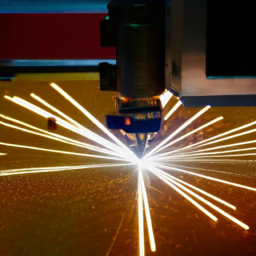

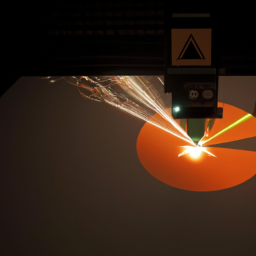

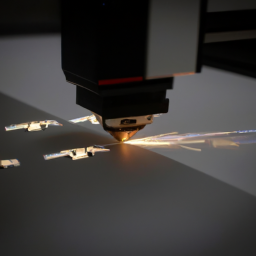

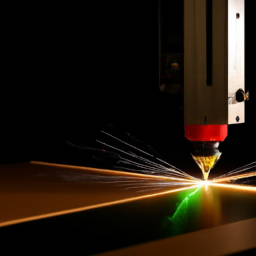

So, you’ve invested in a CO2 laser cutter for your business. Congratulations! With its precision cutting capabilities, it’s sure to take your projects to the next level. But here’s the catch – if you want to keep enjoying optimal performance, you need to put in a little effort.

Don’t worry, though – we’ve got you covered with these 10 essential tips for maintaining your CO2 laser cutter.

First things first, regular cleaning and inspection are key. Dust and debris can wreak havoc on your machine’s performance, so make sure to keep it spick and span.

Next, lubricate those moving parts to ensure smooth and seamless operation. And don’t forget to calibrate the laser power – it’s all about finding that perfect balance.

Maintaining the optics is crucial too. Keep them clean and free from scratches to ensure accurate cutting. And when it comes to consumable parts, don’t wait for them to completely wear out before replacing them.

Lastly, always prioritize safety by following the guidelines provided.

Now, let’s dive into these tips and unleash the full potential of your CO2 laser cutter!

Key Takeaways

- Regularly clean and inspect the CO2 laser cutter to ensure optimal performance

- Use silicone-based lubricants to lubricate the moving parts for smooth operation

- Calibrate the laser power and find the right balance between power and speed for efficiency

- Regularly clean the mirrors and lenses, check for alignment issues, and replace consumable parts to maintain optimal performance

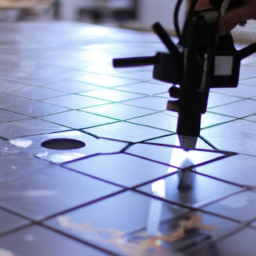

Clean and Inspect the Machine Regularly

Don’t forget to regularly clean and inspect your CO2 laser cutter for top-notch performance! Keeping up with a thorough inspection checklist is crucial to ensure your machine is running smoothly.

Start by visually inspecting the entire cutter, checking for any loose or damaged parts. Pay close attention to the mirrors, lenses, and the laser tube itself. Clean them gently using lint-free wipes and a mild cleaning solution to remove any dirt or residue.

Additionally, inspect the exhaust system and ensure it’s properly functioning to avoid any potential ventilation issues. Lastly, be mindful of common maintenance mistakes such as neglecting to clean the cutting bed or forgetting to replace the water coolant. By diligently following these maintenance practices, you can prevent costly repairs and keep your CO2 laser cutter operating at its best.

Now, let’s move on to lubricating the moving parts.

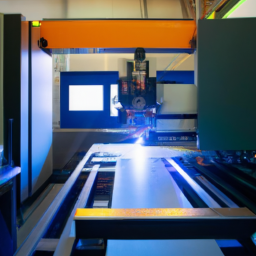

Lubricate Moving Parts

Make sure to regularly lubricate the moving parts of your CO2 laser cutter to keep it functioning smoothly and efficiently. Proper lubrication is essential for the optimal performance of your machine. Without regular lubrication, friction can cause wear and tear on the moving parts, leading to decreased accuracy and potential damage.

To ensure the longevity of your CO2 laser cutter, it is important to use the right type of lubricant. Silicone-based lubricants are commonly recommended for laser cutters as they provide excellent lubrication and do not interfere with the laser’s performance. Avoid using petroleum-based lubricants as they can leave residue and cause damage to the machine.

Here is a table outlining the importance of lubrication and the types of lubricants to use:

| Importance of Lubrication | Types of Lubricants to Use |

|---|---|

| Reduces friction and wear | Silicone-based lubricants |

| Maintains smooth operation | |

| Prevents damage |

Regularly lubricating the moving parts of your CO2 laser cutter will help maintain its optimal performance. Once you have completed this step, you can proceed to calibrating the laser power for precise cutting and engraving.

