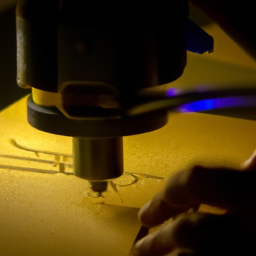

Have you ever marveled at the precision and intricacy of laser-cut wood designs?

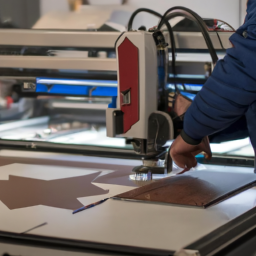

Laser cutting machines have revolutionized the woodworking industry, allowing craftsmen to create stunning pieces with unparalleled accuracy. However, even the most experienced woodworkers can make common mistakes when using these machines.

To ensure that your woodworking projects are a success, it is crucial to understand the machine’s settings and capabilities, properly prepare your materials, consider design elements, prioritize safety precautions, and maintain and monitor the machine regularly.

By avoiding these common pitfalls, you can maximize the potential of your laser cutting machine and achieve flawless results every time.

In this article, we will explore these five common mistakes in detail, providing you with the knowledge and expertise to overcome them and elevate your woodworking skills to new heights.

Key Takeaways

- Understand the machine’s settings and capabilities to ensure accurate cuts.

- Properly prepare materials to prevent hazards and complications.

- Consider design factors such as creating vector files and adding kerf compensation.

- Follow safety precautions, maintain a clear workspace, and regularly monitor and maintain the machine for optimal performance and safety.

Understanding the Machine’s Settings and Capabilities

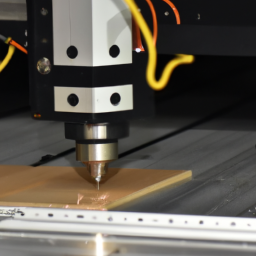

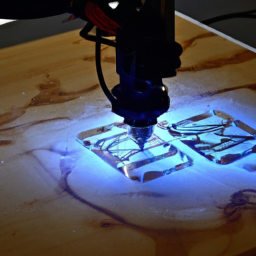

Make sure you understand the laser cutting machine’s settings and capabilities so you can avoid any potential mistakes while using it in your woodworking projects. Proper machine calibration is crucial to ensure accurate cuts and prevent any errors.

Take the time to calibrate the machine before starting your project, as this will save you from costly mistakes later on. Additionally, optimizing cutting speed is essential for achieving clean and precise cuts. Adjust the speed according to the type of material you’re working with to avoid burning or charring.

Understanding the machine’s capabilities in terms of speed and power will help you achieve the desired results.

Now, let’s move on to the next section about proper material preparation.

Proper Material Preparation

Before operating a laser cutter in woodworking, it’s crucial to ensure that the materials are adequately prepared to prevent any potential hazards or complications. Proper material preparation involves two key aspects: material selection and surface preparation.

When it comes to material selection, it’s essential to choose materials that are suitable for laser cutting. Certain materials, such as PVC or vinyl, can release toxic fumes when cut with a laser, posing health risks. Additionally, materials with reflective surfaces, like metals, can cause the laser beam to bounce back and potentially damage the machine or pose a safety risk. Therefore, it’s important to carefully consider the materials before using them in the laser cutting process.

In terms of surface preparation, it’s crucial to ensure that the materials are clean and free from any debris or contaminants. Dust, dirt, or oils on the material’s surface can interfere with the laser cutting process and result in uneven or incomplete cuts. By properly preparing the materials, you can ensure optimal cutting results and prolong the lifespan of your laser cutting machine.

Next, we will discuss design considerations to keep in mind when operating a laser cutting machine in woodworking, which will further enhance your cutting outcomes.

Design Considerations

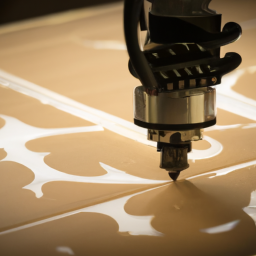

When designing for laser cutting, it’s essential to create vector files that are compatible with the machine. Pay close attention to the design scale and proportions to ensure accurate cuts and avoid any distortions.

Additionally, remember to add kerf compensation to account for the material that’ll be burned away during the cutting process, ensuring precise and clean cuts.

Creating Vector Files for Laser Cutting

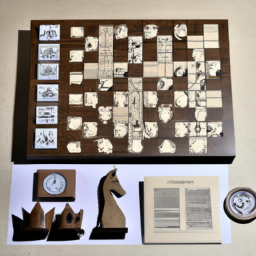

Creating vector files for laser cutting is an essential step in unleashing the full potential of your woodworking projects, allowing you to bring precision and intricacy to life with every cut. When it comes to laser cutting techniques, using the right software is crucial. Laser cutting software such as Adobe Illustrator or CorelDRAW can help you create vector files that define the paths for the laser to follow. These software programs offer a wide range of tools and features to ensure accurate and efficient cutting. In addition to the software, it’s important to pay attention to design scale and proportions. This ensures that your final product turns out exactly as you envision it. By carefully considering design scale and proportions, you can avoid any potential issues and achieve the desired result.

