Imagine you’re a sculptor, chiseling away at a block of marble, shaping it into a masterpiece. Every stroke of your tool must be deliberate and precise, or else you risk ruining your creation.

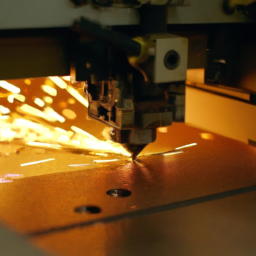

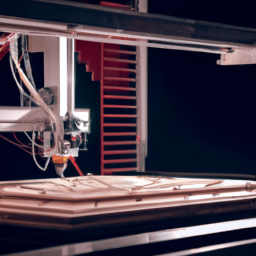

The same principle applies when using a 3D laser cutting machine. This powerful tool can shape and transform various materials with incredible accuracy, but only if you avoid common mistakes that could compromise the quality of your work.

In this article, we will explore five of these mistakes and provide practical tips on how to avoid them. From understanding the machine’s specifications to setting the right cutting parameters, we’ll guide you through the process of using a 3D laser cutting machine effectively.

By following these guidelines, you’ll be able to unleash the full potential of this remarkable technology and create flawless, intricate designs with ease.

Key Takeaways

- Understanding the machine’s specifications and capabilities is crucial

- Proper material preparation and fixturing is essential for accurate results

- Setting the right cutting parameters optimizes efficiency and precision

- Implementing safety precautions reduces the risk of accidents and injuries

Understanding the Machine’s Specifications and Capabilities

You’ll want to make sure you understand the machine’s specifications and capabilities before diving into your 3D laser cutting adventures. Knowing the machine’s limitations can save you from unnecessary frustration and prevent potential damage.

Start by familiarizing yourself with the machine maintenance requirements. Regular cleaning and lubrication are essential to keep the machine running smoothly. Additionally, learn about troubleshooting techniques to quickly address any issues that may arise during operation. Familiarize yourself with common problems and their solutions, such as dealing with misaligned mirrors or adjusting the focal length.

By understanding the machine’s specifications and capabilities, along with proper machine maintenance and troubleshooting techniques, you’ll be well-prepared for a successful 3D laser cutting experience.

Now, let’s move on to discussing proper material preparation and fixturing.

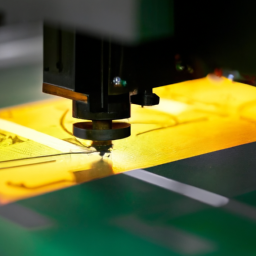

Proper Material Preparation and Fixturing

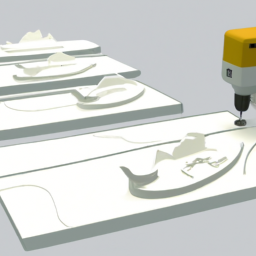

To ensure precise and accurate results, it’s crucial to properly prepare and secure your materials when using a 3D laser cutting machine.

First and foremost, you need to consider the material compatibility with the machine. Not all materials are suitable for laser cutting, so it’s important to consult the machine’s specifications and guidelines to ensure you’re using the appropriate materials.

Additionally, you must pay attention to the precision cutting techniques required for each specific material. This includes adjusting the cutting speed, power, and focus to achieve the desired results.

Proper fixturing is also essential to hold the material securely in place during the cutting process, minimizing any potential movement or vibration.

By taking these steps, you’ll ensure that your materials are well-prepared and properly fixed for the laser cutting process. This will set the stage for the next section on setting the right cutting parameters.

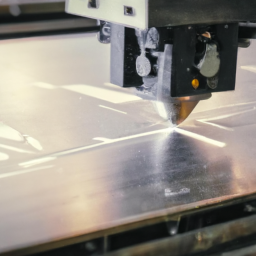

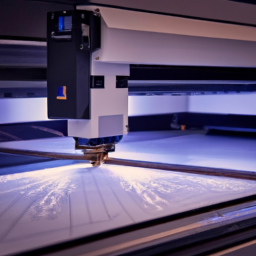

Setting the Right Cutting Parameters

Get ready to dial in the perfect settings for your 3D laser cutting adventure – it’s time to find the sweet spot where your laser beam dances on the material with precision and finesse!

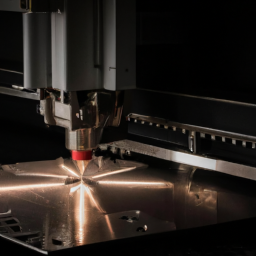

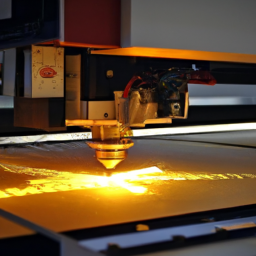

Setting the right cutting parameters is crucial for optimizing efficiency and maximizing precision. Start by considering the thickness and type of material you’re working with. Adjust the power, speed, and focus of the laser beam accordingly to achieve the desired results.

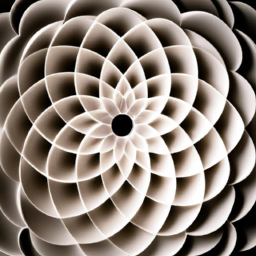

Take into account the desired cutting quality and the intricacy of the design. Fine-tune the settings to strike the perfect balance between speed and accuracy. Remember, finding the optimal cutting parameters may require some trial and error, but the effort will be worth it.

By fine-tuning these settings, you’ll achieve the best possible outcome for your 3D laser cutting projects. Speaking of precision, regular maintenance and cleaning are essential for keeping your machine in top shape and ensuring consistent performance.

Regular Maintenance and Cleaning

Ensure that your 3D laser cutting machine remains in optimal condition by regularly performing maintenance and cleaning procedures. By implementing preventive maintenance, you can avoid costly breakdowns and ensure the longevity of your machine.

