Tired of spending countless hours fixing your laser cutter? Frustrated with subpar results when cutting and engraving acrylic? Well, my friend, you’re in luck! In this article, we’re going to reveal five laser cutter maintenance tips that will revolutionize your acrylic cutting and engraving game.

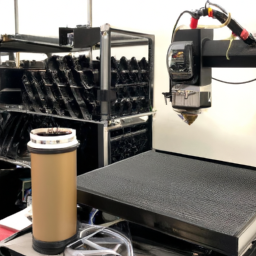

First things first, let’s talk about cleanliness. You wouldn’t want to operate in a dusty, grimy environment, would you? Of course not! So, make sure to regularly clean your laser cutter to ensure optimal performance.

Next up, keep an eye out for worn parts. Just like a worn-out pair of shoes, worn parts can lead to sloppy cuts and unsatisfactory engravings. So, check and replace them as needed.

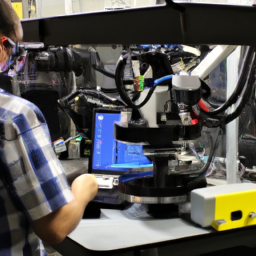

Now, let’s dive into calibration. Acrylic cutting and engraving requires precision, my friend. So, make sure to calibrate your laser cutter specifically for this task.

Power and speed settings, oh boy! Using the correct settings is crucial for achieving desired results. Don’t be afraid to experiment and find that perfect balance.

Last but not least, proper ventilation is key. Nobody wants to inhale toxic fumes, right? So, ventilate your workspace properly to ensure a healthy and safe environment.

By following these five laser cutter maintenance tips, you’ll not only save time and frustration, but you’ll also elevate your acrylic cutting and engraving to a whole new level. So, grab your tools and let’s get started!

Key Takeaways

- Regularly clean the laser cutter using a soft cloth or brush to remove loose debris.

- Signs of worn parts include decreased cutting power and poor engraving quality, and the necessary actions to take are replacing the worn parts.

- Calibration is important for acrylic cutting and engraving, including adjusting the focal length of the laser beam, fine-tuning power and speed settings, and using correct settings for clean and precise cuts.

- Proper ventilation is essential for a safe and healthy workspace, including using an exhaust system, positioning the laser cutter in a well-ventilated area, and regularly cleaning and replacing filters in the exhaust system.

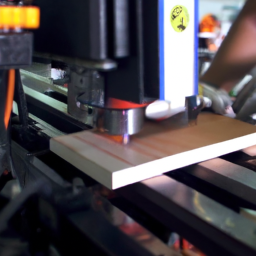

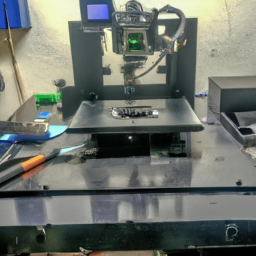

Regularly Clean the Laser Cutter

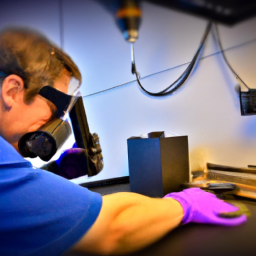

Make sure you regularly clean the laser cutter to keep it running smoothly and to prevent any buildup that can affect the quality of your cuts and engravings.

To remove stubborn dirt, start by turning off the laser cutter and disconnecting it from power. Use a soft cloth or brush to gently remove any loose debris from the machine. For more stubborn dirt, you can use a recommended cleaning solution such as isopropyl alcohol. Apply the solution to a cloth and wipe down the affected areas, being careful not to get any liquid inside the machine. After cleaning, ensure that all parts are completely dry before reconnecting the power.

Cleaning the laser cutter on a regular basis will not only extend its lifespan but also improve the overall performance.

Now, let’s move on to the next section and check and replace any worn parts.

