When it comes to precision cutting, you need a method that can slice through materials with the finesse of a surgeon’s scalpel.

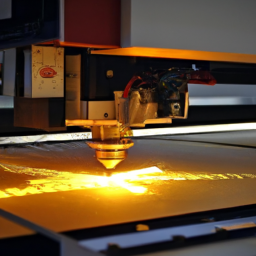

Enter 3D laser cutting and plasma cutting, two techniques that have revolutionized the world of fabrication. These cutting-edge methods offer unparalleled accuracy and speed, making them the go-to choices for engineers, manufacturers, and DIY enthusiasts alike.

But which one should you choose for your project? In this article, we will compare and contrast the key factors that differentiate 3D laser cutting from plasma cutting. From the lightning-fast speed of laser cutting to the raw power of plasma cutting, we will delve into the nuances of each method, exploring their strengths and weaknesses.

By the end, you will have a clear understanding of which method is best suited for your specific needs.

So, let’s dive into the world of precision cutting and discover the perfect technique for your next project.

Key Takeaways

- Laser cutting offers lightning-fast speed and exceptional accuracy, making it ideal for precise and intricate cuts in industries such as aerospace and electronics.

- Plasma cutting is up to 50% cheaper than laser cutting and better suited for thicker materials, but it may result in rougher edges and less precise cuts.

- Both methods require comprehensive operator training and the use of protective gear to ensure safe operation.

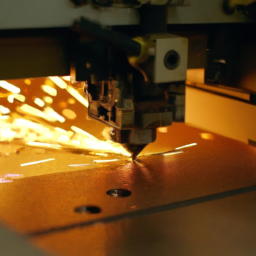

- Laser cutting produces clean, sharp edges and intricate designs with minimal distortion, while plasma cutting may require additional finishing processes and may pose a fire hazard due to the high amount of heat and sparks it produces.

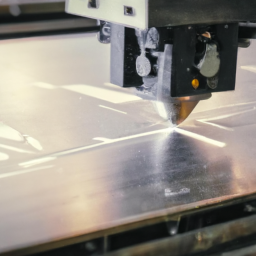

Speed of Cutting

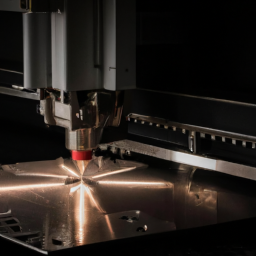

If you’re in a hurry to get your project done, laser cutting is the way to go with its lightning-fast speed. Laser cutting has a significant advantage over plasma cutting when it comes to cutting speed and production efficiency.

The laser beam moves quickly and precisely, allowing for rapid cuts with minimal downtime. This speed is especially beneficial for large-scale production runs where time is of the essence. Laser cutting machines can easily cut through various materials, including metals, plastics, and wood, with remarkable speed and accuracy. This efficiency not only saves time but also increases overall production output.

However, speed is not the only factor to consider when choosing between laser cutting and plasma cutting. The accuracy of cutting is another crucial aspect that needs to be taken into account.

Accuracy of Cutting

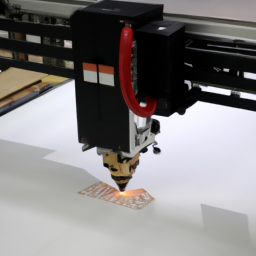

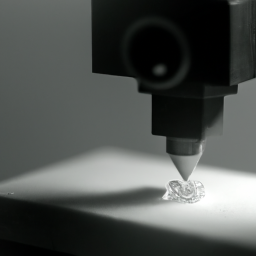

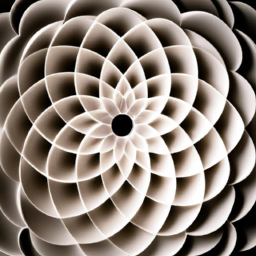

For the most precise and intricate cuts, opt for laser cutting over plasma cutting. Laser cutting is highly regarded for its exceptional accuracy and the ability to achieve tight tolerances in cutting. This precision is crucial, as it directly impacts the quality of the final product.

