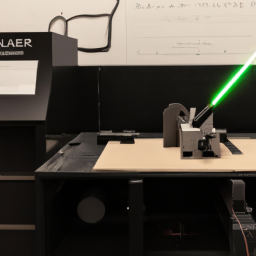

Are you ready to unlock the full potential of your laser cutter? Just like a well-oiled machine, your laser cutter has the ability to create intricate designs with precision and finesse. But in order to ensure its longevity, you need to take proactive steps to extend its lifespan. Think of your laser cutter as a delicate instrument that requires proper care and maintenance.

In this article, we will explore ten ways to maximize the lifespan of your laser cutter. From regular cleaning and maintenance to implementing safety measures, we will provide you with practical tips to keep your machine running smoothly. By following these guidelines, you can ensure that your laser cutter remains a reliable tool in your arsenal for years to come.

So, let’s dive in and discover how you can make your laser cutter last longer.

Key Takeaways

- Regular cleaning and maintenance can extend the lifespan of a laser cutter by up to 25%.

- Using proper materials and settings is crucial for maximizing the lifespan of a laser cutter.

- Implementing safety measures, such as safety training and regular inspections, can minimize accidents and injuries.

- Regularly calibrating and aligning the laser cutter ensures precise cuts and engravings.

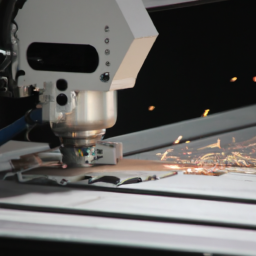

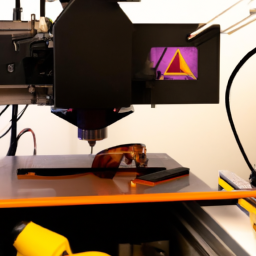

Clean and Maintain Your Laser Cutter Regularly

To extend the lifespan of your laser cutter, you should regularly clean and maintain it, as studies have shown that laser cutters that are properly cared for can last up to 25% longer than those that aren’t. Performing preventive maintenance on your laser cutter is crucial to keep it in top working condition.

This includes cleaning the lens, mirrors, and exhaust system regularly to prevent any buildup of debris or dust that can affect the performance of the machine. Additionally, it’s important to conduct laser cutter troubleshooting on a regular basis to identify and address any issues before they become major problems.

By following these maintenance practices, you can ensure that your laser cutter operates efficiently and effectively.

Moving on to the next section, using proper materials and settings is equally important in maximizing the lifespan of your laser cutter.

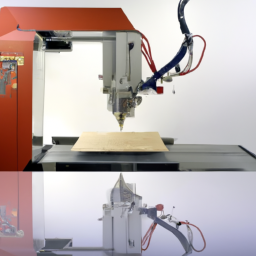

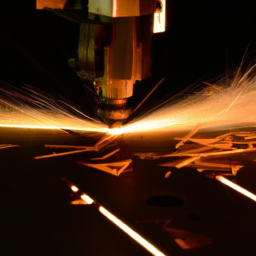

Use Proper Materials and Settings

By utilizing appropriate materials and settings, you can ensure that your laser cutting machine operates at its full potential, allowing for precise and efficient cuts.

When choosing compatible materials for your laser cutter, it’s important to consider their composition and thickness. Opt for materials that are specifically designed for laser cutting, as they’ve been tested and proven to work well with the machine.

Additionally, be mindful of the optimal laser cutter settings for different materials. Adjust the power, speed, and focus settings accordingly to achieve the best results. Remember to consult the manufacturer’s guidelines for recommended settings.

By using compatible materials and optimal settings, you can maximize the lifespan of your laser cutter and achieve high-quality cuts.

As you move on to the next section about implementing safety measures, it’s essential to prioritize the well-being of yourself and others.

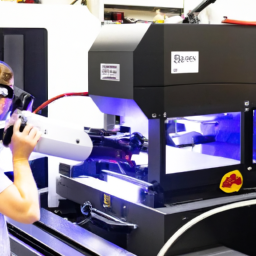

Implement Safety Measures

Ensure the safety of yourself and those around you by implementing proper safety measures when operating the laser cutting machine. Are you taking all necessary precautions to prevent accidents and injuries?

To begin, it’s crucial to implement safety training for all individuals operating the laser cutter. This training should cover proper handling of materials, safe operating procedures, and emergency protocols.

Additionally, conducting regular safety inspections is essential to identify any potential hazards or equipment malfunctions. Inspections should include checking the condition of the laser cutter, ensuring the presence of safety guards, and verifying the functionality of emergency stop buttons.

