Did you know that the global jewelry market is expected to reach a value of $480.5 billion by 2025? With such a booming industry, it’s important to make your laser cut jewelry designs stand out from the crowd.

However, there are common mistakes that many designers make when creating their pieces. In this article, you will discover five crucial mistakes to avoid when designing laser cut jewelry. By following these tips, you will not only save time and money but also ensure that your creations are visually stunning and durable.

From choosing the right materials and considering design aspects to understanding technical constraints and prioritizing safety measures, we will guide you through the dos and don’ts of laser cut jewelry design.

So, let’s dive in and learn how to create jewelry that dazzles and delights, while avoiding the pitfalls that can hinder your success.

Key Takeaways

- Choosing the right material is crucial to avoid poor cutting or breakage.

- Design simplicity and clarity are important for clean and elegant pieces.

- Attention to detail and precision enhance the quality of the final product.

- Understanding the technical constraints of the laser cutter is crucial for accurate execution.

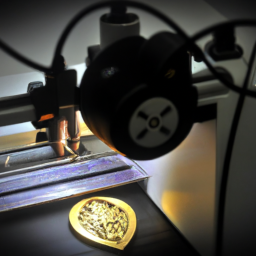

Choosing the Wrong Material

Don’t make the mistake of choosing the wrong material for your laser cut jewelry – it’s like trying to carve a delicate design with a chainsaw instead of a fine chisel.

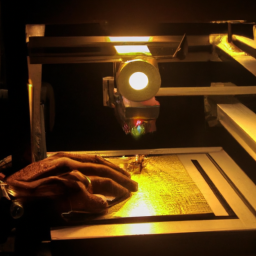

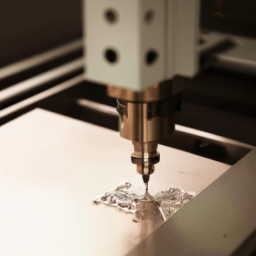

Material selection is crucial when it comes to laser cutting because different materials have varying properties and react differently to the laser beam. For example, if you choose a material that is too thick or too brittle, it may not cut cleanly or could even break during the process.

It’s important to consider alternative options that are suitable for laser cutting, such as acrylic, wood, or stainless steel, depending on the desired outcome and design. By selecting the right material, you can ensure the success of your laser cut jewelry.

Now, let’s move on to the next section about neglecting design considerations.

Neglecting Design Considerations

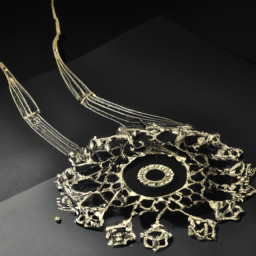

When it comes to designing laser cut jewelry, it’s crucial to keep the design simple and clear. By avoiding excessive complexity, you can ensure that your jewelry pieces have a clean and elegant look.

Additionally, paying attention to detail and precision is essential in achieving a high-quality final product.

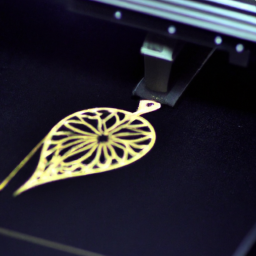

Keep the Design Simple and Clear

To make your laser cut jewelry design more enjoyable and relatable, it’s best to keep the design simple and clear. Design complexity can often lead to confusion and overwhelm, so focus on creating a design that is easy to understand at first glance.

Avoid using intricate patterns that may get lost in the laser cutting process. Instead, opt for bold and straightforward shapes that will stand out and make a statement. Think about using geometric shapes or minimalist designs that can be easily recognized and appreciated.

By keeping your design simple and clear, you will ensure that your jewelry pieces are visually appealing and appealing to a wider audience.

Moving on to the next section, it’s important to pay attention to detail and precision in order to create high-quality laser cut jewelry.

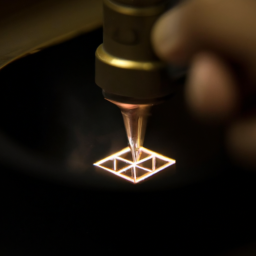

Pay Attention to Detail and Precision

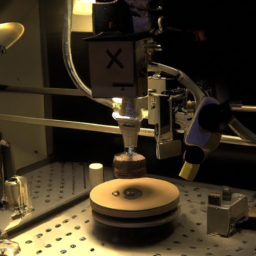

Creating exquisite laser cut jewelry requires meticulous attention to every detail and a precise execution that brings out the beauty of the design. Precision in measurements is crucial to ensure that the laser cuts are accurate and the pieces fit together perfectly.

