In the world of laser cutting, proper ventilation is crucial to ensure the safety of both operators and the surrounding environment. However, there are common challenges that arise when it comes to effectively ventilating laser cutters. These challenges can range from inadequate airflow management to the need for regular maintenance and cleaning.

But fear not! In this article, we will delve into the depths of these ventilation challenges and provide you with precise solutions to overcome them. From the installation of a proper exhaust system to the implementation of filtering and purification techniques, we will guide you through the intricate process of optimizing ventilation for laser cutters.

Additionally, we will emphasize the importance of safety precautions and training to ensure a secure working environment. So, let’s dive in and discover how to conquer the ventilation challenges that come with laser cutting!

Key Takeaways

- Inadequate airflow management and lack of regular maintenance and cleaning are common challenges in ventilating laser cutters.

- Installing a proper exhaust system and implementing filtering and purification techniques are effective solutions to overcome these challenges.

- Proper installation of the exhaust system, including the placement of ventilation ducts and positioning of the laser cutter, is crucial for optimal performance.

- Safety precautions, training, and regular inspection and maintenance of the laser cutter are essential for a secure and efficient working environment.

Proper Exhaust System Installation

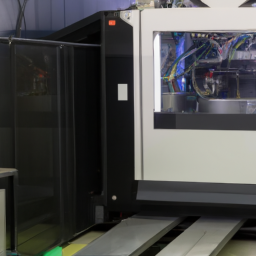

To ensure the proper installation of your exhaust system, you’ll need to carefully consider the placement of the ventilation ducts and the positioning of the laser cutter within your workspace. Proper exhaust system maintenance and ventilation system optimization are essential for maintaining a safe and efficient laser cutting environment.

Start by positioning the laser cutter in a way that allows for easy access to the exhaust system. This will make it easier to perform regular maintenance and cleaning tasks.

Ensure that the ventilation ducts are installed in a way that efficiently captures and removes the fumes and particulates generated during laser cutting. Consider the length and diameter of the ducts to optimize airflow.

Regular maintenance and cleaning of the exhaust system are crucial to keep it functioning effectively. This includes checking and cleaning filters, inspecting ducts for any obstructions, and ensuring proper airflow.

By properly installing and maintaining your exhaust system, you can create a safe and productive workspace for laser cutting.

Regular Maintenance and Cleaning

Regular maintenance and cleaning are essential for ensuring optimal performance and extending the lifespan of laser cutters. To maintain a laser cutter properly, it’s crucial to follow a maintenance schedule that includes routine cleaning tasks.

Start by disconnecting the machine from the power source and removing any debris or dust from the cutting bed and surrounding areas. Use a soft brush or vacuum cleaner to clean the internal components, such as the lens and mirrors, to prevent any build-up that could affect the cutter’s accuracy.

Additionally, inspect and replace any worn-out or damaged parts as needed. Cleaning techniques may vary depending on the manufacturer’s recommendations, so refer to the machine’s manual for specific instructions.

By regularly maintaining and cleaning your laser cutter, you can ensure its longevity and optimal performance.

Adequate airflow management is the next crucial aspect to consider in order to prevent ventilation challenges.

Adequate Airflow Management

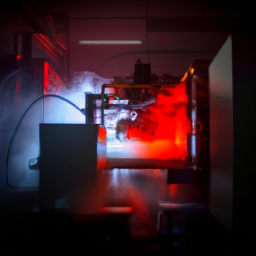

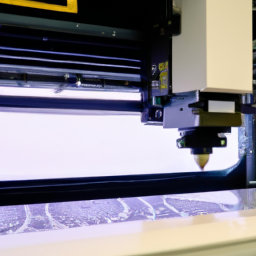

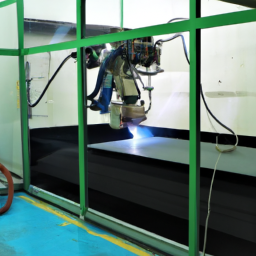

Ensure that you properly manage the airflow in your workspace to optimize the performance and lifespan of your laser cutter. Adequate airflow control is crucial for maintaining a safe and efficient laser cutting environment.