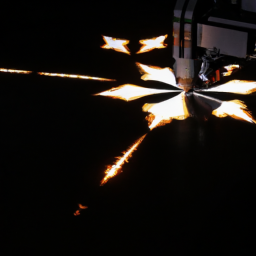

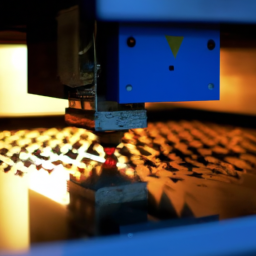

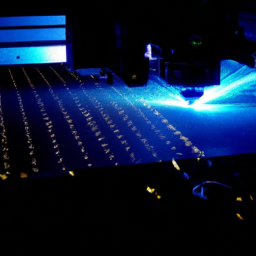

Calibrate the Laser Power

To ensure accurate cutting and engraving, it’s crucial to calibrate the laser power according to the material being used. For example, if the laser power is not properly calibrated when engraving on wood, the result may be too shallow or too deep, compromising the final design.

To achieve laser power efficiency, it is important to find the right balance between power and speed. Setting the laser power too high can lead to excessive heat and damage the material, while setting it too low may result in incomplete cuts or engravings.

Additionally, maintaining laser power stability is essential for consistent performance. Regularly check and adjust the laser power settings to ensure optimal output. By calibrating the laser power accurately, you can achieve precise and consistent results.

Moving on to the next section, it’s important to maintain the optics to further enhance the performance of your CO2 laser cutter.

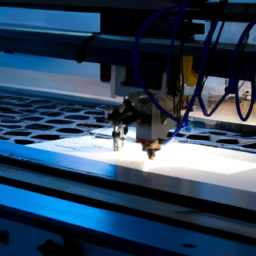

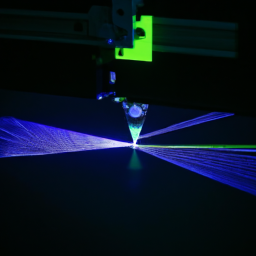

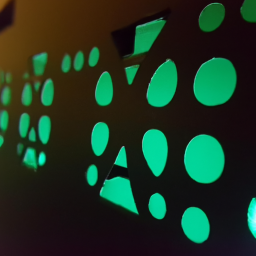

Maintain the Optics

To maintain the optics of your CO2 laser cutter for optimal performance, there are two key points to keep in mind. First, regularly clean the mirrors and lenses to ensure they’re free from debris and dirt that can affect the laser beam’s quality.

Secondly, check for alignment issues to ensure the laser beam is properly directed onto the material being cut or engraved.

By staying diligent with these maintenance tasks, you can ensure that your CO2 laser cutter operates at its best.

Clean the Mirrors and Lenses

Keep your co2 laser cutter performing at its best by regularly cleaning the mirrors and lenses, ensuring crystal clear precision in your cutting and engraving projects. Preventive maintenance is crucial for maintaining optimal performance, and cleaning the mirrors and lenses should be a part of your routine. Dust particles can accumulate on these surfaces, leading to reduced beam quality and potential damage to the optics. To clean the mirrors and lenses, use a lint-free cloth and a mild cleaning solution specifically designed for optical surfaces. Gently wipe the surfaces in a circular motion, being careful not to scratch or damage them. Regular cleaning will help to remove any dust or debris that may have settled, maintaining the clarity and effectiveness of your laser cutter. After cleaning the mirrors and lenses, it is important to check for alignment issues to ensure that your machine is in top condition for your next project.

Check for Alignment Issues

Make sure you give your co2 laser cutter a thorough once-over to check for any alignment issues, as even the smallest misalignment can greatly affect the precision and quality of your cutting and engraving projects.

Start by checking the laser tube alignment. Ensure that it’s properly secured and aligned with the laser head.

Next, troubleshoot any errors or warnings related to alignment in the machine’s software or control panel. If you notice any misalignment, consult the manufacturer’s instructions or contact customer support for guidance on how to realign the machine.

Proper alignment is crucial for achieving accurate cuts and engravings.

Once you’ve checked for alignment issues, it’s time to move on to the next step of maintenance – replacing consumable parts.

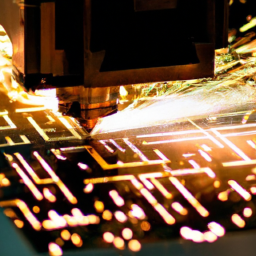

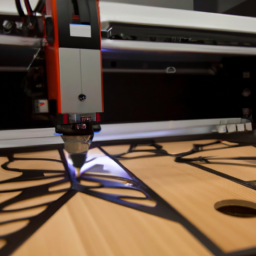

Replace Consumable Parts

Regularly swapping out worn parts is key to ensuring your CO2 laser cutter operates at peak efficiency. Preventive maintenance is crucial to extend the lifespan of your machine and avoid costly repairs. Consumable parts such as lenses, mirrors, and belts are prone to wear and tear due to constant use. By replacing these parts regularly, you can maintain the optimal performance of your CO2 laser cutter.

