In today’s fast-paced business world, efficiency and productivity are the driving forces behind success. Like a well-oiled machine, your business needs to operate seamlessly and with precision. Imagine your business as a symphony orchestra, where every instrument plays its part perfectly in sync.

To achieve this level of harmony, you need to ensure that your workflow and integration with laser cutter software are at their peak performance. In this article, we will explore 11 compelling reasons why this synergy is crucial for the growth and sustainability of your business.

From streamlining your production process to reducing errors and waste, from expanding your capabilities and offerings to saving time and labor costs, and ultimately staying competitive in the market, each of these reasons will shed light on the immense value that workflow and integration with laser cutter software can bring to your business.

So let’s dive in and discover how you can optimize your operations and propel your business to new heights.

Key Takeaways

- Laser cutter software streamlines the production process, saving time and improving accuracy.

- Integrating business with laser cutter software boosts efficiency, productivity, and output quality.

- Laser cutter software enables automation of tasks, reducing time and effort required for manual operations.

- Laser cutter software helps optimize workflow, reduce production time, and increase productivity.

Streamline Your Production Process

You’ll love how streamlining your production process with laser cutter software integration saves you time and makes your business run like a well-oiled machine. By integrating laser cutter software into your workflow, you can improve accuracy and optimize operations.

The software allows you to create precise designs and patterns, ensuring that every cut is accurate and consistent. This eliminates the need for manual measurements and reduces the chances of errors or wastage.

With laser cutter software, you can also automate the cutting process, allowing for faster and more efficient production. This not only increases productivity but also frees up your time to focus on other important aspects of your business.

By streamlining your production process, you’ll increase efficiency and productivity, giving your business a competitive edge in the market.

Increase Efficiency and Productivity

Boost your operation’s effectiveness and output by seamlessly connecting your manufacturing processes with the laser cutter system. This allows for a smooth and streamlined workflow that maximizes productivity. By integrating your business with laser cutter software, you can significantly improve output and enhance output quality.

The laser cutter software enables you to automate tasks, reducing the time and effort required for manual operations. With precise control over the cutting process, you can achieve higher precision and accuracy, resulting in better quality products. Additionally, the software provides real-time monitoring and reporting, allowing you to identify bottlenecks and make necessary adjustments to optimize efficiency.

By increasing your efficiency and productivity, you can meet customer demands faster and stay ahead of the competition.

As we move into the next section about reducing errors and waste, it’s crucial to note that integrating laser cutter software can help eliminate costly mistakes and minimize material wastage.

Reduce Errors and Waste

Minimize costly mistakes and material wastage by seamlessly integrating laser cutter software, which allows for precise control over the cutting process, ensuring high-quality results and reducing errors. Here’s how it can improve accuracy and minimize material loss:

-

Advanced design capabilities: Laser cutter software enables you to create intricate designs with precise dimensions, reducing the chances of errors during the cutting process.

-

Real-time visual feedback: With live previews and simulations, you can identify any potential issues before starting the actual cutting, saving time and material.

-

Automatic optimization: The software automatically optimizes the cutting path, reducing the amount of material wasted and maximizing efficiency.

-

Error detection and correction: Laser cutter software can detect and correct errors, such as incomplete cuts or incorrect settings, preventing unnecessary material loss.

By reducing errors and waste, integrating laser cutter software into your workflow allows you to expand your capabilities and offerings seamlessly.

Expand Your Capabilities and Offerings

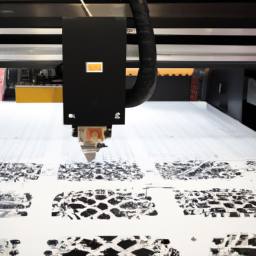

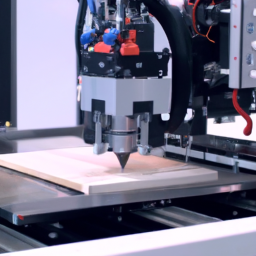

Expand your capabilities and offerings by seamlessly integrating laser cutter software into your operations. This will allow you to take on more intricate and complex designs for your customers. By incorporating laser cutter software into your workflow, you can improve creativity and enhance precision in your designs.

The software provides advanced tools and features that enable you to create intricate patterns, detailed engravings, and precise cuts. These were previously difficult or time-consuming to achieve. With the ability to handle more complex designs, you can attract a wider range of customers and offer unique products that set you apart from your competitors.

