Did you know that the average lifespan of a laser cutter is only 5 to 10 years?

That’s right, despite their precision and efficiency, these powerful machines have a relatively short lifespan.

But fear not, because in this article, we are going to debunk 11 common myths about extending the lifespan of your laser cutter.

From cleaning techniques to material thickness, maintenance frequency to cooling systems, calibration to professional servicing, we will separate fact from fiction and provide you with the knowledge you need to ensure your laser cutter lasts for years to come.

So, if you want to maximize the lifespan of your laser cutter and avoid costly repairs or replacements, keep reading.

We are here to set the record straight and debunk the myths that may be holding you back from getting the most out of your machine.

Let’s dive in and discover the truth behind extending the lifespan of your laser cutter.

Key Takeaways

- Cleaning the laser lens with alcohol can damage the coating, so alternative cleaning methods should be used.

- Regular maintenance, including cleaning the exhaust system and ensuring proper ventilation, is crucial for preventing fire hazards and increasing the lifespan of the laser cutter.

- Material thickness is an important factor to consider when using a laser cutter, as cutting materials that are too thin or too thick can result in damage to the machine.

- Professional servicing, including thorough cleaning and calibration checks, is necessary to identify and address hidden issues and extend the lifespan of the laser cutter.

Cleaning Techniques: Myth vs Reality

Forget the old wives’ tales about cleaning your laser cutter – let’s separate fact from fiction when it comes to extending the lifespan of this valuable tool.

When it comes to laser cutter safety and optimizing cutting speed, there are a few common myths that need debunking.

First, many believe that cleaning the laser lens with alcohol will improve performance. In reality, using alcohol on the lens can damage the coating and negatively affect the quality of your cuts. Instead, use a specialized lens cleaner recommended by the manufacturer.

Secondly, some people think that cleaning the exhaust system is unnecessary. However, a clogged exhaust can lead to poor ventilation and potential fire hazards. Regularly cleaning and maintaining the exhaust system is crucial for the longevity of your laser cutter.

Now, let’s move on to the next myth: material thickness – fact or fiction?

Material Thickness: Fact or Fiction?

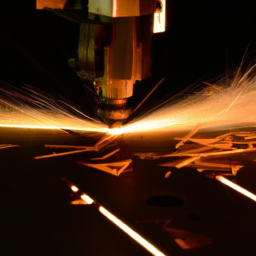

Don’t be fooled by the misconception that material thickness doesn’t matter when it comes to maximizing the life of your laser cutter. The truth is, material thickness plays a crucial role in determining the limits of laser power. If you try to cut materials that are too thick for your laser’s power capabilities, you risk damaging the machine and shortening its lifespan.

On the other hand, cutting materials that are too thin can result in incomplete cuts and wasted time. Finding the sweet spot for cutting speed is also essential. Cutting too fast can lead to poor quality cuts, while cutting too slow can cause excessive heat buildup and damage the laser.

By understanding the importance of material thickness and finding the optimal cutting speed, you can ensure the longevity of your laser cutter.

Now that we’ve debunked the myth about material thickness, let’s move on to the next section about maintenance frequency: setting the record straight.

Maintenance Frequency: Setting the Record Straight

Maintaining your laser cutter regularly ensures its optimal performance and allows you to enjoy uninterrupted cutting sessions. Setting priorities when it comes to maintenance frequency is crucial.

Some laser cutter owners believe that less frequent maintenance saves money in the long run, but this is a common misconception. In fact, neglecting regular maintenance can lead to costly repairs and decreased lifespan of your machine. By investing in regular maintenance, you can identify and address potential issues before they escalate, saving you from expensive repairs down the line. Additionally, regular maintenance helps to keep your laser cutter running smoothly, reducing downtime and increasing productivity.

Don’t fall into the trap of thinking that saving on maintenance cost is a wise decision – prioritize the longevity and performance of your laser cutter.

Now, let’s delve into another important aspect of laser cutter maintenance: cooling systems.

Cooling Systems: Separating Fact from Fiction

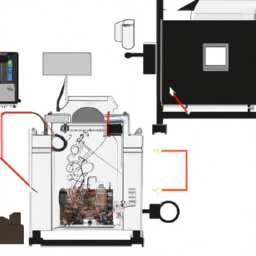

Keep your laser cutter running smoothly and avoid any overheating mishaps by getting the facts straight about cooling systems. Proper cooling system maintenance is essential to ensure the longevity of your laser cutter.

Many people mistakenly believe that their laser cutter’s cooling system requires little to no maintenance. However, this couldn’t be further from the truth. Regularly checking and cleaning the cooling system is crucial to prevent any blockages or inefficiencies. Additionally, proper ventilation is essential to keep the temperature under control. Make sure your laser cutter is placed in a well-ventilated area to avoid overheating.

By understanding the importance of cooling system maintenance and proper ventilation, you can prevent costly repairs and extend the lifespan of your laser cutter.

Now, let’s move on to the next section and uncover the truth behind the myths about calibration.

Calibration: The Truth Behind the Myths

Calibration plays a crucial role in determining the lifespan of your laser cutter. It ensures that your machine is performing at its best, resulting in accurate and precise cuts. However, there are common misconceptions surrounding calibration, and it’s important to separate fact from fiction.

Understanding the truth behind these myths will help you optimize your laser cutter’s performance and extend its lifespan.

