Are you in the manufacturing industry and looking for the most precise method for cutting materials? If so, you’ve come to the right place.

In this article, we will explore the age-old question: 3D laser cutting or milling – which method is more precise? When it comes to precision, both 3D laser cutting and milling have their advantages.

To understand which method is superior, we must delve into the basics of each technique. 3D laser cutting utilizes a high-powered laser beam to precisely cut through materials, while milling involves removing material using rotating cutting tools.

To determine the precision levels of these methods, we will compare various factors that influence the accuracy of both processes. Additionally, we will discuss the factors that can impact precision in 3D laser cutting and milling.

Armed with this knowledge, you will be able to make an informed decision and choose the right method for your precision needs. So, let’s dive in and uncover the intricate details of 3D laser cutting versus milling.

Key Takeaways

- 3D laser cutting is a precise method with minimal wastage and is ideal for intricate designs or delicate materials.

- Milling machines have improved precision with an average error rate of 0.002 inches and CNC systems allow for accurate and consistent cuts.

- Factors influencing precision in 3D laser cutting include material and machine calibration, such as reflectivity, absorption, thermal conductivity, laser beam alignment, cutting bed stability, and positioning system accuracy.

- Factors influencing precision in milling include tooling requirements, material properties, such as hardness, stability, and machinability, as well as tool material, geometry, and coating.

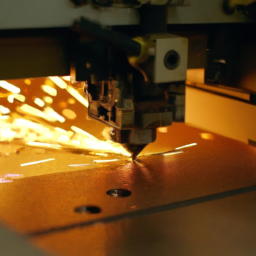

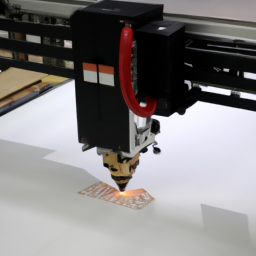

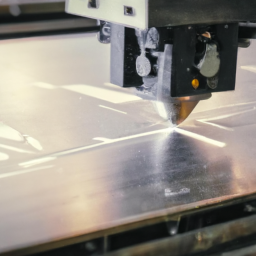

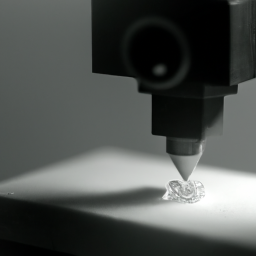

Understanding the Basics of 3D Laser Cutting

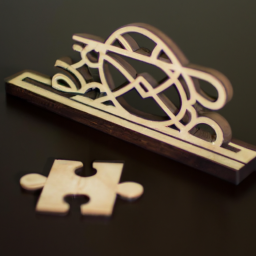

Get ready to be amazed by the incredible precision of 3D laser cutting! This cutting-edge technology offers numerous advantages that make it a popular choice in various industries.

The main advantage of 3D laser cutting lies in its unmatched precision. The laser beam, with its small focal point, allows for intricate and accurate cuts with minimal material wastage. This precision makes 3D laser cutting ideal for applications that require intricate designs or delicate materials.

Industries such as automotive, aerospace, and jewelry find great value in this technology due to its ability to create complex shapes and patterns with utmost accuracy.

Exploring the precision of milling, on the other hand, reveals a different approach to achieving accuracy and will be discussed in the subsequent section.

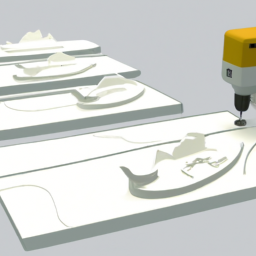

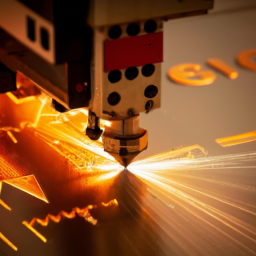

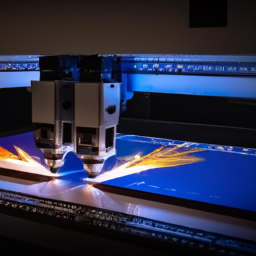

Exploring the Precision of Milling

To better understand the precision of milling, you’ll be interested to know that the average error rate in milling machines is only 0.002 inches.

