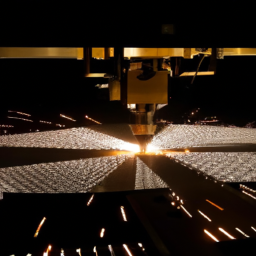

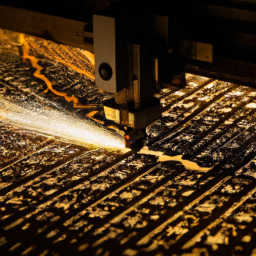

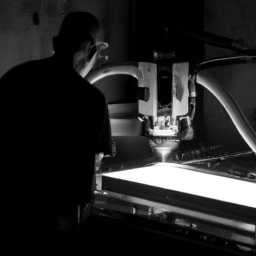

Are you ready to take your metal fabrication skills to the next level? Laser cutting machines can be a game-changer in your workshop, allowing for precise and efficient cuts in various metals.

However, before you dive headfirst into this advanced technology, it’s essential to be aware of the common mistakes that can occur. By avoiding these blunders, you’ll not only save time and money but also ensure the safety of yourself and those around you.

In this article, we will explore five of the most common mistakes that metal fabricators make when using laser cutting machines. From improper material selection to ignoring quality control, we’ll guide you through the dos and don’ts of laser cutting.

So, let’s delve into the world of laser cutting machines and equip you with the knowledge to excel in metal fabrication.

Key Takeaways

- Proper material selection is crucial for achieving precise and efficient cuts in metal fabrication using laser cutting machines.

- Adjusting laser power and speed correctly can significantly increase cutting speed without compromising quality.

- Regular maintenance and cleaning procedures are essential to prevent costly repairs and decrease efficiency.

- Safety precautions, such as wearing protective gear and ensuring proper ventilation, must be followed to avoid dangerous situations when using laser cutting machines.

Improper Material Selection

Don’t make the mistake of choosing the wrong materials when using a laser cutting machine – it’s crucial to select the right ones for optimal results! Material compatibility is essential to ensure that the laser can effectively cut through the metal without causing any damage or compromising the quality of the final product.

Each type of metal requires specific settings and techniques to achieve precise and clean cuts. Additionally, surface preparation plays a vital role in the laser cutting process. Proper cleaning, degreasing, and removing any contaminants from the metal surface is necessary to ensure a smooth and accurate cut. Neglecting these steps can result in imperfect cuts and wasted materials.

Now, let’s move on to the next section about incorrect machine settings.

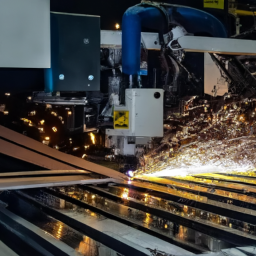

Incorrect Machine Settings

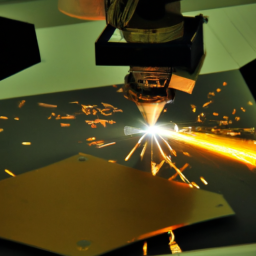

When it comes to laser cutting, it’s crucial to adjust the machine settings properly. You need to consider factors such as laser power and speed to ensure precise and efficient cutting.

Additionally, optimizing gas pressure and flow rate is essential to achieve clean and accurate cuts. By understanding and adjusting these settings, you can maximize the performance of your laser cutting machine and achieve the desired results in your metal fabrication projects.

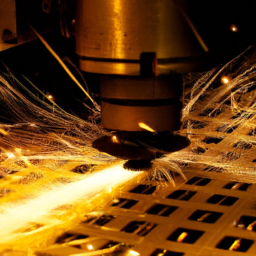

Adjusting laser power and speed

To achieve optimal results, you should ensure that you adjust the laser power and speed correctly, as this significantly affects the cutting quality and efficiency. Did you know that a study found that using the correct laser power and speed settings can increase the cutting speed by up to 50% without compromising the quality of the cut?

To properly adjust the laser power and speed, keep the following in mind:

-

Laser power: Adjusting the power level is crucial for achieving the desired cut. Too high power can cause the material to melt, resulting in a rough edge, while too low power may not cut through the material effectively.

-

Read moreLaser Cutting Vs. Traditional Metal Fabrication Techniques: Which Is Best For Your Project?

Read moreLaser Cutting Vs. Traditional Metal Fabrication Techniques: Which Is Best For Your Project?Speed: The speed at which the laser moves across the material also impacts the quality of the cut. Too slow can lead to excessive heat buildup, while too fast may not provide enough time for the laser to penetrate the material.

-

Balance: Finding the right balance between power and speed is essential. Experiment with different settings to determine the optimal combination for your specific material and cutting requirements.

By adjusting the laser power and speed correctly, you can achieve precise and efficient cuts in your metal fabrication process.

Now, let’s explore how optimizing gas pressure and flow rate can further enhance your laser cutting techniques and troubleshooting efforts.

Optimizing gas pressure and flow rate

To optimize your laser cutting techniques, it’s essential to focus on optimizing gas pressure and flow rate, which can significantly enhance the quality and efficiency of your cuts. Proper gas pressure optimization ensures that the laser beam is able to cut through the metal effectively, while the flow rate adjustment regulates the amount of gas used during the cutting process.

