Are you ready to cut through the challenges of using a laser cutting machine for your paper crafts? Don’t let your creative endeavors go up in smoke! In this article, we will guide you through five common mistakes to avoid when working with a laser cutting machine.

Just like a skilled surgeon wielding a scalpel, you need to master the precision and intricacies of this powerful tool.

First and foremost, understanding the machine’s settings and capabilities is essential. With the right knowledge, you can achieve unparalleled results.

Additionally, proper design and file preparation are crucial to ensure a seamless cutting process. Don’t let a simple oversight ruin your masterpiece.

Moreover, we will delve into the importance of ensuring proper alignment and positioning, as well as choosing the right material and thickness. By making informed decisions, you can avoid costly mistakes and achieve the desired outcome.

Lastly, we will discuss the maintenance and cleaning of the machine to ensure its longevity and optimal performance. Safety precautions and personal protective equipment are also vital to protect yourself and others from potential hazards.

So, let’s dive into the world of laser cutting machines for paper crafts and equip you with the knowledge to create flawless and awe-inspiring masterpieces.

Key Takeaways

- Understanding machine settings and capabilities is crucial to avoid mistakes when using a laser cutting machine for paper crafts.

- Optimizing cutting speed is important to prevent burning or scorching of the paper.

- Proper design and file preparation are essential for efficient cutting and minimizing wastage.

- Ensuring proper alignment and positioning of the material is necessary for accurate cuts.

Understanding the Machine’s Settings and Capabilities

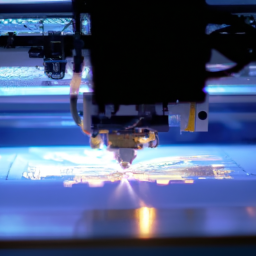

You need to familiarize yourself with the laser cutting machine’s settings and capabilities so that you can confidently navigate its various options and unleash your creativity with precision and ease. Understanding the machine’s settings is crucial for effective troubleshooting in case of any issues that may arise during the cutting process.

Additionally, optimizing cutting speed is essential to ensure efficient and accurate results. By adjusting the cutting speed according to the thickness and type of paper, you can prevent burning or scorching of the material.

Moreover, being aware of the machine’s capabilities allows you to explore different cutting techniques and experiment with intricate designs. Properly understanding and utilizing the machine’s settings and capabilities will set the foundation for successful paper crafts.

Moving forward, it’s equally important to focus on proper design and file preparation to further enhance your laser cutting experience.

Proper Design and File Preparation

To ensure successful outcomes with your paper crafts, it is crucial to properly design and prepare your files before utilizing a laser cutting device. Proper file organization and optimizing cutting paths are essential for a smooth and efficient cutting process. When designing your files, it is important to keep in mind the size and shape of your paper crafts, as well as any intricate details or patterns. Organizing your files in a logical and systematic manner will help you easily locate and access them when needed. Additionally, optimizing the cutting paths will minimize the time and effort required for the laser cutting machine to complete the task. By arranging the cutting paths efficiently, you can reduce material wastage and increase the precision of your cuts. Ensuring proper alignment and positioning of your paper crafts will be discussed in the next section, which will further enhance the quality of your laser-cut paper crafts.

Ensuring Proper Alignment and Positioning

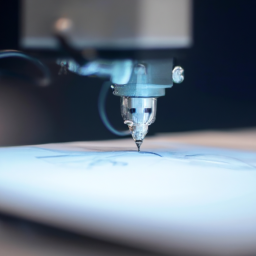

When using a laser cutting machine for paper crafts, it’s crucial to ensure proper alignment and positioning. You can achieve this by using registration marks or alignment tools to accurately place your material.

Double-check the material’s position before cutting to avoid any mistakes or misalignment. Additionally, secure the material properly to prevent shifting during the cutting process, ensuring precise and accurate results.

Using Registration Marks or Alignment Tools

Don’t forget to utilize registration marks or alignment tools to ensure precise cuts when using a laser cutting machine for paper crafts!

Registration marks offer several benefits, such as ensuring accurate alignment and maintaining consistency throughout the cutting process. By incorporating registration marks into your design, you can easily align your paper with the laser cutting machine, resulting in clean and precise cuts.

Additionally, alignment tools, such as rulers or guides, can help you position your paper correctly and maintain its position throughout the cutting process. These tools provide stability and prevent any unwanted movements that could affect the accuracy of your cuts.

Once you have utilized registration marks and alignment tools, you can confidently move on to the next step of double-checking the material’s position.