Milling machines are capable of achieving extremely high levels of precision due to advancements in technology. The use of computer numerical control (CNC) systems allows for precise control over the cutting tools, resulting in accurate and consistent cuts. Additionally, the development of high-speed milling techniques has further improved the precision of milling.

These advancements have opened up new possibilities for precision milling in various industries, such as aerospace and medical fields. With further advancements in milling technology, the future holds even greater possibilities for achieving higher levels of precision.

As we move forward, it’s important to compare the precision levels of milling with other methods, such as laser cutting, to determine the most suitable technique for specific applications.

Comparing Precision Levels

When comparing precision levels, it’s important to consider the advancements in technology and the potential for even greater possibilities in the future. Here are four key factors to consider when measuring precision levels in manufacturing:

-

Accuracy: Precision is all about accuracy, and advancements in technology have allowed for higher levels of precision in both laser cutting and milling processes. The ability to achieve precise measurements ensures that the final product meets the required specifications.

-

Repeatability: Precision is not a one-time achievement, but rather a consistent and repeatable process. Both laser cutting and milling have made significant advancements in achieving repeatable precision, allowing manufacturers to consistently produce high-quality products.

-

Versatility: Precision is crucial in manufacturing, as it allows for the creation of intricate and complex designs. Laser cutting and milling both offer versatile options for achieving precision, allowing manufacturers to produce a wide range of products with intricate details.

-

Time and cost efficiency: Precision levels in manufacturing can directly impact time and cost efficiency. Higher precision levels reduce the need for additional finishing processes and minimize material waste, resulting in cost savings and faster production times.

Considering these advantages of precision in manufacturing, it becomes clear that both laser cutting and milling have made significant strides in achieving precise results. However, to understand the factors influencing precision in 3D laser cutting, we need to delve deeper into the technology and techniques involved.

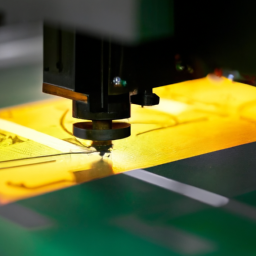

Factors Influencing Precision in 3D Laser Cutting

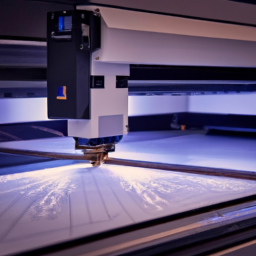

Imagine yourself operating a 3D laser cutting machine, carefully manipulating the intricate designs with precision and finesse, as you navigate through the factors that influence the accuracy and quality of the final product.

Two significant factors that greatly affect the precision in 3D laser cutting are the material being cut and the calibration of the machine itself.

The type of material being cut plays a crucial role in determining the precision achievable. Different materials have varying levels of reflectivity, absorption, and thermal conductivity, which can impact the laser’s effectiveness in cutting with precision.

Additionally, the calibration of the machine, including the alignment of the laser beam, the stability of the cutting bed, and the accuracy of the positioning system, can greatly influence the final precision of the cut.

These factors must be meticulously considered and fine-tuned to ensure optimal precision in 3D laser cutting.

Moving on to factors influencing precision in milling…

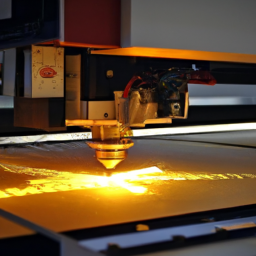

Factors Influencing Precision in Milling

Step into the world of milling, where precision is paramount and every detail matters, as you explore the factors that influence the accuracy and quality of the final product.

One of the key factors in achieving precision in milling is the tooling requirements. The choice of tools, such as end mills, face mills, and drills, can greatly impact the accuracy of the milling process. Factors such as the tool material, geometry, and coating can affect the tool’s ability to cut through the material with precision.

Additionally, the material properties of the workpiece itself play a crucial role. The hardness, stability, and machinability of the material can all influence the accuracy of the milling process.

