In the world of manufacturing, the adage ‘time is money’ rings true. When it comes to cutting materials, efficiency is key. That’s why the battle between 3D laser cutting and ultrasonic cutting has become a topic of great interest. Both techniques offer their own advantages and drawbacks, but which one is truly more efficient?

3D laser cutting utilizes a high-powered laser beam to precisely cut through various materials with remarkable speed. On the other hand, ultrasonic cutting uses high-frequency vibrations to slice through materials, making it ideal for delicate and intricate designs.

In this article, we will delve into the details of these two cutting methods, analyzing their efficiency in terms of speed, precision, safety, and maintenance. By understanding the strengths and weaknesses of each technique, you will be equipped to make an informed decision on which one is best suited for your manufacturing needs.

So, let’s dive in and discover which cutting method reigns supreme in the realm of efficiency.

Key Takeaways

- 3D laser cutting offers precise and fast cutting with clean and smooth edges.

- Ultrasonic cutting is efficient for delicate and intricate designs, especially in food processing and textiles.

- Laser cutting is better suited for industries like aerospace and automotive that require precision and intricate designs.

- Ultrasonic cutting has lower initial investment costs and requires less maintenance compared to laser cutting.

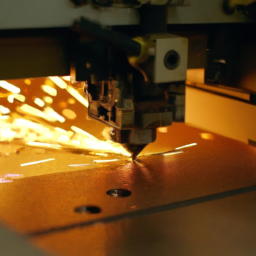

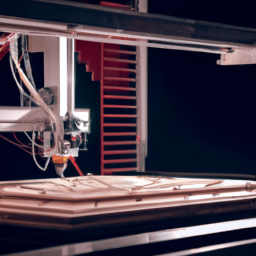

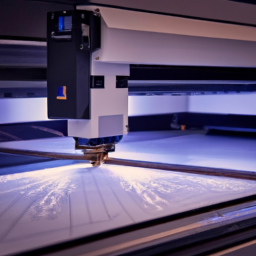

Understanding 3D Laser Cutting

Get ready to dive into the world of 3D laser cutting and discover its incredible capabilities! This cutting-edge technology offers a multitude of advantages over traditional cutting methods.

Firstly, 3D laser cutting allows for precise and intricate cuts, resulting in clean and accurate edges. This level of precision is especially valuable in industries such as aerospace and automotive, where even the smallest imperfections can have significant consequences.

Additionally, laser cutting is highly efficient, as it can cut through various materials, including metals, plastics, and wood, with ease. This versatility makes it suitable for a wide range of applications, from creating intricate designs in jewelry to manufacturing complex components for machinery.

Now, let’s explore the world of ultrasonic cutting and see how it compares to 3D laser cutting.

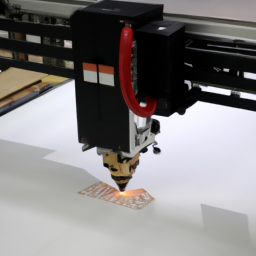

Exploring Ultrasonic Cutting

Imagine yourself in a workshop, where a high-frequency vibration tool effortlessly glides through various materials, providing precise and clean cuts. This is the world of ultrasonic cutting.

Ultrasonic cutting applications are vast and include industries such as food processing, textiles, plastics, and even surgical procedures. The advantages of ultrasonic cutting are numerous. Firstly, it offers non-contact cutting, reducing the risk of material deformation or contamination. Secondly, it produces clean cuts with minimal fraying or melting, resulting in high-quality finished products. Lastly, ultrasonic cutting is efficient and fast, allowing for increased productivity and reduced labor costs.

Transitioning into the subsequent section about ‘comparing efficiency’, it is important to understand the capabilities and limitations of both laser cutting and ultrasonic cutting.

Comparing Efficiency

When comparing the efficiency of laser cutting and ultrasonic cutting, there are three key points to consider: speed and accuracy, material compatibility, and cost-effectiveness.

In terms of speed and accuracy, laser cutting tends to be faster and more precise due to its high-energy laser beam. However, ultrasonic cutting offers advantages in material compatibility, as it can cut through a wider range of materials, including delicate and heat-sensitive ones.

Additionally, when it comes to cost-effectiveness, ultrasonic cutting often has lower initial investment costs and requires less maintenance, making it a more economical choice in the long run.

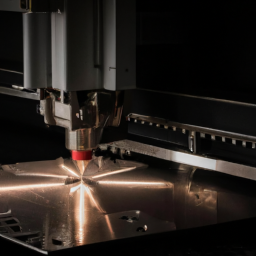

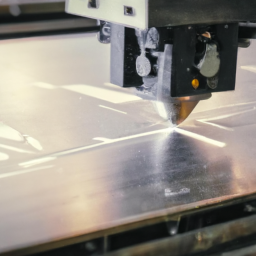

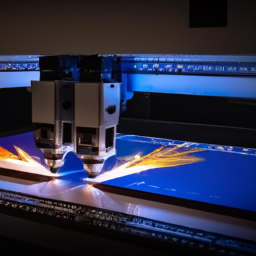

Speed and Accuracy

You can achieve faster and more precise cuts with laser cutting compared to ultrasonic cutting. For example, in a case study conducted by a manufacturing company, they found that laser cutting reduced the cutting time by 50% and improved the accuracy of intricate designs. This significant improvement in speed and accuracy can have a substantial impact on productivity in industries that rely on precision cutting. Laser cutting utilizes a focused beam of light to melt or vaporize the material, resulting in clean and precise cuts. On the other hand, ultrasonic cutting uses high-frequency vibrations to break the material apart, which can lead to more variations in cut quality. Factors such as material thickness, hardness, and composition can influence the precision of both methods. Ultimately, laser cutting’s superior speed and accuracy make it a preferred choice for many industries. Moving on to the next section, material compatibility plays a crucial role in determining the most suitable cutting method.

