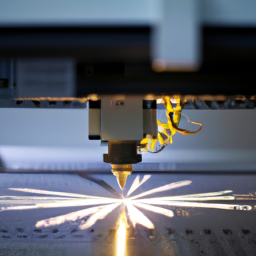

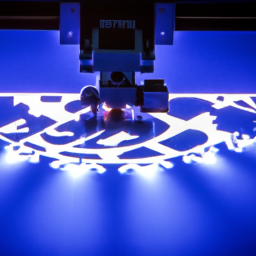

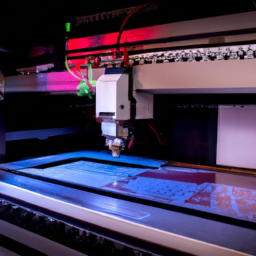

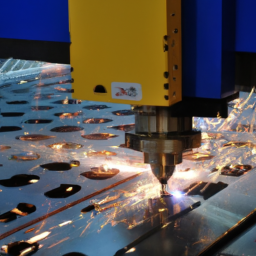

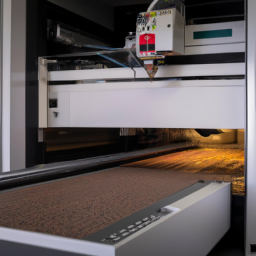

Are you tired of your fiber laser cutter not performing up to its full potential? Well, fret no more! We have compiled a list of 10 essential tips that will help you maintain your fiber laser cutter for optimal performance.

These tips will ensure that your machine operates at its peak efficiency, delivering precise and impeccable results every time.

From cleaning the machine regularly to checking and replacing consumables as needed, we cover all the necessary steps to keep your fiber laser cutter in top shape.

Don’t forget to lubricate the moving parts and calibrate and align the machine to guarantee maximum accuracy and longevity.

But that’s not all! We also delve into the importance of monitoring and controlling temperature and humidity levels, as well as scheduling professional maintenance and servicing.

With these 10 tips, you’ll be able to unleash the true potential of your fiber laser cutter and achieve outstanding results with ease.

So, let’s dive in and elevate your laser cutting game to new heights!

Key Takeaways

- Regularly clean the machine, laser head, lens, and mirrors to prevent buildup and smudges

- Check and replace consumables, cutting nozzles, lenses, and protective covers to maintain optimal cutting quality

- Ensure proper ventilation and control temperature and humidity levels to prevent damage and maintain consistent performance

- Schedule regular professional maintenance and servicing, and follow safety precautions to maximize performance and ensure longevity of the fiber laser cutter.

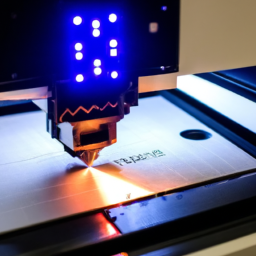

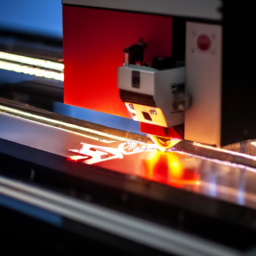

Clean the Machine Regularly

To keep your fiber laser cutter operating at its best, you need to make sure you’re regularly cleaning the machine. Proper preventive maintenance is crucial for optimal performance.

Start by shutting off the machine and disconnecting it from the power source. Use a soft, lint-free cloth to wipe down the exterior, removing any dust or debris. Pay extra attention to the laser head and lens, as they’re particularly susceptible to buildup.

Carefully inspect the mirrors for any smudges or scratches. If necessary, use a specialized cleaning solution and a clean, non-abrasive cloth to gently remove any residue.

Additionally, regularly check the machine for any signs of wear or damage. In case of troubleshooting, refer to the manufacturer’s guidelines or seek professional assistance for effective troubleshooting techniques.

Regular cleaning and preventive maintenance will ensure your fiber laser cutter functions optimally, providing reliable performance for years to come.

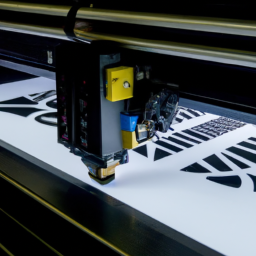

Check and Replace Consumables as Needed

Regularly checking and replacing consumables is crucial for keeping your fiber laser cutter running smoothly and at its best. Proper ventilation is essential to prevent the buildup of dust and particles that can clog the machine and affect its performance.

