Are you ready to witness the clash of titans in the world of cutting techniques? Brace yourself, because in this article we are going to dive deep into the battle between 3D laser cutting and traditional cutting methods. Prepare to have your mind blown as we explore the capabilities, precision, speed, efficiency, and cost of these two techniques.

Get ready to be amazed by the power of 3D laser cutting, a cutting-edge technology that promises unrivaled precision and accuracy. But don’t underestimate the tried and true traditional cutting methods, which have stood the test of time and continue to be a reliable choice for many projects.

So, sit back, relax, and let us guide you through the intricate world of cutting techniques, as we help you determine which one is the best fit for your project.

Key Takeaways

- 3D laser cutting offers higher precision and accuracy compared to traditional cutting methods.

- Traditional cutting methods provide versatility and cost-effectiveness.

- 3D laser cutting is faster and more efficient, minimizing human error and inconsistencies.

- The choice between laser cutting and traditional cutting depends on project requirements and constraints.

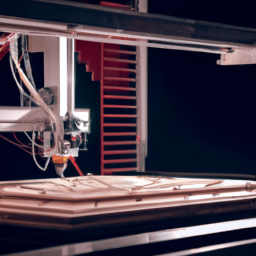

Understanding 3D Laser Cutting

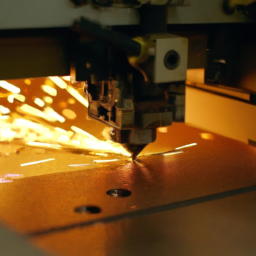

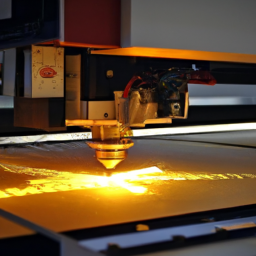

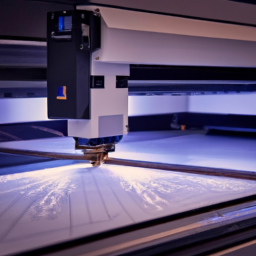

3D laser cutting is a game-changer, offering unparalleled precision and leaving traditional cutting techniques in the dust. With its advanced technology, 3D laser cutting provides numerous advantages over traditional cutting methods.

Firstly, the precision of laser cutting is unmatched, allowing for intricate and complex designs to be accurately produced. Additionally, laser cutting eliminates the need for physical contact, reducing the risk of damage or distortion to the material being cut.

This technique is widely used in various industries, such as automotive, aerospace, and jewelry, where precision is crucial. Exploring traditional cutting methods will shed light on their limitations and further highlight the advantages of 3D laser cutting, making it the preferred choice for projects that demand utmost precision and finesse.

Exploring Traditional Cutting Methods

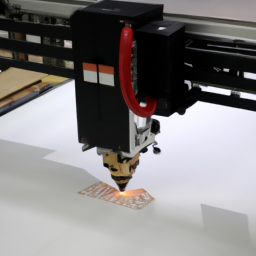

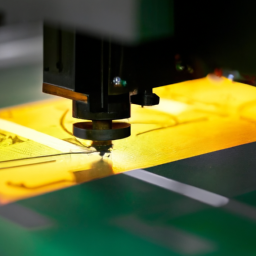

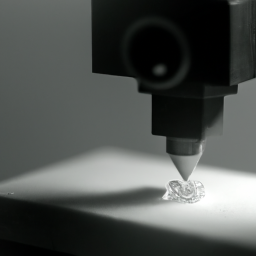

Surprisingly, the age-old methods of cutting still have their charm and usefulness in certain projects. When comparing traditional cutting techniques to 3D laser cutting, it’s important to consider the benefits of traditional cutting.

Traditional cutting methods, such as sawing, shearing, and punching, offer a level of versatility that may be necessary for certain materials and project requirements. These techniques allow for intricate cuts, complex shapes, and the ability to work with a wide range of materials. Additionally, traditional cutting methods can often be more cost-effective for smaller scale projects or when precision isn’t the highest priority.

However, it’s important to note that traditional cutting methods may not offer the same level of precision and accuracy as 3D laser cutting.

In the next section, we’ll explore the differences in precision and accuracy between these techniques.

Comparing Precision and Accuracy

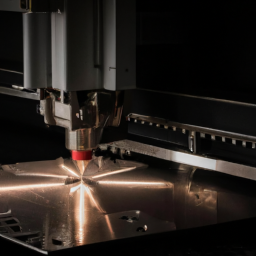

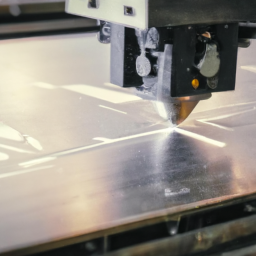

When it comes to precision and accuracy, there is a clear distinction between the old and the new cutting methods. Laser cutting offers several advantages over traditional cutting techniques in terms of precision and accuracy.