Double-checking the Material’s Position

Make sure you’ve got your paper in the perfect position before proceeding any further, otherwise your cuts may end up as crooked as a winding river. Achieving accurate positioning is crucial to ensure clean and precise cuts when using a laser cutting machine for paper crafts. The positioning accuracy of the material plays a significant role in the quality of the final product.

Take the time to align the paper correctly within the machine, using registration marks or alignment tools if necessary. This will optimize cutting speed and minimize any potential errors or mistakes. Once you have double-checked the material’s position, you can move on to securing it to prevent shifting during the cutting process.

This will be discussed in the subsequent section.

Securing the Material to Prevent Shifting

To ensure your paper stays in place during the cutting process, it’s essential to secure it properly. Here are some tips to prevent material warping and shifting:

-

Use adhesive spray: Applying a light coat of adhesive spray on the back of your paper can provide a better hold and prevent it from moving during cutting.

-

Position the paper correctly: Make sure the paper is aligned properly on the cutting bed. Align it with the machine’s guides or use registration marks to ensure accurate positioning.

By following these steps, you can minimize the risk of your paper shifting or warping during the cutting process. This will help you achieve precise and clean cuts.

Now, let’s move on to the next section about choosing the right material and thickness.

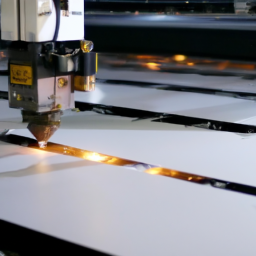

Choosing the Right Material and Thickness

Ensure you select the appropriate material and thickness, as it’s crucial when using a laser cutting machine for paper crafts. When choosing alternative materials, keep in mind that not all types of paper are suitable for laser cutting. Thin materials like regular printer paper may burn easily, while thick cardstock may be difficult to cut through. It’s essential to experiment with different thicknesses to find the right balance between cutting ability and material stability. Thicker materials may require slower cutting speeds and higher power settings.

Additionally, consider the type of paper, such as textured or coated paper, as it may affect the cutting quality. By carefully selecting the material and thickness, you can ensure precise and clean cuts in your paper crafts.

Moving on to the next section about maintaining and cleaning the machine, it’s equally important to keep your laser cutting machine in proper working condition for optimal results.

Maintaining and Cleaning the Machine

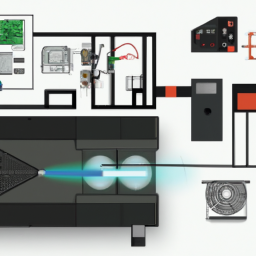

To ensure optimal performance and longevity of your laser cutting machine, it’s crucial to regularly clean the lens and mirrors. Use a soft, lint-free cloth and a mild cleaning solution to gently remove any dust or debris.

Additionally, lubricating the moving parts will help reduce friction and maintain smooth operation. Be sure to use a lubricant recommended by the manufacturer and follow their guidelines.

Lastly, regularly check and replace worn-out parts such as belts, bearings, and motors to avoid any potential disruptions in the machine’s functionality.

Regularly Cleaning the Lens and Mirrors

Regularly cleaning the lens and mirrors is crucial for maintaining optimal performance and avoiding potential issues when using a laser cutting machine for paper crafts. The lens and mirrors are essential components of the machine that directly affect the quality and precision of the laser beam.

To ensure effective cleaning, start by using lens cleaning techniques recommended by the manufacturer. Avoid using harsh chemicals or abrasive materials that could damage the lens or mirrors. Additionally, preventing lens fogging is important to maintain clear visibility and prevent damage to the lens.

Regularly inspect the lens and mirrors for any smudges, dust, or debris, and clean them using a soft, lint-free cloth or lens cleaning solution. By regularly cleaning the lens and mirrors, you can ensure optimal performance and minimize the risk of any potential issues.

Moving on to the next section, lubricating the moving parts is another important maintenance task to keep your laser cutting machine in top shape.

Lubricating Moving Parts

Keeping the moving parts well-lubricated is essential for ensuring smooth operation and prolonging the lifespan of your laser cutter. Proper lubrication reduces friction, prevents wear and tear, and enhances overall performance.

Here are three crucial reasons why you should prioritize lubricating the moving parts of your laser cutting machine:

-

Improved Cutting Precision: Lubrication reduces the chances of jerky movements, ensuring precise laser cutting techniques and delivering accurate results.

-

Minimized Noise and Vibration: Well-lubricated parts reduce noise and vibration, creating a quieter and more stable working environment.

-

Enhanced Machine Durability: By reducing friction, lubrication minimizes the risk of parts getting stuck or damaged, ultimately prolonging the lifespan of your laser cutter.