Proper ventilation optimization will prevent the buildup of harmful fumes, smoke, and dust that are generated during the laser cutting process. To achieve this, start by positioning your laser cutter in a well-ventilated area, away from walls or obstructions.

Additionally, consider using a dedicated exhaust system or installing an air filtration unit to effectively remove the contaminants from the air. Regularly inspect and clean the ventilation system, ensuring that all filters and ducts are free from debris.

By implementing these airflow management strategies, you can ensure a healthy working environment for your laser cutter and transition seamlessly into the subsequent section about proper ventilation design.

Proper Ventilation Design

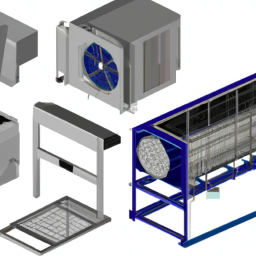

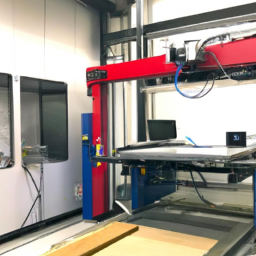

Creating a well-designed ventilation system is essential for maintaining a safe and healthy environment when operating a laser cutter, as studies have shown that inadequate ventilation can increase the risk of respiratory problems and long-term health issues. To ensure proper ventilation, it is important to consider the ventilation requirements and optimize the ventilation system accordingly.

One way to achieve this is by designing an efficient airflow path. This involves strategically placing intake and exhaust vents to ensure a continuous flow of fresh air while removing contaminated air. Additionally, it is crucial to consider the size of the laser cutter and the volume of air it produces to determine the appropriate airflow rate.

To make the design process easier, a table can be used to outline the ventilation requirements and optimize the system accordingly. The table can include columns for factors such as laser cutter size, airflow rate, and vent placement, and rows for different parameters to be considered. This allows for a systematic approach to ventilation design, ensuring all necessary aspects are taken into account.

In the subsequent section about filtering and purification techniques, it is important to address how these techniques can complement the ventilation system and further enhance air quality.

Filtering and Purification Techniques

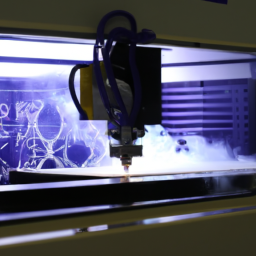

One of the most effective ways to improve air quality and protect your health is by implementing filtering and purification techniques in your laser cutter ventilation system. Here are three key techniques to consider:

-

Particulate Filters: These filters are designed to remove small particles from the air, such as dust and smoke, which can be harmful to your respiratory health. They work by trapping these particles in a filter media, allowing only clean air to pass through.

-

Activated Carbon Filters: These filters are effective at removing odors, gases, and volatile organic compounds (VOCs) from the air. The activated carbon has a large surface area that adsorbs these pollutants, improving the air quality and reducing the risk of respiratory issues.

-

HEPA Filters: High-Efficiency Particulate Air (HEPA) filters are designed to capture ultrafine particles, including airborne pathogens and allergens. These filters are crucial for maintaining a high level of air quality and protecting your respiratory health.

By incorporating these filtering and purification techniques into your laser cutter ventilation system, you can ensure cleaner air and reduce the risk of respiratory issues.

Moving on to safety precautions and training…

Safety Precautions and Training

Now that you understand the importance of filtering and purification techniques in maintaining a clean and safe working environment for laser cutters, it’s time to delve into the next crucial aspect: safety precautions and training. When it comes to laser cutters, safe handling is paramount to prevent accidents and injuries. This involves following strict protocols and guidelines to ensure the well-being of both operators and the surrounding environment.

