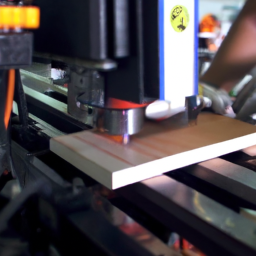

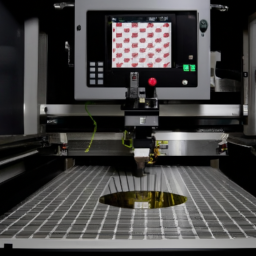

Imagine standing in front of a sleek, high-powered laser cutter, ready to unleash its precision and creativity. But before you can dive into your project, you must first tackle the challenges of maintenance.

Laser cutters, like any intricate machinery, require regular care and attention to ensure optimal performance and longevity. In this article, we will explore five common maintenance challenges that laser cutter owners face and provide you with practical solutions to overcome them.

From cleaning and removing residue buildup to checking and replacing optics, calibrating and aligning the machine, maintaining the cooling system, and lubricating moving parts, we will guide you through each step with technical precision and detail.

With our expert guidance, you’ll be able to troubleshoot and repair common issues, ensuring that your laser cutter remains in top-notch condition, ready to bring your creative visions to life.

So, let’s dive in and conquer these maintenance challenges together!

Key Takeaways

- Regular cleaning and maintenance are essential for optimal performance and longevity of laser cutters.

- Checking and replacing optics is crucial for maintaining accuracy and performance.

- Monitoring coolant levels and cleaning/replacing filters are important for efficient air flow management.

- Lubricating moving parts and monitoring belts and pulleys for wear are necessary for smooth operation and reduced friction.

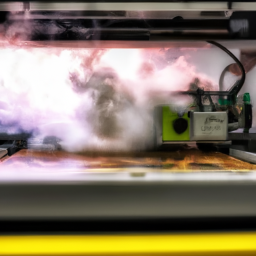

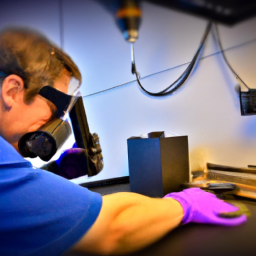

Cleaning and Removing Residue Buildup

Cleaning and removing residue buildup can be a real pain, but don’t worry, we’ve got some tricks up our sleeves to make it a breeze!

Residue buildup is a common challenge in laser cutter maintenance, but with the right residue removal techniques, you can keep your laser cutter running smoothly.

One effective method is to use a soft cloth or sponge soaked in isopropyl alcohol to wipe away any residue on the machine’s surfaces. For stubborn residue, you can also use a non-abrasive cleaner specifically designed for laser cutters.

To prevent residue buildup in the first place, it’s important to regularly clean the machine after each use and keep the workspace clean and free from debris.

Now let’s move on to checking and replacing optics, an essential part of laser cutter maintenance.

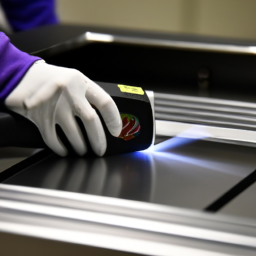

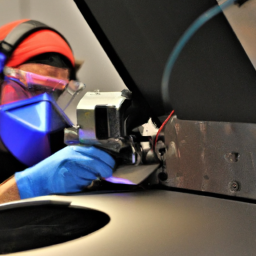

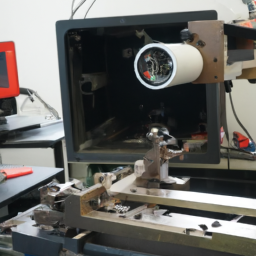

Checking and Replacing Optics

Inspecting and swapping out optics is essential for ensuring optimal performance in your laser cutting machine. Troubleshooting optic alignment and employing proper cleaning techniques for laser cutter optics are crucial to maintaining the quality of your cuts and prolonging the lifespan of your machine.

