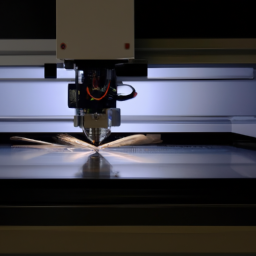

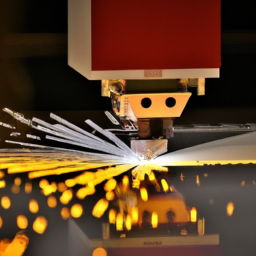

Are you tired of your Nd:YAG laser cutter performing at suboptimal levels? Well, you’re in luck! We have compiled a list of 10 tips that will surely make your laser cutter shine like never before.

Maintaining this powerful tool may seem like a daunting task, but it’s essential for achieving optimal performance. From regular cleaning to professional servicing, we’ve got you covered.

You might think that keeping your laser cutter in top shape is as easy as pressing a button, but it’s not that simple. It requires dedication, attention to detail, and a willingness to put in the effort. But fear not, because with our expert guidance, you’ll become a master at maintaining your Nd:YAG laser cutter.

So, get ready to dive into the world of laser cutter maintenance. By following these 10 tips, you’ll ensure that your laser cutter operates at its peak performance, allowing you to achieve precise and flawless cuts every time.

Let’s get started on this journey to laser perfection!

Key Takeaways

- Regular cleaning and inspection

- Importance of using genuine parts

- Regularly checking and replacing consumable parts

- Scheduling regular professional maintenance and servicing

Understand the Basics of Nd:YAG Laser Cutter Maintenance

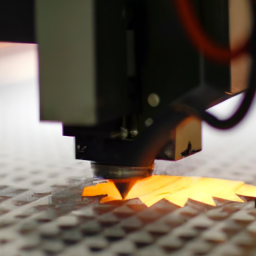

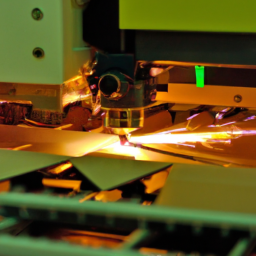

If you want to keep your nd:yag laser cutter performing at its best, it’s essential to understand the basics of maintenance. Laser cutter troubleshooting is a crucial aspect of maintenance, as it allows you to identify and fix any issues that may arise.

Familiarize yourself with the laser cutter’s maintenance checklist, which typically includes tasks such as checking the coolant levels, inspecting the optics, and cleaning the lens. Regularly clean and inspect the laser cutter to ensure optimal performance.

Dust and debris can accumulate on the lens and other components, affecting the quality of the laser beam and overall functionality. By following a regular cleaning and inspection routine, you can prevent potential problems and keep your nd:yag laser cutter in top shape.

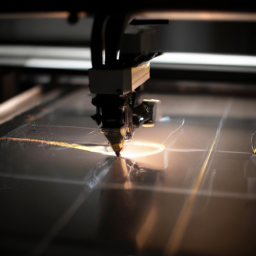

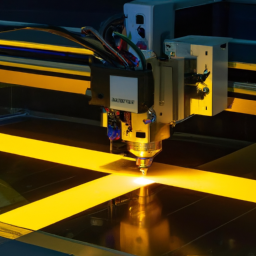

Clean and Inspect the Laser Cutter Regularly

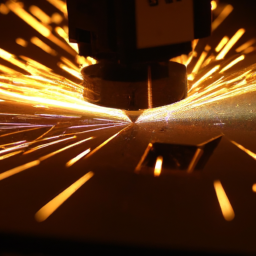

To ensure your laser cutter operates at its best, regularly cleaning and inspecting it will help prevent any potential issues and extend its lifespan, even if you may initially find it time-consuming.

Performing routine maintenance on your Nd:YAG laser cutter is crucial to maintaining its optimal performance. Proper cleaning is of utmost importance, as any dust or debris buildup can affect the laser’s efficiency and accuracy. Use a soft brush or compressed air to remove dirt and particles from the machine’s exterior and interior components.

Inspect the lens and mirrors for any signs of damage or contamination, and clean them gently with a lint-free cloth and a specialized cleaning solution if necessary.

Regularly checking and cleaning your laser cutter will ensure its continuous functionality and minimize the need for repairs.

