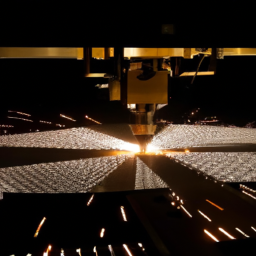

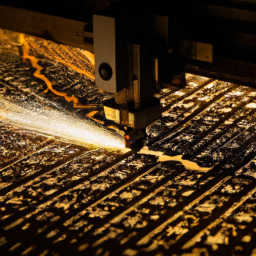

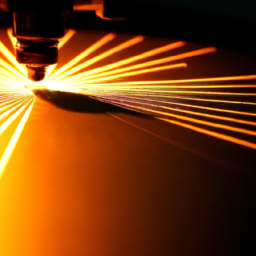

Coincidentally, as you delve into the world of metal fabrication, you find yourself in possession of a laser cutting machine. A powerful tool capable of precision and efficiency, but did you know that there are accessories that can enhance its capabilities even further?

In this article, we will explore 10 must-have accessories that will elevate your laser cutting machine to new heights in metal fabrication.

First and foremost, a precision focusing lens is essential for achieving the utmost accuracy in your cuts. By fine-tuning the focal point of the laser beam, you can ensure that every detail is captured flawlessly.

Additionally, an air assist system is crucial for preventing material from overheating and causing damage, while also improving the overall cutting quality.

To expand your machine’s capabilities, a beam combiner allows for the simultaneous use of multiple lasers, increasing productivity and versatility.

A rotary attachment enables you to rotate cylindrical objects, opening up a world of possibilities for intricate engraving and cutting.

Furthermore, a honeycomb cutting table provides optimal support and ventilation, ensuring clean and precise cuts.

Lastly, an exhaust system is vital for removing fumes and debris, maintaining a safe and clean working environment.

With these 10 must-have accessories, your laser cutting machine will become an unstoppable force in the realm of metal fabrication. So, gear up and prepare to take your creations to the next level.

Key Takeaways

- Precision focusing lens is essential for accuracy in cuts and optimizing the quality of cuts by focusing the laser beam.

- An air assist system improves cutting quality, reduces heat damage, increases cutting speeds, extends lens life, and enhances safety.

- A beam combiner merges multiple laser beams into one focused beam, simplifying setup, reducing costs, improving cutting accuracy, and enhancing laser safety.

- A rotary attachment allows for 360-degree cutting and engraving on cylindrical objects, making it ideal for customization and personalization of various items.

Precision Focusing Lens

If you’re serious about achieving the highest level of precision in your metal fabrication projects, you’ll definitely want to invest in a precision focusing lens for your laser cutting machine. This essential accessory allows you to optimize the quality of your cuts by ensuring that the laser beam is focused precisely on the material.

With a precision focusing lens, you can make fine adjustments to the focal length, enabling you to achieve the desired depth of cut with utmost accuracy. Additionally, regular lens cleaning is crucial to maintain optimal performance. Dust or debris on the lens can cause beam distortion and compromise the quality of your cuts.

By investing in a precision focusing lens and diligently performing lens cleaning and focal length adjustments, you can ensure that your laser cutting machine operates at its best, delivering precise and clean cuts.

Now let’s move on to the next important accessory: air assist.

Air Assist

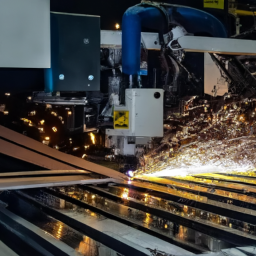

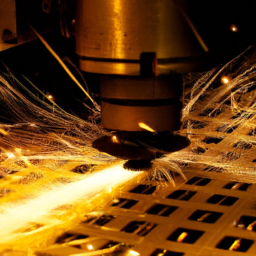

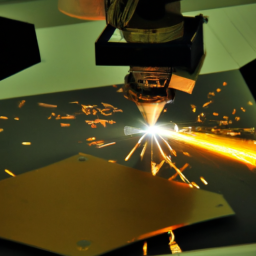

Enhance your metal fabrication process with the addition of air assist for optimal laser cutting results. Air assist is an essential accessory for your laser cutting machine, providing numerous benefits that improve the efficiency and quality of your cuts. Here are five key benefits of using air assist:

-

Improved cutting quality: The introduction of compressed air helps blow away molten metal and debris, resulting in cleaner and smoother cuts.