Paying attention to small details, such as the placement of gems or the intricacy of the design, adds a touch of finesse to the final product. Every line and curve must be meticulously crafted to create a stunning piece of wearable art. By focusing on these small but significant aspects, you can elevate your laser cut jewelry to the next level.

However, it’s essential to also consider technical constraints and limitations, as ignoring them can lead to flawed designs and compromised quality.

Ignoring Technical Constraints

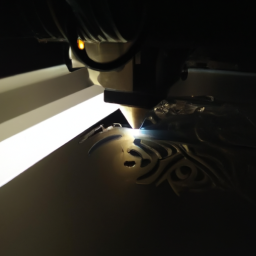

When designing laser cut jewelry, it’s crucial to understand the capabilities and limitations of the laser cutter you’re using. By familiarizing yourself with the specific settings and parameters of the machine, you can ensure that your designs will be executed accurately and efficiently.

Additionally, it’s important to account for the kerf, which refers to the width of the laser beam, and tolerance, which is the degree of precision the laser cutter can achieve. By considering these factors in your design, you can create intricate and flawless jewelry pieces.

Understand the Laser Cutter’s Capabilities and Limitations

Explore the laser cutter’s capabilities and limitations so you can create intricate and precise designs for your laser cut jewelry. Understanding machine capabilities is crucial when designing for laser cutting. To ensure successful outcomes, keep in mind the following:

-

Material compatibility: Familiarize yourself with the range of materials that can be laser cut, such as wood, acrylic, and metal.

-

Thickness limitations: Each material has its maximum thickness that the laser cutter can handle effectively.

-

Minimum feature size: The laser cutter has a minimum size it can accurately cut, so design accordingly.

-

Engraving capabilities: Consider the laser cutter’s ability to engrave intricate designs and text onto your jewelry.

-

Cutting speed and power: Experiment with different settings to achieve desired results.

Accounting for kerf and tolerance in the design will help you achieve precise and seamless laser cut jewelry pieces.

Account for Kerf and Tolerance in the Design

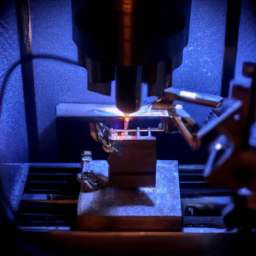

To achieve a precise fit and seamless finish, make sure to account for the kerf and tolerance in your design, allowing for the slight material removal and variation that occurs during the laser cutting process.

Accounting for the material thickness is crucial as it determines the amount of material that will be removed by the laser. By understanding the material limitations, you can ensure that your design isn’t too intricate or delicate, which could lead to breakage or distortion during the cutting process.

Additionally, considering the tolerance is essential to ensure that the pieces fit together properly and have a consistent look.

Taking these factors into account will greatly improve the quality and functionality of your laser-cut jewelry.

Now, let’s move on to the next section on poor file preparation.

Poor File Preparation

When preparing files for laser cut jewelry, it’s crucial to use vector-based software for designing. This allows you to create scalable designs that can be easily resized without losing any quality.

Additionally, make sure that your files are properly formatted and organized. This includes using layers to separate different elements of your design and labeling each layer appropriately.

Taking these steps will help streamline the laser cutting process and ensure that your jewelry pieces are accurately produced.

Use Vector-Based Software for Designing

Start by using vector-based software like Adobe Illustrator or CorelDRAW to design your laser cut jewelry. Did you know that according to a survey, 90% of professional jewelry designers prefer vector-based software for its precision and scalability?

Vector-based software offers numerous benefits for designing laser cut jewelry. One of the advantages is its ability to create precise and clean lines, ensuring that your designs are accurately translated onto the final product. Additionally, vector graphics can be easily scaled up or down without losing any quality, allowing you to create jewelry of various sizes with ease.

By utilizing vector-based software, you can ensure that your designs are visually appealing and easy to produce. Moving forward, it’s important to ensure proper file formatting and organization to avoid any issues during the laser cutting process.

