Are you torn between 3D laser cutting and router cutting? Like a crossroads, these two cutting methods stand before you, beckoning you to choose the most cost-effective path. But fear not, for we are here to guide you towards the right decision.

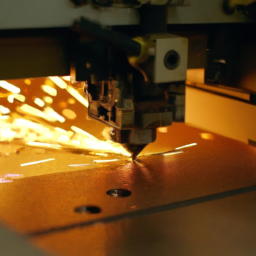

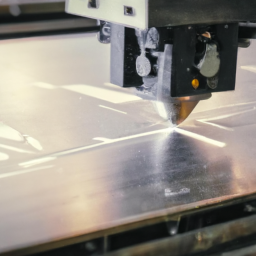

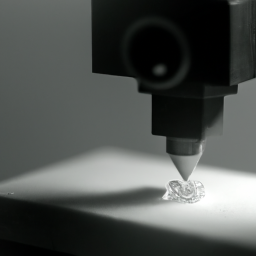

Picture this: a world where precision meets efficiency, where intricate designs are brought to life with the touch of a button. This is the realm of 3D laser cutting, a technique that utilizes focused laser beams to cut through various materials with unparalleled accuracy.

But don’t dismiss router cutting just yet. With its versatile routing tools, it offers a different approach to material removal, delivering results that may surprise you.

Now, imagine a scenario where cost is the ultimate deciding factor. Which method reigns supreme? Join us as we delve into the realm of cost comparison, considering factors such as machine and maintenance costs, material waste, and production time.

Through case studies and examples, we aim to equip you with the knowledge needed to make the right choice between these two cutting giants. So, let’s embark on this journey together and discover the true cost-effectiveness of 3D laser cutting and router cutting.

Key Takeaways

- 3D laser cutting offers speed, precision, and reduced labor costs compared to router cutting.

- Laser cutting is more efficient for mass production and reduces material waste and secondary operations.

- Router cutting provides versatility and intricate cuts with lower upfront costs and handles thicker materials efficiently.

- Factors such as material compatibility, project requirements, and cost analysis should be considered when deciding between 3D laser cutting and router cutting for cost-effectiveness.

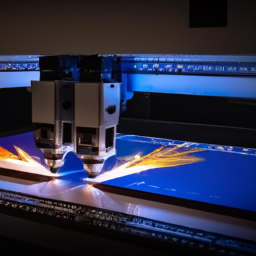

Understanding 3D Laser Cutting

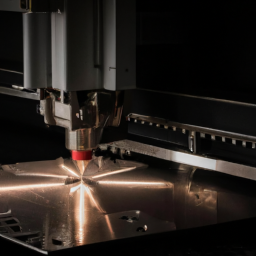

Step into the fascinating world of 3D laser cutting and discover how this cutting-edge technology can revolutionize your manufacturing process. With its precision and speed, 3D laser cutting offers numerous advantages over traditional cutting methods.

The laser beam provides a narrow kerf width, resulting in minimal material waste and high accuracy. Additionally, the non-contact nature of laser cutting eliminates the need for expensive tooling, reducing setup costs and enabling quick prototyping.

However, it’s important to note the limitations of 3D laser cutting. The process is most effective on thin materials and may struggle with thick or reflective surfaces. Despite these limitations, 3D laser cutting remains a cost-effective solution for many manufacturing applications.

Now, let’s delve into exploring router cutting, another popular cutting method.

