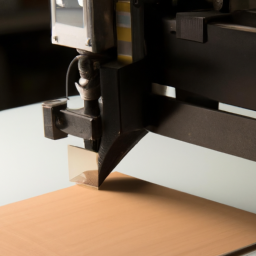

Imagine you are a skilled sculptor, working tirelessly to carve a masterpiece out of a block of marble. Your chisel is sharp, your vision is clear, but there’s one problem – you lack the right tools. In the world of laser cutting, the software you use is your chisel, your guiding hand. It is the key to unlocking the full potential of your laser cutter and transforming your ideas into reality.

However, integrating laser cutter software into your existing workflow can be a daunting task, filled with challenges that can hinder your progress. But fear not, for in this article, we will explore five common laser cutter software integration challenges and provide you with practical solutions to overcome them. Whether it’s compatibility issues, lack of training, or limited customization options, we’ve got you covered.

So grab your chisel and let’s dive into the world of laser cutter software integration!

Key Takeaways

- Compatibility issues can be overcome by identifying specific problems and exploring potential solutions like finding software that supports both existing systems and the laser cutter or using third-party software as a bridge.

- Lack of training can be addressed by utilizing training resources provided by software manufacturers, online tutorials, video guides, online forums, and workshops.

- Difficulty in importing and exporting files can be overcome by understanding file format compatibility, converting designs into compatible formats, staying up to date with software updates, and using file conversion tools.

- Inadequate support and troubleshooting resources can be addressed by seeking assistance from online forums or user communities.

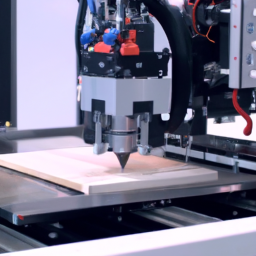

Compatibility Issues with Existing Software Systems

Are you struggling with compatibility issues between your current software systems and your laser cutter?

Integrating software can be a complex task, but with the right software integration strategies and troubleshooting techniques, you can overcome these challenges.

Start by identifying the specific compatibility issues you’re facing. Is it a matter of file formats or communication protocols? Once you’ve pinpointed the problem, you can explore potential solutions.

This may involve finding software that supports both your existing systems and the laser cutter, or using a third-party software that acts as a bridge between the two.

Additionally, consider reaching out to the software manufacturers for guidance and support.

By addressing compatibility issues head-on, you can ensure a smooth workflow and maximize the efficiency of your laser cutter.

Now, let’s move on to the next challenge: lack of training and familiarity with the software.

Lack of Training and Familiarity with the Software

Get ready to feel frustrated and overwhelmed when you first encounter a laser cutter software, as lack of training and familiarity with the program can leave you feeling lost and confused. However, with the right resources and software tutorials, you can quickly overcome this challenge.

Here are four key ways to address the lack of training and familiarity:

-

Utilize training resources provided by the software manufacturer to learn the basics and gain a better understanding of the software’s features and functionality.

-

Take advantage of online tutorials and video guides that offer step-by-step instructions on using the software for laser cutting purposes.

-

Join online forums and communities where experienced users can provide guidance and answer your questions.

-

Consider attending workshops or training sessions offered by experts in laser cutting software.

By taking advantage of these training resources, you can build your knowledge and confidence in using the software.

Now, let’s dive into the next challenge: difficulty in importing and exporting files.

Difficulty in Importing and Exporting Files

Facing a steep learning curve, users often find themselves grappling with the intricate process of importing and exporting files, causing them to feel like a fish out of water in the vast ocean of laser cutting software. One of the major challenges they face is file format compatibility. Laser cutter software typically supports a limited range of file formats, requiring users to convert their designs or drawings into compatible formats. This can be time-consuming and frustrating, especially for those who are not familiar with file conversion tools. Additionally, software updates can further complicate the process as they may introduce changes in file format requirements or compatibility. Users must stay up to date with the latest software updates and ensure their files are in the correct format to avoid any issues. Transitioning into the next section, inadequate support and troubleshooting resources can exacerbate these challenges.

Inadequate Support and Troubleshooting Resources

Laser cutting enthusiasts often struggle to find the necessary assistance and troubleshooting guidance, leaving them stranded in a vast sea of unanswered questions. Insufficient customer service is a common challenge faced by users of laser cutter software. When encountering technical issues or needing help with specific features, it can be frustrating to find that support resources are limited or non-existent.

Additionally, outdated software versions can compound the problem, as the lack of updates and bug fixes can lead to compatibility issues and hinder the overall performance of the laser cutter. To overcome these challenges, it’s important to actively seek out alternative sources of support, such as online forums or user communities, where experienced individuals can offer guidance and solutions.

