Looking to bring precision and innovation to your cutting processes? The world of cutting technology offers two powerful options: 3D laser cutting and die cutting. Both techniques have their advantages, but when it comes to versatility, one reigns supreme.

Enter the realm of 3D laser cutting, a technique that pushes boundaries and opens up a world of possibilities. With its advanced laser technology, this cutting method allows you to manipulate and shape materials with unparalleled accuracy.

On the other hand, die cutting, a tried and true technique, is known for its efficiency and reliability.

In this article, we will delve into the depths of these two methods, exploring their capabilities and examining their versatility. By weighing the unique features of each technique, we will help you make an informed decision for your cutting needs.

Prepare to be amazed as we showcase real-life examples and highlight the factors you should consider. It’s time to choose between 3D laser cutting and die cutting – which will you crown as the ultimate champion of versatility?

Key Takeaways

- 3D laser cutting offers unparalleled precision and accuracy, making it ideal for intricate designs and industries such as automotive, aerospace, and medical equipment manufacturing.

- Die cutting is known for its efficiency and reliability, making it advantageous for industries like packaging, printing, and electronics.

- Laser cutting is faster and more automated, making it suitable for large-scale production, while die cutting is slower but more efficient for smaller quantities.

- When deciding between laser cutting and die cutting, it is important to consider specific needs, material options, setup costs, production time, and production volume, and consult with experts for technical considerations.

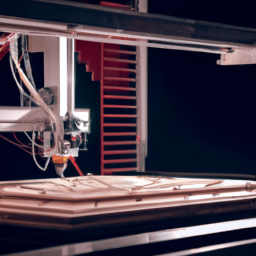

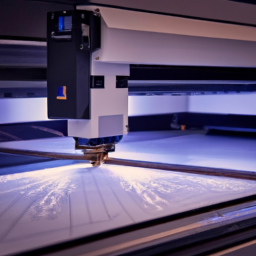

Understanding 3D Laser Cutting

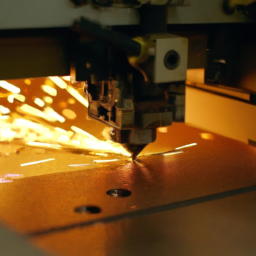

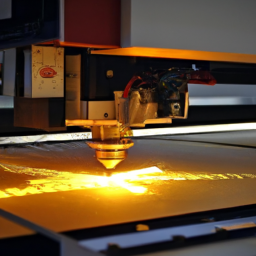

3D laser cutting is mind-blowingly precise and will leave you in awe of its capabilities. This cutting-edge technology offers numerous advantages that make it an ideal choice for a wide range of applications.

One of the main advantages of 3D laser cutting is its unparalleled precision. With laser beams that can be focused to incredibly small diameters, it allows for intricate and detailed cuts with minimal material wastage.

Additionally, 3D laser cutting offers excellent repeatability, ensuring consistent results even for complex designs. Its versatility allows it to be used in various industries, including automotive, aerospace, and electronics.

From creating intricate patterns on metal sheets to crafting delicate prototypes, 3D laser cutting can handle it all.

Now, let’s transition into exploring die cutting, another popular cutting method.

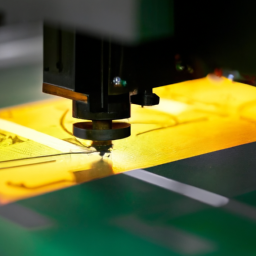

Exploring Die Cutting

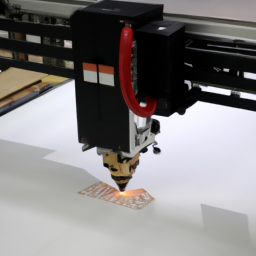

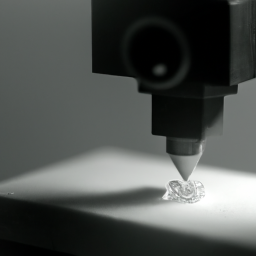

Exploring die cutting reveals a myriad of possibilities for creating intricate designs and patterns. Die cutting is a versatile technique that offers several advantages and has numerous applications. Here are some key points to grab your attention:

-

Precision: Die cutting allows for precise and accurate cuts, ensuring consistent and high-quality results every time.

