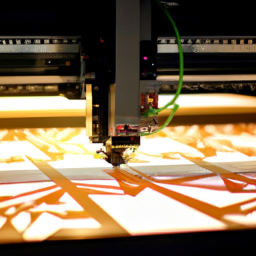

Are you tired of seeing your laser cut models fall apart before your eyes? Are you frustrated with wasting time and money on designs that just don’t cut it? Well, fret no more! In this article, we will unveil the top 5 common mistakes to avoid when designing laser cut models.

Brace yourself, because these blunders can turn your dreams of precision and perfection into a nightmare of epic proportions.

First and foremost, choosing the wrong material for your design is like using a butter knife to carve a masterpiece. It’s simply not going to cut it.

Secondly, ignoring the design constraints of laser cutting is like trying to fit a square peg into a round hole – it’s just not going to work.

And let’s not forget about the kerf width, that sneaky little devil that can throw off your measurements and ruin your entire design.

But wait, there’s more! Neglecting to include proper ventilation and support structures is like building a house of cards in a windstorm – disaster waiting to happen.

And finally, overcomplicating your design is like trying to reinvent the wheel – unnecessary, time-consuming, and likely to end in frustration.

So, buckle up and get ready to learn from these common mistakes. By avoiding these pitfalls, you’ll be well on your way to creating laser cut models that are as flawless as they are awe-inspiring.

Key Takeaways

- Choosing the wrong material

- Ignoring design constraints

- Neglecting proper ventilation and support structures

- Overcomplicating the design

Choosing the Wrong Material for Your Design

Choosing the wrong material for your design can lead to disastrous results, making it essential to carefully consider the specific properties and requirements of each material before proceeding with the laser cutting process.

Material compatibility is a crucial factor to consider, as different materials have varying levels of compatibility with laser cutting machines. Some materials, such as wood and acrylic, are commonly used in laser cutting due to their excellent cutting properties and versatility. However, other materials, like metals and certain plastics, may require special techniques or equipment to achieve desired results.

Additionally, cost considerations should not be overlooked, as some materials may be more expensive to work with than others. Ignoring the design constraints of laser cutting, such as minimum feature sizes and kerf width, can also lead to suboptimal outcomes. Thus, it is vital to thoroughly understand and adhere to these constraints to ensure a successful laser cut model.

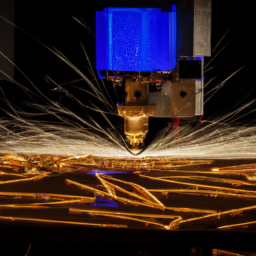

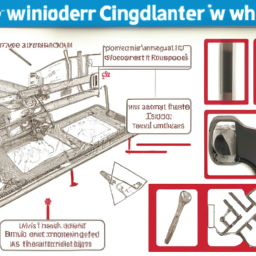

Ignoring the Design Constraints of Laser Cutting

Neglecting the limitations of laser cutting can lead to disappointing results, as 80% of designs that ignore these constraints end up with unusable or damaged pieces.

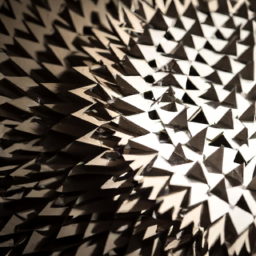

When designing intricate patterns for laser cutting, it’s crucial to consider the capabilities of the laser cutting techniques and tips. Laser cutting has certain limitations such as the minimum feature size, which affects the level of detail that can be achieved. Additionally, the cutting speed and power settings must be optimized to prevent excessive heat buildup or charring of the material.

Ignoring these design constraints can result in distorted or incomplete cuts, compromising the overall quality of your model. Therefore, it’s essential to thoroughly understand the capabilities and limitations of laser cutting and incorporate them into your design process.

Failing to account for kerf width, the amount of material removed by the laser beam, can further impact the accuracy and fit of your laser cut model.