How Calibration Affects Lifespan

To ensure your laser cutter operates at its optimal lifespan, it’s crucial to understand how calibration impacts the machine’s performance. Calibration accuracy plays a key role in the overall functionality of your laser cutter. Proper calibration ensures that the machine is able to accurately position and focus the laser beam, resulting in precise cuts and engravings.

The calibration process involves adjusting various parameters such as the beam alignment, power settings, and focal length. These adjustments are made to ensure that the laser beam is directed exactly where it needs to be, with the right amount of power and focus.

Imagine a 3-column and 3-row table, with one column representing the beam alignment, another column representing the power settings, and the third column representing the focal length. Each row represents a different calibration adjustment, with the corresponding values for each parameter.

By understanding how calibration affects the lifespan of your laser cutter, you can ensure that the machine is operating optimally and avoid common misconceptions about calibration.

Common Misconceptions about Calibration

Don’t be fooled by popular misconceptions – understanding the true impact of calibration on your laser cutter’s performance is key.

Here are a few common misconceptions about calibration that you should be aware of:

-

Laser cutter alignment doesn’t matter: This couldn’t be further from the truth. Proper alignment ensures that the laser beam hits the intended spot, resulting in accurate cuts and engravings. Neglecting alignment can lead to wasted materials and subpar results.

-

Power settings can’t compensate for calibration issues: While adjusting power settings might temporarily solve some problems, it won’t fix calibration issues. Calibration ensures that the laser cutter is working at its optimal performance, while power settings control the intensity of the laser beam.

-

Calibration is not a one-time task: Laser cutter calibration should be an ongoing process. Over time, the machine can drift out of alignment, affecting its performance. Regular calibration checks and adjustments are necessary to maintain consistent results.

-

Calibration is not easy to do yourself: While some basic calibration tasks can be done by the user, more complex adjustments often require specialized knowledge and equipment. It’s best to rely on professionals for accurate and precise calibration.

Now that you know the truth about calibration, let’s explore the next topic: professional servicing – do you really need it?

Professional Servicing: Do You Really Need It?

Professional servicing is like giving your laser cutter a rejuvenating spa treatment, ensuring it remains in peak condition for optimal performance and longevity. While some may think that DIY maintenance is enough to keep their laser cutter running smoothly, professional servicing is crucial to its overall health.

A trained technician can identify and address issues that may not be visible to the untrained eye, preventing potential damage and costly repairs down the line. Additionally, professional servicing involves thorough cleaning of the machine, removing any debris or residue that may affect its performance. It also includes calibration checks to ensure the laser cutter is operating at its highest precision.

By investing in professional servicing, you can extend the lifespan of your laser cutter and ensure that it consistently delivers high-quality results.

Frequently Asked Questions

Can I use any cleaning product to clean my laser cutter, or are there specific cleaning techniques that I should follow?

When it comes to cleaning your laser cutter, it’s important to use the right products and techniques. While you may be tempted to use any cleaning product, it’s best to stick to specific options designed for laser cutter maintenance.

Using the wrong cleaning product can damage the delicate components of your machine. Additionally, DIY laser cutter calibration can have its pros and cons. It can save you money, but it requires technical knowledge and can be time-consuming.

Is it true that using thicker materials in my laser cutter can cause it to wear out faster?

Using thicker materials in your laser cutter can indeed cause it to wear out faster. The increased resistance and heat generated by cutting through thicker materials puts more strain on the machine, leading to accelerated wear and tear.

However, this can be mitigated by using proper cleaning techniques. Regularly cleaning and maintaining your laser cutter is crucial to ensure its longevity. By keeping it free from debris and using appropriate cleaning products, you can minimize the effects of wear caused by cutting thicker materials.

How often should I perform maintenance on my laser cutter to ensure its longevity?

Performing regular maintenance on your laser cutter is crucial for ensuring its longevity. By doing so, you can prevent potential issues and keep your machine running smoothly.

Signs that indicate your laser cutter needs maintenance include decreased cutting quality, unusual noises, and frequent breakdowns.

Regularly inspecting and cleaning the machine, checking for loose parts, and replacing worn-out components will help extend its lifespan. Remember, investing time in maintenance now can save you from costly repairs or even the need for a new laser cutter in the future.

Are there any specific cooling systems that are recommended for laser cutters, or can I use any cooling system?

For laser cutters, it’s important to use recommended cooling systems to ensure optimal performance and longevity. Not all cooling systems are suitable. Laser cutters require specific cooling methods that can handle the high heat generated during operation. Using the wrong cooling system can result in overheating and damage to the machine. Therefore, it’s crucial to follow the manufacturer’s guidelines and use the recommended cooling system as part of your regular maintenance schedule.

Can I calibrate my laser cutter myself, or do I need to hire a professional to do it?

You can definitely calibrate your laser cutter yourself, but it’s recommended to hire a professional for this task. Calibrating a laser cutter involves adjusting its settings to ensure accurate cutting and engraving.

While it may seem like a simple process, it requires technical expertise and knowledge of the machine’s components. A professional can ensure that the calibration is done correctly, optimizing the performance of your laser cutter and avoiding any potential issues.

Conclusion

So there you have it, dear reader! After debunking these 11 common myths about extending the lifespan of your laser cutter, you’re now armed with the truth.

Cleaning techniques, material thickness, maintenance frequency, cooling systems, calibration, and professional servicing have all been demystified.

It’s time to put these misconceptions to rest and take good care of your laser cutter. Remember, knowledge is power, and now you have the power to ensure the longevity of your beloved machine.

Happy cutting, and may your laser always be sharp and precise!