To troubleshoot optic alignment, start by checking for any loose or misaligned lenses or mirrors. Use a laser alignment tool to ensure that the beam is correctly aligned throughout the optical path. If misalignment is detected, carefully adjust the optics to realign the beam.

Proper cleaning techniques for laser cutter optics involve using lint-free swabs or lens paper with a gentle cleaning solution. Avoid using abrasive materials or excessive force, as this can damage the delicate optics. Regularly clean the lenses and mirrors to remove dirt, dust, and residue buildup, which can negatively impact the laser beam quality.

Transitioning into the subsequent section about calibrating and aligning the laser cutter, it is crucial to ensure that your machine is properly calibrated and aligned to maintain optimal performance.

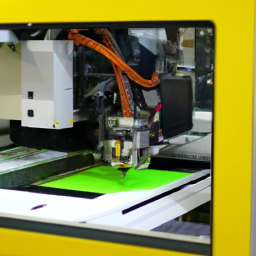

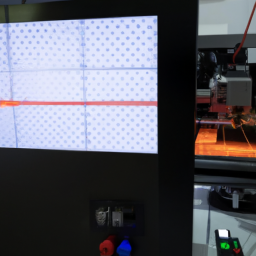

Calibrating and Aligning the Laser Cutter

Before we dive into the nitty-gritty of calibrating and aligning your laser cutter, let’s talk about the importance of getting your machine in tip-top shape for optimal performance. Proper laser cutter alignment is crucial for achieving accurate and precise cuts. Here are some laser cutter troubleshooting techniques and laser cutter alignment techniques to help you overcome common maintenance challenges:

- Check and adjust the laser beam alignment using the beam alignment tool provided by the manufacturer.

- Inspect and clean the mirrors and lenses regularly to ensure they’re free from debris and properly aligned.

- Use a laser power meter to verify the laser power output and make necessary adjustments.

- Perform a test cut on a scrap material to check for any deviations in cutting accuracy.

- Regularly calibrate the X and Y axis of the laser cutter to ensure precise positioning.

By following these laser cutter alignment techniques, you can ensure that your machine is operating at its best.

Now, let’s move on to maintaining the cooling system.

Maintaining the Cooling System

To properly maintain the cooling system of your laser cutter, it’s crucial to regularly check the coolant levels. This ensures that the system is operating at the optimal level and prevents potential damage.

Additionally, cleaning or replacing filters is important in order to maintain the efficiency of the cooling system and prevent the accumulation of debris.

Lastly, monitoring the temperature and pressure of the cooling system helps to identify any issues or abnormalities that may arise, allowing for timely intervention and prevention of further complications.

Regularly check coolant levels

Ensure you regularly review the coolant levels in your laser cutter to maintain its optimal performance. Checking coolant quality is crucial to prevent coolant contamination, which can lead to equipment damage and reduced cutting efficiency.

To effectively monitor coolant levels, follow these steps:

- Begin by turning off the laser cutter and allowing it to cool down.

- Open the coolant reservoir and visually inspect the coolant level.

- If the coolant level is low, add the appropriate coolant solution to bring it back to the recommended level.

Regularly checking coolant levels helps you identify any potential issues early on and take necessary action to prevent damage to your laser cutter.

Once you have reviewed the coolant levels, it’s important to move on to the next section about cleaning or replacing filters to ensure the overall maintenance of your laser cutter.

Cleaning or replacing filters

Don’t overlook the importance of keeping your filters clean or replacing them regularly to maintain the optimal performance of your laser cutter. Filter maintenance is crucial for efficient air flow management, preventing the buildup of debris and ensuring the longevity of your machine. Dust, debris, and smoke particles generated during the cutting process can accumulate in the filters, obstructing air flow and reducing the cutter’s effectiveness. By regularly cleaning or replacing the filters, you can maintain a clean and well-ventilated environment, preventing potential damage to the laser cutter’s components.