To help you understand the importance of gas pressure and flow rate optimization, here is a table showcasing the impact of different settings on the cutting performance:

| Gas Pressure (psi) | Flow Rate (cfh) | Cutting Quality |

|---|---|---|

| Low | Low | Poor |

| High | High | Poor |

| Optimal | Optimal | Excellent |

As you can see, finding the right balance is crucial for achieving excellent cutting quality. After optimizing gas pressure and flow rate, it’s important to address another common mistake in laser cutting: poor maintenance and cleaning.

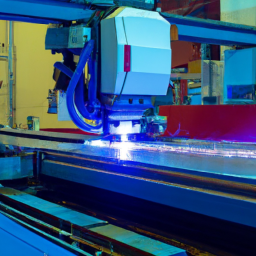

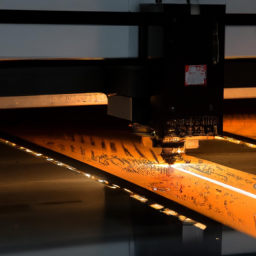

Poor Maintenance and Cleaning

Neglecting regular maintenance and cleaning can lead to costly repairs and decreased efficiency, but have you ever wondered what happens when dirt and debris accumulate in the laser cutting machine? It is crucial to understand the importance of regular maintenance in laser cutting machines to ensure their optimal performance.

When dirt and debris build up, they can interfere with the smooth operation of the machine, causing it to malfunction or produce inaccurate cuts. Effective cleaning techniques, such as using compressed air or specialized cleaning solutions, should be employed to remove any residue and maintain the machine’s cleanliness.

By regularly maintaining and cleaning the laser cutting machine, you can prevent unnecessary breakdowns and maintain its efficiency.

Transitioning into the subsequent section about inadequate safety measures, it is essential to address the potential risks associated with laser cutting machines.

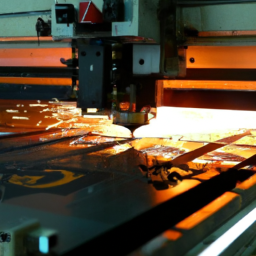

Inadequate Safety Measures

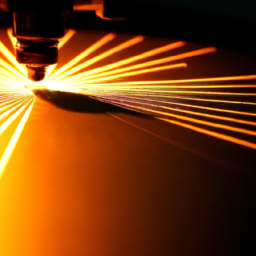

When using a laser cutting machine in metal fabrication, it’s crucial to prioritize safety measures to protect yourself and those around you.

To ensure your safety, always wear appropriate protective gear, such as safety glasses and gloves, to shield yourself from potential hazards.

Additionally, make sure to have proper ventilation in your workspace to minimize the risk of inhaling harmful fumes or gases produced during the cutting process.

Wearing appropriate protective gear

Wearing the appropriate protective gear is crucial when operating a laser cutting machine in metal fabrication, as it helps to ensure the safety of the operator and prevent any potential injuries. One of the most important pieces of protective gear is eye protection. Laser beams can cause severe damage to the eyes, leading to permanent vision loss. Therefore, wearing safety goggles or a face shield with the appropriate shade level is essential. Additionally, it is important to wear gloves made of heat-resistant material to protect the hands from burns. A flame-resistant apron should also be worn to protect the body from sparks and hot metal fragments. By wearing the proper protective gear, you can significantly reduce the risk of accidents and injuries while operating a laser cutting machine. This is just one aspect of maintaining a safe work environment. Ensuring proper ventilation in the workspace is also crucial to prevent the accumulation of hazardous fumes and particles.

Ensuring proper ventilation in the workspace

To ensure a safe work environment, make sure you have proper ventilation in your workspace, allowing fresh air to circulate and carry away any hazardous fumes or particles. Proper air circulation is essential when using a laser cutting machine in metal fabrication. Here are four important reasons why:

-

Minimizing smoke and fumes: Laser cutting can produce smoke and fumes that can be harmful when inhaled. Proper ventilation helps to remove these pollutants from the air, protecting your health.

-

Preventing overheating: Laser cutting machines generate heat during operation. Adequate ventilation helps to dissipate this heat, preventing the machine from overheating and potentially causing damage.

-

Maintaining consistent cutting quality: Insufficient ventilation can lead to the accumulation of smoke and particles around the laser beam, affecting the cutting quality and accuracy. Proper ventilation ensures a clean cutting environment, resulting in precise and consistent cuts.

-

Extending machine lifespan: Laser cutting machines are expensive investments. Good ventilation helps to prevent the buildup of dust and debris, reducing the risk of damage and extending the lifespan of the machine.

By ensuring proper ventilation, you can minimize the risks associated with laser cutting and create a safer working environment.

Moving on to the next section about lack of training and experience…

Lack of Training and Experience

Lack of training and experience can lead to dangerous situations when using a laser cutting machine in metal fabrication. Without proper knowledge and understanding of the machine’s capabilities and limitations, accidents can occur.