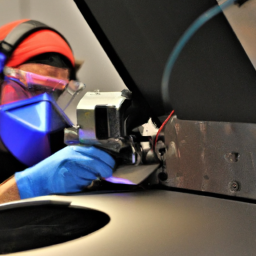

Check and Replace Worn Parts

To ensure optimal performance, regularly inspect and update any worn components in order to achieve the best results when working with acrylic materials. Laser cutter troubleshooting is crucial for identifying signs of worn parts. By addressing these issues promptly, you can prevent further damage and maintain the efficiency of your laser cutter.

| Signs of Worn Parts | Actions to Take |

|---|---|

| Decreased cutting power | Check and potentially replace the laser tube or optics |

| Poor engraving quality | Inspect and possibly replace the focusing lens or mirrors |

| Unusual noises or vibrations | Examine and potentially replace the belts, bearings, or motors |

By keeping a close eye on these signs, you can avoid potential problems and maintain the performance of your laser cutter. After checking and replacing any worn parts, the next step is to calibrate the laser cutter for acrylic cutting and engraving.

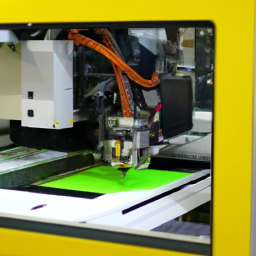

Calibrate the Laser Cutter for Acrylic Cutting and Engraving

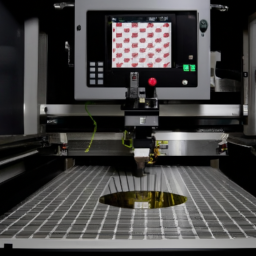

Ensure your laser cutter is finely tuned and perfectly aligned, like a maestro directing a symphony, to achieve flawless results when working with acrylic materials. Calibration is crucial for laser cutter troubleshooting and preventing acrylic melting.

Start by adjusting the focal length of the laser beam to match the thickness of the acrylic. This will ensure the laser cuts through the material cleanly without excessive heat buildup.

Next, check and adjust the laser power and speed settings to optimize cutting and engraving results. Too much power or speed can cause the acrylic to melt, while too little may result in incomplete cuts or weak engraving. Take the time to fine-tune these settings for optimal performance.

Once you have calibrated your laser cutter, you can proceed to the next section on using the correct power and speed settings.

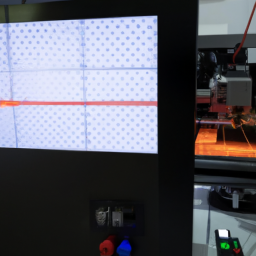

Use the Correct Power and Speed Settings

Optimal results can be achieved by utilizing the appropriate power and speed settings when working with acrylic materials on the laser cutter. When cutting acrylic, it’s important to find the right balance between power and speed. If the power is too high, the acrylic may melt and create a rough edge. On the other hand, if the power is too low, the acrylic may not be fully cut through.

Similarly, the speed should be adjusted accordingly. If the speed is too slow, the acrylic may overheat and warp. If it’s too fast, the cut may not be clean and precise. Troubleshooting power issues is crucial to ensure consistent and accurate cutting results.

With the correct power and speed settings, you can achieve clean and smooth cuts on acrylic materials. Properly ventilate the workspace to ensure the safety of the laser cutter and prevent any potential hazards.

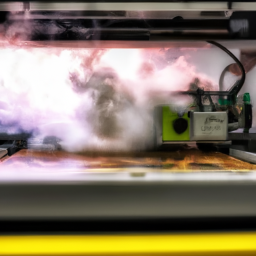

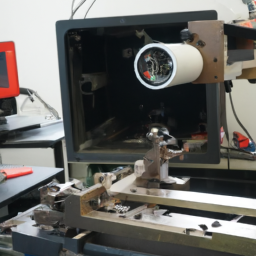

Properly Ventilate the Workspace

Good ventilation is essential for a safe and clean workspace when working with acrylic materials on the laser cutter. To improve air circulation and maintain a healthy environment, it’s crucial to use an exhaust system that effectively removes fumes and particles generated during the cutting and engraving process.

Ensure that the exhaust system is properly installed and functioning optimally. Position the laser cutter in a well-ventilated area, away from other equipment or objects that may obstruct airflow. Regularly clean and replace the filters in the exhaust system to prevent buildup and maintain its efficiency.

