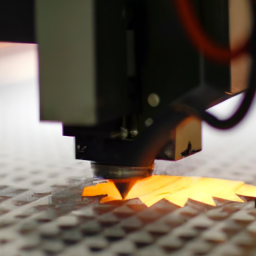

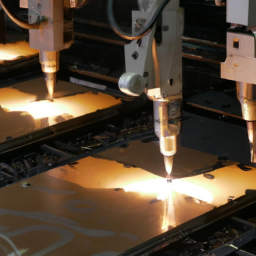

So, you think you’ve mastered the art of using your Nd:YAG laser cutter? Think again. Prepare to be amazed as we delve into the world of advanced techniques that will take your laser cutting skills to the next level.

In this article, we will explore five cutting-edge methods that will unlock the full potential of your laser cutter.

Imagine etching and engraving with unparalleled precision, creating intricate designs that will leave your peers in awe. With variable beam control, you can achieve levels of detail and complexity that were once unimaginable.

But why stop there? Expand your materials palette with multi-wavelength capabilities, allowing you to work with a wider range of materials and explore new possibilities.

Precision is the name of the game, and advanced beam delivery systems will enhance your ability to achieve it. And let’s not forget about pulse duration control, where the power of the laser is harnessed to achieve the perfect balance between speed and accuracy.

Finally, we’ll dive into the exciting world of 3D laser cutting techniques, where you can bring your designs to life in three dimensions. So buckle up and get ready to elevate your laser cutting game to new heights.

Key Takeaways

- Variable beam control allows for precise etching and engraving, resulting in intricate designs.

- Multi-wavelength capabilities expand the materials palette and enable the creation of more complex designs.

- Advanced beam delivery systems enhance precision in laser cutting.

- Pulse duration control improves accuracy, efficiency, and edge quality in laser cutting.

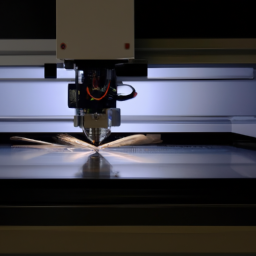

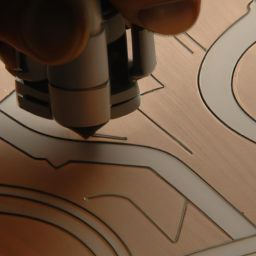

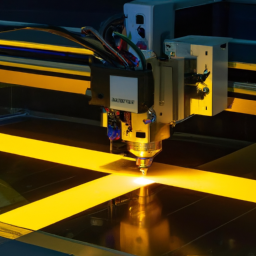

Mastering the Art of Etching and Engraving

To truly excel in the art of etching and engraving, you must familiarize yourself with the intricate techniques that can be achieved through the use of your nd:YAG laser cutter.

Improving speed and efficiency in etching and engraving is crucial to mastering this craft. One way to achieve this is by optimizing the laser power settings and adjusting the scanning speed to match the desired depth and detail.

Troubleshooting common etching and engraving issues is also essential. For example, if you notice inconsistent depth or burning, you may need to clean the focusing lens or adjust the focal length.

Additionally, ensuring proper ventilation and maintaining a clean work surface can help prevent residue buildup that may affect the quality of your etchings and engravings.

By mastering these techniques, you can achieve precise and flawless results, setting the stage for the subsequent section about achieving intricate designs with variable beam control.

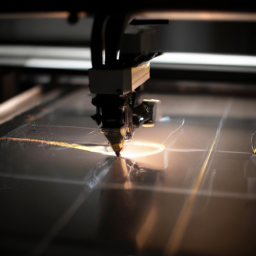

Achieving Intricate Designs with Variable Beam Control

Master the art of harnessing the full potential of your laser cutter by skillfully manipulating the beam to create intricate designs that dance like poetry on your materials. Achieving intricate designs requires mastering beam shaping techniques and optimizing cutting speed. By controlling the shape and intensity of the laser beam, you can achieve precise and detailed cuts that bring your designs to life.

Here is a visual representation of ideas to help you understand beam shaping techniques:

| Beam Shaping Techniques | Benefits | Examples |

|---|---|---|

| Focusing | Increases cutting precision | Creating intricate patterns |

| Defocusing | Enhances engraving depth | Achieving gradient effects |

| Beam modulation | Controls beam intensity | Creating 3D effects |

By skillfully using these techniques, you can take your laser cutting to the next level, creating stunning designs that stand out from the crowd.