-

Versatility: With die cutting, you can work with a wide range of materials, including paper, fabric, leather, and even metal.

-

Efficiency: Die cutting is a fast and efficient process, making it ideal for mass production and large-scale projects.

Die cutting finds applications in various industries such as packaging, automotive, and even fashion. Its ability to produce intricate shapes and designs makes it a popular choice for creating custom packaging, labels, and promotional materials.

Transitioning into the subsequent section about comparing versatility, it becomes evident that die cutting offers unique advantages compared to 3D laser cutting.

Comparing Versatility

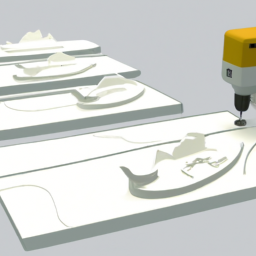

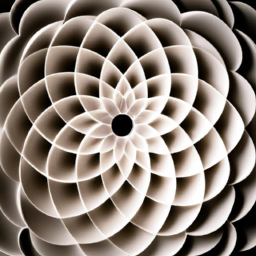

When comparing versatility, you’ll discover that die cutting offers a wide range of possibilities for creating intricate designs and patterns, allowing you to work with various materials and achieve precise and consistent results every time. Die cutting has several advantages that make it a preferred choice for many applications. Firstly, it allows for intricate and complex designs to be created with ease, ensuring high levels of precision. Secondly, die cutting can be used on a wide range of materials, including paper, fabric, leather, and even metal. However, die cutting also has its limitations. It requires a custom-made die for each design, which can be time-consuming and costly. Additionally, die cutting may not be suitable for certain materials that are too thick or rigid. When considering these advantages and limitations, it is important to weigh them against other factors such as cost, production time, and design complexity. Transitioning into the next section, these factors should be carefully considered when deciding between die cutting and laser cutting.

Factors to Consider

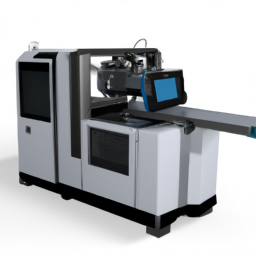

Consider these important factors when deciding between the two options: cost, production time, and design complexity.

-

Cost comparison: Laser cutting often requires expensive machinery and maintenance costs, while die cutting is generally more affordable due to its simpler equipment requirements.

-

Production time: Laser cutting is faster and more automated, making it ideal for large-scale production. Die cutting, on the other hand, can be slower and requires manual setup, but is more efficient for smaller quantities.

-

Design complexity: Laser cutting offers greater versatility and precision when it comes to intricate designs and fine details. Die cutting is better suited for simpler shapes and patterns.

-

Precision comparison: Laser cutting provides high precision and accuracy, especially for complex cuts and intricate shapes. Die cutting, while precise, may have limitations in achieving the same level of intricacy.

Considering these factors, you can make an informed decision based on your specific needs and requirements. In real-life examples, these considerations play a crucial role in determining the most suitable cutting method.

Real-Life Examples

In discussing real-life examples, it’s important to highlight the industries that greatly benefit from 3D laser cutting.

Industries such as automotive, aerospace, and medical equipment manufacturing have found 3D laser cutting to be highly versatile and efficient in producing complex shapes and designs.

On the other hand, die cutting has proven to be advantageous for industries like packaging, printing, and electronics. These industries require precise and repetitive cutting for materials like paper, cardboard, and thin metals.

