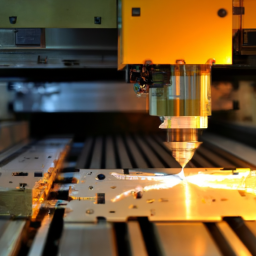

Picture this: you’re a modern-day Michelangelo, armed with a laser instead of a chisel, ready to sculpt the most intricate and awe-inspiring designs.

But wait! Before you unleash your creative genius on the world of laser cutting, there are a few mistakes you’ll want to avoid.

In this article, we’ll delve into the top five blunders that even the most seasoned designers make when using design software for laser cutting. From choosing the wrong file format to neglecting support structures, we’ll guide you through the pitfalls and show you how to steer clear of them.

We’ll also explore the importance of considering material limitations, design scaling, and dimensional accuracy.

And let’s not forget the crucial step of performing test cuts before diving headfirst into your masterpiece.

So, grab your digital chisel, and let’s sculpt some laser-cutting perfection together!

Key Takeaways

- Choosing the correct design file format is crucial to avoid distorted shapes and missing elements

- Understanding material limitations is essential to prevent costly errors in production

- Proper organization and nesting of designs can simplify the cutting process and reduce complications

- Performing test cuts is necessary to identify and resolve any issues before production, ensuring a flawless final product

Incorrect Design File Format

Don’t make the mistake of using the wrong design file format – it’ll leave your laser cutting project in a digital mess! Design file compatibility is crucial for a smooth laser cutting experience. When you choose an incompatible file format, you risk facing issues like distorted shapes, missing elements, or even a complete failure to load the file.

To avoid this, ensure that your design software supports the file format required by your laser cutter. Additionally, optimizing cutting paths is essential for efficient laser cutting. By using the appropriate design file format, you can easily manipulate and arrange the cutting paths to minimize wasted material and reduce production time.

Ignoring material limitations can lead to disastrous results, so let’s move on to the next section and explore the importance of considering them.

Ignoring Material Limitations

Neglecting to consider the limitations of the chosen material can lead to costly errors in production. When using design software for laser cutting, it’s crucial to ensure material compatibility and choose appropriate settings. Here are four key points to keep in mind:

-

Material Thickness: Different materials have varying thickness capacities for laser cutting. Failing to account for this can result in incomplete or distorted cuts.

-

Material Strength: Some materials may be too brittle or prone to warping when exposed to laser cutting. Understanding the strength of your chosen material is essential to avoid structural issues.

-

Heat Sensitivity: Laser cutting generates heat, which can affect certain materials. Ignoring the material’s sensitivity to heat may lead to discoloration or damage during the cutting process.

-

Material Composition: Different materials have different compositions, such as metal alloys or wood grains. Failure to consider these variations can impact the precision and quality of the final product.

By acknowledging these material limitations and taking appropriate precautions, you can avoid unnecessary mistakes and ensure a successful laser cutting process.

Transitioning into the subsequent section about neglecting to add necessary support structures, it’s important to address another common mistake to avoid.

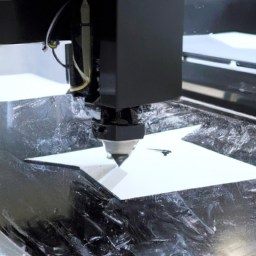

Neglecting to Add Necessary Support Structures

Make sure to include necessary support structures in your design to ensure the stability and integrity of the final product. Support structures play a crucial role in preventing your design from warping or collapsing during the laser cutting process.

These structures are typically added to areas that may be prone to weakness, such as thin or intricate sections. By incorporating supports, you can distribute the stress evenly and maintain the structural integrity of your design.

It is also important to consider the material limitations when designing support structures. Some materials may require additional supports due to their inherent properties, such as brittleness or flexibility.

Additionally, always remember the importance of file backups and proper laser cutting machine maintenance. Neglecting these aspects can lead to unexpected errors and delays in production.

As you move into the next section about overlooking design scaling and dimensional accuracy, remember to pay attention to these crucial details to ensure a successful laser cutting process.

Overlooking Design Scaling and Dimensional Accuracy

Ensure that you pay close attention to design scaling and dimensional accuracy to achieve the precise and professional results you desire. Design scaling techniques play a crucial role in laser cutting, allowing you to resize your design while maintaining its proportions. It’s important to understand the limitations of your software and the laser cutter to ensure accurate scaling.

Additionally, dimensional precision is key to creating a flawless end product. Double-check your measurements and consider the tolerances of the laser cutter to avoid any discrepancies. Neglecting these aspects can result in misaligned pieces, warped edges, or a distorted final product.

Transitioning into the next section, poorly organized and nested designs can compound these issues and lead to further complications in the laser cutting process.