By properly ventilating the workspace, you can minimize the risk of inhaling harmful fumes and maintain a clean environment for precise and high-quality acrylic cutting and engraving.

Moving on to the next section about performing routine maintenance and inspections…

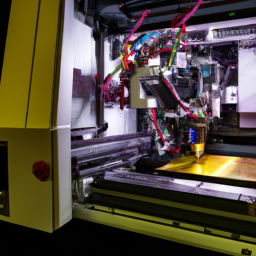

Perform Routine Maintenance and Inspections

Regularly checking and maintaining your equipment is like an ounce of prevention to avoid a pound of cure. When it comes to laser cutter maintenance for cutting and engraving acrylic, scheduling routine maintenance and inspections is crucial.

Set a regular schedule to inspect and clean the laser cutter, focusing on key components such as the lens, mirrors, and exhaust system. Inspect for any signs of wear or damage, and replace any worn-out parts promptly.

Additionally, troubleshoot any issues that may arise during operation, such as misalignment or power fluctuations. Keep a checklist of troubleshooting tips handy, which may include adjusting the laser power, cleaning the lens, or checking the exhaust system for blockages.

By following these maintenance practices, you can ensure optimal performance and prolong the lifespan of your laser cutter.

Frequently Asked Questions

Can I use the same power and speed settings for cutting and engraving acrylic?

When it comes to cutting and engraving acrylic, it’s not recommended to use the same power and speed settings. For cutting, you need higher power and slower speeds to achieve clean and precise cuts. On the other hand, engraving requires lower power and faster speeds to create accurate and detailed designs.

Optimizing the laser cutter settings for acrylic cutting and engraving involves adjusting the power and speed settings accordingly to achieve the desired results.

How often should I clean the laser cutter to maintain its performance?

To maintain peak performance, you must clean your laser cutter with almost religious zeal. It’s crucial to establish a regular cleaning frequency and adhere to a meticulous maintenance schedule. Neglecting this sacred duty will result in diminished cutting precision and engraving quality.

Set aside dedicated time to remove debris, dust, and residue from the machine’s interior and exterior. Remember, cleanliness is the key to unlocking the full potential of your laser cutter.

Are there any specific safety precautions I should take when ventilating the workspace?

When ventilating the workspace, it’s crucial to take specific safety precautions to ensure workspace safety. Proper ventilation is essential to remove fumes and smoke generated during laser cutting and engraving acrylic. Make sure the ventilation system is functioning properly and filters are clean. Keep the workspace well-ventilated by ensuring there is adequate airflow and maintaining a safe distance from the laser cutter. Regularly monitor the ventilation system and address any issues promptly to minimize potential hazards.

What are the signs that indicate worn parts in the laser cutter?

One statistic that might surprise you is that worn parts in a laser cutter can decrease its cutting accuracy by up to 40%.

To ensure optimal performance, it’s crucial to regularly inspect the machine for signs of wear. Look out for symptoms like inconsistent cutting depth, charring or scorching on the material, and unusual noises during operation. These could indicate worn parts such as belts, lenses, mirrors, or bearings that need immediate replacement.

Is there a recommended frequency for routine maintenance and inspections of the laser cutter?

To ensure optimal performance and prolong the lifespan of your laser cutter, it’s crucial to adhere to a recommended frequency for routine maintenance and inspections.

Regular upkeep is essential in identifying potential issues before they escalate, minimizing downtime and costly repairs. By diligently following a maintenance schedule, you can ensure that all components are functioning properly, including the laser tube, mirrors, and lenses.

Don’t underestimate the importance of routine inspections in keeping your laser cutter operating at its best.

Conclusion

In conclusion, by following these laser cutter maintenance tips, you can ensure optimal performance when cutting and engraving acrylic.

Regular cleaning will prevent residue build-up, while checking and replacing worn parts will guarantee accuracy and efficiency.

Calibrating the laser cutter specifically for acrylic will result in clean and precise cuts.

Using the correct power and speed settings is crucial for achieving desired results.

Lastly, proper ventilation will promote a safe and comfortable working environment.

Remember, maintaining your laser cutter is essential for achieving top-notch acrylic projects.