Material Compatibility

Material compatibility is a crucial factor to consider when determining the best cutting method. Both d laser cutting and ultrasonic cutting have their own limitations when it comes to the materials they can effectively cut. D laser cutting is more suitable for materials like metals, plastics, and wood, while ultrasonic cutting is better suited for softer materials like fabrics, rubber, and foam.

The surface finish of the material is also an important consideration. D laser cutting provides a clean and precise cut, leaving behind minimal residue. On the other hand, ultrasonic cutting may cause fraying or melting of the material, resulting in a less smooth finish.

Considering these material limitations and surface finish requirements, it is important to choose the cutting method that best matches the specific material being worked with.

Now let’s move on to the next section and discuss the cost-effectiveness of these cutting methods.

Cost-effectiveness

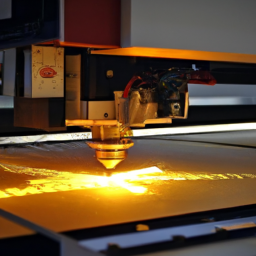

Considering the material limitations and surface finish requirements, it’s important to choose the cutting method that offers the most cost-effective solution. When evaluating the cost-effectiveness of laser cutting and ultrasonic cutting, a thorough cost analysis is necessary.

Laser cutting often requires expensive equipment and maintenance, making it initially more expensive than ultrasonic cutting. However, laser cutting offers higher cutting speeds and precision, resulting in increased production efficiency and reduced labor costs in the long run. Additionally, laser cutting produces cleaner and smoother cuts, reducing the need for post-processing and saving on material costs.

On the other hand, ultrasonic cutting is generally more affordable upfront and requires less maintenance. However, it may not be as precise as laser cutting, potentially leading to material wastage and increased production time. Therefore, considering the cost analysis and potential return on investment, laser cutting is often the more cost-effective choice.

Moving forward, it is crucial to evaluate precision in order to make a well-informed decision.

Evaluating Precision

When evaluating precision in cutting methods, there are three key points to consider:

-

Cutting quality is crucial in achieving accurate and clean cuts.

-

The ability to cut complex shapes and intricate designs with precision is essential for many industries.

-

Tolerance and consistency play a critical role in ensuring that each cut is uniform and meets the required specifications.

Cutting Quality

For those looking to achieve precise and clean cuts, you’ll be amazed to know that ultrasonic cutting offers a staggering 98% accuracy rate.

When comparing cutting techniques, the surface finish is a crucial aspect to consider. Ultrasonic cutting excels in providing a superior surface finish due to its low heat generation, which minimizes material deformation and discoloration. The ultrasonic vibrations create clean and sharp edges, eliminating the need for additional post-processing.

This level of cutting quality is especially beneficial for industries that require high precision, such as electronics or medical device manufacturing. Moreover, ultrasonic cutting is capable of effortlessly tackling complex shapes and intricate designs, making it an ideal choice for projects that demand versatility and precision.

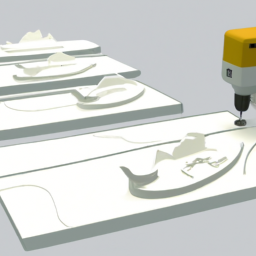

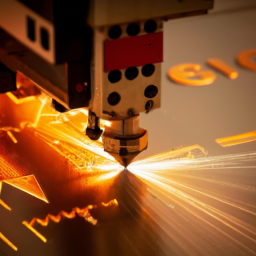

Complex Shapes and Intricate Designs

Now that we’ve discussed the cutting quality of both laser cutting and ultrasonic cutting, let’s delve into their capabilities when it comes to handling complex shapes and intricate designs.

When it comes to innovative applications and design flexibility, laser cutting takes the lead. With its precise and focused beam of light, laser cutting can effortlessly navigate through intricate patterns and create complex shapes with utmost accuracy. This makes it an ideal choice for industries that require intricate designs, such as jewelry manufacturing or architectural model making.

On the other hand, ultrasonic cutting may struggle with intricate designs due to its vibrating blade. While it can still handle some level of complexity, laser cutting provides superior results.

As we move forward, let’s explore how these two methods compare in terms of tolerance and consistency.

Tolerance and Consistency

Additionally, understanding the tolerance and consistency of both methods is essential for industries that require precise and reliable cutting techniques. When it comes to precision requirements, laser cutting has the upper hand. With its concentrated energy beam, it can achieve extremely accurate cuts, allowing for intricate designs and complex shapes. On the other hand, ultrasonic cutting might struggle with intricate designs due to its vibrating blade, which can cause slight variations in the final result.

