Are you tired of spending countless hours on intricate cutting tasks? Do you crave a more convenient solution that guarantees precision and efficiency? Look no further than the battle between 3D Laser Cutting and Electric Cutting. These two cutting methods have revolutionized the manufacturing industry, offering unparalleled convenience and accuracy. But which one will reign supreme?

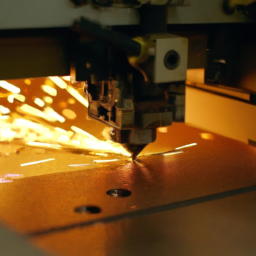

Enter the realm of 3D Laser Cutting, a cutting-edge technology that utilizes lasers to slice through various materials with utmost precision. With its ability to navigate complex geometries and produce intricate designs, it has become the go-to choice for industries seeking perfection.

On the other hand, Electric Cutting emerges as a versatile option, providing a wide range of cutting techniques and applications.

In this article, we will delve into the depths of these cutting methods, comparing their precision, efficiency, material compatibility, and cost considerations. By the end, you will have a clear understanding of which option is more convenient for your specific needs.

So, buckle up and let us embark on this journey to determine the ultimate cutting convenience.

Key Takeaways

- 3D Laser Cutting offers precise cuts and complex geometries, while Electric Cutting provides versatile cutting techniques and applications.

- 3D Laser Cutting allows for intricate designs and minimizes material waste, while Electric Cutting can handle various materials with lower maintenance requirements.

- Laser Cutting is faster than Electric Cutting, but Electric Cutting may struggle with certain materials and Laser Cutting may have limitations with thicker materials.

- Laser Cutting is suitable for delicate materials, while Electric Cutting is better for thick and conductive materials.

Understanding 3D Laser Cutting

When it comes to understanding 3D laser cutting, it’s crucial to grasp the intricate precision and versatility it offers. Laser cutting applications encompass a wide range of industries, from automotive to aerospace, due to its ability to precisely cut through various materials such as metal, wood, and plastic.

The benefits of 3D laser cutting are abundant. Firstly, it allows for intricate designs and complex geometries that would be challenging to achieve with traditional cutting methods. Additionally, laser cutting minimizes material waste and provides cleaner, more precise cuts, resulting in increased efficiency and cost-effectiveness. Moreover, the non-contact nature of laser cutting reduces the risk of material damage and distortion.

Transitioning into the subsequent section about electric cutting, it’s important to explore another versatile option for precision cutting.

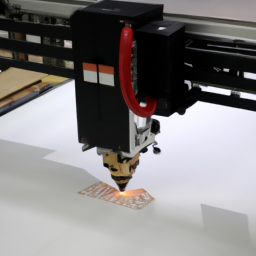

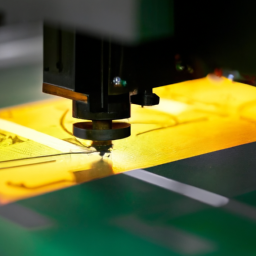

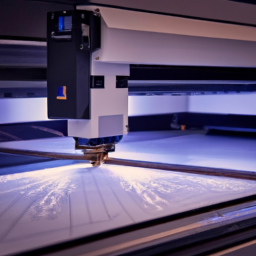

Electric Cutting: A Versatile Option

For a more versatile option, you should consider electric cutting. Electric cutting offers a wide range of applications, making it suitable for various industries such as automotive, aerospace, and electronics. It utilizes electrical energy to power the cutting process, allowing for greater flexibility and precision. Unlike 3D laser cutting, which is limited to certain materials, electric cutting can handle a variety of materials including metals, plastics, and composites. Additionally, electric cutting machines have lower maintenance requirements compared to laser cutting machines. This means less downtime and reduced costs for businesses. In the next section, we will compare the precision and accuracy of electric cutting and laser cutting to help you make an informed decision.

Comparing Precision and Accuracy

To determine the best option for your needs, let’s take a closer look at how electric cutting and laser cutting compare in terms of precision and accuracy.

Precision benefits of electric cutting:

- Electric cutting machines offer high precision due to their ability to maintain consistent cutting depths and angles.

- The accuracy of electric cutting is enhanced by advanced control systems that ensure precise movements and measurements.

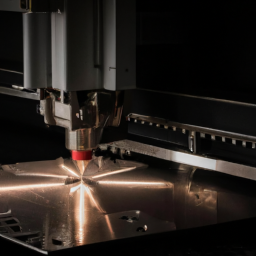

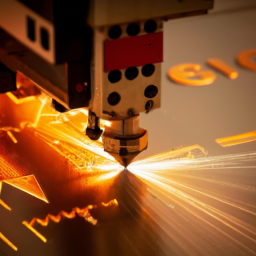

Accuracy advantages of laser cutting:

- Laser cutting excels in accuracy as it uses a focused laser beam to create precise cuts with minimal material wastage.

- The laser’s ability to follow intricate patterns and cut complex shapes makes it highly accurate.

Both methods provide impressive precision and accuracy, but laser cutting’s ability to create intricate designs gives it an edge in certain applications.

Moving on to the next section on efficiency and speed, we will explore how these two cutting methods compare in terms of productivity.

