Are you in need of precision cutting technology, but unsure which method is best suited for your needs?

Like a surgeon with a scalpel, 3D laser cutting and waterjet cutting offer distinct advantages in their own right.

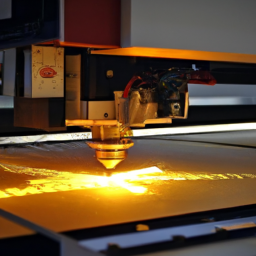

3D laser cutting is akin to a meticulous painter, using a highly focused beam of light to slice through materials with utmost precision.

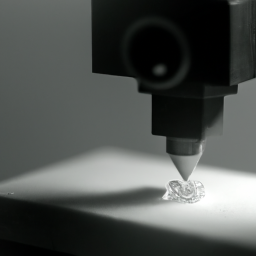

On the other hand, waterjet cutting is like a powerful torrent, using a high-pressure stream of water mixed with abrasive particles to effortlessly cut through various materials.

Both methods have their merits, and understanding their differences is crucial in determining which is right for you.

In this article, we will delve into the intricacies of 3D laser cutting and waterjet cutting, exploring their advantages and factors to consider when choosing between the two.

So, let us embark on this journey of precision cutting technology, and discover which method will best suit your needs.

Key Takeaways

- 3D laser cutting is ideal for intricate parts with tight tolerances, offering exceptional precision and speed.

- Waterjet cutting is versatile and can cut various materials, making it suitable for large projects with complex designs and thicker materials.

- Laser cutting is more cost-effective for simple designs and thinner materials, while waterjet cutting is generally more cost-effective for complex designs.

- The choice between laser cutting and waterjet cutting depends on factors such as material type and thickness, complexity of the design, and budget considerations.

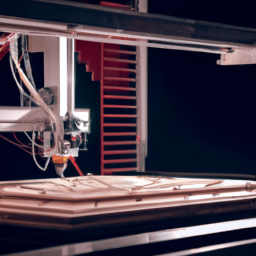

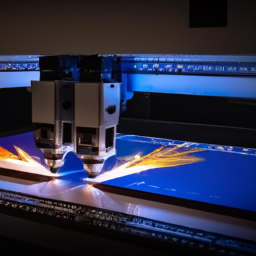

What is 3D Laser Cutting?

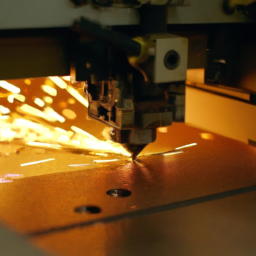

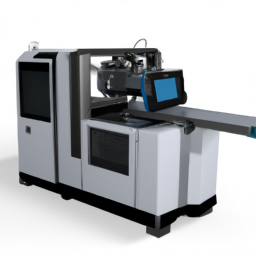

3D Laser Cutting is a highly precise and efficient method of cutting materials using a laser beam. It is widely used in various applications, including automotive, aerospace, electronics, and medical industries.

The laser beam is directed onto the material, melting or vaporizing it with extreme precision. This process allows for intricate and complex cutting patterns that are difficult to achieve with other methods. The laser beam can cut through a wide range of materials, including metals, plastics, wood, and even diamonds.

The precision cutting capabilities of 3D Laser Cutting make it ideal for creating intricate parts with tight tolerances. It offers a level of accuracy and consistency that is unmatched by other cutting methods.

Moving on to the advantages of 3D Laser Cutting…

Advantages of 3D Laser Cutting

When it comes to choosing the right method, you’ll be impressed by the advantages of 3D laser cutting. This method offers exceptional precision and accuracy, ensuring that your cuts are clean and precise every time.

With its advanced technology, 3D laser cutting allows for intricate and complex designs to be executed with ease. Not only does it deliver high-quality results, but it also operates at a remarkable speed and efficiency. This means that you can complete your projects in a shorter amount of time, increasing productivity and reducing production costs.

Additionally, 3D laser cutting is a non-contact process, minimizing the risk of material damage or distortion.

Transitioning into the subsequent section about ‘what is waterjet cutting?’, you’ll discover another method that offers its own unique benefits.

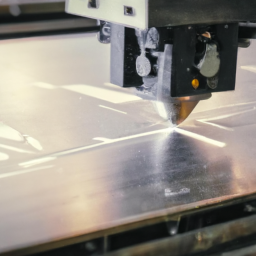

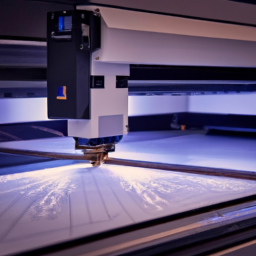

What is Waterjet Cutting?

Explore the incredible precision and versatility of waterjet cutting, a method that will leave you amazed at the endless possibilities it offers.

