Did you know that when it comes to precision cutting, every millimeter matters? In the world of manufacturing and fabrication, accuracy is crucial in achieving the desired results. That’s why it’s important to understand the differences between 3D laser cutting and rotary cutting, and determine which method is more accurate for your specific project.

3D laser cutting utilizes a high-powered laser beam to precisely cut through various materials with intricate designs and shapes. On the other hand, rotary cutting involves the use of a rotating cutting tool to make precise cuts. But which method provides a higher level of accuracy?

In this article, we will explore the intricacies of both 3D laser cutting and rotary cutting, and analyze the key factors that affect their accuracy levels. By comparing their precision levels and considering important factors, you will be able to make an informed decision on which cutting method is best suited for your needs.

So let’s dive in and discover which method will help you achieve the utmost precision in your cutting projects.

Key Takeaways

- Precision cutting is crucial in manufacturing and fabrication, and factors such as cutting tool maintenance and cutting speed affect accuracy.

- 3D laser cutting offers exceptional accuracy and versatility, controlled by computer software for minimal error.

- Laser cutting is suitable for a wide range of materials, including metals and plastics, resulting in precise and clean edges.

- Rotary cutting offers high accuracy and repeatability, ideal for intricate designs and tight tolerances, but is limited to certain materials and slower than laser cutting.

Understanding 3D Laser Cutting

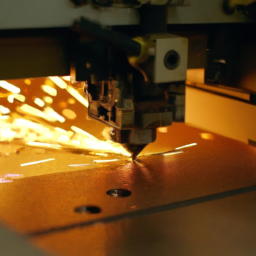

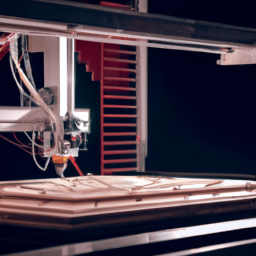

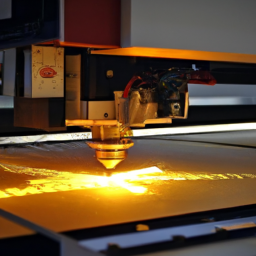

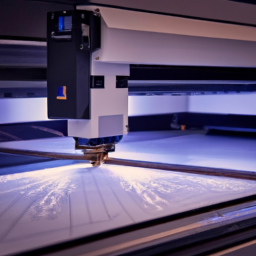

If you’re looking to understand 3D laser cutting, you’re in for an illuminating experience that will reveal the precision and intricacy behind this cutting-edge technology. 3D laser cutting offers numerous advantages over traditional cutting methods.

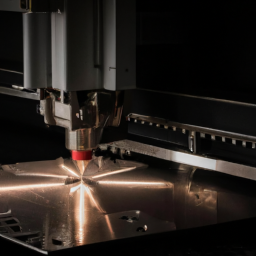

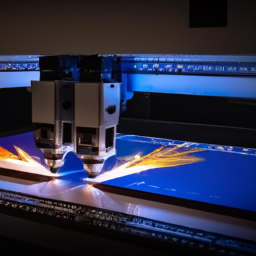

One of the key benefits is its exceptional accuracy. The laser beam is controlled by computer software, allowing for precise and intricate cuts with minimal error. This level of precision is particularly useful in industries where fine details are crucial, such as aerospace and electronics manufacturing.

Additionally, 3D laser cutting has a wide range of applications, including prototyping, signage, and jewelry making. With its ability to cut through various materials, including metals and plastics, 3D laser cutting provides versatility and efficiency.

Now, let’s delve into exploring rotary cutting and its own unique set of advantages.

Exploring Rotary Cutting

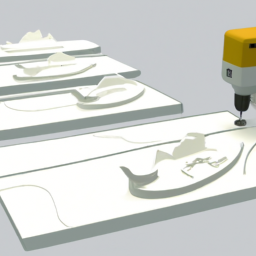

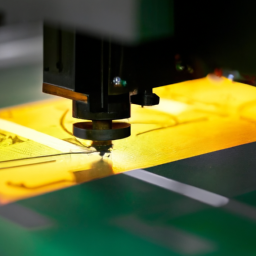

When it comes to precision, rotary cutting offers a distinct advantage over other methods. The rotary cutting process involves a rotating cutting tool that moves along a fixed path to cut the material. This method allows for high accuracy and repeatability, making it ideal for applications that require intricate designs or tight tolerances.

To emphasize the advantages and limitations of rotary cutting, consider the following table:

| Advantages | Limitations |

|---|---|

| High accuracy | Limited to certain materials |

| Repeatability | Slower than laser cutting |

| Suitable for intricate designs | Not ideal for thick materials |

| Cost-effective | Requires careful tool maintenance |

| Wide range of applications | Limited cutting depth |

As you can see, rotary cutting offers several benefits, such as high accuracy and repeatability, making it a preferred choice for many applications. However, it is important to consider the limitations, such as its suitability for certain materials and slower speed compared to laser cutting. These factors affect the overall accuracy of the cutting process.

Transitioning into the subsequent section about factors affecting accuracy, it is crucial to understand how various parameters impact the precision of both laser cutting and rotary cutting methods.

Factors Affecting Accuracy

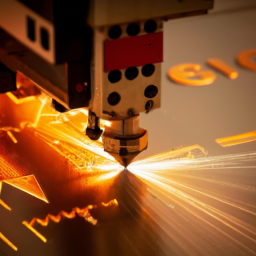

One key factor that significantly impacts the precision of both laser and rotary cutting methods is the careful maintenance of the cutting tools. Proper maintenance ensures that the laser beam remains focused and aligned, and that the rotary cutter is sharp and free from any defects that could affect its accuracy.