Regularly inspect the machine for any signs of wear and tear, such as loose screws or damaged components, and address them promptly. Cleaning the machine regularly is also crucial, as dust and debris can accumulate and affect the cutting quality. Use a soft brush or compressed air to remove any residue from the machine’s interior and exterior.

Additionally, familiarize yourself with troubleshooting techniques in case any issues arise during operation. This will help you quickly identify and resolve problems, minimizing downtime. By following these preventive measures and troubleshooting techniques, you can ensure that your machine operates smoothly and efficiently, avoiding overlapping and overburning.

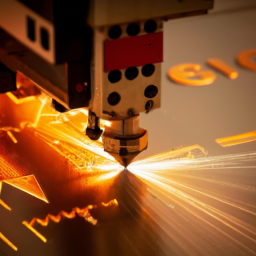

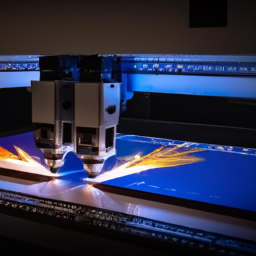

Avoiding Overlapping and Overburning

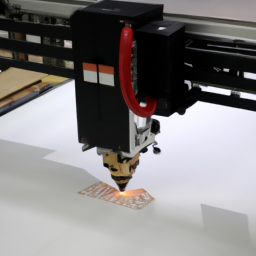

Avoid the frustration of creating tangled webs and burnt edges by carefully aligning your materials and adjusting the cutting settings. Overlapping and overburning can result in distorted designs and wasted materials. To prevent this, ensure that your materials are properly aligned before starting the cutting process. This will help to avoid any unnecessary overlaps and ensure clean, precise cuts.

Additionally, optimizing the cutting settings is crucial in preventing overburning. Adjust the power and speed settings according to the material being used to avoid excessive burning and charring. By taking these preventive measures, you can optimize the efficiency of your 3D laser cutting machine and achieve high-quality results.

Now, let’s move on to discussing the important safety precautions and personal protective equipment (PPE) required when operating the machine.

Safety Precautions and Personal Protective Equipment (PPE)

Stay safe and protect yourself by following the necessary safety precautions and wearing the appropriate personal protective equipment (PPE) when operating the machine. Here are some important measures to consider:

- Have an emergency response plan in place to quickly address any accidents or mishaps that may occur during operation.

- Ensure that the workspace has proper ventilation to minimize the exposure to potentially harmful fumes and gases that may be produced during the cutting process.

- Always wear the recommended PPE, such as safety goggles, gloves, and a dust mask, to protect yourself from any potential hazards.

By implementing these safety precautions and using the appropriate PPE, you can significantly reduce the risk of accidents and injuries while operating the 3D laser cutting machine. Remember, your safety should always be a top priority when working with any machinery.

Frequently Asked Questions

What are the common safety hazards associated with using a 3D laser cutting machine?

To troubleshoot common issues with a 3D laser cutting machine, follow these steps:

- First, ensure that the machine is properly calibrated and aligned.

- Next, check the power supply and connections to make sure they’re secure.

- If the machine isn’t cutting accurately, adjust the cutting speed and power settings accordingly.

- Additionally, clean the lens regularly to maintain optimal precision.

Following these best practices will help optimize the cutting speed and precision of your 3D laser cutting machine.

How often should the machine undergo regular maintenance and cleaning?

Regular maintenance and cleaning are crucial for optimal performance of your 3D laser cutting machine. By ensuring regular upkeep, you can prevent potential issues and maximize the lifespan of your equipment.

To maintain cleanliness and safety in your work area, follow best practices like removing debris, regularly inspecting and lubricating moving parts, and cleaning the lens and mirrors. Adhering to these practices will not only enhance the longevity of your machine but also ensure safer and more efficient operations.

Are there any specific materials that cannot be used with a 3D laser cutting machine?

There are specific material limitations when using a 3D laser cutting machine. Some materials, such as reflective or transparent substances, can pose challenges due to the way the laser interacts with them. In such cases, alternative cutting methods like waterjet or plasma cutting may be more suitable.

It’s important to consult the machine’s user manual and manufacturer recommendations to ensure safe and efficient cutting with compatible materials.

What are the consequences of overlapping and overburning during the cutting process?

When it comes to 3D laser cutting, overlapping and overburning can lead to undesirable consequences.

Overlapping occurs when the laser path traces the same area multiple times, resulting in imprecise cuts and potential damage to the material.

Overburning, on the other hand, causes excessive heat, leading to material distortion and reduced cut quality.

To prevent these issues, ensure proper programming and positioning of the laser, use appropriate power settings, and maintain a consistent cutting speed.

What is the recommended personal protective equipment (PPE) to wear when operating a 3D laser cutting machine?

When operating a 3D laser cutting machine, it’s crucial to prioritize your safety. To ensure protection, it’s recommended to wear personal protective equipment (PPE). This includes safety glasses and gloves. Safety glasses shield your eyes from potential laser radiation or debris, while gloves keep your hands safe from burns or cuts. By wearing these essential PPE items, you can confidently operate the machine, minimizing the risk of injury.

Conclusion

In conclusion, when using a 3D laser cutting machine, it’s crucial to avoid common mistakes to ensure optimal results.

By understanding the machine’s specifications and capabilities, properly preparing materials, and setting the right cutting parameters, you can avoid costly errors.

Performing regular maintenance and following safety precautions are also important steps to take.

Remember, a 3D laser cutting machine is like a skilled surgeon, precise and efficient, but it also requires proper care and attention to deliver exceptional outcomes.

Just as a surgeon’s steady hand can save lives, your attention to detail will create masterful creations with the laser cutting machine.