By implementing safety training and conducting regular safety inspections, you can minimize the risk of accidents and injuries while operating the laser cutter.

Transitioning into the subsequent section about keeping the laser cutter in a stable environment, it’s important to maintain a controlled workspace to optimize the machine’s performance.

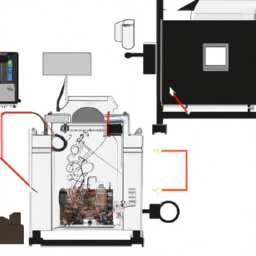

Keep the Laser Cutter in a Stable Environment

Create a stable environment for your laser cutter by maintaining a controlled workspace that is free from vibrations and fluctuations in temperature. To ensure the longevity of your laser cutter, follow these guidelines:

-

Keep the laser cutter in a dedicated room or area to minimize vibrations caused by foot traffic or nearby machinery.

-

Use vibration-dampening materials, such as rubber pads or foam, to absorb any residual vibrations.

-

Maintain a consistent temperature within the workspace to prevent thermal expansion and contraction of the laser cutter’s components.

-

Control humidity levels to prevent moisture buildup, which can damage sensitive electronics.

-

Install an air conditioning system to regulate the temperature and humidity more effectively.

By maintaining a stable environment, you can mitigate potential issues that may arise from temperature fluctuations and vibrations. This sets the stage for the next step, which involves regularly calibrating and aligning your laser cutter.

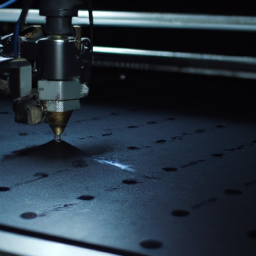

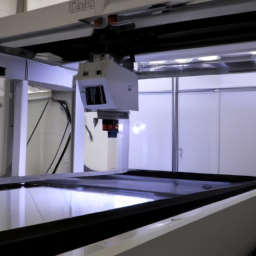

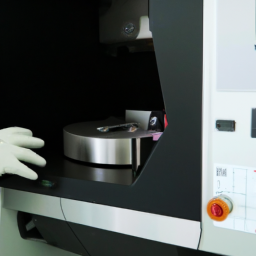

Regularly Calibrate and Align Your Laser Cutter

Make sure you keep your laser cutter in tip-top shape by regularly calibrating and aligning it, ensuring that it’s always performing at its best.

Laser cutter troubleshooting often starts with calibration and alignment. Proper calibration ensures that the laser beam is accurately hitting the desired spot, resulting in precise cuts and engravings.

To calibrate your laser cutter, follow the manufacturer’s guidelines and use calibration tools provided. Check the alignment of the laser beam with mirrors and lenses to ensure it is focused correctly. Laser cutter calibration techniques may vary depending on the model, so refer to the user manual for specific instructions.

By regularly calibrating and aligning your laser cutter, you can avoid potential issues and maintain optimal performance.

Next, we will discuss the importance of investing in professional servicing and repairs.

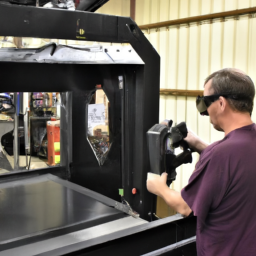

Invest in Professional Servicing and Repairs

To extend the lifespan of your laser cutter, it’s crucial to invest in professional servicing and repairs. Schedule regular maintenance with a technician to ensure that your machine is operating at its optimal condition. Address any issues promptly to prevent further damage and follow the manufacturer’s recommendations for servicing to maintain the efficiency and longevity of your laser cutter.

Schedule Regular Maintenance with a Technician

Ensure that you regularly schedule maintenance appointments with a technician to optimize the lifespan of your laser cutter. Scheduled maintenance is crucial for keeping your machine in top condition and preventing potential issues from arising.

By having a technician inspect and service your laser cutter at regular intervals, you can identify and address any minor problems before they become major ones. These appointments allow the technician to thoroughly clean the machine, check for signs of wear and tear, and make any necessary adjustments or repairs. Additionally, they can ensure that all the components are properly calibrated, maximizing the cutter’s efficiency and accuracy.

By adhering to a schedule of technician appointments, you can extend the lifespan of your laser cutter and avoid costly breakdowns.

Moving forward, prompt issue resolution is equally important to maintain the machine’s optimal performance.