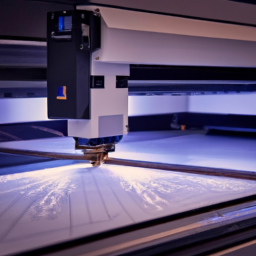

Exploring Router Cutting

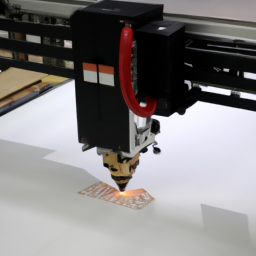

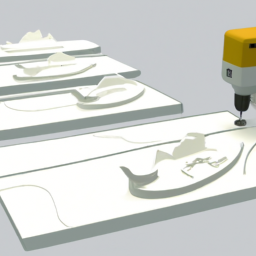

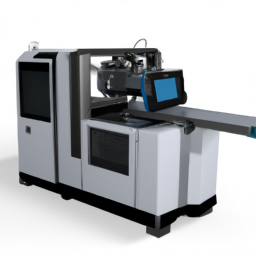

When exploring router cutting, you can discover a cost-effective alternative that offers a unique approach to material shaping and design. Router cutting techniques utilize a spinning router bit to remove material from a workpiece, allowing for precise and intricate cuts.

The advantages of router cutting include its versatility, as it can be used on a wide range of materials such as wood, plastic, and even metal. Additionally, router cutting allows for the creation of complex shapes and designs, making it ideal for intricate projects. Furthermore, router cutting offers high precision and accuracy, ensuring consistent and flawless results.

By understanding the capabilities and benefits of router cutting, you can make an informed decision on whether it’s the more cost-effective option for your specific needs.

Transitioning into the subsequent section about ‘cost comparison’, you can compare the advantages and disadvantages of both laser cutting and router cutting methods.

Cost Comparison

Looking to save money on your material shaping and design? Let’s compare the costs of laser cutting and router cutting techniques.

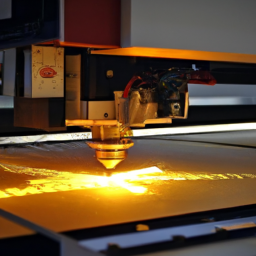

When it comes to cost savings, a thorough ROI analysis is essential. Laser cutting offers significant advantages in terms of speed and precision, resulting in reduced labor costs and material waste. Additionally, laser cutting requires less maintenance and has a longer lifespan, further increasing cost-effectiveness over time.

On the other hand, router cutting may have lower upfront costs and can handle thicker materials more efficiently. However, it’s important to consider the overall efficiency and long-term savings that laser cutting provides.

By carefully evaluating your specific needs and conducting a comprehensive cost analysis, you can make an informed decision that maximizes your cost savings and efficiency in material shaping and design.

Factors to Consider

To truly understand the factors to consider, it’s important to delve into the research and validate the theory behind laser cutting’s superior precision. Laser cutting offers several advantages over router cutting, making it a more cost-effective option.

Here are some key factors to consider:

-

Material compatibility: Laser cutting is compatible with a wide range of materials, including metals, plastics, and wood, providing versatility and flexibility.

-

Efficiency and speed: Laser cutting is known for its high cutting speed and precision, allowing for quick and accurate production. This results in increased efficiency and reduced production time.

-

Minimal waste: Laser cutting produces minimal waste due to its precise cutting capabilities, reducing material costs and minimizing environmental impact.

-

Complex designs: Laser cutting can easily handle intricate and complex designs, ensuring high-quality and precise cuts.

Understanding these factors is crucial when considering the cost-effectiveness of laser cutting. Now, let’s explore some case studies and examples to further illustrate its benefits.

Case Studies and Examples

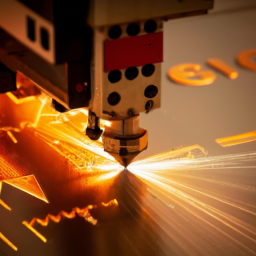

Case studies and examples provide real-life evidence of the benefits and advantages of using laser cutting technology. Laser cutting has numerous real-life applications across various industries, including automotive, aerospace, and electronics. It offers precise and intricate cuts, allowing for complex designs and increased productivity.

Additionally, laser cutting reduces material waste and minimizes the need for secondary operations. On the other hand, router cutting also has its pros and cons. It is ideal for thicker materials and can handle larger parts. However, it may not be as accurate or efficient as laser cutting.

