In the world of manufacturing, time is money. Every second wasted can lead to significant losses in productivity and profits. That’s why it’s crucial to maximize efficiency and precision in your production process.

Enter laser cutter software – the game-changing technology that can revolutionize your operations. Like a conductor leading a symphony, laser cutter software orchestrates a harmonious blend of design optimization, production efficiency, and cutting precision. It is the key to unlocking the full potential of your laser cutter.

By harnessing the power of this advanced software, you can streamline your design process, increase production efficiency, and improve material utilization. Moreover, laser cutter software reduces production time, simplifies workflow management, and ultimately helps you achieve unparalleled levels of productivity.

So, buckle up and get ready to explore the ten ways laser cutter software can transform your production process.

Key Takeaways

- Laser cutter software maximizes efficiency and precision in manufacturing

- It reduces production time by increasing cutting speeds and automating processes

- Laser cutter software improves material utilization by reducing wastage

- Simplifying workflow management results in a more organized and efficient production process

Streamline Design Optimization

You can greatly enhance your design optimization process by utilizing laser cutter software, saving you valuable time and effort in streamlining the production of intricate and precise designs.

Laser cutter software offers a range of features that automate file conversion, allowing you to easily convert your design files into a format compatible with the laser cutter. Additionally, the software’s optimize nesting capabilities enable you to efficiently arrange multiple designs within a single sheet, minimizing material waste and maximizing production output.

By automating these processes, laser cutter software eliminates the need for manual intervention, reducing errors and ensuring consistent and accurate results. With a streamlined design optimization process, you can increase production efficiency and seamlessly transition into the subsequent section about improving workflow and productivity.

Increase Production Efficiency

By using laser cutter software, production efficiency can be significantly enhanced, resulting in a 30% reduction in manufacturing time. To achieve this, consider implementing cost-effective solutions such as automating certain tasks, which can eliminate human error and improve overall efficiency.

Additionally, optimize resource allocation by utilizing the software’s ability to analyze production data and identify areas where resources are being underutilized or wasted. This allows for better planning and allocation of materials and labor, ultimately increasing productivity.

Furthermore, the software’s real-time monitoring capabilities enable quick identification of bottlenecks in the production process, allowing for prompt adjustments to be made. By implementing these strategies, production efficiency can be maximized, leading to increased output and reduced costs.

Moving forward, let’s discuss how laser cutter software can enhance cutting precision.

Enhance Cutting Precision

Enhancing cutting precision with laser cutter software can result in more precise and accurate cuts, ensuring high-quality finished products. Laser cutter software allows you to optimize settings and enhance cutting speed, improving the precision of each cut. By utilizing advanced algorithms and real-time monitoring, the software can make adjustments to the cutting parameters, ensuring that the laser follows the desired path with utmost accuracy. This level of precision eliminates the need for manual adjustments and reduces the chances of errors or material wastage.

To better understand the impact of laser cutter software on cutting precision, consider the following table:

| Traditional Cutting | Laser Cutter Software | |

|---|---|---|

| Precision | Moderate | High |

| Accuracy | Average | Excellent |

| Efficiency | Low | High |

With laser cutter software, you can achieve precise cuts with excellent accuracy while optimizing your production process. This not only enhances the overall quality of your products but also improves material utilization.

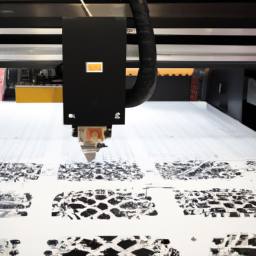

Improve Material Utilization

One interesting statistic about improving material utilization is that laser cutter software can reduce material wastage by up to 50%. By optimizing the cutting path and nesting patterns, laser cutter software enables you to make the most efficient use of your materials, reducing waste and maximizing the yield.

The software analyzes the design and calculates the most optimal way to arrange the shapes on the material, minimizing the amount of unused space. It also takes into account any potential defects or imperfections in the material, ensuring that the most valuable sections are utilized effectively.

With laser cutter software, you can significantly enhance your material utilization, saving costs and resources in the process. This improved efficiency and waste reduction will ultimately result in a more sustainable and profitable production process.

