Are you a small business owner looking to enhance safety measures in your workplace? When it comes to laser cutters, ensuring the well-being of your employees is of utmost importance. Laser cutters can be incredibly useful tools, but they also come with potential risks if not handled properly.

That’s why we’re here to guide you through the 11 best laser cutter safety practices that every small business should implement.

Have you thought about the importance of conducting proper training for your employees? It is crucial to equip them with the necessary knowledge and skills to operate the laser cutter safely. Additionally, regular inspections and maintenance of the machine are essential to identify any potential hazards and ensure its optimal performance.

Creating a controlled work area and using personal protective equipment (PPE) are also vital steps to protect your employees from harm. Safe material handling practices and having an emergency response plan in place further contribute to a safer work environment.

In this article, we will delve into each of these practices, providing you with thorough and detailed information on how to implement them effectively. By following these guidelines, you can prioritize the safety of your employees and foster a secure workplace environment.

Key Takeaways

- Proper training and regular inspections are crucial for safe operation of laser cutters

- Creating a controlled work area and using personal protective equipment (PPE) are vital for employee safety

- Regular inspection and maintenance ensure optimal performance and safety of the laser cutter

- Having an emergency response plan in place and conducting regular drills minimizes risks and protects the well-being of the team.

Conduct Proper Training for Employees

Make sure you’re providing comprehensive training sessions for all your employees to ensure they know how to use the laser cutter safely and effectively. Employee training is crucial in ensuring that everyone understands the safety protocols and can operate the machine without any risks.

During the training, cover topics such as the correct operation of the laser cutter, proper handling of materials, and emergency procedures. Emphasize the importance of wearing appropriate personal protective equipment, such as safety goggles and gloves, and instruct employees on how to handle potential hazards like fire or smoke. Additionally, teach them how to properly shut down and secure the machine after use.

By conducting thorough training, you can minimize accidents and risks in the workplace.

Moving forward, regularly inspect and maintain the laser cutter to ensure its optimal performance and safety.

Regularly Inspect and Maintain the Laser Cutter

Ensure you don’t neglect the vital task of regularly inspecting and maintaining your laser cutter, as the consequences of overlooking this could be catastrophic. Proper equipment maintenance is essential to ensure the safe and efficient operation of your laser cutter.

Implementing regular inspection procedures will help identify any potential issues before they become major problems. Start by checking the laser cutter’s components, such as the mirrors, lenses, and exhaust system, for any signs of wear or damage. Clean and replace these parts as needed to maintain optimal performance.

Additionally, inspect the machine’s cooling system, ensuring proper water flow and temperature regulation. Don’t forget to regularly clean and lubricate the moving parts to prevent friction and ensure smooth operation.

By regularly inspecting and maintaining your laser cutter, you can minimize the risk of accidents and keep your business running smoothly.

Moving on to the next section, it’s important to establish a controlled work area to further enhance safety precautions.

Establish a Controlled Work Area

Create a secure work environment by establishing a controlled area for operating the laser cutting machine. This is essential for ensuring the safety of your employees and minimizing the risk of accidents.

Start by designating a specific area solely for laser cutting operations. This will help contain any potential hazards and prevent unauthorized personnel from entering the workspace.

Additionally, it’s crucial to ensure proper ventilation in the controlled work environment. Laser cutters generate fumes and smoke that can be harmful if inhaled. Install an effective ventilation system that can effectively remove these airborne contaminants. Adequate ventilation not only protects the health of your employees but also helps maintain the longevity of the laser cutter.

Transitioning into the next section, using personal protective equipment (PPE) is another crucial aspect of laser cutter safety.

Use Personal Protective Equipment (PPE)

When using a laser cutter, it’s crucial to prioritize your safety by wearing the appropriate personal protective equipment (PPE).

Start by always wearing safety glasses or goggles to protect your eyes from potential laser beam hazards.

Additionally, use gloves and protective clothing to safeguard your hands and body from burns and other injuries.

Lastly, considering respiratory protection is essential to prevent inhaling harmful fumes or particles that may be generated during the cutting process.

Remember, taking these precautions will greatly reduce the risk of accidents and ensure a safe working environment.

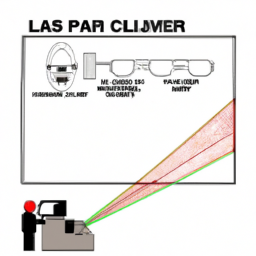

Wear Safety Glasses or Goggles

Wearing safety glasses or goggles is essential when operating a laser cutter, as they can protect your eyes from potential injuries. In fact, a study conducted by the Occupational Safety and Health Administration (OSHA) found that 70% of eye injuries in the workplace could have been prevented with the use of proper eye protection.

When working with a laser cutter, there are several safety precautions you should take, and wearing safety glasses or goggles is one of the most important ones. Laser beams can cause severe eye damage, including permanent blindness, if they come into direct contact with your eyes. Therefore, it is crucial to wear safety glasses or goggles that are specifically designed for laser work. These glasses or goggles should have appropriate shielding to block out the harmful laser radiation. They should also fit securely on your face to prevent any particles or debris from getting into your eyes.

By following this safety practice, you can ensure the well-being of your eyes and minimize the risk of serious injuries. Moving on to the next safety measure, it is also important to use gloves and protective clothing when operating a laser cutter.

Use Gloves and Protective Clothing

Now that you understand the importance of wearing safety glasses or goggles while operating a laser cutter, let’s move on to the next crucial safety practice: using gloves and protective clothing. When it comes to glove selection, it is crucial to choose gloves that are resistant to heat and provide a good grip. Consider using gloves made of materials like Kevlar or leather. Additionally, it is important to wear appropriate protective clothing while operating a laser cutter. This includes long-sleeved shirts and pants made of non-flammable materials such as cotton or wool. Avoid wearing synthetic materials like nylon or polyester, as they can melt and stick to your skin in case of a fire. Remember, proper glove selection and clothing requirements are essential to protect yourself from potential hazards. As we move forward, let’s discuss the importance of considering respiratory protection in laser cutter safety.