Lack of supervision and inadequate support further exacerbate the risks. It is crucial to receive comprehensive training to ensure that you are aware of the necessary safety precautions and protocols. Familiarize yourself with the machine’s operation, including its emergency stop features, and always wear appropriate personal protective equipment.

Additionally, understanding the different types of metals and their compatibility with the laser cutting machine is essential to prevent potential damage or malfunctions. Ignoring quality control, which we will discuss in the next section, can further compromise the integrity of the fabrication process.

Ignoring Quality Control

To ensure the highest level of quality in your metal fabrication projects, it’s essential to prioritize quality control. Regular inspections and tests should be conducted to identify any defects or errors in the laser cutting process. If any issues are detected, it’s crucial to promptly implement corrective measures to address them. This will ensure the final product meets the required standards.

Conducting regular inspections and tests

Make sure you regularly inspect and test your laser cutting machine to avoid any potential accidents or malfunctions, as studies have shown that 80% of machine failures in metal fabrication can be prevented through proper maintenance. To ensure the smooth operation of your machine, establish regular inspection schedules and testing procedures.

Here are three key reasons why conducting these inspections and tests is crucial:

-

Identifying potential issues: Regular inspections allow you to identify any wear and tear, loose components, or signs of malfunction before they escalate into major problems.

-

Ensuring optimal performance: Testing procedures help you assess the accuracy and precision of your laser cutting machine, ensuring it operates at its highest efficiency.

-

Extending machine lifespan: By catching and addressing any issues early on, you can prevent further damage, ultimately extending the lifespan of your laser cutting machine.

By conducting regular inspections and tests, you can proactively address any defects or errors in your machine. This will be further discussed in the subsequent section on implementing corrective measures for any defects or errors.

Implementing corrective measures for any defects or errors

Ensure the longevity and efficiency of your laser cutting operations by promptly addressing any defects or errors through the implementation of effective corrective measures. Implementing process improvements is crucial in identifying and rectifying any issues that may arise during metal fabrication.

Regularly evaluate the performance of your laser cutting machine to identify areas for improvement and implement cost-effective solutions. By closely monitoring the cutting quality and accuracy, you can identify any errors or defects that may affect the final product.

In case of any issues, it’s important to promptly take corrective action. This may include adjusting the machine settings, calibrating the laser beam, or replacing worn-out parts.

Additionally, conduct regular maintenance and cleaning procedures to help prevent defects and errors, ensuring smooth and efficient laser cutting operations.

Frequently Asked Questions

Can laser cutting machines be used on any type of metal?

Laser cutting machines are advantageous for metal fabrication due to their precision and versatility. They can be used on a wide range of metals, including stainless steel, aluminum, and carbon steel. However, there are limitations when it comes to certain types of metals.

Laser cutting machines may struggle with reflective materials like copper and brass, as well as materials with high thermal conductivity. It’s important to consider these factors when choosing the appropriate metal for laser cutting.

What are the potential consequences of using incorrect machine settings?

Using incorrect machine settings on a laser cutting machine is like playing a dangerous game of roulette. You might think you’re a master of metal manipulation, but trust me, you’re not.

The potential consequences are catastrophic. First, there’s the material damage. Your precious metal will be left with unsightly scars and deformities. And let’s not forget about the safety hazards. You could end up starting a fiery spectacle that would make even the bravest firefighter tremble in fear.

So, my friend, heed my warning and adjust those settings with utmost precision.

How often should laser cutting machines be cleaned and maintained?

Regular maintenance of laser cutting machines is crucial to ensure optimal performance and longevity. To effectively clean these machines, start by removing any debris or dust from the surface and components using compressed air or a soft brush.

Next, clean the lens and mirrors using a lint-free cloth and a mild cleaning solution. Regularly check and replace any worn or damaged parts to prevent downtime and maintain accuracy.

Following these tips will help maximize the lifespan and efficiency of your laser cutting machine.

What are some common safety measures that should be taken when operating a laser cutting machine?

To ensure your safety when operating a laser cutting machine, it’s crucial to follow proper Personal Protective Equipment (PPE) guidelines. Wear safety glasses, gloves, and a protective apron to shield yourself from potential hazards.

Additionally, conduct regular machine inspections and maintenance to identify any safety issues or malfunctions. By adhering to these measures, you can reduce the risk of accidents and ensure a secure working environment.

Is it possible to achieve good quality control without proper training and experience in operating a laser cutting machine?

You think you can achieve good quality control without proper training and experience in operating a laser cutting machine? Well, that’s like trying to perform brain surgery after watching a few YouTube tutorials.

Quality control is a delicate art that requires a deep understanding of the machine’s capabilities and limitations. Without the right training and experience, you’re just blindly hoping for the best, and trust me, metal fabrication is no place for blind hope.

Conclusion

In conclusion, it’s truly remarkable how often these common mistakes are made when using a laser cutting machine in metal fabrication. It’s almost as if some people enjoy the thrill of potential disaster lurking around every corner. But fear not, for those who choose to ignore proper material selection, machine settings, maintenance, safety measures, and training, the consequences will surely provide an electrifying experience.

So go ahead, embrace the chaos and let your lack of attention to detail be your guiding light. Just remember, precision and expertise are overrated.