Transitioning into the subsequent section, limited customization and personalization options can further limit the user experience with laser cutter software.

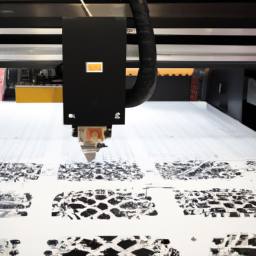

Limited Customization and Personalization Options

To truly enhance your experience with laser cutter software, you’ll need to explore more flexible and personalized options that allow you to tailor the software to your specific needs. However, many common laser cutter software solutions come with customization limitations and personalization restrictions.

These limitations can hinder your ability to optimize the software for your unique workflow and requirements. For example, you may be limited in the number of custom settings you can create or the extent to which you can modify existing features. This can be frustrating, as it prevents you from fully utilizing the software’s potential.

Fortunately, there are ways to overcome these limitations. Some software providers offer more customizable versions or additional plugins that expand the software’s capabilities. By seeking out these options and exploring alternative solutions, you can find ways to overcome the customization and personalization restrictions of common laser cutter software.

This adaptability is crucial when facing cost and budget constraints in the next step.

Cost and Budget Constraints

If you’re struggling with limited customization and personalization options for your laser cutter software, you’ll be relieved to know that there are ways to overcome this challenge. However, before we delve into that, let’s address another common hurdle: cost and budget constraints.

Managing the financial aspect of integrating laser cutter software can be a daunting task, but there are cost-saving strategies that can help. One approach is to explore alternative software options that offer similar functionality at a lower price point. By researching and comparing different software solutions, you can find one that aligns with your budget without compromising on essential features.

Furthermore, consider reaching out to software providers directly to inquire about discounts or flexible payment plans. Some providers may be willing to negotiate pricing based on your specific needs and circumstances. With careful planning and resourcefulness, you can find a cost-effective solution that meets your requirements without breaking the bank.

Frequently Asked Questions

Are there any recommended software systems that are compatible with laser cutters?

Recommended software options that are compatible with laser cutters include popular programs such as Adobe Illustrator, AutoCAD, and CorelDRAW. These software systems offer precise design tools and support various file formats that can be easily transferred to laser cutting machines. By utilizing these recommended options, you can ensure seamless integration between your design software and laser cutter. This allows for efficient and accurate production of your projects.

How long does it typically take to become familiar with laser cutter software?

Typically, it takes a few weeks to become familiar with laser cutter software. The learning curve can vary depending on your previous experience with similar software. To expedite the process, it’s recommended to start with user-friendly software systems that are compatible with laser cutters. These recommended software options often provide intuitive interfaces and comprehensive tutorials to help you quickly grasp the necessary skills.

With consistent practice and hands-on experience, you can become proficient in laser cutter software in no time.

Are there any specific file formats that are difficult to import or export with laser cutter software?

When it comes to laser cutter software, some file formats can be as stubborn as a rusty lock. Difficulties may arise when importing or exporting uncommon formats, causing frustration and wasted time. But fear not! Here are some tips for optimizing your file designs.

Firstly, convert files to more widely supported formats like SVG or DXF.

Secondly, ensure your designs are properly scaled and organized.

With these tricks up your sleeve, you’ll conquer any format obstacle with ease.

What kind of support and troubleshooting resources are available for laser cutter software users?

For laser cutter software users, there are various support resources and troubleshooting tips available.

Online forums and communities dedicated to laser cutting provide a platform for users to seek assistance and share experiences.

Additionally, many software providers offer comprehensive documentation, including user manuals and video tutorials, to guide users through common issues.

If further assistance is required, contacting the software provider’s customer support team can provide personalized troubleshooting advice and solutions.

Can laser cutter software be customized to fit specific needs or preferences?

Yes, laser cutter software can be customized to fit your specific needs and preferences. The customization options available allow you to tailor the software to your exact requirements, improving efficiency and productivity. By customizing the software, you can streamline your workflow, automate repetitive tasks, and create a user interface that’s intuitive and easy to navigate.

The benefits of tailored software include increased accuracy, reduced errors, and a more seamless integration with your existing systems and processes.

Conclusion

In conclusion, tackling the challenges of integrating laser cutter software requires a proactive approach. By investing in training and familiarizing yourself with the software, you can overcome the initial learning curve.

Additionally, seeking support and troubleshooting resources can help address any issues that may arise. Importing and exporting files can be made easier by using compatible formats and exploring different file conversion options.

While customization options may be limited, finding creative solutions within your budget constraints is possible. Remember, just like a laser cutter carefully crafts intricate designs, you too can navigate these challenges and unlock the full potential of your software.