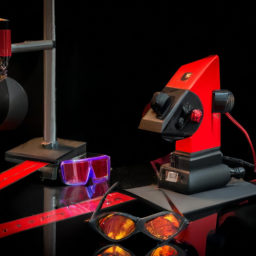

Discover the dynamic dance of design and laser cutting with our five essential techniques for optimizing your creations.

Laser cutting is a powerful tool that allows you to shape materials with precision and finesse. But to truly unlock its potential, you must master the art of designing with precision and accuracy.

By simplifying and minimizing complexity, you can create designs that are not only visually stunning but also efficient to produce. Choosing the right materials is crucial to achieving the desired outcome, as different materials react differently to laser cutting.

Additionally, optimizing for speed and efficiency ensures that your designs are created in a timely and cost-effective manner. Finally, testing and iterating allow you to refine your designs and achieve perfection.

So, step onto the stage of laser cutting and let these techniques guide you towards design excellence.

Key Takeaways

- Use vector-based software for precise scaling and consider line thickness to control cut width.

- Simplify and minimize complexity by avoiding overlapping or intersecting lines and minimizing small cuts and intricate patterns.

- Choose suitable materials like acrylic or wood, considering their properties and thickness.

- Optimize designs by nesting them to save material and reduce costs, and plan efficient cutting paths for reduced processing time.

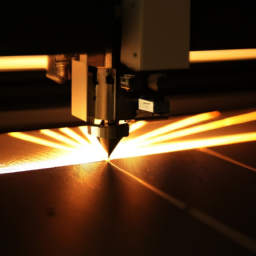

Understand the Laser Cutting Process

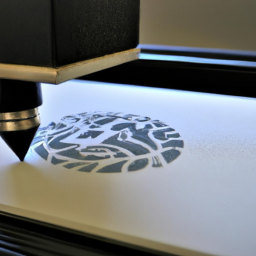

Understanding the laser cutting process is crucial for optimizing designs for laser cutting. Laser cutting is widely used in various industries and applications, thanks to its precision and versatility. By comprehending the laser cutting process, you can effectively utilize its benefits for your designs.

Laser cutting offers numerous advantages, such as the ability to cut complex shapes, high cutting speed, and minimal material wastage. It allows for intricate designs and precise cuts, making it ideal for industries like manufacturing, automotive, and aerospace.

With this understanding, you can design with precision and accuracy, ensuring that your designs are optimized for laser cutting. This involves considering factors like material thickness, kerf width, and the capabilities of the laser cutting machine.

By comprehending the laser cutting process, you can create designs that maximize the potential of laser cutting technology.

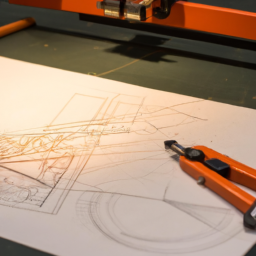

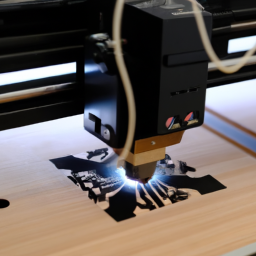

Design with Precision and Accuracy

To ensure your designs are executed with utmost finesse, it’s crucial to master the art of crafting precise and accurate blueprints. Designing for laser engraving requires attention to detail and a deep understanding of the capabilities of the laser cutting process. Achieving intricate cuts and designs requires precision in measurement and alignment.

Here are some key points to keep in mind:

- Use vector-based design software to create your blueprints and ensure accurate scaling.

- Pay attention to the line thickness, as thicker lines may result in wider cuts.

- Avoid overlapping lines or shapes, as this can cause the laser to cut multiple times in the same area.

- Consider the kerf, or width of material removed by the laser, and adjust your designs accordingly.

By designing with precision and accuracy, you can maximize the potential of laser cutting technology.

Now, let’s explore how to simplify and minimize complexity in your designs.

Simplify and Minimize Complexity

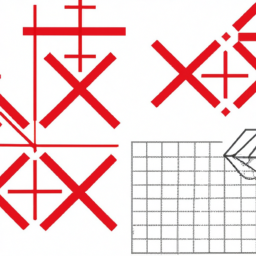

When designing for laser cutting, it’s important to simplify and minimize complexity. Reduce the number of intricate details and small cuts to ensure a smoother and more efficient cutting process. Avoid overlapping or intersecting lines to prevent cutting errors and ensure the accuracy of your designs.

Remember to keep it simple and clean for optimal results.

Reduce the number of intricate details and small cuts

Minimize the amount of intricate details and small cuts to enhance the efficiency of your laser cut designs. By reducing intricate details and simplifying your design, you can optimize the laser cutting process and achieve better results.