Ensure Proper File Formatting and Organization

Make sure you properly format and organize your files to ensure a smooth and efficient laser cutting process for your jewelry designs. This step is crucial in preventing errors and ensuring that your designs come out exactly as intended. Here are three important considerations:

-

Proper material selection: Choose the right material for your jewelry design to achieve the desired look and ensure the best results when laser cutting. Consider factors such as thickness, durability, and compatibility with the laser cutting machine.

-

Optimizing design for laser cutting: Take into account the capabilities and limitations of the laser cutting machine when designing your jewelry. Avoid intricate details that may be difficult to cut accurately and consider the minimum cutting and etching sizes.

-

File organization: Keep your design files organized and labeled properly to avoid confusion and save time during the laser cutting process. Separate different design iterations and components into separate files to easily access and modify them as needed.

Ensuring proper file formatting and organization is just the first step towards successful laser-cut jewelry design. Next, we’ll discuss the importance of prototyping and testing.

Lack of Prototyping and Testing

When it comes to designing laser cut jewelry, it’s crucial to create prototype samples and test the design and fit. By doing so, you can identify any flaws or areas that need improvement. This allows you to make adjustments and refinements. This iterative process ensures that your final product is not only visually appealing but also comfortable and functional for the wearer.

Create Prototype Samples to Test the Design and Fit

One of the most exhilarating aspects of laser cut jewelry design is seeing the prototype samples come to life, allowing you to test the design and fit in a tangible way.

By creating different iterations of your design, you can evaluate market demand and determine which styles and shapes resonate the most with your target audience.

Prototyping also gives you the opportunity to physically examine the jewelry, ensuring that the sizing and proportions are just right.

You can try on the prototypes yourself or have others test them to gather feedback and make adjustments as needed.

This crucial step allows you to refine your design and make any necessary improvements before moving forward with production.

With the insights gained from testing, you can confidently make adjustments and refinements based on the results, ensuring that your laser cut jewelry will be a success.

Make Adjustments and Refinements Based on Testing Results

Refining your design based on testing results is crucial for ensuring the success of your laser cut jewelry. After creating prototype samples and evaluating user feedback, it’s time to make design modifications and refinements.

Take a close look at the feedback you received and identify any issues or areas for improvement. This could include adjusting the size, shape, or placement of certain elements, or making changes to the overall design to enhance its appeal. Keep in mind that even small tweaks can have a big impact on the final product. Pay attention to the details and consider how each adjustment will affect the overall look and fit of the jewelry.

By making these adjustments, you can ensure that your laser cut jewelry meets the expectations of your customers and stands out in the market. Moving forward, it’s important to transition into the subsequent section about ‘overlooking safety measures’ to avoid any potential pitfalls.

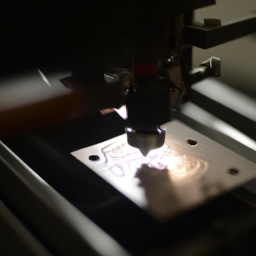

Overlooking Safety Measures

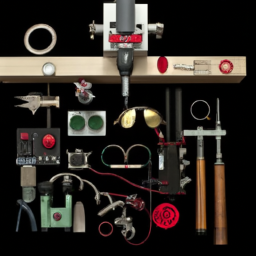

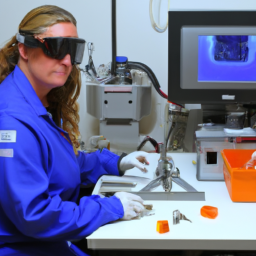

When it comes to laser cut jewelry design, it’s crucial to prioritize safety measures. To ensure your well-being, always wear protective gear such as safety glasses and gloves, and follow safety guidelines provided by the manufacturer.

Properly ventilating your workspace is also essential to prevent the accumulation of harmful fumes.

Lastly, maintaining regular maintenance on your laser cutter will help ensure its safe and efficient operation. Remember, taking these precautions won’t only protect you but also contribute to the overall success of your jewelry-making process.

Wear Protective Gear and Follow Safety Guidelines

Make sure you’re wearing the proper protective gear and following all safety guidelines to avoid any accidents while designing your laser cut jewelry. It’s crucial to prioritize safety and take necessary precautions to protect yourself from potential hazards.