Understanding these factors and selecting the appropriate tools and materials is essential in achieving the desired level of precision in milling.

As you delve deeper into these considerations, you’ll gain a better understanding of choosing the right method for your precision needs.

Choosing the Right Method for Your Precision Needs

To achieve the precision you desire in your milling process, it’s important to carefully consider the different methods available and select the one that best meets your needs and requirements.

Here are some key factors to help you make an informed decision:

-

Benefits of laser cutting:

- High precision: Laser cutting offers exceptional accuracy, with minimal material waste and precise cutting paths.

- Versatility: It can handle a wide range of materials, including metals, plastics, and wood.

- Speed: Laser cutting is generally faster than milling, allowing for increased productivity.

- Non-contact process: This minimizes the risk of tool wear or damage, resulting in cleaner cuts.

-

Advantages of milling:

- Greater flexibility: Milling allows for complex shapes and intricate designs.

- Wide range of materials: It can handle various materials, including harder metals.

- Surface finish: Milling can achieve smoother surface finishes, often eliminating the need for additional post-processing.

- Cost-effective: Milling can be more cost-effective for larger production runs.

By understanding the benefits of laser cutting and the advantages of milling, you can choose the method that aligns best with your precision needs and project requirements.

Frequently Asked Questions

Can 3D laser cutting be used on all types of materials?

Yes, 3D laser cutting can be used on a wide range of materials, including delicate materials and those with high heat resistance.

When it comes to delicate materials, such as thin plastics or fabrics, 3D laser cutting offers a precise and clean cut without causing any damage or distortion.

Additionally, for materials with high heat resistance, like metals or ceramics, laser cutting provides an efficient and accurate method, ensuring minimal heat-affected zones and maintaining the material’s integrity.

What are the limitations of precision in milling?

When it comes to precision, milling has its limitations. Factors such as tool wear, machine vibrations, and material properties can affect the accuracy of milling operations.

Tool wear can lead to dimensional inaccuracies, while machine vibrations can cause unwanted movement during the milling process. Additionally, variations in material properties can result in uneven cutting forces and affect the overall precision of milling.

These limitations must be carefully considered when aiming for high levels of precision in milling operations.

Is 3D laser cutting more expensive than milling?

Cost comparison is an essential factor when deciding between 3D laser cutting and milling.

3D laser cutting is generally more expensive than milling due to the high cost of laser cutting machines and the specialized training required to operate them. However, the advantages of 3D laser cutting, such as its ability to produce intricate and precise cuts in various materials with minimal waste, can justify its higher cost.

Ultimately, the decision depends on the specific requirements of the project and the desired level of precision.

How does the speed of 3D laser cutting compare to milling?

When comparing the speed of 3D laser cutting to milling, it’s important to consider both the cutting and processing time. Laser cutting is known for its high cutting speed, as the laser beam moves quickly across the material. On the other hand, milling involves the removal of material through rotational cutting tools, which may take longer.

However, it’s crucial to note that the speed comparison also depends on the specific machine, material, and complexity of the design. Additionally, accuracy comparison is equally important when evaluating the performance of these two methods.

Are there any safety concerns associated with 3D laser cutting or milling?

Oh, safety concerns with 3D laser cutting or milling, how thrilling! Let’s dive into the technical world of these processes.

When it comes to 3D laser cutting, one must be cautious of the high-intensity laser beam, which can cause eye damage if proper safety measures aren’t followed. Additionally, regular maintenance is crucial to ensure the laser is functioning optimally.

As for milling, safety concerns revolve around the rotating cutting tools, which can pose a risk of injury if not handled with care. Maintenance-wise, regular tool inspection and replacement are necessary to maintain precision and avoid accidents.

Conclusion

In conclusion, when it comes to precision, both 3D laser cutting and milling offer impressive results. However, it’s evident that 3D laser cutting takes the cake in terms of accuracy and finesse.

With its advanced technology and ability to create intricate designs, it provides a visual masterpiece that is simply unmatched. While milling certainly has its advantages, it falls slightly short in terms of precision when compared to 3D laser cutting.

Therefore, if precision is your utmost priority, 3D laser cutting is the way to go.