In today’s fast-paced world, time is of the essence. Every second counts, and any opportunity to streamline processes and increase productivity should not be overlooked. Enter laser cutter software, the modern tool that revolutionizes workflow and integration.

With its cutting-edge technology and seamless compatibility, laser cutter software offers a multitude of benefits that will propel your projects to new heights. From saving precious time to achieving unparalleled precision, the advantages are undeniable.

By integrating laser cutter software into your workflow, you unleash a world of creative possibilities while ensuring superior results and quality. Furthermore, the streamlined organization and efficient management provided by this software will transform the way you work, enabling you to focus on what truly matters – bringing your visions to life.

It’s time to embrace the power of laser cutter software and embark on a journey of enhanced efficiency and success.

Key Takeaways

- Time savings and increased efficiency

- Automation and streamlining of tasks

- Improved collaboration and communication

- Reduction in material waste and optimal use of resources achieved

Time Savings and Efficiency

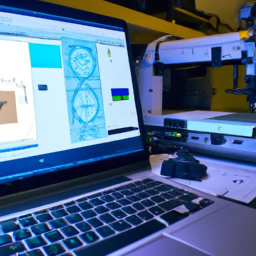

The integration of workflow tools with laser cutter software leads to significant time savings and increased efficiency. By automating various tasks and streamlining the overall workflow, these tools enable you to complete projects faster and with greater accuracy. This not only reduces costs but also minimizes the chances of errors occurring during the production process.

With the ability to automate repetitive tasks such as file preparation and material selection, you can focus on more value-added activities, improving overall productivity. Additionally, the integration of workflow tools with laser cutter software allows for better collaboration and communication between team members, further enhancing efficiency. By seamlessly transferring data and instructions, you can avoid delays and ensure a smooth production flow.

With these time-saving and error-minimizing benefits, the integration of workflow tools with laser cutter software ultimately leads to increased productivity.

Increased Productivity

Maximize your productivity and get more done with the seamless integration of our laser cutter and workflow system. By streamlining your workflow and integrating it with our laser cutter software, you can experience improved collaboration and reduced errors.

With our integrated system, you can easily share files, communicate with team members, and track the progress of projects in real-time. This improved collaboration allows for better coordination and eliminates the need for time-consuming back-and-forth communication.

Additionally, the integration between the workflow system and the laser cutter software ensures that designs are accurately translated into cuts, reducing errors and minimizing material waste. By leveraging this integration, you can achieve increased productivity and efficiency in your laser cutting processes.

Transitioning into the next section, this seamless integration also leads to improved precision and accuracy in your cuts.

Improved Precision and Accuracy

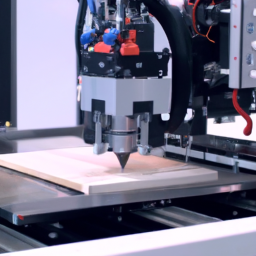

By seamlessly integrating our laser cutter and workflow system, you can achieve a level of precision and accuracy that will blow your mind. Imagine reducing cutting errors by 80%, resulting in significant cost savings and minimizing material waste.

With our advanced software, you can experience higher productivity and improved cutting speed, allowing you to complete projects faster and more efficiently. The laser cutter software analyzes the design and optimizes the cutting path, ensuring that each cut is made with utmost precision. This level of accuracy helps you create intricate designs with intricate details, even on delicate materials, without any compromise. It’s like having a steady hand guiding the laser cutter every step of the way.

Now, let’s explore how this improved precision and accuracy opens up enhanced creative possibilities.

Enhanced Creative Possibilities

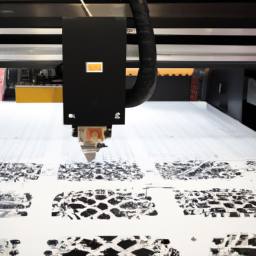

Unlock a world of limitless creativity with our laser cutting technology, allowing you to bring your wildest design ideas to life. The integration of workflow and laser cutter software not only improves precision and accuracy but also enhances creative possibilities. With this seamless integration, you can explore new design opportunities and undertake innovative projects that were previously unimaginable. Whether you’re creating intricate patterns, personalized gifts, or architectural models, the laser cutter software enables you to achieve intricate details and precise cuts. You can experiment with different materials, sizes, and shapes, pushing the boundaries of your designs. The table below showcases some of the creative projects made possible through this integration:

| Project | Material |

|---|---|

| Custom jewelry | Acrylic |

| Intricate signage | Wood |

| Architectural models | Cardboard |

| Decorative ornaments | Leather |

By leveraging the benefits of workflow and integration, you can take your creative projects to new heights, achieving better results and quality.