-

Reduced heat damage: Air assist helps dissipate heat generated during the cutting process, preventing material warping and minimizing heat-affected zones.

-

Faster cutting speeds: By clearing away debris, air assist allows the laser to cut at higher speeds, increasing productivity.

-

Extended lens life: The constant flow of air helps to keep the lens clean, reducing the risk of contamination and prolonging its lifespan.

-

Enhanced safety: Air assist helps to prevent fires by removing combustible gases and dust particles from the cutting area.

In case you encounter any issues with air assist, such as inadequate airflow or uneven distribution, troubleshooting steps should be followed to identify and rectify the problem.

Transitioning to the subsequent section, the next must-have accessory for your laser cutting machine in metal fabrication is the beam combiner.

Beam Combiner

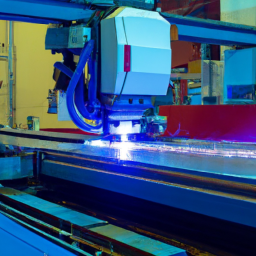

The beam combiner is like a powerful lens that merges multiple laser beams into one focused beam for precise and efficient cutting. It plays a crucial role in the laser cutting process by ensuring laser alignment and enhancing laser safety.

By combining the beams, the beam combiner eliminates the need for multiple laser sources, simplifying the setup and reducing costs. Additionally, it improves the cutting accuracy by minimizing the divergence of the laser beam. This results in cleaner and more precise cuts, especially when working with intricate designs or materials of varying thicknesses.

Laser safety is also enhanced as the beam combiner helps to minimize the risk of stray laser beams, reducing the chances of accidental eye damage.

Now, let’s move on to the next important accessory, the rotary attachment, which allows for 360-degree cutting and engraving.

Rotary Attachment

Get ready to take your laser cutting to the next level with the rotary attachment. It will allow you to engrave and cut in a complete circle, like a spinning top. This accessory is specifically designed for laser engraving and cutting machines. It provides the capability to rotate cylindrical objects while they are being engraved or cut.

With the rotary attachment, you can easily customize and personalize items such as glasses, bottles, pens, and even curved surfaces like pipes and tubes. It offers precise control and stability, ensuring that your engravings are accurate and symmetrical. This attachment is a must-have for any metal fabrication workshop that requires intricate and detailed engraving on cylindrical objects.

Now, let’s move on to the next essential accessory, the honeycomb cutting table.

Honeycomb Cutting Table

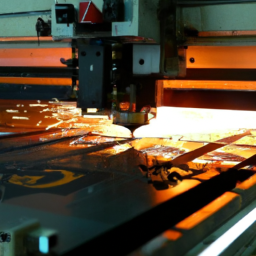

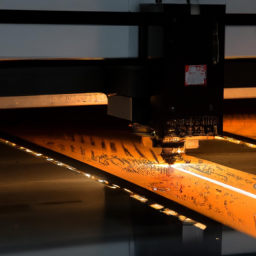

Discover the versatility of the honeycomb cutting table, a game-changing addition that allows you to effortlessly tackle intricate designs and delicate materials with your laser cutter. This essential accessory provides a stable and reliable material support system, ensuring precise and accurate cuts every time.

Here’s why the honeycomb cutting table is a must-have for your metal fabrication needs:

-

Laser Beam Alignment: The honeycomb design allows the laser beam to pass through the table, ensuring optimal alignment and reducing the risk of deflection or distortion during the cutting process.

-

Enhanced Material Support: The honeycomb structure provides excellent support for thin and delicate materials, preventing them from sagging or warping during cutting, resulting in cleaner and more precise cuts.

-

Efficient Smoke and Debris Removal: The honeycomb design allows smoke and debris to be efficiently drawn downwards through the table, keeping your work area clean and reducing the risk of damage to the laser cutter.

-

Versatile Applications: Whether you’re working with wood, acrylic, or other materials, the honeycomb cutting table offers versatility, allowing you to achieve intricate designs and fine details with ease.

