Did you know that efficient workflow and integration with laser cutter software can increase productivity by up to 30%? With laser cutting becoming increasingly popular in various industries, it is crucial to optimize your workflow to stay ahead of the competition.

In this article, we will explore 10 proven strategies that will help you streamline your workflow and seamlessly integrate with laser cutter software.

To begin, familiarize yourself with the software interface. Understanding the layout and functionality of the software will enable you to work more efficiently.

Next, optimize file preparation and organization by using file naming conventions and folder structures. This will save you time searching for files and ensure a smooth workflow.

Additionally, take advantage of shortcut keys and customizable settings to speed up your work process. Software automation features can also be utilized to automate repetitive tasks, further increasing efficiency.

Using templates and libraries will save you time and effort by providing pre-designed elements and resources.

Lastly, regularly updating and maintaining your software is essential to ensure it runs smoothly and efficiently.

By implementing these strategies, you can maximize your laser cutter software’s potential and achieve a streamlined workflow for optimal productivity.

Key Takeaways

- Efficient workflow and integration with laser cutter software can increase productivity by up to 30%.

- Optimizing file preparation and organization using naming conventions and folder structures is crucial for maximum efficiency.

- Shortcut keys and customizable settings can speed up the work process and enhance productivity.

- Templates and libraries save time and effort by providing pre-designed elements and ensuring consistency.

Familiarize Yourself with the Software Interface

Get ready to dive into the software interface and watch your excitement soar as you navigate your way through the laser cutter software like a pro! Mastering laser cutter software tools is crucial for a streamlined workflow and integration with the machine.

Familiarize yourself with the various tools available, such as the selection, drawing, and editing tools, to efficiently create and modify designs. Additionally, understanding the software’s interface will help you troubleshoot common software issues that may arise during the design process.

Take the time to explore the software’s menus, panels, and shortcuts to optimize your workflow. Now that you have a solid foundation in using the laser cutter software, let’s explore how to optimize file preparation and organization for seamless integration with the machine.

Optimize File Preparation and Organization

Improve your file preparation and organization to maximize efficiency when working with a laser cutter.

- Utilize file naming conventions to easily identify and locate files for laser cutting projects.

- Integrate cloud storage solutions to securely store and access your design files from anywhere.

- Organize your files in a logical folder structure to streamline workflow and avoid confusion.

File naming conventions are essential for efficient file management. Use descriptive names that include project details, such as material type, dimensions, and version numbers. This will help you quickly identify the correct file for laser cutting and prevent mistakes.

Integrating cloud storage services like Google Drive or Dropbox allows you to access your design files from multiple devices and share them with collaborators. This ensures seamless collaboration and minimizes the risk of file loss or data corruption.

By organizing your files in a logical folder structure, you can easily locate and retrieve the files you need. Create folders for different projects or categories, and consider adding subfolders for specific components or versions. This will save time and effort when searching for files.

Transitioning to the next section, "utilize shortcut keys and customizable settings," will further enhance your workflow and productivity.

Utilize Shortcut Keys and Customizable Settings

Enhance your laser cutting experience by harnessing the power of shortcut keys and customizable settings, allowing you to effortlessly navigate through your design software like a seasoned pianist playing a familiar melody. By utilizing shortcut keys, you can execute commands with a single keystroke, saving valuable time and enhancing productivity through automation. Customizable settings further maximize precision, enabling you to fine-tune parameters and tailor the software to your specific needs. For example, you can adjust cutting speeds, power levels, and material settings, ensuring optimal results for every project. To provide a visual representation of these settings, refer to the table below:

| Setting | Description |

|---|---|

| Cutting Speed | Determines the speed of the laser |

| Power Level | Controls the intensity of the laser |

| Material | Specifies the type of material to be cut |

By incorporating shortcut keys and customizable settings into your workflow, you can streamline your design process and achieve precise laser cutting results. Take advantage of software automation features to further enhance your efficiency and workflow.

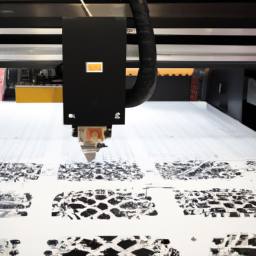

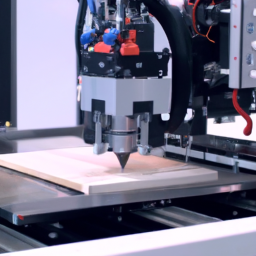

Take Advantage of Software Automation Features

Maximize your productivity by harnessing the power of software automation features in your laser cutting process. Implementing batch processing is a key strategy that allows you to streamline your workflow by processing multiple files at once.

By grouping similar jobs together, you can save time and increase efficiency. Another powerful automation feature is leveraging machine learning algorithms. These algorithms can analyze patterns in your design files and optimize the cutting process for maximum precision and speed.