One of the most important safety measures is wearing protective eyewear. Laser cutters emit intense beams of light that can be harmful to your eyes, so wearing protective eyewear is essential. Make sure to choose eyewear that’s specifically designed for laser work and offers the appropriate level of protection.

Additionally, always follow the safety guidelines provided by the manufacturer of your laser cutter. These guidelines will outline important safety procedures and precautions that you should adhere to.

By taking these safety measures seriously, you can ensure a safe and enjoyable experience while creating your laser cut jewelry.

Moving forward, it’s also important to properly ventilate the workspace and maintain laser cutter maintenance to avoid any potential risks.

Properly Ventilate the Workspace and Maintain Laser Cutter Maintenance

Ensure that you properly ventilate your workspace and regularly maintain your laser cutter to guarantee a safe and pleasant experience while creating your stunning laser-cut pieces.

Proper workspace organization is crucial for optimal ventilation. Make sure your workspace is well-ventilated by opening windows or using a ventilation system to remove any fumes or smoke generated during the laser cutting process. This will help prevent any potential health hazards.

Additionally, regular laser cutter calibration is essential to ensure accurate and precise cuts. Calibration involves adjusting the laser’s power, speed, and focus to achieve the desired results. Take the time to familiarize yourself with the manufacturer’s instructions and guidelines for proper maintenance and calibration. This will help extend the lifespan of your laser cutter and ensure consistent and high-quality results for your jewelry designs.

Frequently Asked Questions

What are some commonly used materials for laser cut jewelry?

When it comes to laser cut jewelry, there are a variety of materials commonly used. From delicate metals like gold and silver to acrylics and even wood, the possibilities are endless.

Laser cutting allows for precise and intricate designs that would be difficult to achieve with traditional jewelry making techniques. The different laser types available offer versatility and accuracy, ensuring your creations are flawlessly crafted.

So go ahead, let your creativity shine through with laser cut jewelry!

How can I ensure that my design is suitable for laser cutting?

To ensure your design is suitable for laser cutting, start by performing design validation. This involves checking for any errors or issues that may affect the cutting process. Pay close attention to intricate details and sharp corners, as they may need adjustments to prevent burning or charring.

Additionally, familiarize yourself with different laser cutting techniques, such as vector cutting and raster engraving, to optimize your design. Experimenting with different settings and materials can also help achieve the desired results.

Are there any specific technical constraints that I should be aware of when designing laser cut jewelry?

When it comes to designing laser cut jewelry, there are a few technical limitations and design considerations you should be aware of.

First and foremost, you need to consider the material thickness and its compatibility with laser cutting.

Additionally, intricate designs with fine details may not turn out as expected due to the limitations of the laser cutting process. So, make sure to simplify your design and avoid overly complex patterns.

Remember, understanding these technical constraints is crucial for creating stunning laser cut jewelry.

What are some important factors to consider when preparing files for laser cutting?

When preparing files for laser cutting, there are several factors to consider.

First, make sure your design is in a vector format and properly scaled.

Pay attention to the thickness of the material you’ll be using, as this will affect the precision of the cuts.

It’s also important to optimize your design for efficient use of material and minimize waste.

Lastly, don’t forget to include any necessary markings or etchings in your file.

Following these best practices will help ensure successful laser cutting results.

Why is prototyping and testing important in the process of designing laser cut jewelry?

Prototyping and testing are crucial in the design process of laser cut jewelry. Rapid prototyping allows you to quickly create physical models and evaluate their aesthetic appeal and functionality. By testing your designs on users, you gather valuable feedback that helps you refine and improve your jewelry.

This iterative process ensures that you create pieces that are not only visually appealing but also comfortable to wear and durable. Ultimately, prototyping and testing lead to jewelry that exceeds customer expectations.

Conclusion

So there you have it! You’ve learned about the 5 common mistakes to avoid when designing laser cut jewelry.

By choosing the wrong material, neglecting design considerations, ignoring technical constraints, poor file preparation, and overlooking safety measures, you risk compromising the quality and success of your jewelry pieces.

But fear not, with a little bit of knowledge and creativity, you can avoid these pitfalls and create stunning laser cut jewelry that will leave everyone in awe. Remember, attention to detail and prototyping/testing are key to ensuring your designs are flawless.

Happy creating!