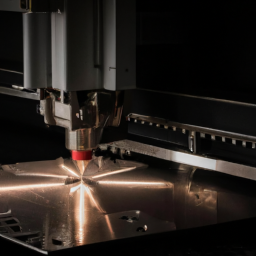

Waterjet cutting is a highly effective technique used to cut various materials, including metals, composites, stone, glass, and plastics. It works by using a high-pressure jet of water mixed with an abrasive substance, such as garnet, to erode the material and create clean, precise cuts.

The waterjet cutting process involves the use of computer-controlled machines that propel the waterjet at extremely high speeds, allowing for intricate and detailed cuts. This method is ideal for a wide range of applications, including aerospace, automotive, architecture, and manufacturing.

Now, let’s delve into the advantages of waterjet cutting, which further highlight its superiority over other cutting methods.

Advantages of Waterjet Cutting

Waterjet cutting offers several advantages for your cutting needs. First, it provides versatility and material compatibility, allowing you to cut a wide range of materials, including metals, plastics, and composites.

Second, waterjet cutting doesn’t create a heat-affected zone, ensuring that the material remains unaffected by heat and maintains its structural integrity.

Lastly, waterjet cutting is environmentally friendly, as it uses water and abrasive materials, eliminating the need for hazardous chemicals or fumes.

Versatility and Material Compatibility

If you’re looking for a cutting method that offers versatility and is compatible with a wide range of materials, laser cutting might be the perfect choice for you. Laser cutting exhibits exceptional versatility in industrial applications, making it suitable for various industries such as automotive, aerospace, and electronics. It can cut through materials like metals, plastics, wood, and even fabrics with precision and accuracy.

Laser cutting is also ideal for delicate materials, as it allows for intricate and detailed cuts without causing any damage or distortion. Additionally, laser cutting produces a narrow heat-affected zone, minimizing the risk of thermal damage to the surrounding material. This feature ensures that laser cutting is highly efficient and effective, making it a preferred choice for many applications.

Transitioning into the subsequent section, laser cutting’s minimal heat-affected zone also contributes to its superiority over waterjet cutting.

No Heat-Affected Zone

Imagine the satisfaction you’ll feel when you realize there’s absolutely no heat-affected zone to worry about when using laser cutting. This is because laser cutting operates by utilizing a focused beam of light to precisely cut through materials.

Unlike other cutting methods, such as waterjet cutting, laser cutting doesn’t generate excessive heat that can potentially warp or damage the surrounding material. This lack of heat-affected zone ensures that the precision cutting remains intact, allowing for intricate designs and complex shapes to be achieved with utmost accuracy.

Additionally, laser cutting provides a clean and smooth edge finish, eliminating the need for further processing or finishing. Not only does this save time and effort, but it also reduces material waste.

Transitioning into the subsequent section about being environmentally friendly, laser cutting proves to be an ideal choice for those seeking a sustainable and efficient cutting method.

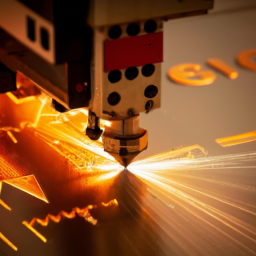

Environmentally Friendly

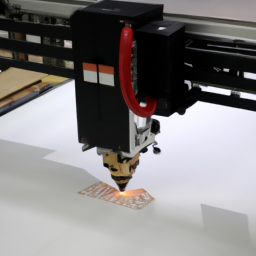

When it comes to being environmentally friendly, you’ll love how laser cutting minimizes waste and reduces the need for additional processing or finishing.

Laser cutting is a sustainable and eco-friendly process that uses a high-powered laser beam to cut through materials with precision and accuracy. The laser beam vaporizes or melts the material, leaving behind a narrow cut with minimal kerf width. This means that there is less material wasted compared to other cutting methods.

Additionally, laser cutting does not require any additional chemicals or substances, making it a clean and green option for your cutting needs.

Now that you understand the environmental benefits of laser cutting, let’s delve into the factors to consider when choosing between 3D laser cutting and waterjet cutting.

Factors to Consider When Choosing Between 3D Laser Cutting and Waterjet Cutting

When choosing between 3D laser cutting and waterjet cutting, there are three key factors to consider.

First, you need to assess the material type and thickness of your project. Different cutting methods have different limitations and capabilities when it comes to various materials.

Second, you should evaluate the complexity and design requirements of your project. Certain cutting methods may be better suited for intricate designs or complex shapes.

Finally, you must consider the cost and budget of your project. Each cutting method has its own associated expenses, so it’s important to weigh the financial aspect alongside the other considerations.