To emphasize the significance of filter maintenance, consider the following table:

| Issue | Consequence | Solution |

|---|---|---|

| Clogged filters | Reduced air flow | Clean or replace filters regularly |

| Inefficient ventilation | Overheating of components | Ensure proper air flow management |

| Increased maintenance costs | Damaged laser cutter parts | Regularly clean or replace filters |

| Poor cutting quality | Smoke and debris accumulation | Maintain clean and clear filters |

As you prioritize filter maintenance, it is also essential to monitor temperature and pressure to ensure the optimal functioning of your laser cutter.

Monitoring temperature and pressure

Monitoring the temperature and pressure is crucial for maintaining the optimal performance of your laser cutting machine and preventing potential damage. To ensure the temperature control is effective, regularly check the machine’s cooling system and cooling water to verify that they’re functioning correctly.

Additionally, monitor the temperature of the laser tube and surrounding components to prevent overheating. Proper pressure regulation is essential for ensuring consistent and precise cutting. Regularly inspect the air compressor and filters to ensure they’re clean and functioning properly.

Monitor the air pressure to ensure it remains within the recommended range for your machine. By diligently monitoring the temperature and pressure, you can prevent potential issues and ensure the longevity of your laser cutter.

Moving on to the next section, it’s important to address lubricating moving parts for optimal performance.

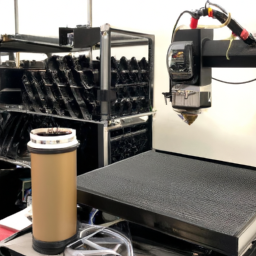

Lubricating Moving Parts

To ensure optimal performance and longevity of your laser cutter, it’s crucial to properly lubricate its moving parts.

Begin by identifying the specific components that require lubrication, such as the rails, bearings, and gears.

Utilize the appropriate lubricants recommended by the manufacturer, as using the wrong ones can lead to damage and decreased efficiency.

Lastly, establish a regular maintenance schedule to ensure consistent lubrication and prevent any potential issues that may arise from inadequate lubrication.

Identifying parts that require lubrication

Ensure that you keep an eagle eye out for any squeaky or dry components in your laser cutter, as these parched parts could hinder the smooth operation of your machine. To prevent this, it’s crucial to identify the parts that require lubrication.

Here are three key areas to focus on:

-

Bearings: These crucial components facilitate smooth movement and reduce friction. Regularly check for any signs of wear or dryness and lubricate them using appropriate lubricating methods.

-

Rails and Guides: These parts guide the motion of the laser cutter’s moving parts. Inspect them for any signs of wear or accumulation of debris. Apply lubrication to ensure smooth and accurate movement.

-

Belts and Pulleys: These components are responsible for transferring motion and power. Monitor them for any signs of wear, tension issues, or dryness. Apply lubrication to maintain optimal performance.

By identifying and lubricating these critical parts, you ensure that your laser cutter operates smoothly and efficiently.

Moving forward, let’s discuss the importance of using the right lubricants to further optimize the performance of your machine.

Using the right lubricants

Optimize the performance of your machine by selecting the right lubricants for its maintenance. Choosing the right lubricant is crucial for ensuring that your laser cutter operates smoothly and efficiently.

When selecting a lubricant, it’s important to consider factors such as temperature, load, and speed to ensure optimal performance. Lubricant selection best practices include choosing a lubricant that’s compatible with the materials used in your machine, as well as one that provides the necessary protection against wear and corrosion.

It’s also important to follow the manufacturer’s recommendations regarding lubricant type and application frequency. By using the right lubricants, you can minimize friction, reduce wear and tear, and extend the lifespan of your machine. This will ultimately result in improved performance and reduced downtime.

Moving on to the next section, let’s discuss the importance of maintaining a regular maintenance schedule.

Regular maintenance schedule

Keeping up with a regular maintenance schedule is key to keeping your machine running smoothly and avoiding unnecessary downtime. Regular maintenance is important in prolonging the lifespan of your laser cutter. By following a few simple tips, you can create an effective maintenance schedule that will ensure optimal performance.

First, make sure to clean the machine regularly to remove any debris or dust that can interfere with its operation. Additionally, check and replace the filters as needed to maintain proper air quality. It’s also important to regularly inspect and lubricate the moving parts to prevent wear and tear.