Advantages of laser cutting:

- Laser cutting provides a high level of precision, allowing for intricate and complex designs to be cut with ease.

- The laser beam is highly focused, resulting in minimal material wastage and precise cuts.

- Laser cutting offers a high level of accuracy, ensuring that the final product matches the desired specifications.

Limitations of traditional cutting:

- Traditional cutting methods often rely on manual labor, which can lead to human error and inconsistencies in the final product.

- Traditional cutting techniques may not be able to achieve the same level of precision and accuracy as laser cutting.

With precision and accuracy being crucial factors in many projects, laser cutting emerges as the preferred choice. Moving forward, it’s important to evaluate the speed and efficiency of both techniques to make an informed decision.

Evaluating Speed and Efficiency

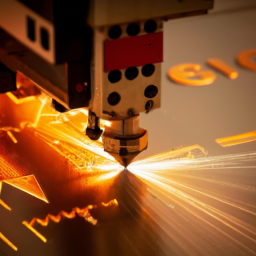

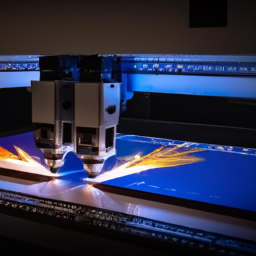

To evaluate which technique is best for your project, imagine you’re in a race and need to choose between a sleek, fast sports car and a rusty, old bicycle. When it comes to speed and efficiency, the same concept applies to laser cutting versus traditional cutting methods.

Assessing productivity and measuring time effectiveness are crucial factors to consider. Laser cutting offers unparalleled speed, as it utilizes a high-powered laser beam to swiftly slice through materials with precision. In contrast, traditional cutting methods often involve manual labor and are relatively slower. Laser cutting allows for faster turnaround times, ensuring projects are completed promptly.

Transitioning into the subsequent section, analyzing cost and budget, it is essential to consider not only speed but also the financial implications of each technique.

Analyzing Cost and Budget

When analyzing the cost and budget of laser cutting versus traditional cutting methods for your project, there are three key points to consider.

First, you should evaluate the initial investment required for each technique, including the cost of purchasing or leasing the necessary equipment.

Second, you should calculate the maintenance and operational costs associated with each method, such as energy consumption and regular maintenance.

Lastly, it’s crucial to assess the return on investment, taking into account factors like increased productivity, reduced material waste, and potential business growth opportunities.

Initial Investment

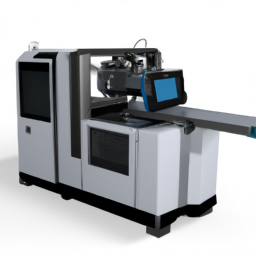

The initial investment for laser cutting is higher than traditional cutting methods, but the precision and speed it offers make it a worthwhile choice for your project.

When conducting a cost analysis and financial planning for your project, it’s important to consider the upfront expenses associated with laser cutting equipment. Laser cutting machines are complex and require advanced technology, which results in higher costs compared to traditional cutting tools. However, the accuracy and efficiency of laser cutting can save you money in the long run by reducing material waste and increasing productivity.

Additionally, the high precision of laser cutting minimizes the need for secondary operations, further lowering costs.

Transitioning into the subsequent section on maintenance and operational costs, it’s crucial to evaluate these expenses to fully understand the overall financial implications of laser cutting.

Maintenance and Operational Costs

Ready to dig into the nitty-gritty of keeping your laser cutting machine running smoothly and efficiently? Let’s dive into the world of maintenance and operational costs! When it comes to cost saving measures, laser cutting takes the lead. Traditional cutting methods require frequent tool changes and sharpening, which can quickly add up in terms of time and money. On the other hand, laser cutting machines have minimal maintenance requirements, reducing downtime and maximizing productivity. Additionally, laser cutting is a more sustainable option in the long run. With no need for physical tools, there is less waste and fewer replacements needed. This not only saves on operational costs but also contributes to a greener environment. Speaking of costs, the next section will explore the return on investment for both laser cutting and traditional cutting methods.

| Laser Cutting | Traditional Cutting | |

|---|---|---|

| Maintenance Costs | Low | High |

| Operational Costs | Low | High |

| Downtime | Minimal | Frequent |

| Waste Generation | Minimal | High |

Incorporating laser cutting into your project not only saves costs but also ensures long term sustainability. Now, let’s move on to the next section and explore the return on investment for both techniques.