Now, let’s move on to the next section about paying attention to design scale and proportions.

Paying Attention to Design Scale and Proportions

To achieve the perfect results, make sure you pay close attention to the scale and proportions of your design. This is crucial in laser cutting because any inaccuracies can result in a flawed final product. Here are four important things to consider when it comes to design scale and proportions:

-

Design inspiration: Start by gathering design inspiration from various sources such as magazines, websites, or even nature itself. This will help you visualize the desired end product and guide your design choices.

-

Choosing suitable wood types: Different wood types have varying densities and cutting characteristics. Selecting the right wood for your design is essential to ensure clean and precise cuts.

-

Scale experimentation: Before finalizing your design, it’s important to experiment with different scales. This will help you determine the optimal size and proportions for your project.

-

Testing and refining: Once you have a design in mind, it’s crucial to test it on a small scale before proceeding to the actual cutting. This allows you to make any necessary adjustments and ensure a flawless end result.

When considering these factors, you can now move on to the next section about adding kerf compensation for accurate cuts.

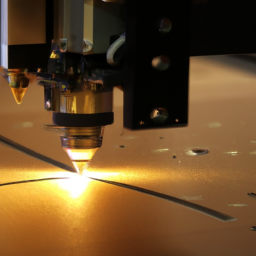

Adding Kerf Compensation for Accurate Cuts

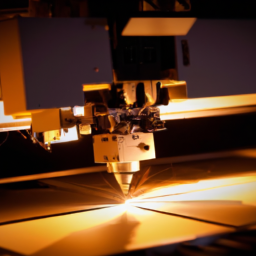

Make sure you add kerf compensation to your design for precise and accurate cuts that will result in a flawless final product. Kerf width refers to the material that is removed during the cutting process, and it can vary depending on the type of material and the laser cutting machine being used. By incorporating kerf compensation into your design, you can account for this width and ensure that your cuts are exactly where they need to be. This is especially important when working with intricate designs or when precise measurements are required. Without kerf compensation, your cuts may not be accurate, leading to a flawed end result. So take the time to adjust your design and account for the kerf width to achieve cutting accuracy. Now, let’s move on to discussing important safety precautions to keep in mind when operating a laser cutting machine.

Safety Precautions

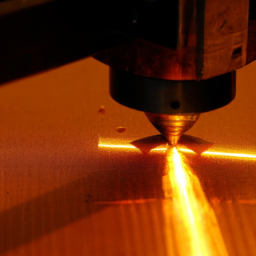

One important aspect of using a laser cutting machine in woodworking is ensuring you’re following all necessary safety precautions. To protect yourself from potential hazards, make sure to always wear the appropriate safety gear, such as safety glasses and gloves. Familiarize yourself with the location of the emergency shut off button in case of any emergencies.

Additionally, keep a clear workspace and remove any flammable materials to prevent fires. Regularly inspect the laser cutting machine for any signs of damage or malfunction, and perform routine maintenance to ensure its optimal performance. By adhering to these safety precautions, you can minimize the risk of accidents and ensure a safe working environment.

Moving on to monitoring and maintenance, it’s important to…

Monitoring and Maintenance

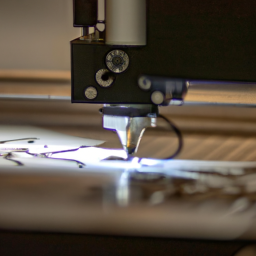

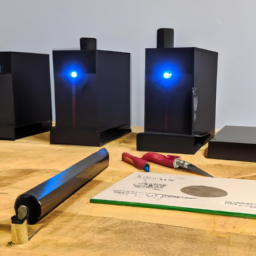

To ensure the optimal performance of your laser cutting machine, it’s important to regularly check for dust and debris build-up. This accumulation can not only affect the accuracy of the cuts but also pose a fire hazard.

Cleaning and replacing the lens as needed is also crucial, as a dirty or damaged lens can result in poor cutting quality.

Additionally, performing routine maintenance, such as lubricating moving parts and checking for any loose connections, will help keep your machine in optimal condition and extend its lifespan.

Regularly Checking the Machine for Dust and Debris Build-up

Checking the machine for dust and debris build-up is crucial, as neglecting this could result in a catastrophic explosion of epic proportions. Regularly inspecting the laser cutting machine ensures that it’s operating at its optimal level. Start by checking the machine calibration to ensure precise cutting and prevent any misalignment.

Dust and debris can accumulate inside the machine, causing smoke and unpleasant odors during operation. By regularly cleaning out the dust and debris, you can prevent these issues and maintain a safe working environment. Additionally, it’s important to check the lens for any dirt or damage. Cleaning and replacing the lens as needed will ensure clear and accurate cutting.

Moving forward to the next section, proper maintenance also involves regular inspection of the machine’s ventilation system.