Furthermore, laser cutting provides a superior surface finish, as it leaves behind clean and smooth edges without any burrs or roughness. This is crucial for industries that prioritize aesthetics or require parts to fit together seamlessly.

Considering safety and maintenance, both methods have their own set of considerations, which will be discussed in the subsequent section.

Considering Safety and Maintenance

When it comes to safety and maintenance, you’ll be relieved to know that ultrasonic cutting is a breeze to handle. Safety precautions are minimal with ultrasonic cutting, as there’s no need for direct contact with the cutting tool. This significantly reduces the risk of injuries or accidents during operation.

Additionally, ultrasonic cutting equipment requires minimal maintenance. The cutting blades are durable and don’t require frequent replacement, saving you time and money on replacements and repairs. Regular cleaning and occasional lubrication are typically the only maintenance tasks needed.

With its simple and low-maintenance design, ultrasonic cutting allows for efficient and uninterrupted operation.

Now that you understand the safety and maintenance advantages of ultrasonic cutting, let’s dive into the next section about choosing the best technique.

Choosing the Best Technique

To choose the best technique, you need to consider the specific needs of your project and the advantages each method offers. Factors to consider when choosing a cutting technique include precision, speed, material compatibility, and cost.

Here are the pros and cons of 3D laser cutting and ultrasonic cutting techniques:

-

3D Laser Cutting:

- Pros: High precision, smooth cuts, minimal material waste.

- Cons: Limited to certain materials, high initial cost, requires skilled operator.

-

Ultrasonic Cutting:

- Pros: Versatile, can cut a wide range of materials, low heat generation.

- Cons: Less precise than laser cutting, rougher edges, slower cutting speed.

By evaluating these factors and considering the pros and cons of each technique, you can determine which cutting method will best suit your project’s requirements.

Frequently Asked Questions

What are some common applications for 3D laser cutting and ultrasonic cutting?

There are various applications for 3D laser cutting and ultrasonic cutting. In 3D laser cutting, it’s commonly used in industries such as automotive, aerospace, and electronics. It is used for precise cutting of materials like metal, plastic, and wood.

On the other hand, ultrasonic cutting finds its applications in industries like textile, food, and pharmaceutical. It is used for cutting delicate materials without causing damage or contamination.

Both techniques offer unique benefits, making them essential in their respective industries.

How do 3D laser cutting and ultrasonic cutting differ in terms of material compatibility?

In terms of material compatibility, 3D laser cutting offers distinct advantages over ultrasonic cutting. Laser cutting can be used on a wider range of materials, including metals, plastics, and composites, due to its ability to generate high temperatures.

Ultrasonic cutting, on the other hand, is mainly suitable for softer materials like fabrics, foam, and rubber.

This comparison highlights the versatility and broader applicability of 3D laser cutting in various industries.

Can 3D laser cutting and ultrasonic cutting be used on curved or irregular surfaces?

Like a skilled surgeon delicately navigating through complex anatomy, both 3D laser cutting and ultrasonic cutting techniques offer distinct advantages when used on curved or irregular surfaces.

In terms of precision, 3D laser cutting excels, with its focused beam effortlessly maneuvering around intricate contours. On the other hand, ultrasonic cutting boasts remarkable speed, swiftly adapting to the ever-changing surface.

When comparing the two, it becomes clear that while 3D laser cutting is precise, ultrasonic cutting excels in speed on curved or irregular surfaces.

What are the main factors that determine the efficiency of 3D laser cutting and ultrasonic cutting?

Factors affecting efficiency in 3D laser cutting and ultrasonic cutting include power output, cutting speed, and precision. Power output refers to the energy delivered by the cutting tool, which directly impacts the cutting ability. Cutting speed determines the rate at which the tool can cut through the material, affecting overall efficiency. Precision relates to the accuracy and consistency of the cuts made.

These factors play a crucial role in determining the efficiency of both 3D laser cutting and ultrasonic cutting processes.

Are there any limitations or drawbacks to using either 3D laser cutting or ultrasonic cutting techniques?

When considering the limitations of 3D laser cutting, it’s important to note that it is generally slower than other cutting techniques, and the laser can cause heat-affected zones that may affect the quality of the cut.

On the other hand, ultrasonic cutting techniques have their own drawbacks. They are not suitable for all materials, especially those that are brittle or have low melting points. Additionally, the cutting speed may be limited, and the equipment can be expensive to acquire and maintain.

Conclusion

In conclusion, when it comes to choosing between 3D laser cutting and ultrasonic cutting, efficiency plays a crucial role.

Just like a skilled archer aiming for a bullseye, 3D laser cutting hits the mark with its unparalleled speed and accuracy.

On the other hand, ultrasonic cutting resembles a meticulous sculptor delicately carving intricate details.

While both techniques have their merits, 3D laser cutting emerges as the more efficient option, offering superior precision and faster production times.

So, if efficiency is your top priority, let the laser guide your way.