Transitioning to the next section, it’s also essential to check and replace consumable parts as needed to keep your laser cutter in top shape.

Check and Replace Consumable Parts as Needed

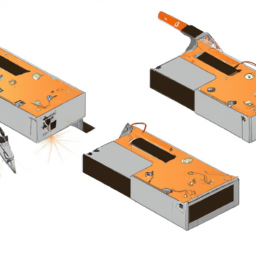

Regularly checking and replacing consumable parts as needed will ensure that your laser cutter continues to operate efficiently and effectively. To help you keep track of the necessary maintenance tasks, here is a maintenance checklist for your nd:yag laser cutter:

| Consumable Part | Replacement Frequency | Importance of Using Genuine Parts |

|---|---|---|

| Laser tube | Every 2,000 hours | Genuine parts ensure optimal performance and longevity. |

| Optics | Every 500 hours | Genuine parts maintain beam quality and minimize downtime. |

| Water filters | Every 3 months | Genuine filters prevent water contamination and system damage. |

| Belts and pulleys | Every 1,000 hours | Genuine parts guarantee smooth and accurate motion. |

| Fume extraction | Every 6 months | Genuine filters maintain proper ventilation and air quality. |

Using genuine parts is crucial as they are specifically designed for your laser cutter, ensuring compatibility and optimal performance. Now that you know how to maintain the consumable parts, let’s move on to the next section and learn how to calibrate and align the laser cutter for precision cutting.

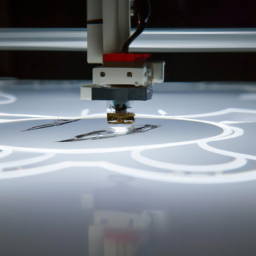

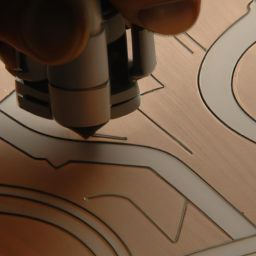

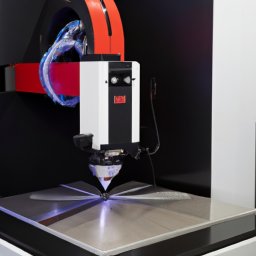

Calibrate and Align the Laser Cutter for Precision Cutting

Are you struggling to achieve precise cuts with your laser cutter? Let’s dive into how you can calibrate and align it for impeccable cutting accuracy.

Here are some tips to help you troubleshoot and maintain the alignment of your laser cutter:

- Attend laser cutter maintenance training to learn the proper calibration techniques.

- Check and adjust the laser beam alignment regularly to ensure it’s perpendicular to the cutting surface.

- Verify that the laser mirrors are clean and properly aligned.

- Ensure the focal length is set correctly for the material being cut.

- Use a laser beam alignment tool to fine-tune the alignment if needed.

By following these steps, you can ensure that your laser cutter is properly calibrated and aligned for precise cutting.

Now, let’s move on to the next section about keeping the laser cutter in a controlled environment.

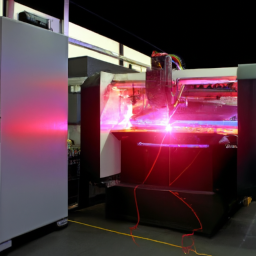

Keep the Laser Cutter in a Controlled Environment

Creating a controlled environment for your laser cutter ensures that it operates at its best and delivers flawless results. Temperature control is crucial for maintaining the optimal performance of your ND:YAG laser cutter. Extreme temperatures can affect the accuracy and stability of the laser beam, leading to inconsistent cutting results. Therefore, it’s important to keep the laser cutter in a temperature-controlled room, ideally between 18-25°C (64-77°F).

Additionally, humidity regulation is equally important. High humidity levels can cause condensation on the laser optics, leading to reduced cutting quality and potential damage to the machine. Aim for a humidity level between 40-60%.

By maintaining a controlled environment with proper temperature and humidity levels, you can ensure that your laser cutter performs at its best. To further enhance its longevity and prevent potential issues, schedule regular professional maintenance and servicing.