Laser cutting can produce clean, sharp edges and intricate designs with minimal distortion or heat-affected zones. With the ability to cut through a wide range of materials, including metals, plastics, and wood, laser cutting offers unmatched accuracy and consistency. By ensuring precise cuts, laser cutting minimizes the need for additional finishing processes, saving time and resources.

Moving forward to cost considerations, it’s important to evaluate the financial implications of these cutting methods.

Cost Considerations

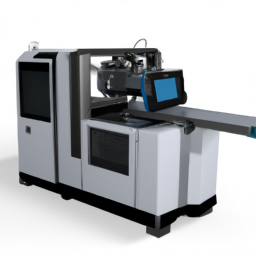

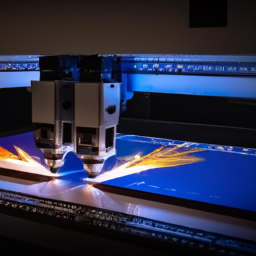

When considering cost, it’s important to note that plasma cutting can be up to 50% cheaper than laser cutting, making it a more budget-friendly option. This cost effectiveness stems from the fact that plasma cutting machines are generally less expensive to purchase and maintain compared to laser cutting machines. Additionally, plasma cutting consumes less electricity and requires fewer consumables, such as gases and nozzles, further reducing costs.

However, it’s worth mentioning that laser cutting offers higher production efficiency due to its faster cutting speed and greater accuracy. This increased efficiency can result in reduced labor costs and higher throughput. Therefore, when deciding between plasma cutting and laser cutting, it’s crucial to consider both the initial cost and long-term production efficiency.

In the subsequent section about applications and materials, we will explore the suitability of each method in different scenarios.

Applications and Materials

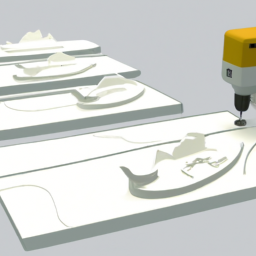

Explore the vast range of applications and materials that can be effectively processed using plasma and laser cutting methods. Both methods offer unique advantages and disadvantages depending on the specific needs of your project.

Laser cutting is ideal for precise and intricate cuts, making it a popular choice for industries such as aerospace and electronics. It offers a high level of accuracy and can cut through a wide range of materials, including metals, plastics, and wood.

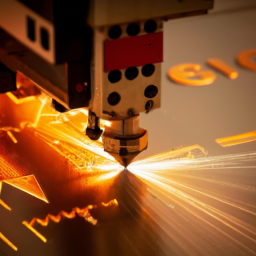

On the other hand, plasma cutting is better suited for thicker materials and can make faster cuts. It is commonly used in industries like construction and automotive. However, plasma cutting may result in a rougher edge compared to laser cutting.

Transitioning into the next section on maintenance and safety, it’s vital to understand how to properly maintain and operate these cutting methods to ensure optimal performance and safety.

Maintenance and Safety

When it comes to maintenance and safety considerations, it’s important to compare the requirements for 3D laser cutting and plasma cutting.

Each method has its own set of maintenance needs, and understanding them is crucial for ensuring smooth operation.

Additionally, taking precautions and following best practices for safe operation is essential to prevent accidents and injury.

Comparison of the maintenance requirements and safety considerations for 3D laser cutting and plasma cutting

Maintenance and safety are key factors to consider when deciding between 3D laser cutting and plasma cutting. In terms of maintenance requirements, laser cutting machines typically require less frequent maintenance compared to plasma cutting machines. Laser cutting machines have fewer consumable parts, which means less time and money spent on replacing parts. Additionally, laser cutting machines have a longer lifespan and are less prone to breakdowns.

When it comes to safety considerations, both methods have their own risks. Plasma cutting produces a high amount of heat and sparks, posing a fire hazard. On the other hand, laser cutting produces hazardous fumes and requires proper ventilation. It is crucial to have safety measures in place such as wearing protective gear, having fire extinguishers nearby, and ensuring proper training for operators.

Transitioning into the next section, it is important to discuss precautions and best practices for ensuring safe operation of each method.

