieces.

Conclusion

In conclusion, to ensure successful laser cutting of jewelry, avoid these ten critical mistakes.

By choosing the wrong material, ignoring design guidelines, and neglecting safety precautions, you risk ruining your precious creations.

Don’t overlook the importance of testing settings and parameters, as well as maintaining and calibrating your laser cutter. Rushing the process can result in costly errors.

Remember, precision and attention to detail are key when crafting exquisite jewelry. Take the time to avoid these pitfalls and watch your designs come to life with flawless brilliance.