Material Type and Thickness

For your specific material type and thickness, you’ll find that laser cutting excels with its precision. It can cut through materials as thin as a strand of hair. Laser cutting is highly compatible with a wide range of materials, including metals, plastics, wood, and fabrics.

The cutting precision of laser technology allows for intricate designs and complex shapes to be achieved with utmost accuracy. Additionally, laser cutting is capable of handling both thick and thin materials, making it a versatile option for various projects. However, it’s important to note that laser cutting may not be suitable for certain materials that are highly reflective or contain chlorine.

Moving forward, it’s essential to consider the complexity of your project and the specific design requirements.

Project Complexity and Design Requirements

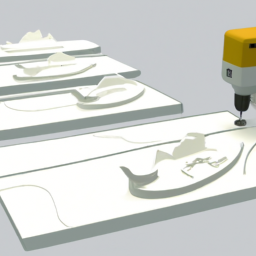

Consider the complexity of your project and your specific design requirements to determine the most suitable method. When it comes to project size, both laser cutting and waterjet cutting can handle a wide range of dimensions. However, if you have a particularly large project, waterjet cutting may be more suitable due to its ability to accommodate larger materials.

On the other hand, if your project involves intricate designs, laser cutting might be the better choice. Laser cutting offers high precision and intricate detail, making it ideal for projects that require fine workmanship.

Now that you’ve considered the complexity of your project and your design requirements, it’s time to move on to the next section and explore the cost and budget aspects.

Cost and Budget

Now let’s delve into the cost and budget implications of your project.

When it comes to choosing between laser cutting and waterjet cutting, it’s essential to consider the cost-effectiveness of each option.

Laser cutting is generally more cost-effective for projects with simple designs and thinner materials. The process is faster and requires less setup time, resulting in reduced labor costs.

On the other hand, waterjet cutting is ideal for complex designs and thicker materials. While it may have a higher initial cost due to the need for specialized equipment, it offers greater versatility and precision.

To maximize budget efficiency, it’s crucial to evaluate the complexity of your project and the specific design requirements. This will help you determine whether laser cutting or waterjet cutting is the most cost-effective solution for your needs.

Frequently Asked Questions

Can 3D laser cutting be used on all types of materials?

3D laser cutting offers several advantages when it comes to cutting different materials. It can be used on a wide range of materials, including metals, plastics, wood, and ceramics. The precision and accuracy of the laser cutting process allow for intricate designs and fine details. Additionally, 3D laser cutting is faster and more efficient compared to other cutting methods. This makes it suitable for various applications in industries such as automotive, aerospace, and electronics.

What are the maintenance requirements for a 3D laser cutting machine?

To keep your 3D laser cutting machine running smoothly, regular maintenance is essential.

Maintenance requirements include cleaning the machine regularly to remove dust and debris that can affect its performance.

Additionally, lubricating moving parts, such as the rails and bearings, is crucial to prevent friction and ensure accurate cuts.

Troubleshooting tips may involve checking the laser alignment, inspecting the optics for any damage, and calibrating the machine regularly to maintain precision.

How does waterjet cutting compare to other cutting methods in terms of precision?

When comparing waterjet cutting to other cutting methods, such as laser cutting, it is important to consider precision. Waterjet cutting, with its high-pressure stream of water and abrasive material, offers exceptional accuracy.

In fact, waterjet cutting is known for its ability to achieve intricate cuts with tight tolerances. When it comes to precision, waterjet cutting can often surpass laser cutting and other methods, making it a preferred choice for projects that require meticulous and accurate results.

Are there any safety concerns when using waterjet cutting?

When it comes to waterjet cutting safety, it’s important to take certain precautions. First, ensure that operators receive proper training to operate the equipment safely. They should wear appropriate personal protective equipment, including gloves and safety glasses.

It’s crucial to follow all manufacturer guidelines and instructions, including proper maintenance and inspection of the waterjet cutting system. Additionally, it’s important to have proper safety measures in place, such as emergency stop buttons and barriers to prevent access to the cutting area.

Can waterjet cutting be used on highly reflective materials?

Waterjet cutting has limitations when it comes to highly reflective materials. The powerful stream of water can cause the light to reflect and scatter, making it difficult to achieve precise cuts. On the other hand, laser cutting offers distinct advantages for these materials. Its concentrated beam of light can easily cut through reflective surfaces with precision and accuracy.

So, if you’re working with highly reflective materials, laser cutting is the way to go.

Conclusion

In conclusion, when it comes to choosing between 3D laser cutting and waterjet cutting, you must carefully consider your specific needs and requirements.

Both techniques offer distinct advantages and it is crucial to weigh them against each other.

Just like a skilled artist selects the perfect brush for their masterpiece, you too must select the right cutting method to bring your vision to life.

Remember, precision and efficiency are the keys to unlocking the doors of success in the world of cutting technologies.