Better Results and Quality

Improve the outcome of your creative projects and experience a higher level of craftsmanship and precision – can you imagine the satisfaction of creating something truly exceptional? By integrating your workflow with laser cutter software, you can achieve better results and quality in your projects.

Here are some benefits of this integration:

-

Improved workflow processes: By integrating laser cutter software, you can streamline your design process and eliminate manual steps, allowing for a more efficient and effective workflow.

-

Optimized laser cutting techniques: The software offers advanced features and functionalities that can enhance the precision and accuracy of your laser cutting, resulting in cleaner and more precise cuts.

-

Increased productivity: By automating certain tasks and reducing manual intervention, you can save time and increase your overall productivity.

-

Consistent output: The software ensures consistent and repeatable results, minimizing errors and variations in your projects.

-

Enhanced creativity: With the software handling technical aspects, you can focus more on your creative ideas and bring them to life.

By leveraging these benefits, you can achieve a higher level of craftsmanship and precision in your creative projects. This streamlined workflow and organization will allow you to seamlessly transition into the subsequent section.

Streamlined Workflow and Organization

Experience the satisfaction of effortlessly managing your creative projects with a streamlined workflow and organized system that allows you to bring your ideas to life with ease. By integrating laser cutter software into your workflow, you can enjoy improved collaboration and cost effectiveness. With a streamlined workflow, you can easily manage multiple projects simultaneously, reducing the time spent on administrative tasks and increasing productivity. The laser cutter software provides a centralized platform where you can organize and track your projects, ensuring that everything is in order and easily accessible. This organization not only saves time but also reduces the risk of errors and miscommunication. Additionally, the integration of laser cutter software allows for seamless collaboration with team members, enabling you to work together efficiently and effectively. Ultimately, the streamlined workflow and organization provided by laser cutter software enhance your creative process, allowing you to achieve better results while optimizing resources.

| Improved Collaboration | Cost Effectiveness | |

|---|---|---|

| Benefits | – Easy communication and sharing of project files – Real-time collaboration with team members – Efficient feedback and revisions |

– Reduction in material waste – Optimal use of resources – Lower production costs |

Frequently Asked Questions

Can laser cutter software be integrated with other design software programs?

Yes, laser cutter software can be seamlessly integrated with other design software programs, creating a harmonious flow of creativity. The benefits of this integration are numerous. It allows for the transfer of design files, ensuring a smooth transition from concept to finished product.

Additionally, it enables real-time adjustments and precise control over the laser cutting process. This integration enhances efficiency, saves time, and maximizes the potential of both the laser cutter software and the design software programs.

How long does it take to learn and become proficient in using laser cutter software?

Learning and becoming proficient in laser cutter software requires a significant time commitment due to the steep learning curve involved. It typically takes several weeks of dedicated practice and training to gain a strong understanding of the software’s features and functionality.

However, with consistent effort and hands-on experience, you can become proficient in using laser cutter software and effectively utilize its capabilities for your design projects.

Are there any limitations to the types of materials that can be used with laser cutter software?

While there are limitations to the types of materials that can be used with laser cutter software, the advantages for intricate designs are significant.

Laser cutter software may have compatibility issues with certain materials, such as reflective or transparent surfaces. However, it excels in working with materials like wood, acrylic, and leather.

Its precision and accuracy allow for intricate and complex designs to be easily executed, making it a valuable tool for various creative applications.

Can laser cutter software be used for both personal and professional projects?

Laser cutter software can indeed be used for both personal and professional projects. When considering personal use, cost is a key factor. Many laser cutter software options are available at affordable prices or even free, making it accessible for hobbyists.

On the other hand, professional projects require more advanced features and technical support, which may come at a higher cost. However, the precision and versatility of laser cutters make them valuable for both personal and professional applications.

Are there any safety considerations or precautions to take when using laser cutter software?

When using laser cutter software, there are several safety considerations and precautions to keep in mind.

First, always wear appropriate protective gear such as safety glasses and gloves.

Ensure that the laser cutter is installed in a well-ventilated area to prevent the buildup of harmful fumes.

Additionally, it’s crucial to regularly inspect and maintain the machine to prevent any potential hazards.

Finally, make sure to receive proper training on how to operate the laser cutter software safely to minimize the risk of accidents.

Conclusion

In conclusion, integrating workflow with laser cutter software brings a plethora of benefits. From time savings and increased productivity to improved precision and enhanced creative possibilities, the advantages are undeniable.

Not only does it streamline workflow and organization, but it also ensures better results and quality. By seamlessly combining these elements, users can achieve a streamlined and successful laser cutting process.

So, why wait? Embrace this advantageous integration and witness the wonders it can bring to your projects.