In the next section, we will explore how expanding your materials palette with multi-wavelength capabilities can further unleash the potential of your laser cutter.

Expanding Your Materials Palette with Multi-Wavelength Capabilities

Once you’ve got the hang of manipulating the laser beam, it’s time to explore the exciting possibilities of expanding your materials palette with multi-wavelength capabilities. This advanced technique allows you to work with a wider range of materials and achieve even more intricate designs.

Here are some ways you can take advantage of the multi-wavelength capabilities of your nd:yag laser cutter:

-

Selecting the right focal length for optimal results: By adjusting the focal length of the laser beam, you can achieve different levels of precision and depth in your cuts. This is particularly useful when working with materials of varying thicknesses.

-

Utilizing beam expansion for large scale projects: When working on larger projects, beam expansion can help you cover a larger area in a shorter amount of time. This technique allows for faster production and greater efficiency.

-

Enhancing precision with advanced beam delivery systems: By incorporating advanced beam delivery systems, you can further enhance the precision and accuracy of your cuts. These systems ensure that the laser beam remains stable and consistent throughout the cutting process.

With these advanced techniques, you can push the boundaries of what is possible with your nd:yag laser cutter and achieve even more precise and intricate designs.

Enhancing Precision with Advanced Beam Delivery Systems

When you incorporate cutting-edge beam delivery systems, you can take your precision game to the next level with your laser cutter.

Advanced focus techniques and optimizing beam quality are essential for achieving the highest level of precision in laser cutting. By using advanced focus techniques, such as dynamic focus control, you can ensure that the laser beam is focused precisely on the material, resulting in clean and accurate cuts.

Additionally, optimizing beam quality through techniques like beam shaping and beam profiling can further enhance the precision of your laser cutting process. These advanced techniques allow you to control the shape and intensity of the laser beam, ensuring that it is perfectly suited for the material you are working with.

By harnessing the power of pulse duration control, you can further refine your laser cutting process and achieve even greater precision in your cuts.

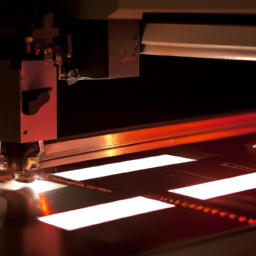

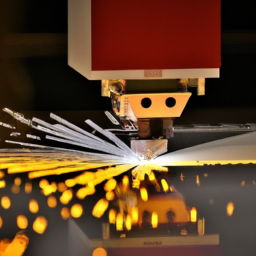

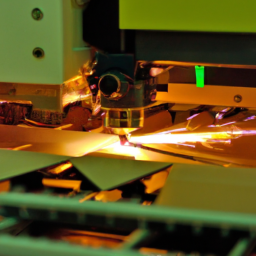

Harnessing the Power of Pulse Duration Control

To truly unlock the full potential of pulse duration control, you’ll be amazed at how it revolutionizes the precision of your laser cutting process. By optimizing cutting speeds and understanding the effects of pulse duration on different materials, you can achieve unparalleled accuracy and efficiency.

Here are some key points to consider:

- Shorter pulse durations result in reduced heat-affected zones, minimizing material distortion and improving edge quality.

- Longer pulse durations are ideal for cutting thicker materials, as they provide more energy for deeper penetration.

- Adjusting the pulse duration can help control the amount of material vaporization, preventing excessive heat buildup.

Pulse duration control allows for precise control over the laser beam, enabling intricate and detailed cuts. Experimenting with different pulse durations can help determine the optimal settings for specific materials and applications.

By harnessing the power of pulse duration control, you can take your laser cutting capabilities to new heights.

Now, let’s explore 3D laser cutting techniques.

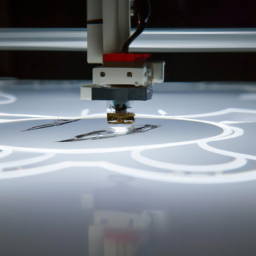

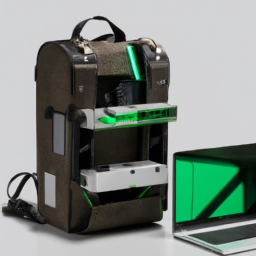

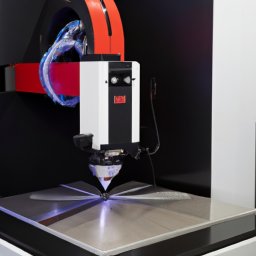

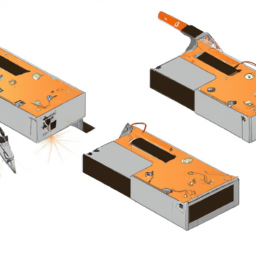

Exploring 3D Laser Cutting Techniques

Get ready to explore a whole new dimension of laser cutting with 3D techniques – you’ll be amazed at the possibilities!