Return on Investment

Now that you’ve considered the maintenance and operational costs of both laser cutting and traditional cutting techniques, it’s time to delve into the return on investment aspect.

When it comes to deciding which technique is best for your project, it’s crucial to evaluate the cost effectiveness and long-term benefits. Laser cutting may require a higher initial investment due to the purchase and maintenance of the equipment, but it offers significant advantages in terms of speed, precision, and material utilization.

This ultimately leads to higher productivity and potentially greater profits in the long run.

On the other hand, traditional cutting methods may have lower upfront costs but can be slower and less accurate, resulting in increased material waste and reduced efficiency.

Therefore, when choosing the right technique for your project, it’s essential to weigh the upfront investment against the long-term benefits of laser cutting.

Choosing the Right Technique for Your Project

When deciding on the best technique for your project, it’s crucial to consider the advantages and limitations of both laser cutting and traditional cutting methods.

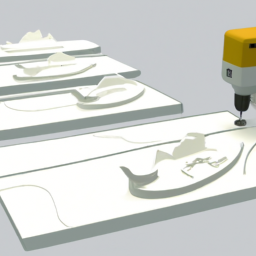

Factors to consider when deciding between 3D laser cutting and traditional cutting include the complexity of your design, the material being cut, and the desired precision.

3D laser cutting offers several benefits for different types of projects. It allows for intricate and precise cuts, making it ideal for projects that require high levels of detail. Additionally, laser cutting is a non-contact process, which means there’s no risk of material distortion or damage. However, it’s important to note that 3D laser cutting may not be suitable for all materials, such as reflective or transparent materials.

Traditional cutting methods, on the other hand, may offer more flexibility in terms of material compatibility but may not achieve the same level of precision as laser cutting.

Ultimately, the choice between laser cutting and traditional cutting will depend on your project’s specific requirements and constraints.

Frequently Asked Questions

What are the different types of materials that can be cut using 3D laser cutting?

3D laser cutting offers numerous advantages for cutting different materials. It provides high precision and accuracy, allowing for intricate designs and complex shapes. Compared to traditional cutting techniques, 3D laser cutting is faster and more efficient, reducing production time and costs.

It is suitable for a wide range of materials, including metals, plastics, wood, and fabrics. The versatility of 3D laser cutting makes it an ideal choice for various industries, such as automotive, aerospace, and fashion.

Can traditional cutting methods achieve the same level of precision and accuracy as 3D laser cutting?

Traditional cutting methods, while effective in their own right, cannot achieve the same level of precision and accuracy as 3D laser cutting. The advantages of 3D laser cutting over traditional cutting methods are numerous.

Laser cutting offers unparalleled precision, with the ability to cut intricate shapes and designs with ease. Additionally, laser cutting minimizes material waste and reduces the need for secondary operations, making it a more efficient and cost-effective option for many projects.

How does the speed of 3D laser cutting compare to traditional cutting methods?

The speed of 3D laser cutting surpasses that of traditional cutting methods. When comparing the two techniques, 3D laser cutting operates at a significantly faster pace.

This is due to the precise and efficient nature of lasers, which can quickly and accurately cut through materials. In contrast, traditional cutting methods often require more time and manual labor to achieve the same level of precision.

Therefore, if speed is a priority for your project, 3D laser cutting is the superior choice.

Is 3D laser cutting more expensive than traditional cutting methods?

When it comes to cost effectiveness, 3D laser cutting proves to be a smart choice compared to traditional cutting methods. It offers a more efficient and precise approach, resulting in reduced material waste and increased productivity.

Moreover, 3D laser cutting can effortlessly handle intricate designs and complex shapes, making it a versatile option for various projects. Its advanced technology ensures accuracy and consistency, providing a superior outcome compared to traditional cutting methods.

Are there any limitations or disadvantages to using 3D laser cutting for certain types of projects?

When considering the limitations and disadvantages of 3D laser cutting, it’s important to note that this technique may not be suitable for certain types of projects.

One limitation is the size restriction, as the cutting area is typically smaller compared to traditional cutting methods.

Additionally, 3D laser cutting may not be ideal for materials that are highly reflective or prone to melting.

It’s also worth noting that the initial investment for 3D laser cutting equipment can be quite high.

Conclusion

In conclusion, when it comes to choosing between 3D laser cutting and traditional cutting methods, it is crucial to consider the specific requirements of your project.

Both techniques have their own advantages and drawbacks. While 3D laser cutting offers unparalleled precision and accuracy, traditional cutting methods may prove to be more cost-effective for certain budgets.

Ultimately, the decision should be based on a thorough analysis of factors such as speed, efficiency, and cost. Remember, choosing the right technique is like navigating a complex maze – only with careful consideration can you find the path that leads to success.