Make sure to clean the ventilation system regularly and replace any filters as needed to maintain optimal airflow. Additionally, regularly inspect and replace the cutting nozzles, lenses, and protective covers to ensure clean and precise cuts.

Optimizing cutting parameters is also important for maximizing the efficiency and lifespan of your consumables. Regularly monitor and adjust the power, speed, and focus settings to achieve the best results and minimize wear on the consumables.

By following these maintenance steps, you can prolong the life of your fiber laser cutter and ensure consistent high-quality cuts.

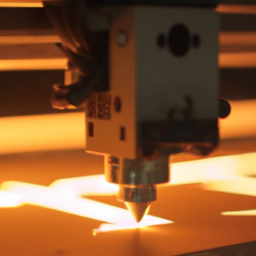

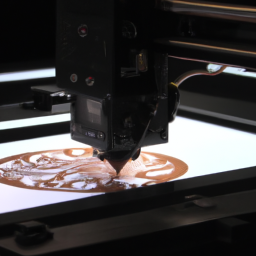

Lubricate Moving Parts

Keep the gears of your fiber laser cutter well-oiled, like a well-tuned engine, to ensure smooth and precise movement of the machine’s components. Regular lubrication of the moving parts is essential for maintaining optimal performance and preventing rust. Here are some crucial steps to follow:

-

Check the bearings regularly: Inspect the bearings for any signs of wear or damage, and replace them if necessary to prevent excessive friction and ensure smooth movement.

-

Clean the moving parts: Before applying lubricant, clean the moving parts thoroughly to remove any dirt or debris that can hinder performance or cause damage.

-

Use the right lubricant: Choose a high-quality lubricant specifically designed for laser cutters, and apply it generously to the gears, rails, and other moving parts to reduce friction and prevent rust.

-

Follow a lubrication schedule: Establish a regular lubrication schedule to ensure consistent performance and extend the lifespan of your fiber laser cutter.

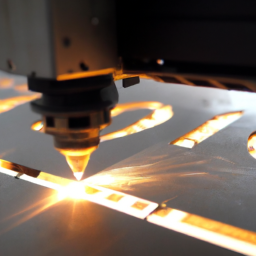

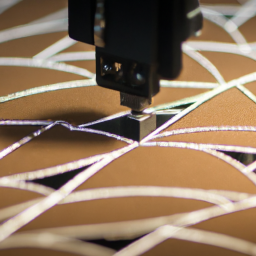

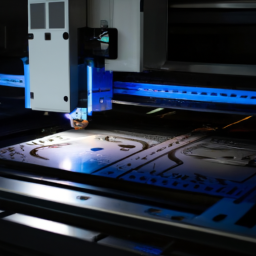

Calibrate and Align the Machine

Make sure you calibrate and align your machine properly for smooth and precise cutting with your fiber laser cutter. Machine calibration is crucial to achieving optimal performance and avoiding any potential inaccuracies. There are various alignment techniques that can be used to ensure the machine is properly calibrated.

One technique is the use of a laser alignment tool, which helps align the laser beam with the cutting head. This ensures that the beam is accurately directed and focused on the material being cut. Another technique involves checking and adjusting the parallelism of the guide rails and the linear motors. This helps maintain the stability and accuracy of the machine’s movement.

Additionally, it is important to regularly check and adjust the beam alignment and focus. This can be done using a beam alignment tool and a focus gauge. By regularly calibrating and aligning your fiber laser cutter, you can ensure that it operates at its maximum efficiency and produces high-quality cuts.

| Alignment Technique | Description | ||

|---|---|---|---|

| Laser Alignment | Align the laser beam with the cutting head using a laser alignment tool. | ||

| Guide Rail Parallelism | Check and adjust the parallelism of the guide rails and linear motors. | ||

| Beam Alignment and Focus | Regularly check and adjust the alignment and focus of the laser beam. | Regularly check and adjust the alignment and focus of the laser beam to ensure optimal cutting performance and accuracy. |

Monitor and Control Temperature and Humidity Levels

To ensure the best results with your fiber laser cutter, it’s crucial that you closely monitor and control the temperature and humidity levels in your workspace. Maintaining proper temperature and humidity is essential for optimal performance and longevity of your machine. Here are some important steps to follow:

- Install temperature and humidity sensors in your workspace to accurately measure and monitor the conditions.

- Regularly check and record the temperature and humidity levels to identify any fluctuations or deviations from the recommended range.