With the advent of advanced laser etching applications, your nd:YAG laser cutter can now create intricate three-dimensional shapes and designs. The key to unlocking this capability lies in utilizing specialized 3D laser cutting software.

This software allows you to import 3D models or designs and convert them into a format that your laser cutter can understand. By utilizing this software, you can easily manipulate and adjust the depth and complexity of your cuts, enabling you to create stunning and intricate 3D designs.

Whether you’re working with wood, acrylic, or other materials, these advanced techniques will take your laser cutting projects to the next level.

So, dive into the world of 3D laser cutting and unleash your creativity today!

Frequently Asked Questions

How do I properly clean and maintain my Nd:YAG laser cutter?

To properly clean and maintain your Nd:YAG laser cutter, follow these proper cleaning techniques and maintenance tips.

Begin by regularly cleaning the laser lens using a lint-free cloth and isopropyl alcohol.

Ensure that the laser bed is clean and free from debris.

Lubricate the moving parts with a recommended lubricant.

Regularly check and clean the exhaust fan and filters.

Perform routine inspections and calibrations to ensure optimal performance and longevity of your laser cutter.

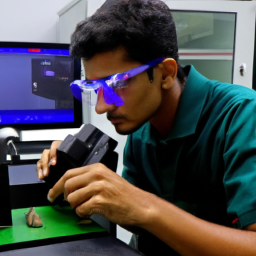

What safety precautions should I take when operating a Nd:YAG laser cutter?

When operating a nd:yag laser cutter, it’s crucial to adhere to laser safety protocols and wear appropriate protective gear.

Laser safety measures include ensuring a well-ventilated area, using laser safety goggles, and implementing a safety interlock system.

Protective gear such as gloves, aprons, and closed-toe shoes should be worn to prevent injuries.

Additionally, proper training on laser operation and emergency procedures is essential to minimize risks and ensure a safe working environment.

Can a Nd:YAG laser cutter be used on reflective materials?

Yes, a Nd:YAG laser cutter can be used on reflective materials, but its effectiveness may vary depending on the specific material. Reflective surfaces such as metals can pose challenges due to their ability to reflect the laser beam. To overcome this, additional techniques can be employed, such as using a beam expander to increase the beam diameter, reducing the laser power, or utilizing a different wavelength. These measures help minimize the reflection and enhance the cutting capabilities on reflective materials.

Are there any limitations to the size of materials that can be cut or engraved with a Nd:YAG laser cutter?

Oh, the limitations of the mighty Nd:YAG laser cutter! While it may seem like a laser god, it does have its boundaries.

When it comes to size, you can’t just go cutting or engraving mammoth materials. There’s a maximum size limit, my friend. And don’t even think about using it on every material under the sun. It has its preferences, you know.

But fear not! This laser wizard has other tricks up its sleeve, like jewelry engraving and circuit board fabrication. So, don’t get too disheartened by its limitations, for it still has plenty to offer.

How does the cost of operating a Nd:YAG laser cutter compare to other types of laser cutters?

Operating a nd:yag laser cutter offers several advantages over other types of laser cutters. One key advantage is its efficiency, as it can cut through materials quickly and with precision.

Compared to other laser cutters, the cost of operating a nd:yag laser cutter can be more affordable due to its high energy efficiency and low maintenance requirements. This makes it an ideal choice for businesses looking to optimize their cutting processes while minimizing costs.

Conclusion

Congratulations! You’ve now unlocked the secrets to truly harnessing the power of your nd:yag laser cutter. By mastering the art of etching and engraving and achieving intricate designs with variable beam control, you can expand your materials palette with multi-wavelength capabilities. Enhance precision with advanced beam delivery systems and harness the power of pulse duration control. You are now equipped with a laser-cutting arsenal like no other.

So, go forth and explore the limitless possibilities of 3D laser cutting techniques. The world is your canvas, and your nd:yag laser cutter is the brush that’ll bring your visions to life.