The honeycomb cutting table sets the foundation for a successful laser cutting process. As you move on to the next section about the exhaust system, you’ll see how these accessories work together to optimize your metal fabrication experience.

Exhaust System

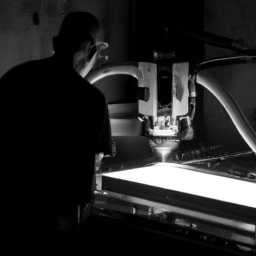

Explore the benefits of the exhaust system to optimize your laser cutting experience and ensure a clean and safe work environment. Proper exhaust system maintenance is crucial in metal fabrication to effectively remove fumes, smoke, and debris generated during the laser cutting process.

By regularly cleaning and inspecting the exhaust system, you can prevent clogs and ensure optimal airflow. Clogged exhaust systems can lead to reduced cutting efficiency, increased risk of fires, and decreased lifespan of the laser machine.

To optimize exhaust airflow, it’s important to position the exhaust vents strategically to capture the fumes as close to the cutting area as possible. Additionally, consider using a high-quality exhaust fan that can handle the volume of air produced during laser cutting.

Taking these steps will not only improve the cutting quality but also enhance the overall safety of your metal fabrication workspace.

Frequently Asked Questions

What is the recommended maintenance schedule for the precision focusing lens of a laser cutting machine?

To ensure optimal performance of your laser cutting machine, it’s crucial to follow a recommended maintenance schedule for the precision focusing lens.

Regularly clean the lens using a lint-free cloth and a mild cleaning solution. Inspect the lens for any signs of damage or scratches, and replace it if necessary.

Additionally, make sure the lens is properly aligned and calibrated to guarantee accurate cutting results.

Adhering to this maintenance schedule will extend the lifespan of your precision focusing lens and maintain the overall efficiency of your laser cutting machine.

Can an air assist system be retrofitted to an existing laser cutting machine?

Yes, you can retrofit an air assist system to an existing laser cutting machine. Retrofitting air assist offers numerous benefits. It enhances cutting quality by removing debris and preventing material from overheating. The focused air stream also helps to cool the material, reducing the risk of warping or distortion. Additionally, air assist improves the efficiency of the cutting process by blowing away the molten material, resulting in cleaner and more precise cuts.

How does a beam combiner improve the efficiency of a laser cutting machine?

A beam combiner is a valuable accessory that greatly enhances the efficiency of a laser cutting machine. By combining multiple laser beams into a single beam, the cutting process becomes more precise and faster.

The beam combiner benefits include improved accuracy, reduced material waste, and increased productivity. This technology allows for better control and manipulation of the laser beam, resulting in cleaner and smoother cuts.

Overall, the beam combiner greatly improves laser cutting efficiency and is a must-have accessory for metal fabrication.

Is a rotary attachment compatible with all types of metal fabrication projects?

Like a chameleon adapting to its surroundings, a rotary attachment seamlessly integrates with various metal fabrication projects. Its compatibility knows no bounds, allowing it to effortlessly accommodate different types of materials and designs.

This versatile tool enhances the capabilities of your laser cutting machine by enabling precise and efficient rotation of objects during the cutting process. Its technical prowess and adaptability make it an indispensable accessory for any metal fabrication project, providing endless possibilities for creative and intricate designs.

What safety precautions should be taken when using an exhaust system with a laser cutting machine?

When using a laser cutting machine exhaust system, it’s important to follow certain safety precautions. First, ensure that the exhaust system is properly installed and functioning correctly to remove smoke and fumes from the cutting area.

Regularly clean and maintain the system to prevent buildup and blockages. Additionally, always wear appropriate personal protective equipment, such as goggles and gloves, when operating the machine.

Finally, establish a maintenance schedule for the precision focusing lens to ensure optimal performance and accuracy.

Conclusion

In conclusion, when it comes to metal fabrication with a laser cutting machine, it’s crucial to have the right accessories. Each accessory plays a vital role in enhancing the machine’s performance. From the precision focusing lens to the exhaust system, these accessories are essential for achieving precise and efficient results.

One interesting statistic to consider is that using a honeycomb cutting table can increase the cutting speed by up to 100% compared to using a standard cutting table. This visual representation highlights the importance of investing in these must-have accessories for a successful metal fabrication process.