Cleaning and Replacing the Lens as Needed

Make sure you clean and replace the lens as needed to ensure clear and accurate cutting with your laser cutter. Cleaning techniques for the lens include using a soft cloth or brush to remove dust and debris. Be careful not to scratch the lens surface. Additionally, you can use a specialized lens cleaning solution to remove smudges or fingerprints.

When replacing the lens, refer to the lens replacement guide provided by the manufacturer. Follow the instructions carefully to ensure proper installation and alignment. Neglecting to clean and replace the lens can result in reduced cutting quality and potential damage to the machine.

By maintaining a clean lens, you can ensure optimal performance and prolong the lifespan of your laser cutting machine.

Moving on to performing routine maintenance to keep the machine in optimal condition…

Performing Routine Maintenance to Keep the Machine in Optimal Condition

Maintaining a regular maintenance schedule is crucial for ensuring the longevity and optimal performance of your laser cutter. By performing regular inspections, you can identify any potential issues before they become major problems.

Check the machine for loose or damaged parts, and tighten or replace them as needed. Additionally, clean the machine regularly to prevent dust and debris from interfering with its operation.

It’s also important to schedule professional maintenance at least once a year to ensure that the machine is thoroughly cleaned and calibrated. Following these maintenance practices will help keep your laser cutter in optimal condition and prevent costly repairs.

Now, let’s move on to troubleshooting common issues that may arise while using a laser cutting machine.

Troubleshooting Common Issues

When faced with common issues, it’s crucial to remember that troubleshooting a laser cutting machine in woodworking can be like untangling a stubborn knot, testing your patience and problem-solving skills.

To optimize cutting speed and power, start by checking the alignment of the laser beam. If it’s misaligned, adjust it accordingly to ensure precise cuts.

Another common issue is the machine not cutting through the material completely. In this case, the power settings might need to be adjusted. Increase the power gradually until the desired cutting depth is achieved.

Additionally, if the machine is cutting slower than usual, check the lens for debris or damage. Cleaning or replacing the lens can significantly improve cutting speed.

Remember, troubleshooting requires a keen eye for detail and a systematic approach to problem-solving.

Frequently Asked Questions

Can a laser cutting machine be used on materials other than wood?

Yes, a laser cutting machine can be used on materials other than wood. There are many other materials suitable for laser cutting, such as acrylic, leather, paper, fabric, and even certain metals. However, it’s important to take precautions when using a laser cutting machine on different materials. Different materials require different settings and techniques, so it’s essential to consult the machine’s manual and adjust the parameters accordingly to ensure accurate and safe cutting.

How often should I clean and maintain the laser cutting machine?

Regular maintenance of your laser cutting machine is crucial to ensure its optimal performance and longevity. To keep your equipment in top shape, follow these tips for effective cleaning and upkeep.

Firstly, clean the machine regularly to remove dust and debris that can affect its functionality.

Additionally, lubricate moving parts to prevent friction and wear.

Lastly, inspect and replace any worn-out components promptly.

By prioritizing regular maintenance, you can maximize the efficiency and lifespan of your laser cutting machine.

What safety gear should I wear when operating a laser cutting machine?

When operating a laser cutting machine, wearing the proper safety gear is of utmost importance. It not only protects you from potential hazards but also ensures a safe working environment.

Some essential safety gear includes safety glasses to shield your eyes from laser radiation, a face shield to protect your face and neck, and gloves to prevent burns or cuts.

Additionally, wearing closed-toe shoes and a long-sleeved shirt is recommended for added protection.

How do I adjust the laser power and speed settings for different wood thicknesses?

To adjust the laser power and speed settings for different wood thicknesses, you need to employ laser cutting techniques and laser engraving techniques.

Start by determining the optimal power and speed settings for the thickest wood you’ll be working with. Then, gradually decrease the power and increase the speed for thinner wood. This’ll ensure clean and precise cuts without burning or scorching the material.

Experimentation and experience will help you find the perfect balance for each wood thickness.

What are some common issues that can occur while using a laser cutting machine and how can they be resolved?

When troubleshooting laser cutting machine issues, it’s important to prioritize safety precautions. Ensure that the machine is properly maintained and cleaned regularly.

If you encounter issues like inconsistent cutting or charring, check the focus of the laser beam and adjust it accordingly. If the laser power is too high, it can cause excessive burning, so lower it to prevent this.

Additionally, make sure the material is properly aligned and securely held in place to avoid errors during cutting.

Conclusion

In conclusion, by avoiding these common mistakes, you can ensure a smooth and efficient operation when using a laser cutting machine in woodworking.

With a keen understanding of the machine’s settings and capabilities, proper material preparation, thoughtful design considerations, strict adherence to safety precautions, and regular monitoring and maintenance, you can achieve precise and flawless results.

Imagine the satisfaction of effortlessly gliding the laser through the wood, creating intricate and beautiful designs with the confidence of an experienced craftsman.

Avoid these pitfalls and unlock the full potential of your laser cutting machine.