Address Issues Promptly

Don’t let problems linger unattended, or risk the performance and longevity of your beloved laser cutter. Addressing issues promptly is crucial in maintaining the optimal functioning of your machine. By troubleshooting techniques and implementing maintenance tips, you can prevent minor problems from escalating into major ones that may require costly repairs or even replacement parts. To help you visualize the importance of addressing issues promptly, take a look at the following table:

| Neglected Issue | Consequence |

|---|---|

| Loose wiring | Fire hazard |

| Dirty lens | Reduced cutting power |

| Misaligned mirrors | Inaccurate cuts |

| Overheating | Damage to internal components |

By taking immediate action and resolving these issues, you can ensure the smooth operation of your laser cutter. Furthermore, it is essential to follow the manufacturer’s recommendations for servicing to maintain your machine’s optimal performance.

Follow Manufacturer’s Recommendations for Servicing

To ensure the longevity of your laser cutter, it’s crucial to address any issues promptly. However, it’s equally important to follow the manufacturer’s recommendations for servicing. By adhering to these guidelines, you can maximize the lifespan of your machine and avoid costly repairs down the line.

To make this process easier for you, here are four key steps you should take when it comes to servicing your laser cutter:

-

Read the manufacturer’s warranty thoroughly to understand what’s covered and what’s not.

-

Keep track of the recommended maintenance schedule and make sure it’s followed diligently.

-

Only use authorized service centers for repairs and servicing to ensure quality and expertise.

-

Regularly check the manufacturer’s website for any updates or recalls related to your laser cutter.

By following these steps, you can maintain your laser cutter’s optimal performance and extend its lifespan significantly.

Frequently Asked Questions

How often should I clean and maintain my laser cutter?

To ensure optimum performance and longevity of your laser cutter, it’s crucial to clean and maintain it regularly. Proper cleaning techniques, such as removing debris and dust from the lens and mirrors, should be performed at least once a week.

Additionally, adopting the best maintenance practices, like lubricating moving parts and checking for wear and tear, should be done every month. By adhering to these routines, you can maximize the lifespan of your laser cutter, guaranteeing consistent high-quality results.

What are some common materials that should be avoided when using a laser cutter?

When using a laser cutter, it’s important to avoid certain materials such as acrylic and PVC. These materials release toxic fumes when cut with a laser, which can be harmful to your health and damage the machine.

Instead, consider using alternative materials like wood or metal, which are safer and produce better results. Additionally, it’s crucial to properly dispose of hazardous materials by following local regulations and guidelines to protect the environment and yourself.

Can you provide some examples of safety measures that should be implemented when using a laser cutter?

When it comes to laser cutter safety measures, you must treat your machine like a delicate flower that needs constant attention. Keep your eyes peeled for any signs of damage or wear and tear, and make sure to clean and lubricate regularly. Don’t forget to wear protective gear, like goggles and gloves, because safety should always be your top priority.

As for maintenance frequency, it’s recommended to follow the manufacturer’s guidelines to keep your laser cutter in tip-top shape.

Are there any specific temperature or humidity requirements for the environment where the laser cutter should be kept?

To ensure optimal performance and prolong the lifespan of your laser cutter, it’s crucial to maintain specific temperature and humidity levels in the laser cutter environment.

The ideal temperature range is typically between 15°C and 30°C, while the recommended humidity level is around 40% to 60%.

Deviations from these requirements can lead to issues with laser cutter functionality and may require additional maintenance and cleaning to rectify.

Monitoring and controlling these factors are essential for the longevity of your laser cutter.

How frequently should I calibrate and align my laser cutter to ensure optimal performance?

To ensure optimal performance of your laser cutter, it’s recommended to follow a regular calibration frequency and alignment schedule. This will help maintain accuracy and efficiency in your machine’s operations. The specific frequency will depend on the usage and manufacturer guidelines, but generally, it’s advisable to calibrate and align your laser cutter at least once every six months.

Regular maintenance in this regard will help extend the lifespan of your equipment and ensure consistent, high-quality results.

Conclusion

In conclusion, by following these 10 ways to extend the lifespan of your laser cutter, you can ensure its optimal performance and longevity.

Regular cleaning and maintenance, along with using proper materials and settings, are essential. Implementing safety measures and keeping the laser cutter in a stable environment are crucial for its efficiency.

Additionally, regular calibration and alignment, as well as investing in professional servicing and repairs, will further enhance its lifespan. So, don’t wait any longer, start implementing these techniques and enjoy a longer-lasting laser cutter that consistently delivers precise results.