Are you tired of the limitations and frustrations of traditional laser cutter software? Look no further! We have compiled a list of 5 laser cutter software programs that will revolutionize your workflow and integration, making your laser cutting projects a breeze.

These cutting-edge programs offer a range of features designed to enhance your design process, from intricate pattern creation to precise control of the laser cutter. Say goodbye to manual adjustments and hello to streamlined workflow with advanced features that will save you time and effort.

Not only that, but these software programs seamlessly integrate with other software and hardware, allowing for a smooth and efficient workflow. Stay ahead of the curve and increase your efficiency and productivity in laser cutting projects with these innovative software programs.

Don’t miss out on the latest advancements in laser cutting technology – try out these programs today!

Key Takeaways

- Laser cutter software programs revolutionize workflow and integration

- Features enhance design process and control of laser cutter

- Seamless integration with other software and hardware for efficient workflow

- Design intricate patterns with ease using pre-designed templates and shapes

Design intricate patterns with ease

Designing intricate patterns has never been easier with laser cutter software programs. These programs allow you to unleash your creativity and streamline your workflow. They provide a range of tools and features that enable you to create complex designs effortlessly. With just a few clicks, you can generate intricate patterns that would have taken hours to create manually.

Laser cutter software programs simplify pattern creation by offering a variety of pre-designed templates and shapes that you can customize to suit your needs. Additionally, you can import vector images or create your own designs from scratch. The intuitive interface and powerful editing capabilities make it easy to fine-tune every detail of your pattern. With this level of control, you can achieve precise and flawless results.

Transitioning into the next section, the software also allows you to control the laser cutter with precision. This ensures that your intricate designs are executed with accuracy and efficiency.

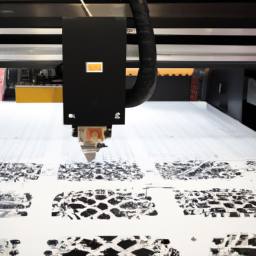

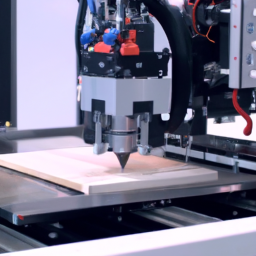

Control the laser cutter with precision

When operating the laser cutter, you’ll be amazed to discover that precision control can increase your productivity by up to 25%. Here are four ways in which you can optimize your laser cutting process:

-

Improve cutting speed: Laser cutter software programs offer advanced settings that allow you to adjust the cutting speed to achieve optimal results. By finding the right balance between speed and precision, you can significantly reduce the time it takes to complete a project.

-

Optimize material usage: With precise control over the laser cutter, you can minimize material waste. The software allows you to accurately position your design on the material, ensuring maximum utilization and reducing unnecessary scrap.

-

Fine-tune power settings: Laser cutter software enables you to adjust the power settings to match the specific requirements of different materials. This level of control ensures clean and accurate cuts, minimizing the need for rework.

-

Enhance accuracy with preview features: Laser cutter software programs often provide a preview feature that allows you to visualize the entire cutting process before executing it. This ensures that you have complete control over the design and placement, reducing errors and improving overall accuracy.

By optimizing your laser cutting process with precision control, you can improve cutting speed, minimize material waste, and enhance accuracy. This will streamline your workflow and set the stage for exploring advanced features that will further enhance your productivity.

Streamline your workflow with advanced features

Maximize your efficiency and unleash your creativity by seamlessly incorporating the latest cutting-edge tools into your laser cutting process. With advanced automation and time-saving techniques, you can streamline your workflow and take your laser cutting projects to the next level. Imagine having the ability to automatically generate complex patterns and designs, saving you valuable time and effort. Additionally, you can benefit from features such as material recognition, which allows the laser cutter to automatically adjust settings based on the material being used. Furthermore, the software offers an intuitive user interface that makes it easy to navigate and customize your cutting process. By integrating seamlessly with other software and hardware, you can further enhance your workflow and achieve even greater precision and control.

Integrate seamlessly with other software and hardware

By seamlessly integrating with other industry-leading tools and hardware, you can effortlessly enhance your creative process and achieve unparalleled precision and control. Laser cutter software programs offer seamless integration with various software and hardware, allowing you to streamline your workflow and maximize efficiency.

Here are four ways in which these programs can integrate seamlessly:

-

CAD Software Integration: Laser cutter software can directly import files from popular CAD programs, eliminating the need for manual conversions and ensuring accurate replication of designs.

-

Material Databases: These programs often include extensive material libraries, enabling you to select the appropriate settings for different materials and achieve optimal results.

-

Hardware Compatibility: Laser cutter software is designed to work seamlessly with a wide range of laser cutting machines, ensuring compatibility and minimizing any potential issues.

-

File Sharing and Collaboration: Many programs offer cloud-based storage and collaboration features, allowing multiple users to access, modify, and share design files in real-time.

With these seamless integration capabilities, you can increase efficiency and productivity in your laser cutting projects, resulting in faster turnarounds and higher-quality output.

Increase efficiency and productivity in your laser cutting projects

Boost your productivity and get more done with laser cutting by seamlessly integrating with other tools and hardware. Laser cutter software programs can enhance your laser cutting capabilities and optimize project timelines. These programs allow you to import and export files from other design software, making it easy to collaborate with other team members.