Implement preventative maintenance techniques to control the temperature and humidity, such as using dehumidifiers or air conditioning units to regulate moisture and ventilation systems to maintain a consistent temperature.

- Keep the laser cutter away from direct sunlight or heat sources that can affect the temperature and humidity levels.

- Clean and inspect the sensors regularly to ensure accurate readings and replace them if necessary.

- Train your staff on the importance of maintaining proper temperature and humidity levels and provide them with the necessary tools and knowledge to monitor and control these conditions.

By closely monitoring and controlling the temperature and humidity levels, you can ensure the optimal performance and longevity of your fiber laser cutter.

Schedule Professional Maintenance and Servicing

Ensure the longevity of your machine by scheduling regular professional maintenance and servicing for your fiber laser cutter. By doing so, you can identify any potential issues early on and prevent them from escalating into major problems.

During these scheduled maintenance visits, trained technicians will inspect and clean your laser cutter, ensuring that all components are working optimally. They will also perform any necessary adjustments and calibrations to maintain the accuracy and precision of your machine.

Additionally, they will check and replace any worn-out parts to prevent downtime and minimize the risk of unexpected breakdowns. It’s also crucial to follow all safety precautions outlined by the manufacturer and to regularly troubleshoot common issues that may arise, such as alignment problems or power fluctuations.

This proactive approach to maintenance will help keep your fiber laser cutter in peak condition and maximize its performance.

Frequently Asked Questions

How often should I clean the exterior of my fiber laser cutter?

To ensure optimal performance of your fiber laser cutter, it’s recommended to clean the exterior regularly. Cleaning frequency depends on the environment, but a general guideline is to clean it every few weeks.

Use non-abrasive cleaning products specifically designed for laser cutters to avoid damaging the surface. Wipe down the exterior with a soft cloth, making sure to remove any dust, debris, or fingerprints.

Regular cleaning will help maintain the aesthetics and functionality of your laser cutter.

What are the signs that indicate a need to replace consumables?

If you notice irregularities in your laser cutting, such as inconsistent cuts or jagged edges, it may be a sign that your consumables need replacing.

Other signs include decreased power output, increased frequency of nozzle clogging, and shorter lifespan of protective lenses.

Regular maintenance is crucial to ensure optimal performance and prevent costly breakdowns. By regularly inspecting and replacing worn-out consumables, you can maintain the efficiency and precision of your fiber laser cutter.

Are there any specific lubricants recommended for lubricating moving parts?

To ensure proper lubrication maintenance for your fiber laser cutter, it’s important to use the recommended lubricants for the moving parts.

These lubricants are specifically designed to minimize friction and extend the lifespan of your machine. Applying the right lubricant at regular intervals will prevent excessive wear and tear, reduce noise, and improve overall performance.

Be sure to consult the manufacturer’s guidelines to identify the appropriate lubricants for your laser cutter’s specific components.

How often should I calibrate and align my fiber laser cutter?

To ensure optimal performance of your fiber laser cutter, it’s important to regularly calibrate and align the machine. The calibration frequency and alignment schedule may vary depending on the specific model and usage. However, as a general guideline, it’s recommended to calibrate and align your fiber laser cutter at least once every six months or after any major maintenance or repair work.

This will help maintain the accuracy and efficiency of the machine, ensuring precise and high-quality cuts.

Is it necessary to monitor and control temperature and humidity levels in the workspace even when the machine is not in use?

To ensure optimal performance of your fiber laser cutter, it’s crucial to monitor and control temperature and humidity levels in the workspace, even when the machine isn’t in use.

Fluctuations in temperature and humidity can affect the stability of the laser system and its components. For example, in a real case study, a laser cutter experienced decreased cutting precision due to high humidity levels causing condensation on the optics.

Maintaining proper temperature and humidity control is therefore essential for the longevity and accuracy of your fiber laser cutter.

Conclusion

In conclusion, maintaining your fiber laser cutter is essential for optimal performance. By following these 10 tips, you can ensure that your machine operates at its best.

Regular cleaning, checking, and replacing consumables, lubricating moving parts, calibrating and aligning the machine, and monitoring temperature and humidity levels are all crucial steps.

Additionally, scheduling professional maintenance and servicing will help keep your machine in top condition.

Remember, a well-maintained fiber laser cutter leads to efficient and accurate cutting. So, why wait? Start implementing these tips today and see the difference in your machine’s performance.