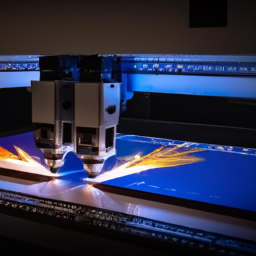

Efficiency and Speed

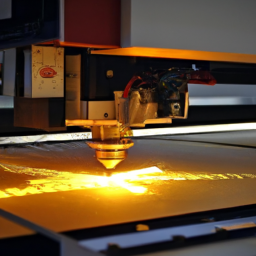

Efficiency and speed are key factors when determining the best cutting method for your needs, and it’s fascinating to explore how these two techniques compare.

In terms of efficiency, electric cutting has made significant strides with improving technology. It offers faster setup times and can handle intricate designs with ease. However, laser cutting still holds an edge in terms of overall speed. Its ability to cut through various materials quickly makes it a preferred choice for many industries.

That being said, both methods have their potential limitations. Electric cutting may struggle with certain materials that require higher precision, while laser cutting may have limitations with thicker materials.

Transitioning to the subsequent section about material compatibility, it is important to consider how these cutting methods interact with different materials.

Material Compatibility

When considering the best cutting method for your needs, it’s crucial to understand how different materials interact with electric and laser cutting techniques. Here’s a list of material compatibility aspects that can invoke an emotional response:

-

Delicate materials: Laser cutting is more suitable for delicate materials like thin fabrics and paper due to its precision and non-contact nature. This allows for intricate designs without causing damage.

-

Thick and conductive materials: Electric cutting has an advantage over laser cutting when it comes to thick and conductive materials like metals. The high power and ability to generate heat quickly make electric cutting more efficient in these cases.

-

Reflective materials: Laser cutting limitations come into play when dealing with highly reflective materials like mirrors or metals. The reflective surface can bounce the laser beam, reducing the effectiveness of the cutting process.

-

Cost considerations: Now that you understand the material compatibility aspects, it’s important to consider the cost implications of each cutting method.

Transitioning into the subsequent section about ‘cost considerations,’ it’s essential to evaluate both initial investment and long-term operational costs when deciding between laser cutting and electric cutting.

Cost Considerations

Consider the financial implications of both methods before making a decision between laser cutting and electric cutting. When it comes to cost effectiveness, laser cutting can be more expensive upfront due to the higher cost of the laser cutting machine and the need for additional safety measures. However, laser cutting is generally more precise and efficient, resulting in less material waste and higher productivity, which can save on long-term costs.

On the other hand, electric cutting machines are usually less expensive initially and have lower maintenance expenses. However, they may require more frequent maintenance and blade replacements, which can add up over time.

Ultimately, the cost effectiveness of each method will depend on factors such as the volume of cutting required, the type of materials being cut, and the specific needs of the business.

Frequently Asked Questions

Are there any safety concerns or precautions to be aware of when using 3D laser cutting or electric cutting?

When using 3D laser cutting or electric cutting, there are several safety concerns and precautions to keep in mind. Firstly, ensure that you’re wearing appropriate personal protective equipment to protect yourself from potential hazards.

Secondly, be aware of materials compatibility to avoid any potential chemical reactions or damage.

Additionally, cutting limitations should be considered to prevent any accidents or damage to the equipment.

Regular maintenance is crucial to ensure safe and efficient operation.

Lastly, environmental considerations, such as proper disposal of waste materials, should be taken into account.

Can 3D laser cutting or electric cutting be used on all types of materials?

When considering the cost effectiveness and quality of 3D laser cutting versus electric cutting, it’s important to note that both methods can be used on a wide range of materials.

However, there may be variations in the precision and speed of the cuts. While electric cutting may offer a lower upfront cost, 3D laser cutting often provides higher quality and more precise results, making it a more cost-effective and efficient choice in the long run.

Are there any limitations or restrictions on the size or thickness of materials that can be cut using 3D laser cutting or electric cutting?

Size limitations and thickness restrictions are important considerations when using 3D laser cutting or electric cutting. The size of the material being cut will determine the maximum dimensions that can be accommodated by the cutting machine. Similarly, the thickness of the material will determine the maximum depth that can be achieved.

These limitations are determined by the capabilities of the cutting equipment and should be carefully considered to ensure the desired results are achieved.

What are the maintenance requirements for 3D laser cutting machines or electric cutting equipment?

To ensure optimal performance, both 3D laser cutting machines and electric cutting equipment require regular maintenance. Maintenance requirements vary depending on the specific model and manufacturer, but generally include tasks such as cleaning, lubrication, and calibration.

Efficient maintenance is crucial for prolonging the lifespan of these machines and ensuring precise cuts. When comparing the maintenance requirements, it’s essential to consider factors such as accessibility for maintenance tasks and the availability of spare parts.

Are there any environmental considerations to take into account when choosing between 3D laser cutting and electric cutting methods?

When choosing between 3D laser cutting and electric cutting methods, there are important environmental considerations to take into account. Energy efficiency plays a crucial role, as 3D laser cutting typically requires less energy compared to electric cutting.

Additionally, waste management is a factor to consider. Laser cutting produces minimal waste due to its precision, while electric cutting may generate more waste.

Therefore, from an environmental standpoint, 3D laser cutting is a more sustainable option in terms of energy efficiency and waste management.

Conclusion

In conclusion, when deciding between 3D laser cutting and electric cutting, it ultimately comes down to your specific needs and requirements.

While 3D laser cutting offers exceptional precision and accuracy, electric cutting provides versatility and flexibility.

Consider a hypothetical case study where a company needs to cut intricate designs on multiple materials. In this scenario, the 3D laser cutting technology would be the more convenient choice due to its ability to deliver precise and intricate cuts on various materials, ensuring optimal results and saving time and resources.