By letting the software learn from previous jobs, you can achieve consistent results and reduce manual adjustments.

In the next section, we’ll explore how to further enhance your workflow by using templates and libraries for even greater efficiency.

Use Templates and Libraries for Efficiency

Save time and boost your productivity by utilizing templates and libraries to streamline your laser cutting process. Maximizing template usage and leveraging pre-built design assets can significantly improve efficiency and eliminate the need to start from scratch for every project. Templates offer pre-defined designs that you can customize to fit your specific requirements, saving you valuable time and effort. Libraries provide a collection of design elements, such as shapes, patterns, and fonts, that you can easily access and incorporate into your projects. By using templates and libraries, you can expedite the design process and ensure consistency across your projects. In the table below, we highlight the benefits of using templates and libraries:

| Benefits of Using Templates and Libraries |

|---|

| Time-saving |

| Consistency in design |

| Easy customization |

| Access to pre-built assets |

| Increased efficiency |

To further enhance your workflow, it is crucial to regularly update and maintain your software. This ensures that you have access to the latest features and improvements, keeping your laser cutting process up to date.

Regularly Update and Maintain Your Software

To ensure a smooth workflow with your laser cutter software, it’s essential to regularly update and maintain it.

By doing so, you can stay up-to-date with the latest features and improvements that can enhance your productivity. Additionally, software updates often include bug fixes and performance enhancements, which can help prevent any potential issues or glitches during your workflow.

However, it’s important to note that software troubleshooting may still be required even with regular updates. In some cases, compatibility issues may arise between your laser cutter software and other programs or hardware components. To mitigate these problems, it’s crucial to check for software compatibility before making any updates or installations.

By following these steps, you can ensure a streamlined workflow and maximize your efficiency when integrating with laser cutter software.

Frequently Asked Questions

How do I connect my laser cutter software to my computer?

Connecting your laser cutter software to your computer is like plugging in a key to unlock a world of possibilities. It enables you to seamlessly transfer designs and control the laser cutter with precision.

If you encounter any issues, troubleshooting the software is crucial. Ensure that your computer meets the software requirements and that the necessary drivers are installed. Additionally, double-check the connection cables and restart both the computer and the laser cutter software if needed.

What are the recommended file formats for laser cutting?

For laser cutting, the recommended file formats are typically vector-based formats such as AI (Adobe Illustrator), DXF (Drawing Exchange Format), or SVG (Scalable Vector Graphics). These formats ensure better precision and scalability compared to raster-based formats like JPEG or PNG.

It’s important to consider file compatibility with your laser cutter software to ensure smooth integration and accurate results. Using vector-based formats also allows for easy editing and customization of designs before sending them to the laser cutter.

Can I use multiple laser cutter software programs simultaneously?

Yes, you can integrate and use multiple laser cutter software programs simultaneously. This allows for simultaneous laser cutting, enabling you to optimize your workflow and increase productivity. By integrating multiple software programs, you can seamlessly transfer and process files between them, ensuring efficient operation.

This level of integration is crucial for managing complex projects and achieving precise results. Symbolically, it represents the harmony and synergy achieved when different tools work together seamlessly.

Is it possible to import designs from other graphic design software into laser cutter software?

Yes, it’s possible to import designs from other graphic design software into laser cutter software. However, there may be compatibility issues between different software programs. To ensure smooth integration, it’s important to convert the file formats appropriately. This process involves converting the design file from the graphic design software format to a format that the laser cutter software can recognize. Paying attention to file format conversion will help ensure seamless compatibility and successful importing of designs.

Are there any specific safety precautions I should take when using laser cutter software?

When navigating the realm of laser cutter software, safety should be your guiding light. Just as a skilled mountain climber respects the treacherous peaks, you must adhere to laser cutter software safety precautions.

Ensure a secure environment by wearing protective eyewear and clothing. Regularly inspect the machine for any signs of damage or malfunction. Familiarize yourself with emergency shutdown procedures and fire prevention measures.

By following these best practices, you’ll carve out a path to success while minimizing risk.

Conclusion

Now that you’ve familiarized yourself with the software interface, optimized file preparation and organization, and utilized shortcut keys and customizable settings, you are well on your way to achieving a streamlined workflow and seamless integration with laser cutter software.

To further enhance your efficiency, take advantage of software automation features and use templates and libraries. These tools can save you time and effort by automating repetitive tasks and providing pre-designed elements.

However, it’s important to remember that maintaining this efficiency requires regular updates and maintenance of your software. By staying up-to-date with the latest features and bug fixes, you can ensure that your workflow remains smooth and uninterrupted.

So, don’t forget to regularly check for updates and keep your software in top shape. Happy laser cutting!