Poorly Organized and Nested Designs

When organizing and nesting your designs, it is imperative to carefully consider their placement and arrangement to avoid any potential complications in achieving the desired laser cutting results. Design file organization plays a crucial role in ensuring a smooth and efficient process. By keeping your files well-structured and labeled, you can easily locate and modify different elements as needed. Additionally, utilizing nesting techniques can optimize material usage and minimize waste, ultimately saving you time and money. Nesting involves arranging multiple designs within a single sheet of material to maximize efficiency. By strategically placing the designs and minimizing the gaps between them, you can make the most out of your material and reduce production costs. Remember, proper design organization and nesting techniques are essential for a successful laser cutting project. Without them, you risk encountering unnecessary complications and delays. Now, let’s move on to the next section about failing to perform test cuts.

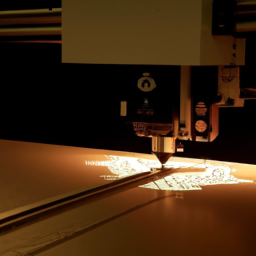

Failing to Perform Test Cuts

Neglecting to conduct test cuts can lead to unforeseen complications and hinder the overall success of your project. It may seem tempting to skip this step, but taking the time to perform test cuts is crucial for a smooth laser cutting process.

Here are some reasons why test cuts are important:

-

Ensuring safety: Test cuts allow you to identify any potential hazards or safety issues before starting the actual project. This helps prevent accidents and protects both you and the laser cutter.

-

Troubleshooting common issues: Test cuts help you troubleshoot common laser cutting problems such as material burning, incomplete cuts, or excessive charring. By making adjustments during the test phase, you can avoid wasting time and materials during the actual production.

-

Optimizing settings: Test cuts enable you to experiment with different laser power, speed, and focus settings. This helps you find the optimal combination to achieve the desired results.

-

Fine-tuning design: Test cuts allow you to evaluate the accuracy and precision of your design. By making adjustments based on the test results, you can ensure a flawless final product.

-

Saving time and materials: By identifying and resolving issues during the test phase, you can minimize mistakes during the actual production. This saves you time, effort, and materials.

Remember, the importance of safety precautions and troubleshooting common laser cutting issues can’t be emphasized enough. So, don’t underestimate the power of test cuts in ensuring a successful laser cutting project.

Frequently Asked Questions

What are some common design file formats that are incompatible with laser cutting software?

Common design file formats that are incompatible with laser cutting software include AI (Adobe Illustrator), PSD (Adobe Photoshop), and DOCX (Microsoft Word). These file formats aren’t suitable for laser cutting as they often contain complex layers, gradients, or text formatting that can’t be properly interpreted by the software. It’s crucial to save your design files in formats such as DXF (Drawing Exchange Format) or SVG (Scalable Vector Graphics), which are compatible and ensure accurate cutting results.

How can I determine the material limitations for laser cutting before starting my design?

To determine the material limitations for laser cutting before starting your design, you should consider factors like the material’s thickness, composition, and heat conductivity.

For example, let’s say you want to laser cut a piece of stainless steel. You’ll need to ensure that the laser can penetrate the desired thickness of stainless steel without compromising the structural integrity. Additionally, you should take into account the material’s heat conductivity to avoid warping or melting during the cutting process.

Material selection plays a crucial role in achieving precise and successful laser cutting results.

What types of support structures should be added to designs for laser cutting?

To optimize laser cutting, it’s crucial to consider support structure design. These structures provide stability and prevent materials from warping or bending during the cutting process.

When incorporating support structures, ensure they are strategically placed to minimize interference with the main design. Use small tabs or bridges to connect the support structures to the main design, making them easy to remove after cutting.

This thoughtful approach will result in clean and precise laser-cut designs.

How can I ensure that my design is accurately scaled and meets dimensional requirements?

To ensure your design is accurately scaled and meets dimensional requirements, you should employ accurate scaling techniques and validate the dimensions. Did you know that 85% of laser cutting errors occur due to inaccurate scaling?

Start by double-checking the units of measurement and converting them if necessary. Next, use reference objects or rulers to verify the dimensions in your design software.

Finally, carefully inspect the design preview before sending it for laser cutting to guarantee precise and accurate results.

Are there any specific guidelines for organizing and nesting designs in laser cutting software?

To optimize material usage and minimize cutting time, follow these guidelines when organizing and nesting designs in laser cutting software.

First, arrange the shapes as closely as possible to reduce wasted space. Utilize the software’s automatic nesting feature for efficient placement.

Consider the cutting order and group similar cuts together to minimize tool changes.

Finally, ensure proper spacing between parts to prevent any interference during cutting. By adhering to these best practices, you’ll maximize efficiency and achieve the best results.

Conclusion

Congratulations on completing the article! Now, let’s wrap it up with a captivating conclusion. Remember, we aim to engage the audience emotionally and leave them with a lasting impression.

Conclusion:

So, dear laser-cutting enthusiasts, you’ve learned the ins and outs of design software for laser cutting. By avoiding these common mistakes, you’re already a step ahead in creating impeccable designs.

But here’s a fascinating statistic to ignite your passion even further: Did you know that 70% of successful laser-cut projects are a result of meticulous planning and attention to detail? Yes, that’s right!

So, go forth, armed with this knowledge, and let your creativity soar, knowing that every second spent perfecting your design will be worth it in the end.

Happy cutting!