Industries that benefit from 3D laser cutting

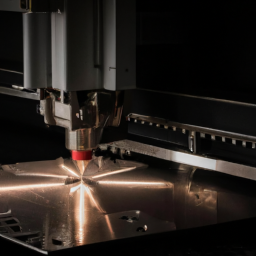

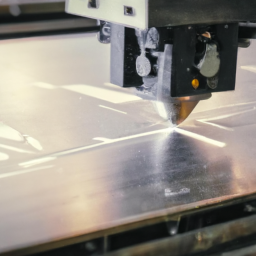

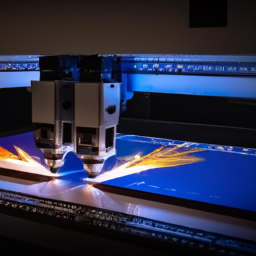

You’ll be amazed at the wide range of industries that can truly flourish with the incredible precision and versatility of 3D laser cutting. From automotive applications to medical devices, this advanced cutting technique offers unparalleled accuracy and efficiency.

In the automotive industry, 3D laser cutting is used to create intricate designs for car interiors, exteriors, and body parts. It allows for the production of complex shapes and patterns with minimal waste.

Similarly, in the medical field, 3D laser cutting is utilized to manufacture precision components for devices such as implants, surgical instruments, and prosthetics. The ability to cut through various materials with high precision ensures optimal functionality and safety.

As we transition to discussing industries that benefit from die cutting, it is important to note the unique advantages provided by 3D laser cutting.

Industries that benefit from die cutting

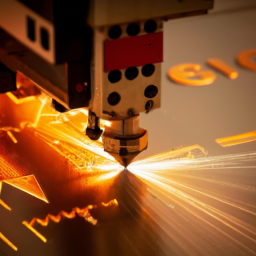

Discover how various industries can benefit from the precision and efficiency of die cutting technology. Die cutting is a versatile process that finds applications in a wide range of industries. Here are three key sectors that benefit from die cutting:

-

Packaging: Die cutting allows for precise and consistent cutting of materials used in packaging production, such as cardboard, foam, and plastics. It enables the creation of custom shapes and designs, ensuring that packaging meets specific requirements while maintaining a high level of efficiency.

-

Automotive: Die cutting plays a crucial role in the manufacturing of automotive components. It’s used to cut materials like rubber, gaskets, and insulation, allowing for precise fitting and sealing. This technology ensures that automotive parts are accurately shaped and assembled, enhancing overall performance and safety.

-

Manufacturing: Die cutting is widely used in various manufacturing processes, including textiles, electronics, and furniture. It enables efficient and precise cutting of materials, increasing productivity and reducing waste.

Understanding how different industries benefit from die cutting technology is essential in making the right choice for your specific needs.

Making the Right Choice

When making the choice between d laser cutting and die cutting, it’s crucial to assess your specific needs. Consulting with experts in the field can provide valuable insights and guidance to help you make an informed decision.

Additionally, maximizing efficiency and productivity should be a key consideration in order to optimize your cutting processes.

Assessing your specific needs

Consider your specific needs when deciding between laser cutting and die cutting. Evaluating options and assessing cost effectiveness are crucial in making the right choice. To help you in your decision-making process, here are three factors to consider:

-

Material: Laser cutting is more suitable for cutting intricate designs on a wide range of materials, including plastics, metals, and fabrics. Die cutting, on the other hand, is better suited for cutting thicker materials, such as cardboard and leather.

-

Precision: Laser cutting offers high precision and accuracy, allowing for intricate and detailed cuts. Die cutting, although precise, may not achieve the same level of intricacy.

-

Volume: If you have high production volume requirements, die cutting may be more cost-effective due to its ability to quickly cut multiple pieces at once. Laser cutting, while versatile, may be more time-consuming for large quantities.

By considering these factors, you can make an informed decision on whether laser cutting or die cutting is the best option for your specific needs. Consulting with experts can further guide you in finding the most suitable solution for your project.