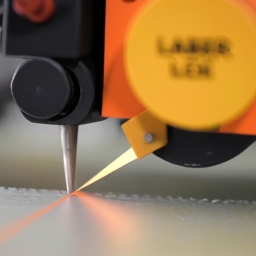

Failing to Account for Kerf Width

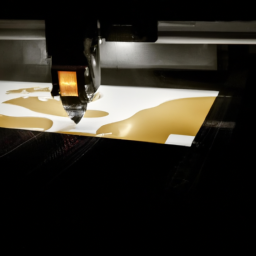

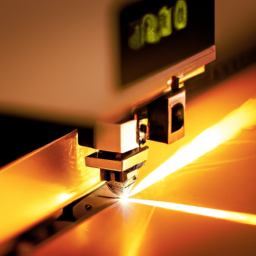

To ensure the precision and accuracy of your laser-cut designs, remember to take into account the kerf width. The kerf width refers to the material that’s removed by the laser during the cutting process. Ignoring this important factor can lead to misaligned or ill-fitting parts.

To properly adjust for kerf in your design, consider the following:

- Use kerf measurement techniques to determine the actual width of the laser beam. This’ll help you accurately adjust your design dimensions.

- Increase the size of your design by the kerf width to compensate for the material that’ll be removed.

- Pay attention to the type and thickness of the material you’re using, as different materials have different kerf widths.

By accounting for the kerf width in your laser-cut designs, you can ensure that the final product matches your intended specifications. Neglecting to include proper ventilation and support structures can lead to issues such as warping or heat damage.

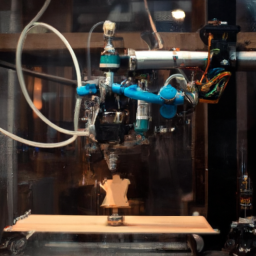

Neglecting to Include Proper Ventilation and Support Structures

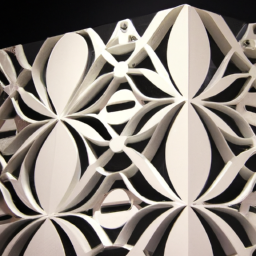

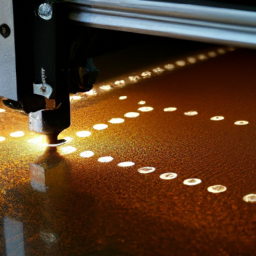

Ensure the success of your laser-cut designs by incorporating proper ventilation and support structures, allowing for optimal airflow and stability in your final product. Neglecting to include these elements can lead to issues such as heat buildup, poor air circulation, and structural weakness. Proper ventilation helps to remove smoke, fumes, and debris generated during the laser cutting process, ensuring a safe working environment. Meanwhile, support structures provide stability to delicate or thin areas of your design, preventing them from warping or breaking during the cutting process. The aesthetics of your laser cut model are also influenced by ventilation and support structures, as they help create clean and precise cuts. Utilizing software specific to laser cutting designs can assist in generating these structures automatically. By considering these factors, you can enhance the overall quality and appearance of your laser cut models. Transitioning into the next section, it is important to avoid overcomplicating your design.

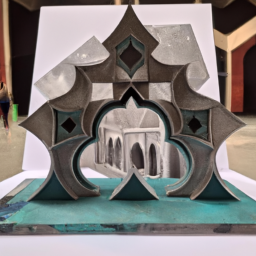

Overcomplicating Your Design

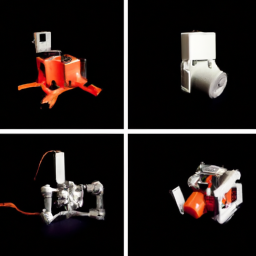

Don’t make the mistake of overcomplicating your laser-cut design, as it can lead to unnecessary challenges and potential issues. When it comes to laser cutting, design simplicity is key. Here are some reasons why you should avoid overcomplicating your design:

- Increased design complexity can result in longer production times and higher costs.

- Overly intricate designs may not be accurately replicated during the laser cutting process, leading to disappointing results.

On the other hand, designing with simplicity in mind offers several benefits:

- Simple designs are easier to execute and require less time and effort to produce.