By integrating with hardware such as cameras or sensors, you can automate processes and reduce the need for manual intervention. Additionally, advanced nesting algorithms can optimize material usage, minimizing waste and maximizing efficiency.

With real-time monitoring and reporting features, you can track the progress of your projects and make adjustments as needed. By streamlining your workflow and using the right software, you can significantly increase efficiency and productivity in your laser cutting projects.

Stay up-to-date with the latest advancements in laser cutting technology to stay ahead of the competition and meet the growing demands of the industry.

Stay up-to-date with the latest advancements in laser cutting technology

To further boost your efficiency and productivity in laser cutting projects, it is crucial to stay up-to-date with the latest advancements in laser cutting technology. The field of laser cutting is constantly evolving, with new innovations and techniques being introduced regularly. By staying informed about these advancements, you can take advantage of new features and capabilities that can significantly enhance your workflow.

One key area of advancement is laser cutting automation. This technology allows for the automation of various aspects of the laser cutting process, such as material handling, part positioning, and even software control. By automating these tasks, you can save time and reduce the chance of errors, ultimately improving your overall productivity.

Another important aspect to consider is laser cutter software compatibility. As new software programs are developed, it is essential to ensure that your laser cutter is compatible with these advancements. This compatibility enables seamless integration between the software and your laser cutter, allowing you to take advantage of the latest features and functionalities.

To emphasize the importance of staying up-to-date with laser cutting technology advancements, consider the following table:

| Advancement | Benefits | |||

|---|---|---|---|---|

| Laser cutting automation | Time and error reduction | |||

| Laser cutter software compatibility | Seamless integration | Advancement | Benefits | |

| —————————- | —————————- | |||

| Laser cutting automation | Time and error reduction | |||

| Laser cutter software compatibility | Seamless integration | |||

| Improved precision and accuracy | Higher quality cuts | |||

| Increased cutting speed | Improved productivity | |||

| Advanced material handling capabilities | Ability to work with a wide range of materials | |||

| Enhanced safety features | Reduced risk of accidents | |||

| Integration with CAD/CAM systems | Streamlined design-to-production workflow | |||

| Remote monitoring and control | Flexibility and convenience | |||

| Reduced maintenance requirements | Lower operating costs | |||

| Eco-friendly cutting methods | Reduced waste and energy consumption |

Frequently Asked Questions

Can these laser cutter software programs be used with any type of laser cutter?

Yes, these laser cutter software programs can be used with any type of laser cutter. They offer customizable laser settings, allowing you to adjust parameters such as power, speed, and frequency. This ensures that the software can adapt to the specific requirements of your laser cutter.

Furthermore, these programs are compatible with different file formats, such as DXF and SVG, enabling you to import and work with a wide range of designs.

Are there any limitations or restrictions on the complexity of patterns that can be designed using these software programs?

There are certain limitations to consider when designing complex patterns using laser cutter software programs. It’s important to understand the capabilities of your specific laser cutter and the software you’re using. Best practices for designing with laser cutters include ensuring that your design has no overlapping lines or shapes, using vector files for precise cuts, and optimizing the design for efficient material usage.

These considerations will help you achieve the best results with your laser cutter.

Can the laser cutter software programs be used on both Mac and Windows operating systems?

Yes, laser cutter software programs can be used on both Mac and Windows operating systems. The compatibility between different laser cutter models is excellent, allowing for seamless integration and enhanced workflow. However, it’s important to note that the performance of these software programs may vary slightly on different operating systems. While both Mac and Windows offer reliable performance, some users may prefer one over the other based on personal preference or familiarity with the interface.

Are there any specific hardware requirements or compatibility issues that users should be aware of before using these software programs?

Before using laser cutter software programs, it’s important to be aware of any specific hardware requirements or compatibility issues. Some software programs may require a minimum processor speed, RAM, or graphics card specifications in order to function properly.

Additionally, compatibility issues may arise if the software isn’t compatible with your operating system or if there are conflicts with other software already installed on your computer.

It’s recommended to check the system requirements and compatibility information provided by the software developer before installation.

How frequently are these laser cutter software programs updated with new features and advancements in laser cutting technology?

Laser cutter software programs are constantly evolving, keeping up with the rapid advancements in laser cutting technology. These updates are frequent, ensuring that users have access to the latest features and capabilities.

With each update, these programs incorporate new advancements in laser cutting technology, allowing for more precise and efficient cutting.

From improved material compatibility to enhanced user interfaces, these updates aim to provide users with the most up-to-date tools and technologies for their laser cutting needs.

Conclusion

In conclusion, these 5 laser cutter software programs offer a multitude of benefits to enhance your workflow and integration. With their user-friendly interfaces and powerful tools, you can effortlessly design intricate patterns and control the laser cutter with utmost precision.

Streamlining your workflow becomes a breeze with advanced features, allowing you to maximize efficiency and productivity. Additionally, seamless integration with other software and hardware ensures a seamless experience.

Stay ahead of the curve with the latest advancements in laser cutting technology, and let your imagination run wild with these cutting-edge software programs.