Additionally, the cutting speed plays a crucial role in determining the precision of the cuts. Higher cutting speeds can result in a decrease in accuracy, as the laser beam or rotary cutter may not have sufficient time to make precise cuts. On the other hand, slower cutting speeds allow for more precise and controlled cuts. It’s important to find the optimal cutting speed for each specific material and desired level of precision.

Transitioning into the subsequent section about comparing precision levels, it’s essential to consider these factors when assessing the accuracy of laser cutting versus rotary cutting.

Comparing Precision Levels

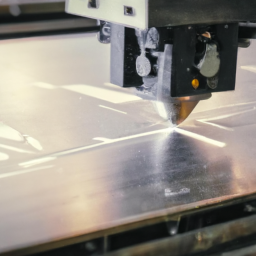

In assessing precision levels, it’s crucial to consider the impact of factors like cutting tool maintenance and cutting speed on the accuracy of laser and rotary cutting methods.

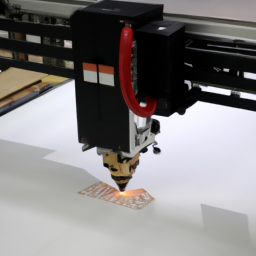

Both methods employ different measurement techniques to achieve accurate cuts. Laser cutting utilizes a focused laser beam to vaporize or melt the material, resulting in precise and clean edges. On the other hand, rotary cutting involves a spinning tool that cuts through the material, which may lead to slight imperfections or jagged edges.

Moreover, material compatibility must be taken into account when comparing precision levels. Laser cutting is suitable for a wide range of materials, including metals, plastics, and fabrics, while rotary cutting may be more limited in its compatibility.

Considering these factors, it becomes essential to evaluate the specific requirements and constraints of the project when choosing the right cutting method.

Considerations for Choosing the Right Method

To choose the right cutting method, you’ll want to consider factors such as material compatibility, precision levels, and project requirements.

When it comes to cost comparison, laser cutting tends to be more expensive upfront due to the high cost of the equipment, while rotary cutting can be more affordable. However, laser cutting offers a higher level of accuracy and can produce intricate designs with smooth edges.

On the other hand, rotary cutting is better suited for thicker materials and can handle a wider range of materials compared to laser cutting. Additionally, laser cutting may cause heat damage to certain materials, while rotary cutting is less likely to have this issue.

Ultimately, the choice between laser cutting and rotary cutting will depend on the specific requirements of your project and the materials you’re working with.

Frequently Asked Questions

What is the cost difference between 3D laser cutting and rotary cutting?

The cost difference between 3D laser cutting and rotary cutting is significant, making it seem like comparing a Lamborghini to a bicycle.

3D laser cutting is a highly precise and accurate method that utilizes laser beams to cut materials with utmost precision. However, it comes with a higher price tag due to the advanced technology involved.

On the other hand, rotary cutting is a more cost-effective option, but its precision falls short in comparison to 3D laser cutting.

Are there any limitations to the size of materials that can be cut using 3D laser cutting?

The precision of 3D laser cutting is remarkable, but there are limitations to the size of materials that can be cut. The cutting process relies on a focused laser beam that vaporizes or melts the material, allowing for intricate and precise cuts. However, the size of the cutting area is restricted by the dimensions of the laser machine.

Therefore, when considering 3D laser cutting, it’s important to assess the size limitations to ensure the desired materials can be accommodated.

Can rotary cutting be used on all types of materials?

Rotary cutting can be used on a wide range of materials, including fabric, paper, and thin metal sheets. Its advantages lie in its simplicity, cost-effectiveness, and ability to quickly cut through thick materials.

However, it may not be suitable for intricate designs or materials that are prone to fraying. Additionally, rotary cutting may require more manual effort and skill to achieve precise cuts compared to other cutting methods.

Is there a difference in the speed of cutting between 3D laser cutting and rotary cutting?

When comparing the speed of cutting between 3D laser cutting and rotary cutting, it’s important to consider the cutting precision and application versatility of each method.

In terms of cutting precision, 3D laser cutting is known for its exceptional accuracy, providing precise and intricate cuts. On the other hand, rotary cutting may not offer the same level of precision.

In terms of application versatility, 3D laser cutting is commonly used in industries such as automotive, aerospace, and electronics, where intricate and precise cuts are required. Rotary cutting, on the other hand, may be more commonly used in industries where speed is prioritized over precision, such as textile or fabric cutting.

Are there any safety concerns associated with either method of cutting?

When it comes to cutting methods, both 3D laser cutting and rotary cutting have their own set of safety concerns. To ensure safe operations, it’s important to take necessary precautions.

This includes regular equipment maintenance to avoid malfunctions and accidents. Additionally, operator training plays a crucial role in minimizing risks. Operators should be well-trained in handling the cutting equipment and following safety protocols.

By adhering to these measures, the risk of accidents can be significantly reduced.

Conclusion

In conclusion, when it comes to accuracy, both 3D laser cutting and rotary cutting have their strengths.

3D laser cutting offers precise and intricate cuts with minimal material waste, making it ideal for complex designs.

On the other hand, rotary cutting provides excellent accuracy for thicker materials and is more cost-effective for larger-scale projects.

Therefore, the choice between the two methods ultimately depends on the specific requirements of your project.

By understanding the factors affecting accuracy and considering the precision levels, you can make an informed decision to achieve the desired results.