- They’re more likely to achieve precise and clean cuts, resulting in better quality finished products.

By keeping your laser-cut design simple, you can minimize potential complications and ensure a smoother production process. However, it’s essential to remember that design simplicity doesn’t mean sacrificing creativity and uniqueness. Instead, it involves thoughtful consideration of the laser cutting process’s limitations and capabilities.

In the next section, we’ll discuss the importance of testing your design before final production.

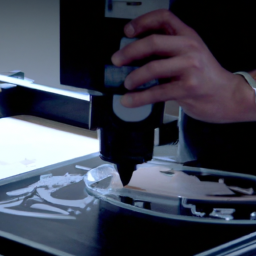

Not Testing Your Design Before Final Production

One important step in the laser-cut design process is to put your design through thorough testing before proceeding with final production. This can help identify any potential issues or challenges.

Not considering safety precautions and underestimating production time are common mistakes to avoid when designing laser cut models. By neglecting safety precautions, you put yourself and others at risk of accidents or injuries. It’s crucial to ensure that your design incorporates proper safety measures, such as adding guards or protective enclosures to prevent accidents.

Additionally, underestimating production time can lead to delays and frustration. It’s essential to allocate enough time for testing and making any necessary adjustments to your design before moving forward with final production. Taking the time to test your design thoroughly will help you produce a safe and efficient laser-cut model.

Frequently Asked Questions

How do I choose the right material for my laser cut design?

When choosing the right material for your laser cut design, there are several factors to consider.

First, think about the thickness and strength required for your project.

Next, consider the material’s compatibility with the laser cutting process. Materials like acrylic, wood, and metal are commonly used for laser cutting due to their versatility and ease of cutting.

Additionally, consider the desired finish and appearance of your design.

Lastly, take into account the cost and availability of the material.

What are the design constraints I should consider when designing for laser cutting?

When designing for laser cutting, there are several important design considerations to keep in mind.

Laser cut design considerations include the thickness and type of material, as well as the intricacy of the design. Precision is crucial in laser cutting to ensure accurate and clean cuts. It is essential to account for the laser beam width and the kerf, or the material that’s removed during cutting.

By paying attention to these factors, you can optimize the quality and efficiency of your laser cut designs.

What is kerf width and why is it important to account for it in laser cut designs?

The kerf width is the amount of material that’s removed during the laser cutting process. It’s important to account for the kerf width in laser cut designs because it can affect the overall dimensions and fit of the final product.

The kerf width measurement is typically provided by the laser cutting machine manufacturer and should be considered when designing parts that need to fit together precisely.

Why is proper ventilation necessary for laser cut models? What are support structures and why should they be included in laser cut designs?

Proper ventilation is crucial for laser cut models to ensure the harmful fumes and gases produced during the cutting process are safely removed. Without adequate ventilation, these substances can pose health risks to operators and damage the laser machine.

Support structures, or tabs, are essential in laser cut designs as they prevent delicate pieces from falling out during the cutting process. They provide stability and ensure accurate and clean cuts, resulting in a high-quality finished product.

How can I simplify my design without compromising its functionality?

To simplify a design without compromising functionality, consider eliminating unnecessary details or features. Focus on the essential elements required for the model’s intended purpose.

Utilize geometric shapes and patterns to streamline the design. Additionally, optimize material usage by minimizing waste and avoiding excessive cuts.

By simplifying complex designs while maintaining functionality, you can create laser cut models that are both efficient and visually appealing.

Conclusion

In conclusion, when designing laser cut models, it’s crucial to avoid common mistakes that can hinder the success of your project.

By carefully selecting the right materials and considering the constraints of laser cutting, you can ensure a smooth and effective manufacturing process.

Accounting for kerf width, incorporating proper ventilation and support structures, and keeping your design simple are also important factors to consider.

Remember the old saying, "Measure twice, cut once," and take the time to thoroughly test your design before final production.

With these tips in mind, you can create laser cut models that are precise, functional, and visually stunning.