Precautions and best practices for ensuring safe operation of each method

To ensure safe operation of each method, it’s essential to implement proper training protocols and adhere to recommended safety guidelines. For 3D laser cutting, operators should receive comprehensive training on the equipment and laser safety procedures. They should wear appropriate personal protective equipment, such as safety glasses and gloves, to minimize the risk of eye injuries and burns.

Additionally, it’s crucial to prevent material deformation by properly securing the workpiece and using the correct cutting parameters.

For plasma cutting, operators should also receive thorough training and wear protective gear. To minimize the heat affected zone, it’s important to adjust the cutting speed and gas flow rate according to the material being cut.

By following these precautions and best practices, you can ensure a safe operation of both methods.

Now, let’s move on to choosing the right method for your project.

Choosing the Right Method for Your Project

If you really want to get the job done quickly and efficiently, you should definitely consider choosing the right method for your project. When deciding between laser cutting and plasma cutting, there are several factors to consider.

Here are the advantages and disadvantages of each method:

-

Precision: Laser cutting offers high precision and can produce intricate designs with smooth edges. Plasma cutting, on the other hand, may result in rougher edges and less precise cuts.

-

Material compatibility: Laser cutting is suitable for a wide range of materials, including metals, plastics, and wood. Plasma cutting is primarily used for metals.

-

Cost and speed: Laser cutting is generally more expensive but offers faster cutting speeds. Plasma cutting is more cost-effective but may take longer to complete the job.

By carefully considering these factors, you can choose the method that best suits your project’s requirements and achieve optimal results.

Frequently Asked Questions

What is the maximum thickness of material that can be cut using 3D laser cutting?

The maximum thickness of material that can be cut using 3D laser cutting depends on the specific laser system being used. However, laser cutting is known for its precision and ability to cut through various materials with high accuracy.

With advancements in technology, laser cutting can now achieve precise cuts on materials of varying thicknesses. This makes it a versatile option for industries requiring intricate and accurate cuts on a wide range of materials.

Can plasma cutting be used for precision cutting of intricate designs?

Yes, plasma cutting can be used for precision cutting of intricate designs. It offers versatility in plasma cutting applications, allowing for detailed and intricate shapes to be cut with precision. However, when compared to 3D laser cutting, plasma cutting has certain limitations. The advantages of 3D laser cutting include higher precision, cleaner cuts, and the ability to cut a wider range of materials.

Are there any specific safety precautions that need to be taken when operating a 3D laser cutting machine?

When operating a 3D laser cutting machine, it’s crucial to follow specific safety precautions to ensure a safe working environment.

First, wear appropriate personal protective equipment, such as safety glasses and gloves.

Second, ensure proper ventilation in the workspace to prevent the accumulation of fumes and dust.

Third, regularly inspect the machine for any signs of damage or malfunction.

Lastly, be knowledgeable about the types of materials that can be cut using 3D laser cutting, including metals, plastics, and wood.

Can plasma cutting be used for cutting non-metallic materials such as wood or plastic?

Plasma cutting can indeed be used for cutting non-metallic materials such as wood or plastic. However, there are some pros and cons to consider.

On the positive side, plasma cutting offers high cutting speeds, making it a quick and efficient option. Additionally, it is able to cut through thicker materials compared to 3D laser cutting.

However, plasma cutting may result in a rougher cut edge and can generate more heat, potentially damaging the material.

How often does a plasma cutting machine need to be maintained and what are the associated costs?

To ensure optimal performance, a plasma cutting machine needs regular maintenance. The maintenance schedule depends on factors such as usage and manufacturer recommendations. Typically, maintenance should be performed every 50-100 hours of operation.

This includes cleaning the machine, inspecting consumable parts, and checking for any signs of wear or damage. The associated costs of maintenance can vary, but they generally include the cost of replacement parts, cleaning supplies, and any necessary professional services.

Conclusion

In conclusion, when it comes to choosing between 3D laser cutting and plasma cutting, you should consider factors such as speed, accuracy, cost, applications, materials, maintenance, and safety.

Both methods have their advantages and disadvantages, but ultimately, the right choice depends on the specific requirements of your project.

So, weigh these factors carefully and make an informed decision. Remember, like a surgeon delicately wielding a scalpel, choose the method that’ll precisely sculpt your project’s destiny with utmost precision.