Here are three ways to achieve this:

-

Use larger shapes and fewer intricate details: Simplify your design by using larger shapes instead of intricate details. This will reduce the time and effort required for laser cutting.

-

Avoid small cuts and intricate patterns: Minimize the number of small cuts and intricate patterns in your design. This will not only make the cutting process faster but also reduce the risk of errors and material wastage.

-

Opt for simpler designs: Keep your designs simple and clean. Avoid unnecessary complexities and intricate details that can complicate the cutting process.

Reducing the number of intricate details and small cuts in your laser cut designs will not only enhance efficiency but also help avoid overlapping or intersecting lines to prevent cutting errors.

Avoid overlapping or intersecting lines to prevent cutting errors

By ensuring that your design lines do not overlap or intersect, you can prevent any potential cutting errors and achieve flawless laser-cut results. Avoiding design complexity is crucial when optimizing for laser cutting efficiency.

When lines overlap or intersect, it can lead to misalignment or incomplete cuts, resulting in subpar quality or wasted materials. To avoid this, carefully review your design and make sure that all lines are distinct and separate. Use software tools to check for any overlapping or intersecting lines before sending your design for laser cutting.

By taking these precautions, you can ensure that your design will be accurately translated into a laser-cut product.

Now, let’s move on to the next section and discuss how to choose the right materials for your laser-cutting project.

Choose the Right Materials

When choosing materials for laser cutting, make sure to select ones that are suitable for the process, such as acrylic or wood.

Consider the thickness and properties of the material to achieve optimal results.

By following these guidelines, you can ensure that your laser cutting designs are successful and efficient.

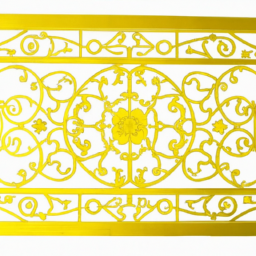

Select materials suitable for laser cutting, such as acrylic or wood

Choose materials like acrylic or wood for laser cutting to create designs that’ll leave your audience in awe. When it comes to material selection, keep in mind the limitations of laser cutting.

Here are a few reasons why acrylic or wood are suitable choices:

-

Acrylic: This versatile material comes in various colors and finishes, allowing you to add a touch of elegance to your designs.

-

Wood: With its natural beauty and texture, wood can bring warmth and sophistication to your laser-cut creations.

-

Easy to work with: Both acrylic and wood are relatively easy to cut and engrave, making them ideal for laser cutting.

-

Compatibility: Acrylic and wood are commonly used materials in laser cutting machines, ensuring optimal results.

Consider the thickness and properties of the material for optimal results. This will help you transition into the subsequent section about considering the thickness and properties of the material for optimal results.

Consider the thickness and properties of the material for optimal results

To achieve the most impressive outcomes, carefully consider the thickness and unique properties of your chosen materials, allowing your designs to take on a captivating dimension.

When considering material thickness, it’s essential to remember that different thicknesses can affect the precision and quality of laser cutting. Thicker materials may require slower speeds to ensure clean and accurate cuts, while thinner materials can be cut at faster speeds.

Additionally, the properties of the material, such as its density and composition, can impact the cutting process. For example, acrylic and wood have different properties, which can affect the speed and intensity of the laser beam needed for optimal results.

By utilizing different materials and considering their thickness and properties, you can create designs that are both visually striking and flawlessly executed.

Now, let’s move on to optimizing for speed and efficiency in the next section.

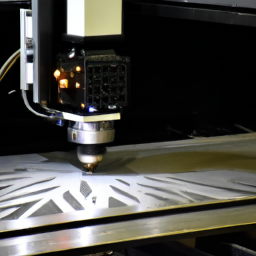

Optimize for Speed and Efficiency

To optimize for speed and efficiency in laser cutting, you should arrange and nest your designs in a way that minimizes material waste. By strategically positioning your designs, you can make the most out of each sheet of material, reducing the amount of scrap and saving costs.

Additionally, using efficient cutting paths will help minimize processing time, resulting in faster production and increased productivity.

Arrange and nest your designs to minimize material waste

By efficiently arranging and nesting your designs, you can drastically reduce material waste, saving both money and the environment. When laser cutting, it is important to minimize scrap and maximize material usage. One effective way to achieve this is by thoughtfully arranging your designs on the cutting sheet and nesting them closely together. This allows you to fit more designs into a single sheet of material, reducing the amount of wasted space.

To illustrate the impact of arranging and nesting, consider the following table:

| Design | Original Size (inches) | Nested Size (inches) |

|---|---|---|

| A | 4×4 | 3×3 |

| B | 3×6 | 2×5 |

| C | 2×2 | 1×1 |

By nesting these designs, you can save a significant amount of material, reducing costs and minimizing waste. Once you have efficiently arranged and nested your designs, you can move on to the next step of using efficient cutting paths to further reduce processing time and costs.