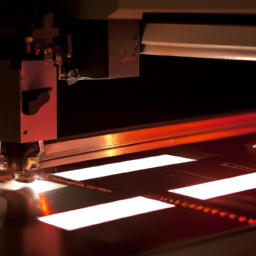

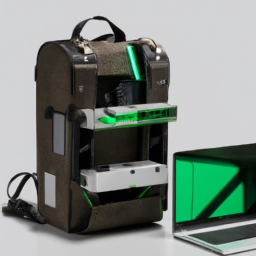

Schedule Regular Professional Maintenance and Servicing

Ensuring that you regularly schedule professional maintenance and servicing for your laser cutter is crucial to keeping it in top shape and maximizing its lifespan. Regular maintenance performed by a reputable service provider offers numerous benefits.

Firstly, it helps identify and address any potential issues before they become major problems, preventing costly breakdowns and downtime. Professional technicians are trained to inspect, clean, and calibrate the various components of the nd:yag laser cutter, ensuring optimal performance. They can also provide software updates and upgrades, keeping your equipment up to date with the latest advancements.

Additionally, regular servicing helps maintain the safety of your laser cutter, ensuring it meets all necessary regulations and standards. By entrusting the maintenance and servicing to professionals, you can have peace of mind knowing that your laser cutter is in the best hands.

Frequently Asked Questions

How often should I clean the external surfaces of my Nd:YAG laser cutter?

To ensure optimal performance of your Nd:YAG laser cutter, it’s important to clean the external surfaces regularly as part of your regular maintenance routines. This helps prevent dust and debris buildup, which can affect cutting quality.

Additionally, understanding the impact of environmental factors on the laser cutter’s performance is crucial. Use approved cleaning agents and materials to avoid damaging the machine.

By following these best practices, you can extend the lifespan of consumable parts and maintain optimal performance.

What are the signs that indicate the need for consumable parts replacement?

Common consumable parts in an Nd:YAG laser cutter include flashlamps, flow tubes, and laser rods. Signs that indicate the need for replacement include reduced cutting power, inconsistent beam quality, and frequent breakdowns.

To prolong the lifespan of consumable parts, ensure proper cooling of the system, regularly clean the optics, and perform routine maintenance checks.

Regularly monitoring and addressing these issues will help to maintain optimal performance and prevent costly repairs.

Are there any specific safety precautions I should take during laser cutter calibration and alignment?

To ensure your safety during laser cutter calibration and alignment, it’s essential to take certain precautions. Start by wearing protective eyewear to shield your eyes from the intense laser beam.

Make sure the machine is turned off and unplugged before starting any adjustments. Use a laser power meter to measure the intensity of the beam and avoid direct exposure.

Always follow the manufacturer’s guidelines for calibration and alignment to prevent accidents or damage to the laser cutter.

How can I ensure that the temperature and humidity levels of the controlled environment are maintained?

To maintain temperature and humidity in a controlled environment, make sure to properly insulate and ventilate the area. Use temperature and humidity sensors to monitor levels and make necessary adjustments. Regularly clean and replace air filters to prevent dust and debris buildup on the laser cutter. Implement a regular maintenance schedule to inspect and clean the laser cutter and its components. Following these steps will help optimize performance and extend the lifespan of your Nd:YAG laser cutter.

What kind of professional maintenance and servicing should I schedule for my Nd:YAG laser cutter?

To ensure the optimal performance of your nd:YAG laser cutter, it’s crucial to schedule regular professional maintenance and servicing. This includes tasks such as cleaning the optics, inspecting and replacing worn parts, calibrating the laser power, and checking the cooling system.

By adhering to a regular maintenance schedule, you can prevent issues before they arise, extend the lifespan of your laser cutter, and ensure consistent, high-quality results. Don’t overlook the importance of laser cutter maintenance and servicing for long-term performance.

Conclusion

In conclusion, maintaining your nd:YAG laser cutter is crucial for optimal performance. By understanding the basics of maintenance and regularly cleaning and inspecting the machine, you can ensure its efficiency. Additionally, checking and replacing consumable parts, calibrating and aligning for precision cutting, and keeping it in a controlled environment are important steps to take. Remember to schedule regular professional maintenance and servicing to address any potential issues. Just like a well-oiled machine, a well-maintained laser cutter will cut through any obstacles effortlessly, making your work a smooth ride.