Once you’ve mastered the art of lubricating, it’s time to move on to the next section about checking and replacing worn-out parts to maintain optimal performance.

Checking and Replacing Worn-out Parts

When checking and replacing worn-out parts, you’ll need to be aware that approximately 40% of laser cutter issues are caused by worn belts and pulleys. These components play a crucial role in the machine’s movement and precision. Regularly inspecting and replacing them is essential for maintaining optimal performance. To help you keep track of the condition of these parts, refer to the table below:

| Component | Signs of Wear | Replacement Interval |

|---|---|---|

| Belts | Fraying | Every 6-12 months |

| Pulleys | Cracks or chips | Every 12-18 months |

| Bearings | Grinding noises | Every 12-18 months |

By following these guidelines, you can ensure that your laser cutting machine operates smoothly and accurately. Now, let’s move on to discussing safety precautions and personal protective equipment to further enhance your experience with the machine.

Safety Precautions and Personal Protective Equipment

To ensure your safety while using a laser cutting machine for paper crafts, it’s essential to wear the appropriate personal protective equipment, such as safety goggles and gloves. These items will protect your eyes from potential laser beams and your hands from any sharp edges or hot surfaces.

Additionally, there are other safety precautions you should follow. Proper ventilation is crucial when using a laser cutting machine. Make sure the area is well-ventilated to prevent the accumulation of harmful fumes and smoke. This can be achieved by using an exhaust system or opening windows and doors.

Another important aspect is the proper handling and disposal of laser cut paper waste. Dispose of the waste material in a designated container or trash bag to prevent accidents or fire hazards. Avoid leaving the waste lying around, as it can easily catch fire due to its flammability.

By following these safety precautions and using the necessary personal protective equipment, you can safely operate a laser cutting machine for paper crafts.

Frequently Asked Questions

How do I fix alignment issues when using a laser cutting machine for paper crafts?

To troubleshoot alignment issues when using a laser cutting machine for paper crafts, follow these tips for achieving precise cuts.

First, make sure the paper is properly aligned on the cutting bed. Ensure it is flat and straight.

Check the laser beam alignment with the cutting path to guarantee accuracy.

Adjust the settings to the appropriate speed and power levels for the paper thickness.

Regularly clean the laser lens to prevent any obstructions.

Lastly, calibrate the machine regularly to maintain optimal performance.

Can I use a laser cutting machine for materials other than paper?

Of course, why limit yourself to just paper when you have a laser cutting machine? You can explore a whole new world of possibilities with its precision and versatility. Whether you’re working with wood or fabric, a laser cutting machine can effortlessly create intricate designs and precise cuts. Just remember to adjust the settings accordingly for different materials, ensuring optimal results. So go ahead, let your creativity soar beyond the confines of paper.

What are the most common mistakes people make when designing files for laser cutting machines?

When designing files for laser cutting machines, it’s important to avoid common design errors that can affect the performance of the machine. To optimize the laser cutting machine’s performance, there are a few tips you should keep in mind.

First, ensure that your design is in the correct file format and properly scaled.

Additionally, pay attention to the line thickness and make sure it’s suitable for the material you’re using.

Lastly, avoid overlapping lines and use proper nesting techniques to maximize material usage.

How often should I clean and maintain my laser cutting machine for optimal performance?

To ensure optimal performance, it’s imperative that you diligently clean and maintain your laser cutting machine. Regular maintenance and cleaning are crucial for the machine’s longevity. Troubleshooting common performance issues involves promptly identifying and addressing any mechanical or electrical faults. This includes regularly inspecting and cleaning the lens, mirrors, and ventilation system. Additionally, regularly lubricating moving parts and ensuring proper alignment will contribute to the machine’s overall efficiency and effectiveness.

What type of personal protective equipment should I wear when operating a laser cutting machine for paper crafts?

When operating a laser cutting machine for paper crafts, it’s crucial to wear the proper personal protective equipment (PPE) to ensure your safety. This includes safety goggles to protect your eyes from laser radiation and flying debris. It’s also important to wear gloves to prevent burns. Additionally, it’s important to choose the right laser cutting machine for paper crafts and ensure proper ventilation requirements are met to maintain a safe working environment.

Conclusion

In conclusion, by avoiding these common mistakes when using a laser cutting machine for paper crafts, you can ensure precise and efficient results. Remember to thoroughly understand the machine’s settings and capabilities and properly prepare your designs and files.

Align and position your materials correctly, choose the appropriate material and thickness, and regularly maintain and clean the machine.

Additionally, always prioritize safety by following precautions and wearing personal protective equipment. With these precautions in mind, you’ll be able to create stunning paper crafts with ease and precision.