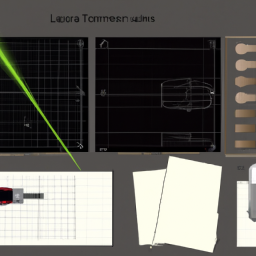

Use efficient cutting paths to reduce processing time and costs

Using efficient cutting paths can dramatically slash processing time and costs, making your production process lightning fast and wallet-friendly. By implementing efficient nesting techniques, you can optimize the arrangement of your designs on the material, reducing waste and maximizing the utilization of each sheet.

This not only saves on material costs but also minimizes the time required for cutting. Additionally, employing cost-effective laser cutting strategies such as minimizing tool changes and reducing travel distances between cuts can further enhance efficiency. By carefully planning and organizing the cutting paths, you can minimize the overall processing time, allowing you to complete more projects in less time.

This not only boosts productivity but also reduces expenses associated with labor and machine usage. Transitioning into the subsequent section about ‘test and iterate,’ you can refine and improve your designs to achieve even greater efficiency in your laser cutting process.

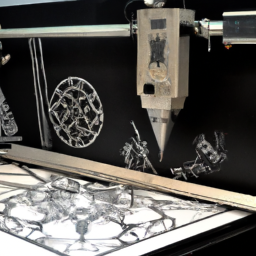

Test and Iterate

Through trial and error, you can refine your laser cutting designs by constantly testing and iterating until you achieve the perfect result. Testing is an essential step in the design process as it allows you to identify any flaws or areas for improvement.

By cutting small test pieces before committing to a full design, you can assess how the laser will interact with different materials and make adjustments accordingly. Iteration is the key to optimizing your design. By analyzing the results of each test, you can make informed decisions about what changes to make, whether it’s adjusting the cutting path or optimizing the design for better efficiency.

This continuous process of testing and iterating will ultimately lead to a design that is both cost-effective and optimized for laser cutting.

Frequently Asked Questions

How does the laser cutting process work?

Have you ever wondered how laser cutting works? Well, let me break it down for you.

Laser cutting is a process that uses a highly focused laser beam to cut through materials with precision. It is commonly used in various industries and applications, such as automotive, aerospace, and even in arts and crafts.

The benefits of laser cutting are numerous, including high accuracy, clean cuts, and the ability to cut through a wide range of materials.

What are some common design mistakes to avoid when designing for laser cutting?

When designing for laser cutting, it’s important to avoid common design mistakes to ensure a successful outcome. Here are some tips for laser cutting designs:

1) Avoid designs with small, intricate details as they may not be cut accurately.

2) Don’t forget to account for the kerf, or the width of the laser beam, when designing parts that need to fit together.

3) Avoid overlapping lines or vectors, as they can cause issues during cutting.

By keeping these tips in mind, you can create designs that are optimized for laser cutting.

Can laser cutting be used for all types of materials?

Laser cutting is a versatile method that can be used on a wide range of materials, from wood and acrylic to metal and fabric. However, there are certain limitations. For example, highly reflective materials like copper and aluminum can be challenging to cut with lasers.

Additionally, laser cutting has its own set of advantages and disadvantages compared to other cutting methods. It offers precision and intricate detailing, but can be slower and more expensive.

What are some additional factors to consider when optimizing a design for speed and efficiency in laser cutting?

When optimizing a design for speed and efficiency in laser cutting, there are additional factors to consider.

Design complexity plays a role as intricate designs may require more time and resources.

Material thickness is also important as thicker materials can slow down the cutting process.

By taking these factors into account, you can ensure that your design is optimized for maximum speed and efficiency in laser cutting.

How can I test and iterate my design before finalizing it for laser cutting?

To test and iterate your design before finalizing it for laser cutting, you can create a prototype for testing and design validation. Just like a chef tasting their dish before serving it, prototyping allows you to fine-tune your design and identify any flaws or improvements needed.

By physically seeing and handling the prototype, you can make adjustments and ensure it meets your requirements for laser cutting. This process enhances your final design, like adding the perfect seasoning to a dish.

Conclusion

So, now you’ve learned the 5 essential techniques for optimizing your designs for laser cutting. By understanding the laser cutting process and designing with precision, you can ensure high-quality results. Simplifying complexity and choosing the right materials are also crucial steps in the process. Additionally, optimizing for speed and efficiency is important to stay competitive in the industry. Did you know that, according to a study by Statista, the global laser cutting market is projected to reach $5.7 billion by 2027? This statistic highlights the growing demand for laser cutting services and emphasizes the importance of mastering these techniques.