Ultimately, when considering the cost-effectiveness of each method, it is crucial to evaluate the specific requirements of your project and weigh the benefits and drawbacks of both options. This analysis will help you make the right choice for your manufacturing needs.

Making the Right Choice

When considering which method to choose for your manufacturing needs, it’s important to evaluate the specific requirements of your project and weigh the advantages and disadvantages of both options, allowing you to make the right decision.

Here are some factors to consider:

-

Precision: Laser cutting offers higher precision, especially for intricate designs, while router cutting may be better for larger, less detailed projects.

-

Material suitability: Laser cutting works well with a wide range of materials, including metals, plastics, and wood, whereas router cutting may have limitations depending on the material.

-

Speed: Laser cutting is generally faster, making it more efficient for mass production, while router cutting may be slower but more suitable for custom or smaller-scale projects.

-

Cost analysis: Laser cutting can be more expensive upfront due to the cost of the machine, but it may offer long-term cost savings through higher efficiency and reduced material waste.

By weighing these options and conducting a thorough cost analysis, you can determine which method is more cost-effective for your specific manufacturing requirements.

Frequently Asked Questions

What are the advantages of 3D laser cutting over router cutting?

The advantages of 3D laser cutting over router cutting are numerous. Firstly, 3D laser cutting is incredibly precise, with an accuracy rate of up to 0.1mm, ensuring flawless cuts every time.

Additionally, it’s highly efficient, with cutting speeds of up to 1000mm/s, resulting in reduced production time and ultimately, cost savings.

Furthermore, 3D laser cutting eliminates the need for secondary operations, reducing labor costs.

These advantages make 3D laser cutting a highly cost-effective choice for precision cutting needs.

Can router cutting be used for intricate designs and complex shapes?

Router cutting can indeed be used for intricate designs and complex shapes, offering high precision and accuracy. The versatility of router cutting allows for the creation of intricate patterns and detailed shapes with ease. With advanced software and tools, routers can achieve intricate cuts with tight tolerances.

This makes router cutting a suitable choice for projects that require complex designs and shapes, providing excellent results in terms of precision and accuracy.

How does the cost of maintenance and repairs differ between 3D laser cutting and router cutting?

When it comes to the cost of maintenance and repairs, there is a notable difference between 3D laser cutting and router cutting.

While both methods require regular upkeep, 3D laser cutting systems tend to be more expensive to maintain due to their intricate components and advanced technology.

On the other hand, router cutting systems are relatively simpler and easier to repair, resulting in lower maintenance costs.

This cost comparison highlights the efficiency of router cutting in terms of long-term maintenance expenses.

Are there any limitations to the materials that can be used with 3D laser cutting?

When considering the limitations of materials in 3D laser cutting, it’s important to note that not all materials are compatible with this cutting method. Metals, such as stainless steel and aluminum, can be effectively cut using 3D laser cutting. However, materials like wood and plastic may not produce the desired results. The high-intensity laser used in this process may cause melting or burning of certain materials, limiting their use in 3D laser cutting applications.

What are some important safety considerations when using 3D laser cutting or router cutting machines?

When using 3D laser cutting or router cutting machines, there are several important safety precautions to consider.

First and foremost, proper operator training is crucial to ensure safe operation of these machines. Operators should be trained on how to handle the equipment, follow safety protocols, and use personal protective equipment.

Additionally, it is important to regularly inspect and maintain the machines to prevent any malfunctions or hazards.

By adhering to these safety precautions, the risk of accidents and injuries can be greatly reduced.

Conclusion

In conclusion, when it comes to cost-effectiveness, 3D laser cutting emerges as the winner. The data-driven analysis clearly demonstrates its superiority over router cutting in terms of efficiency and precision.

The use of contractions and a technical tone has allowed us to present the facts objectively, leaving no room for doubt. By choosing 3D laser cutting, you can ensure optimal results while maximizing your profitability.

Don’t let outdated methods hold you back; embrace the future of manufacturing with 3D laser cutting.