Here is a table highlighting the common consumable parts and their recommended replacement intervals:

| Consumable Part | Recommended Replacement Interval |

|---|---|

| Lenses | Every 6-12 months |

| Mirrors | Every 12-18 months |

| Belts | Every 2-3 years |

| Nozzles | Every 3-6 months |

| Filters | Every 3-6 months |

By following these guidelines and replacing worn parts in a timely manner, you can ensure the longevity and efficiency of your CO2 laser cutter. Next, let’s discuss the importance of following safety guidelines to protect yourself and your machine.

Follow Safety Guidelines

Ensuring your CO2 laser cutter operates safely is crucial to protect both yourself and your machine from potential hazards. One of the most important aspects of maintaining safety is proper ventilation. Adequate ventilation helps to remove harmful fumes and smoke produced during laser cutting, minimizing the risk of respiratory issues and maintaining air quality in the workspace.

Additionally, it’s vital to follow safety guidelines to prevent common hazards. Always wear appropriate protective gear, such as safety glasses and gloves, to shield yourself from potential injuries. Avoid touching the laser beam or the cutting surface while the machine is in operation, as it can cause severe burns.

Regularly inspect and maintain your laser cutter to ensure all safety features are working correctly, such as emergency stop buttons and interlocks. By following these safety guidelines, you can prevent accidents and maintain optimal performance of your CO2 laser cutter.

Frequently Asked Questions

How often should I clean and inspect my CO2 laser cutter?

Regular cleaning and inspection of your CO2 laser cutter is crucial for optimal performance. By cleaning the machine regularly, you can prevent the buildup of dust and debris, which can negatively affect the laser’s efficiency.

Inspecting the cutter allows you to identify any potential issues early on, reducing the risk of major breakdowns and costly repairs. Adopting a preventive maintenance routine ensures that your CO2 laser cutter operates smoothly and extends its lifespan.

What type of lubricant should I use for the moving parts of my laser cutter?

For the moving parts of your CO2 laser cutter, it’s best to use a high-quality lubricant specifically designed for precision machinery. This will ensure smooth and efficient operation.

When applying the lubricant, follow best practices by thoroughly cleaning the parts and applying the lubricant sparingly. Regularly inspect the moving parts for any signs of wear or damage.

If troubleshooting techniques are needed, consult the manufacturer’s guidelines or seek professional assistance.

How can I calibrate the laser power on my CO2 laser cutter?

If you’re experiencing laser power issues on your CO2 laser cutter, don’t worry, it happens. Laser cutter alignment is crucial for optimal performance, but calibrating the laser power can sometimes be tricky. To troubleshoot this, start by checking the laser tube and power supply connections.

Then, ensure the mirrors are clean and properly aligned. Finally, adjust the laser power settings according to the manufacturer’s recommendations.

Following these steps will help you achieve accurate laser power on your CO2 laser cutter.

How often should I maintain the optics of my laser cutter?

Regular maintenance of the optics in your CO2 laser cutter is crucial for ensuring its longevity. By keeping the optics clean and properly aligned, you can optimize the performance and extend the lifespan of your machine.

Signs that indicate the optics need maintenance include decreased cutting efficiency, inconsistent cuts, and visible dirt or debris on the lenses. Regularly inspecting and cleaning the optics will help prevent these issues and keep your laser cutter running smoothly.

What are some common consumable parts that may need replacement in a CO2 laser cutter?

When it comes to laser cutter maintenance, troubleshooting common issues is essential. Some common consumable parts that may need replacement in a CO2 laser cutter include the laser tube, mirrors, lens, and focus gauge.

The laser tube is the heart of the machine and may need to be replaced after a certain number of hours of use.

The mirrors and lens should be cleaned regularly to ensure optimal performance.

The focus gauge should also be checked and replaced if necessary to maintain precise cutting and engraving results.

Conclusion

In conclusion, to ensure peak performance of your CO2 laser cutter, it’s imperative that you diligently clean and inspect the machine.

You should also lubricate its moving parts and calibrate the laser power.

Additionally, it’s important to maintain the optics and replace consumable parts as needed.

By following these maintenance tips, you’ll not only enhance the efficiency and longevity of your machine but also ensure the safety of its operation.

Remember, regular upkeep is the key to a magnificent and meticulous machine.