To ensure everyone’s safety, proper training is essential. Operators must be educated on the potential hazards associated with laser cutters and trained in emergency procedures. This includes knowing how to respond in the event of a fire, power outage, or any other emergency situation. By equipping operators with the necessary knowledge and skills, the risk of accidents can be minimized, and a safe working environment can be maintained. Remember, safety should always be the top priority when working with laser cutters.

To further illustrate the importance of safety precautions and training, refer to the table below:

| Safety Precautions | Emergency Procedures | ||

|---|---|---|---|

| Wear appropriate personal protective equipment (PPE) | Know how to shut off power and gas supply in case of an emergency | ||

| Ensure proper ventilation and air extraction | Evacuate the area and call emergency services if necessary | ||

| Regularly inspect and maintain the laser cutter | Follow the established fire safety protocols | ||

| Keep a clean and organized work area | Have a designated first aid kit readily available | Always wear appropriate personal protective equipment (PPE) when operating the laser cutter. |

Frequently Asked Questions

How much does it cost to install a proper exhaust system for a laser cutter?

Installing a proper exhaust system for a laser cutter involves several cost considerations and a detailed installation process. The cost can vary depending on factors such as the size and power of the laser cutter, the type of exhaust system required, and any additional modifications needed for the workspace.

It’s crucial to consider the cost of equipment, materials, labor, and potential permits or inspections. The installation process typically involves planning, designing, purchasing, and installing the necessary components, and ensuring proper ventilation to maintain a safe working environment.

What are the different types of filters used in laser cutter ventilation systems?

When it comes to laser cutter ventilation systems, there are various types of filters available to ensure optimal air quality. These filters include activated carbon, HEPA, and electrostatic filters.

However, the real star of the show is the HEPA filter. With its exceptional ability to trap particles as small as 0.3 microns, it effectively removes harmful pollutants from the air. This is crucial for maintaining a safe and healthy working environment, as it prevents the release of hazardous fumes and particulates.

Can I use a regular fan for airflow management in my laser cutter?

Using a regular fan for airflow management in your laser cutter may not provide optimal results. Specialized exhaust systems offer several benefits. Firstly, they’re designed specifically for laser cutters, ensuring efficient removal of harmful fumes and particles. Secondly, they provide better control over airflow, preventing potential damage to the laser machine.

To optimize airflow management, ensure proper ducting and sealing, maintain a negative pressure environment, and regularly clean or replace filters. These measures will enhance the performance and lifespan of your laser cutter.

Are there any specific regulations or guidelines for proper ventilation design in laser cutter facilities?

When designing a ventilation system for a laser cutter facility, it’s crucial to adhere to specific regulations and guidelines. These guidelines ensure the safety and efficiency of the ventilation system.

Regulations typically outline the minimum airflow requirements, the use of appropriate filters, and the proper placement of exhaust outlets.

Guidelines offer more detailed recommendations on the design and installation of ductwork, the use of ventilation hoods, and the integration of air quality monitoring systems.

Following these regulations and guidelines will help maintain a healthy and productive laser cutter facility.

How often should I replace the filters in my laser cutter ventilation system?

To ensure optimal performance and safety of your laser cutter ventilation system, regular filter maintenance is crucial. The frequency of filter replacement depends on factors such as the type of laser cutter, the materials being processed, and the level of usage.

Generally, it’s recommended to replace filters every 3 to 6 months. When choosing filters, consider factors like filtration efficiency, compatibility with the laser cutter, and the specific contaminants you need to remove.

Regular maintenance and appropriate filter selection will help maintain an efficient and clean ventilation system.

Conclusion

In conclusion, addressing the ventilation challenges in laser cutters is crucial for ensuring a safe and efficient working environment. By implementing proper exhaust system installation and regular maintenance and cleaning, you can overcome these challenges effectively. Additionally, adequate airflow management, proper ventilation design, and filtering and purification techniques are important. Remember, safety precautions and training are paramount to prevent any accidents or health hazards. Just as a well-oiled machine runs smoothly, so too will your laser cutter when you conquer these ventilation obstacles.

So gear up, folks, and let the clean and filtered air breathe new life into your laser cutting endeavors!