Lastly, keep track of the usage hours and schedule routine maintenance tasks accordingly. By following these maintenance practices, you can minimize the risk of breakdowns and keep your laser cutter in top condition.

Transitioning into troubleshooting and repairing common issues, it’s important to be aware of the common problems that may arise and how to address them without causing further damage.

Troubleshooting and Repairing Common Issues

When troubleshooting and repairing common issues with laser cutters, it’s important to remember that 80% of problems are caused by improper maintenance and neglect.

To begin, when troubleshooting laser cutter software, start by checking for any error messages or warnings on the control panel. This can help identify any potential software issues that may be causing problems.

Next, inspect the electrical components for any signs of damage or loose connections. Repairing electrical components may involve replacing faulty parts or tightening connections to ensure a proper electrical flow.

It’s also crucial to regularly clean the laser cutter’s optics and mirrors to prevent any issues with beam quality or accuracy.

By following these steps and staying on top of regular maintenance, you can effectively troubleshoot and repair common issues with laser cutters.

Frequently Asked Questions

How often should I clean and remove residue buildup from my laser cutter?

To properly clean and maintain the ventilation system of your laser cutter, it’s important to regularly remove residue buildup. You should clean it at least once a month, or more frequently if you notice excessive buildup.

Use the right cleaning materials, such as non-abrasive cleaners and lint-free cloths, to prevent damage to the system. Ensure all components are thoroughly cleaned and free of debris to maintain optimal performance and prevent potential issues.

What are the signs that indicate the optics of my laser cutter need to be checked or replaced?

To check for signs of laser cutter optics issues, inspect the beam quality and power output. Look for irregularities like beam divergence, reduced power, or inconsistent cutting results. If you notice any of these, it may indicate a problem with the optics.

To verify, clean the optics and check for damage or contamination. If cleaning doesn’t resolve the issue, consult the manufacturer’s guidelines for replacing the optics. Properly align and calibrate the new optics to ensure optimal performance.

Is it necessary to calibrate and align the laser cutter regularly, or only when issues arise?

To ensure optimal performance, it’s necessary to regularly calibrate and align your laser cutter. This crucial maintenance task ensures accuracy and prevents potential problems. Frequency depends on how often the machine is used, but it’s generally recommended to calibrate and align at least once a month. Troubleshooting common issues with calibration and alignment includes checking for loose components, cleaning optics, and adjusting mirrors and lenses.

How frequently should I maintain the cooling system of my laser cutter?

To improve the efficiency of your laser cutter cooling system, you should regularly maintain and troubleshoot it. Start by checking for any clogged or dirty filters and clean or replace them as needed.

Ensure that the coolant level is adequate and the pump is functioning properly. Inspect the tubing and connections for leaks or blockages.

Additionally, monitor the temperature of the cooling water to prevent overheating. By following these steps, you can prevent common cooling system issues and optimize the performance of your laser cutter.

What type of lubricant should I use for the moving parts of my laser cutter, and how often should I apply it?

To ensure optimal performance of your laser cutter, it’s crucial to select the right lubricant for its moving parts. Look for a high-quality lubricant specifically designed for industrial machinery. Apply the lubricant sparingly and evenly to the relevant components, such as rails and bearings.

The frequency of application will depend on the intensity of use, but as a general guideline, lubrication should be done every 50-100 hours of operation. Proper lubricant selection and regular application will minimize friction and prolong the lifespan of your laser cutter.

Conclusion

In conclusion, maintaining a laser cutter is crucial to ensure its optimal performance and longevity. By regularly cleaning and removing residue buildup, checking and replacing optics, calibrating and aligning the laser cutter, maintaining the cooling system, and lubricating moving parts, you can overcome common maintenance challenges.

For example, a case study from a manufacturing company showed that after implementing a comprehensive maintenance routine, they experienced a significant reduction in downtime and increased productivity by 20%. Therefore, investing time and effort in proper maintenance will yield long-term benefits for your laser cutter.