Consider Respiratory Protection

It’s crucial to consider respiratory protection when operating a laser cutter. The fumes and smoke produced during the cutting process can contain harmful particles and gases that can be hazardous to your health.

To protect yourself, it’s recommended to wear a respiratory mask that’s specifically designed for laser cutting applications. This mask should have a high level of filtration to remove particles and filter out harmful gases.

Additionally, it’s important to ensure that your workspace has proper air filtration systems in place to remove any airborne contaminants. These systems can include exhaust fans, air purifiers, and ventilation systems.

By wearing a respiratory mask and implementing proper air filtration, you can significantly reduce the risk of inhaling harmful substances.

Now, let’s move on to the next section and discuss the importance of following safe material handling practices.

Follow Safe Material Handling Practices

By properly handling materials, small businesses can ensure the safety of their employees and prevent accidents when operating a laser cutter. Here are some best practices to follow for safe material handling:

-

Store materials in a designated area: Keep materials organized and stored in a secure location to prevent tripping hazards and ensure easy access.

-

Use proper lifting techniques: Lift heavy materials with your legs, not your back, and ask for assistance if needed. Using lifting equipment, such as dollies or forklifts, can also help minimize strain.

-

Avoid overloading the laser cutter: Only load materials that are within the machine’s weight capacity to prevent damage and maintain stability.

-

Implement proper ventilation: Make sure the laser cutter is in a well-ventilated area to minimize exposure to fumes and pollutants.

By following these safe material handling practices, small businesses can create a safer work environment. In the event of an emergency, it’s essential to have an emergency response plan in place.

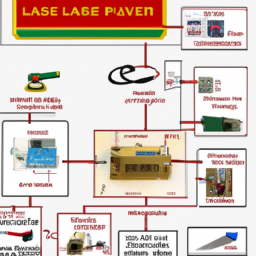

Have an Emergency Response Plan

Ensure the safety of your team by developing an emergency response plan that outlines procedures for potential accidents or incidents. Having an emergency response plan is crucial for small businesses that operate laser cutters.

Start by conducting regular emergency drills to familiarize your team with the necessary actions to take in case of an emergency. This will help them stay calm and act quickly when faced with a real situation.

Additionally, establish clear communication protocols to ensure that everyone is informed and knows what to do in an emergency. Assign specific roles and responsibilities to team members so that there’s no confusion during critical moments.

Regularly review and update the emergency response plan as needed, and make sure that all employees are aware of its contents. By having a well-developed emergency response plan, you can minimize risks and protect the well-being of your team.

Frequently Asked Questions

What are the consequences of not providing proper training for employees?

Not providing proper training for employees is like throwing them into a dark forest without a map or flashlight. It’s a recipe for disaster.

Employee negligence becomes a significant concern when they aren’t trained adequately. Without proper training, employees may not be aware of the potential hazards and safety protocols, leading to accidents and injuries.

Moreover, businesses can face legal liabilities for not providing adequate training, resulting in costly lawsuits and a damaged reputation.

How often should a laser cutter be inspected and maintained?

To ensure the safety and optimal performance of your laser cutter, it’s crucial to prioritize regular inspections and maintenance. Regular laser cutter inspections are important for identifying any potential issues or malfunctions. It’s recommended to inspect and maintain your laser cutter at least once every six months.

This frequency allows for timely detection and resolution of any problems, ensuring that your laser cutter operates efficiently and minimizes the risk of accidents or equipment failure.

What are the potential risks of not establishing a controlled work area?

Not establishing a controlled work area can pose significant risks to your small business. Without a designated space, there is a higher chance of accidents and injuries occurring. Employees may be exposed to hazardous materials or unsafe working conditions, resulting in potential health issues.

Additionally, without proper safety training, workers may not know how to handle emergencies or operate the laser cutter correctly. The consequences of neglecting a controlled work area can be severe, including legal liabilities and a damaged reputation.

What types of personal protective equipment (PPE) should be worn when operating a laser cutter?

When operating a laser cutter, it’s crucial to prioritize your safety by wearing the appropriate personal protective equipment (PPE). Think of PPE as your armor against potential harm.

Safety goggles shield your eyes from the intense laser light, preventing eye damage.

Protective gloves provide a barrier between your hands and any sharp or hot surfaces, reducing the risk of cuts or burns.

Remember, wearing the right PPE is like having a shield that keeps you safe while you work.

Why is it important to have an emergency response plan in place for laser cutter accidents?

Having an emergency response plan in place for laser cutter accidents is crucial for the safety of your small business. By recognizing the importance of an emergency response plan, you’re taking proactive steps to prevent accidents through proper planning.

This plan ensures that all employees know how to react in case of an emergency, minimizing the potential for injuries and damage. It also allows for a swift and organized response, increasing the chances of successful outcomes in the event of an accident.

Conclusion

In conclusion, it’s essential for small businesses to prioritize laser cutter safety practices. By conducting proper training for employees and regularly inspecting and maintaining the laser cutter, businesses can ensure the safety of their workers and prevent accidents.

Establishing a controlled work area and using personal protective equipment are also crucial steps in minimizing risks. Additionally, following safe material handling practices and having an emergency response plan in place can further enhance safety measures.

Remember, a staggering statistic reveals that over 50% of laser cutter accidents can be attributed to inadequate training. Therefore, investing in proper training and safety protocols is not only necessary but also crucial for the well-being of employees and the success of the business.