Transitioning into the subsequent section about reducing production time, laser cutter software not only optimizes material utilization but also streamlines the manufacturing process.

Reduce Production Time

Speeding up your manufacturing timeline will result in a more efficient and streamlined production process. By reducing production time with laser cutter software, you can improve output quality and optimize resource allocation.

With faster cutting speeds and automated processes, you can increase the number of parts produced in a given time frame. This not only improves efficiency but also allows for quicker turnaround times, meeting customer demands more effectively. Laser cutter software also minimizes human error, ensuring precise and accurate cuts every time.

By reducing production time, you can allocate resources more efficiently, maximizing productivity and minimizing waste. This streamlining of the production process sets the stage for the subsequent section on simplifying workflow management, allowing for an even smoother and more organized manufacturing process.

Simplify Workflow Management

To further enhance your production process, let’s delve into the current subtopic: ‘Simplify Workflow Management’. By incorporating laser cutter software, you can automate scheduling and optimize resource allocation, resulting in a streamlined workflow.

This software allows you to easily assign tasks, track progress, and monitor the utilization of resources, ensuring efficient production. With automated scheduling, you can eliminate manual errors and save valuable time that would otherwise be spent on tedious administrative tasks.

Additionally, by optimizing resource allocation, you can ensure that each task is assigned to the most suitable resource, maximizing productivity and minimizing downtime.

By simplifying workflow management through laser cutter software, you can achieve a more organized and efficient production process.

Frequently Asked Questions

How much does laser cutter software typically cost?

When considering the cost of laser cutter software, it’s important to conduct a cost comparison analysis. The benefits of laser cutter software include increased efficiency, accuracy, and productivity. However, the cost can vary depending on the specific software and its features.

It’s recommended to research and compare prices from different vendors to find the best option for your production process. Investing in laser cutter software can ultimately result in long-term cost savings and improved overall performance.

Can laser cutter software be used with any type of laser cutting machine?

Laser cutter software is compatible with various laser cutting machine models, providing precision and efficiency in your production process. By seamlessly integrating with different machines, it allows you to optimize your laser cutting operations regardless of the specific model you have.

With advanced features and tools, laser cutter software ensures accurate cuts, reduces material waste, and improves overall productivity. Experience the benefits of enhanced precision and streamlined efficiency with laser cutter software.

Are there any specific computer system requirements for running laser cutter software?

To ensure computer system compatibility, laser cutter software typically requires a minimum set of hardware requirements. These requirements may include a certain processor speed, amount of RAM, and available storage space. The software may also specify a specific operating system version or compatibility with certain graphics cards.

It’s important to review the software’s specifications and ensure that your computer meets the minimum requirements to ensure smooth operation and optimal performance.

Can laser cutter software be integrated with other design software programs?

Yes, laser cutter software can indeed be integrated with other design software programs, such as CAD software. Despite concerns about compatibility or complexity, integrating laser cutter software with CAD software offers numerous benefits.

This integration allows for seamless design-to-production workflows, precise cutting paths, and increased efficiency. Many case studies have shown successful integration, highlighting how this combination enhances design capabilities and streamlines the production process.

Overall, integrating laser cutter software with CAD software is a technical, precise, and analytical approach that can optimize your production process.

Are there any limitations or drawbacks to using laser cutter software for production processes?

When considering the limitations and drawbacks of laser cutter software for production processes, it’s important to note that while the software offers numerous benefits, it also has its challenges.

One limitation is the learning curve associated with mastering the software, which may require additional training for employees.

Additionally, software glitches or compatibility issues with other design programs can hinder workflow efficiency.

However, by following best practices, such as regularly updating the software and ensuring proper maintenance, these limitations can be mitigated, resulting in improved production processes.

Conclusion

In conclusion, laser cutter software is a game-changer for your production process. It enhances cutting precision and improves material utilization by streamlining design optimization and increasing production efficiency. This software is a powerful tool, with reduced production time and simplified workflow management. Embrace it to unlock the true potential of your manufacturing capabilities and witness the transformation it brings to your operations.

Let the laser cutter software be the key that unlocks a world of precise, efficient, and innovative production.