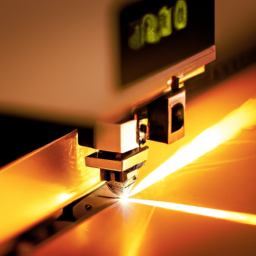

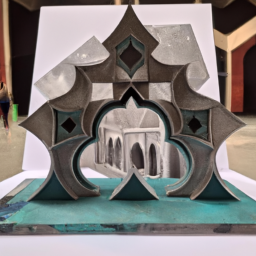

Laser cutting models can be an exhilarating process, allowing you to transform your design ideas into tangible creations. However, amidst the excitement, it’s crucial to avoid common mistakes that could compromise the quality and precision of your final product. In this article, we will explore ten crucial mistakes that you must steer clear of when laser cutting models.

By juxtaposing the thrill of creation with the technical precision required, we aim to guide you towards flawless results.

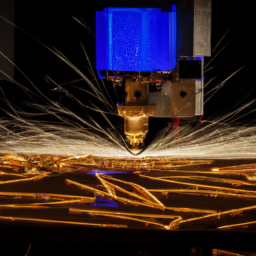

Firstly, choosing the wrong materials can spell disaster for your project. You must carefully select materials that are compatible with laser cutting to ensure clean and precise cuts.

Additionally, neglecting to account for kerf width, the amount of material removed during the cutting process, can lead to misaligned or ill-fitting pieces. Securing your material properly is also paramount, as any movement during cutting can result in errors.

Furthermore, ventilation and safety measures should never be overlooked. Laser cutting produces fumes and heat that can pose health risks, so proper ventilation and protective gear are crucial.

Lastly, ignoring design file preparation and failing to test and adjust settings can lead to flawed outcomes. So, let’s delve into these ten mistakes and equip you with the knowledge to avoid them, ensuring your laser-cut models are nothing short of perfection.

Key Takeaways

- Choosing the wrong materials can compromise the quality and precision of the final product

- Neglecting to account for kerf width can result in misaligned or ill-fitting pieces

- Properly securing the material is important for accurate cuts and to prevent misalignment

- Ventilation systems and safety measures should not be overlooked to avoid health risks and damage to the laser cutter

Choosing the Wrong Materials

Don’t make the mistake of choosing the wrong materials for your laser-cut models – it’s a surefire way to waste time, money, and effort.

When it comes to laser cutting, material compatibility is crucial. Not all materials are suitable for laser cutting, as some may release toxic fumes or damage the laser equipment. It’s important to research and select materials that are compatible with laser cutting, such as wood, acrylic, or metal.

Additionally, choosing cost-effective options is essential to keep your expenses in check. Some materials may be more expensive than others, so it’s important to weigh the benefits and costs.

Now, let’s move on to another common mistake: neglecting to account for kerf width.

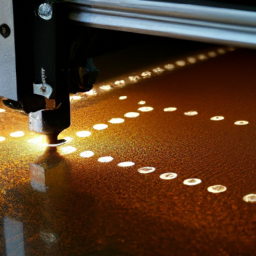

Neglecting to Account for Kerf Width

Be sure to take into consideration the kerf width when designing your project for laser cutting, as it adds an extra touch of precision to the final result. Understanding laser cutting limitations and considering post-processing requirements are crucial when accounting for kerf width. Laser cutting works by vaporizing the material along the cutting path, resulting in a small amount of material loss known as the kerf. This width varies depending on the laser and material being used. Failing to account for kerf width can lead to inaccuracies in the final product, especially if tight tolerances are required. To help you visualize the impact of kerf width, refer to the table below:

| Material | Laser Type | Kerf Width |

|---|---|---|

| Wood | CO2 | 0.2mm |

| Acrylic | CO2 | 0.1mm |

| Metal | Fiber | 0.05mm |

By understanding the kerf width of different materials and laser types, you can design your project accordingly and avoid costly mistakes. Neglecting to account for kerf width can lead to misaligned cuts and parts that do not fit together properly. This can be easily avoided by taking the kerf width into consideration from the start.

Not Properly Securing the Material

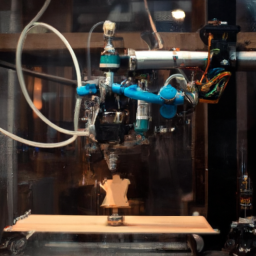

Ensure that your material is securely fastened before proceeding with laser cutting, as this will greatly enhance the overall quality and precision of your project. Proper material alignment is crucial to achieve accurate cuts, so take the time to align your material properly on the laser bed.

Use clamping techniques to secure the material in place, ensuring that it doesn’t move during the cutting process. This will prevent any misalignment or shifting, which can lead to uneven cuts or even damage to the laser cutter. Additionally, make sure to choose appropriate clamps that won’t interfere with the laser beam or obstruct the cutting path.

By securely fastening your material, you can avoid costly mistakes and ensure a successful laser cutting process.

Moving on to the next section, ignoring ventilation and safety measures can have serious consequences for both your health and the performance of the laser cutter.

Ignoring Ventilation and Safety Measures

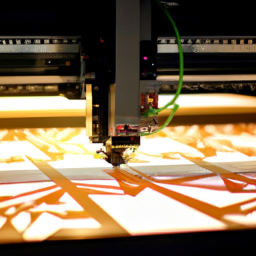

Neglecting proper ventilation and safety measures can leave you in a cloud of danger, risking your health and the efficiency of the laser cutter. When laser cutting models, it’s crucial to take ventilation precautions seriously.

Laser cutting releases harmful fumes and particles that can be detrimental to your respiratory system if not properly ventilated. Ensure that your workspace is equipped with proper ventilation systems, such as exhaust fans or air purifiers, to effectively remove these hazardous substances from the air.