Consulting with experts

If you’re truly clueless about laser cutting and die cutting, it might be a good idea to seek guidance from the wizards of the cutting world to unlock the secrets of the most suitable option for your needs. Expert recommendations are crucial in making the right decision, as they can provide valuable insights into the technical considerations involved. Consulting with experts can help you understand the limitations and advantages of each method, ensuring that you make an informed choice. To provide a visual representation of the benefits and drawbacks, consider the following table:

| Laser Cutting | Die Cutting |

|---|---|

| Precise and intricate cuts | Limited to simpler designs |

| Versatile material options | Restricted to certain materials |

| High setup costs | Lower setup costs |

| Fast production time | Longer production time |

| Suitable for small batches | Ideal for large production runs |

By exploring these expert recommendations and technical considerations, you can determine which cutting method will best maximize efficiency and productivity for your specific requirements. Transitioning into the subsequent section, let’s delve into ways to achieve optimal results.

Maximizing efficiency and productivity

To achieve optimal results, it’s crucial to find ways to maximize efficiency and productivity in your cutting process. By improving productivity and streamlining processes, you can significantly enhance the overall output of your operations. Here are three key strategies to consider:

-

Implement automation: By utilizing automated systems and machinery, you can reduce manual labor and increase the overall speed and accuracy of your cutting process.

-

Optimize material usage: Analyze your material consumption and identify ways to minimize waste. This can include utilizing nesting software to efficiently arrange parts on a sheet, reducing scrap material and maximizing material utilization.

-

Schedule maintenance routines: Regularly maintaining and servicing your cutting equipment ensures optimal performance and prevents unexpected downtime. Implementing a maintenance schedule will help identify and address potential issues before they impact productivity.

By incorporating these strategies, you can maximize efficiency and productivity in your cutting process, ultimately leading to improved results and profitability.

Frequently Asked Questions

What are the typical materials that can be cut using 3D laser cutting?

With 3D laser cutting, you can slice through materials like a hot knife through butter. It offers numerous advantages over traditional cutting methods.

This precise technique works wonders on a variety of materials, including metals, plastics, wood, and fabrics. However, it does have limitations when it comes to reflective surfaces and certain organic materials.

Nevertheless, the versatility and accuracy of 3D laser cutting make it a top choice for many industries.

Is die cutting more cost-effective than 3D laser cutting?

In terms of cost comparison, die cutting can be more affordable in the long run. The initial investment for die cutting equipment is typically lower than that of 3D laser cutting.

Additionally, die cutting can be more efficient for large-scale production runs, resulting in lower costs per unit. However, 3D laser cutting has its advantages in certain applications. It’s a better choice when intricate designs and complex shapes need to be cut, offering more flexibility and precision compared to die cutting.

Can die cutting be used for complex shapes and intricate designs?

Die cutting is a popular method for creating complex shapes and intricate designs on paper-based materials. It offers benefits such as high precision and efficiency. However, die cutting does have limitations when it comes to extremely intricate designs. In such cases, 3D laser cutting may be more versatile.

Nevertheless, die cutting remains a cost-effective and reliable option for a wide range of applications in the paper industry.

Are there any safety concerns or precautions to take when using 3D laser cutting?

When using 3D laser cutting, there are several safety concerns and precautions to consider. Firstly, it’s important to wear appropriate personal protective equipment, such as safety glasses and gloves, to prevent any potential injuries.

Additionally, proper ventilation should be ensured to avoid the inhalation of fumes generated during the cutting process.

It’s also crucial to carefully select and prepare the materials to be cut using 3D laser cutting, as certain materials may pose a fire or explosion risk.

How does the speed of 3D laser cutting compare to die cutting?

Compared to die cutting, 3D laser cutting operates at lightning speed, making it the Usain Bolt of the cutting world. However, this rapid pace comes with some trade-offs.

While die cutting offers advantages in industries like packaging and automotive, 3D laser cutting has potential drawbacks. Its precision can be compromised, leading to less accurate cuts. Furthermore, the heat generated during the process can damage delicate materials.

Conclusion

In conclusion, when comparing 3D laser cutting and die cutting, it’s evident that both methods have their own advantages and limitations. However, if versatility is the primary concern, 3D laser cutting emerges as the winner.

With its ability to accurately cut intricate designs and a wide range of materials, it offers immense flexibility in various industries. Interestingly, a study found that 3D laser cutting can achieve a positioning accuracy of up to 0.01mm, ensuring precise and intricate cuts that meet the most demanding specifications.