This expanded capability will not only increase customer satisfaction but also open up new business opportunities. Furthermore, by saving time and labor costs through efficient software integration, you can focus on delivering high-quality products and services to further grow your business.

Save Time and Labor Costs

By implementing laser cutter software, you’ll be able to significantly reduce time and labor costs, allowing you to focus on delivering high-quality products and services to grow your business efficiently. Laser cutter software automates tasks that would otherwise require manual labor, such as designing and cutting intricate patterns. This automation streamlines your workflow, saving you valuable time and resources. Additionally, laser cutter software improves profitability by minimizing material waste. With precise cutting capabilities, you can optimize material usage and reduce costs associated with excess waste. By utilizing laser cutter software, you can stay competitive in the market by offering faster turnaround times and lower production costs. This gives you an edge over competitors and allows you to attract more customers.

Stay Competitive in the Market

Stay ahead of the competition and position yourself for success by utilizing laser cutter software to streamline your operations and offer faster turnaround times.

With the increasing demand for quick and efficient production, staying competitive in the market is crucial. Laser cutter software allows you to improve customer satisfaction by delivering products in a timely manner, exceeding their expectations.

Additionally, it enhances quality control by ensuring precision and accuracy in every cut, minimizing errors and rework. By investing in laser cutter software, you can optimize your workflow, reduce production time, and ultimately increase your productivity.

This will give you a competitive edge in the market, attracting more customers and boosting your reputation as a reliable and efficient business. Don’t miss out on the opportunity to stay ahead and grow your business with laser cutter software.

Frequently Asked Questions

Can laser cutter software integrate with other machinery or equipment in my production process?

Yes, laser cutter software can seamlessly integrate with other machinery or equipment in your production process. This integration offers numerous benefits, including improved quality control. By integrating the laser cutter software with other machinery, you can ensure precise and accurate cuts, resulting in higher quality products. Additionally, this integration streamlines your workflow, saving you time and effort. Overall, integrating laser cutter software with other machinery is crucial for enhancing productivity and ensuring top-notch quality in your business.

How can laser cutter software help in designing complex and intricate patterns or designs?

Laser cutter software offers a range of features that can greatly assist in designing complex and intricate patterns or designs. With the software’s advanced tools and capabilities, you can easily create and modify intricate designs, ensuring precision and accuracy.

The benefits of using laser cutter software for designing include increased efficiency, reduced production time, and the ability to achieve intricate details that would be difficult or impossible to achieve manually.

Overall, laser cutter software greatly enhances the design process and helps you create stunning and intricate designs.

Is laser cutter software compatible with different file formats for importing designs?

Yes, laser cutter software is compatible with different file formats for importing designs. The software supports a wide range of file formats, including popular ones like SVG, DXF, and AI.

This compatibility allows you to seamlessly import your designs into the software without any hassle. The software makes it easy to transfer complex patterns or intricate designs to the laser cutter, bringing them to life with precision and accuracy.

Can laser cutter software optimize material usage to minimize waste?

Yes, laser cutter software applications have features that can optimize material usage to minimize waste. These software programs have advanced algorithms that analyze your design and automatically calculate the most efficient way to arrange your cuts on the material. By optimizing the layout, the software ensures that you utilize the maximum amount of material and minimize wastage.

This not only saves you money on material costs but also helps in reducing environmental impact.

Does laser cutter software provide real-time monitoring and reporting of production progress and efficiency?

Yes, laser cutter software provides real-time analytics and performance tracking. This allows you to closely monitor and report on your production progress and efficiency. With this feature, you can easily track the status of your projects and identify any bottlenecks or inefficiencies. You can then make timely adjustments to optimize your workflow. This real-time monitoring capability ensures that you stay on top of your production processes and make informed decisions to improve overall productivity and profitability.

Conclusion

In conclusion, integrating workflow with laser cutter software is absolutely essential for your business.

By streamlining your production process, increasing efficiency, and reducing errors and waste, you can save both time and labor costs.

Furthermore, it allows you to expand your capabilities and offerings, staying competitive in the market.

Just like a well-oiled machine, this integration will ensure smooth operations and propel your business towards success.

So, don’t waste any more time and start integrating today! Your business will thank you for it.