Additionally, it’s essential to adhere to safety equipment requirements. Always wear protective goggles to shield your eyes from laser beams and use gloves to prevent burns. Ignoring these safety measures can result in severe injuries and damage to the laser cutter.

By overlooking design file preparation, you risk encountering further issues down the line.

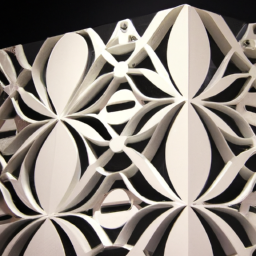

Overlooking Design File Preparation

When it comes to preparing your design files, don’t underestimate the importance of careful attention and thoroughness. Ignoring proper design file preparation can result in inefficiencies and wasted materials during the laser cutting process. Design file optimization is crucial for maximizing laser cutting efficiency and achieving accurate and clean cuts. Here are some key factors to consider:

| Factor | Description |

|---|---|

| File Format | Ensure your design files are compatible with the laser cutting software. |

| Line Colors | Use different line colors to indicate cut, engrave, and etch operations for easy identification. |

| Overlapping Objects | Avoid overlapping objects as it can lead to incorrect cuts or damage to the laser machine. |

| Line Thickness | Optimize line thickness to achieve desired cutting depth and precision. |

| Material Constraints | Take into account material properties and limitations when designing your models. |

By paying attention to these details, you can optimize your design files and avoid costly mistakes. Failing to test and adjust settings can further jeopardize the success of your laser cutting project, so it is essential to approach this step with caution.

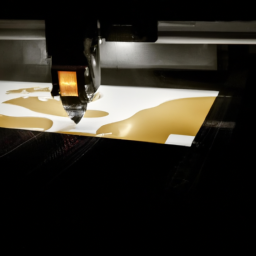

Failing to Test and Adjust Settings

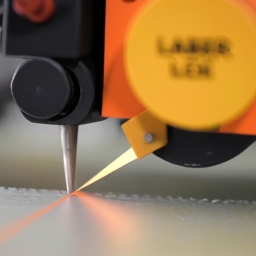

Don’t underestimate the impact of not properly testing and adjusting settings, as it can lead to wasted time, materials, and frustration during your laser cutting project. Testing accuracy and adjusting power are crucial steps to ensure a successful outcome.

Here are two important considerations to keep in mind:

-

Test different power levels: Laser cutters have adjustable power settings, and it’s essential to test different levels to find the optimal one for your specific material. Too high of a power level can result in burnt edges or even damage to the material, while too low of a power level may lead to incomplete cuts.

-

Adjust speed and feed rate: Alongside power, the speed and feed rate of the laser cutter play a significant role in achieving clean and precise cuts. Experiment with different combinations to find the right balance that provides accurate results without causing excessive melting or charring.

By thoroughly testing and adjusting the settings, you can maximize the efficiency and accuracy of your laser cutting project.

Frequently Asked Questions

Can I use any type of material for laser cutting?

When it comes to laser cutting, not all materials are suitable. Choosing the right material is crucial for successful results. Different materials have different properties that affect the cutting process. Factors like thickness, density, and composition should be considered.

Metals like stainless steel, aluminum, and brass are commonly used for laser cutting due to their high heat resistance. Other materials like acrylic, wood, and leather can also be laser cut, but require specific settings.

It’s important to research and test materials before proceeding with laser cutting.

What is kerf width and why is it important to consider?

To optimize laser cutting, it’s crucial to understand the importance of kerf width. Kerf width refers to the material that’s removed by the laser during the cutting process. It’s essential to consider because it affects the accuracy and precision of the cut. By taking into account the kerf width, you can ensure that your laser-cut models are designed with the appropriate dimensions and fit together seamlessly.

How can I secure the material properly during laser cutting?

To prevent material movement during laser cutting, there are several best practices for securing materials.

Firstly, ensure that the material is flat and even by using a level or a flat surface.

Secondly, use clamps or magnets to firmly hold down the material and prevent any shifting.

Additionally, double-sided tape can be applied to the edges of the material for added stability.

These methods will help maintain accuracy and prevent any unwanted movement during the laser cutting process.

Are there any safety measures I should take into account while laser cutting?

When laser cutting, your safety should be paramount. To ensure a secure and accident-free process, it’s crucial to take necessary safety precautions.

First, make sure to wear appropriate protective gear, including safety glasses and gloves.

Additionally, always have a fire extinguisher nearby and avoid using flammable materials.

It’s also essential to have the necessary equipment, such as a ventilation system, to prevent exposure to harmful fumes.

By following these safety measures, you can confidently engage in laser cutting while minimizing risks.

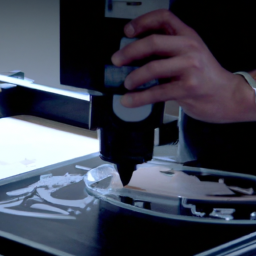

What steps should I follow to prepare my design files for laser cutting?

To prepare your design files for laser cutting, start by creating your design using design software such as Adobe Illustrator or CorelDRAW. Make sure that your design is in the correct file format, usually a vector file format like .ai or .svg.

Next, check your design for any open paths or overlapping lines, as these can cause issues during the cutting process.

Finally, be sure to save your design file with the appropriate settings for laser cutting.

Conclusion

In conclusion, when it comes to laser cutting models, you must tread carefully to avoid stumbling upon the pitfalls that may lie ahead.

Make sure to choose the right materials, account for the kerf width, and secure the material properly.

Don’t forget to prioritize ventilation and safety measures, and always prepare your design files meticulously.

Lastly, never skip the crucial step of testing and adjusting the settings.

By navigating these obstacles with precision and finesse, you’ll carve out a masterpiece that shines brightly in the world of laser cutting.