Imagine your workshop as a bustling city, with laser cutters as the towering skyscrapers that shape the skyline. Within this metropolis, the air is thick with fumes and particles, posing a risk to your health and safety. Just as a city needs a robust infrastructure to thrive, your workshop needs a comprehensive ventilation system to ensure a clean and breathable environment.

To combat the hazards of laser cutter emissions, you need the right safety products in place. In this article, we will explore five essential ventilation safety products that are indispensable in any laser cutter workshop. From air purifiers to personal protective equipment, we will delve into the technical details of each product, guiding you towards creating a workspace that promotes both productivity and well-being.

So, gear up and get ready to fortify your workshop with these essential tools for laser cutter ventilation safety.

Key Takeaways

- Laser cutters emit harmful particles and fumes, requiring a comprehensive ventilation system.

- Regular maintenance and inspection of the ventilation system, including air purifiers, filters, and exhaust fans, is necessary for optimal safety and effectiveness.

- Personal protective equipment (PPE), such as respiratory protection and safety goggles, are crucial for protecting against laser radiation and contaminants.

- Incorporating a fire suppression system in the workshop provides rapid response and extinguishing capabilities, ensuring safety during laser cutting operations.

Air Purifier

You’ll want to invest in an air purifier to keep your workshop air clean and safe while using a laser cutter. An air purifier has several benefits that make it an essential tool for ensuring a healthy working environment.

Firstly, it effectively removes harmful airborne particles such as dust, smoke, and fumes, which are common byproducts of laser cutting. This helps prevent respiratory issues and allergies caused by inhaling these pollutants.

Additionally, an air purifier helps to eliminate odors, ensuring a pleasant working environment.

To maintain the air purifier’s effectiveness, regular maintenance is required. This includes cleaning or replacing filters, emptying the collection tray, and checking the overall performance of the purifier.

By investing in an air purifier and performing regular maintenance, you can ensure that your workshop air remains clean and safe.

Transitioning to the next section, let’s now explore the importance of a proper ventilation system.

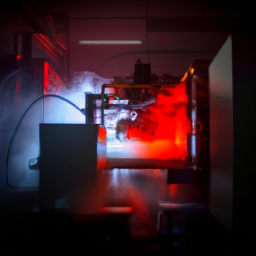

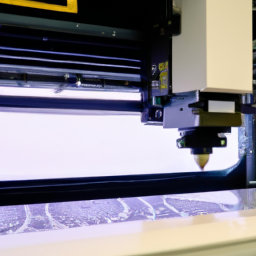

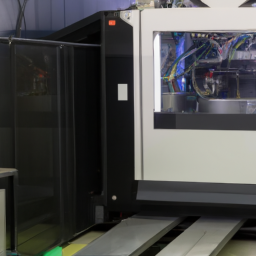

Ventilation System

In your workshop, it’s crucial to have a ventilation system that provides adequate airflow. This system effectively removes fumes and smoke generated by laser cutting. It prevents their accumulation and potential harm to your health. By properly ventilating your workshop, you can maintain a clean and breathable air quality. This allows you to work comfortably and safely.

Provides Adequate Airflow

Ensuring proper airflow is crucial for keeping your workshop safe when using a laser cutter. Adequate airflow helps to control the direction and speed of air movement, effectively removing fumes and smoke from the cutting process. To achieve this, it is essential to have a well-designed ventilation system that meets the specific requirements of your workshop. Regular maintenance of the ventilation system is also necessary to ensure its optimal performance. This includes cleaning or replacing filters, checking the integrity of ductwork, and inspecting the exhaust fan for any signs of wear or damage. By maintaining airflow control and regularly servicing the ventilation system, you can effectively minimize the risk of exposure to harmful fumes and maintain a safe working environment. This leads us to the next section, which discusses how the ventilation system removes fumes and smoke.

Removes Fumes and Smoke

Make sure to regularly inspect and clean the filters, ductwork, and exhaust fan of your ventilation system to effectively remove fumes and smoke from your workspace. Fume extraction is crucial in maintaining a safe and healthy environment when operating a laser cutter. The laser cutting process produces harmful fumes and smoke that can be detrimental to your respiratory system if not properly extracted. By regularly inspecting and cleaning the filters, ductwork, and exhaust fan, you ensure that the ventilation system is functioning optimally.

This not only removes fumes and smoke, but also minimizes the risk of respiratory issues caused by inhaling these harmful substances.

In the next section, we will discuss the importance of maintaining the exhaust fan to further enhance the efficiency of your ventilation system.

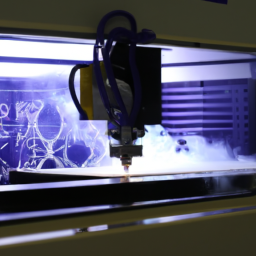

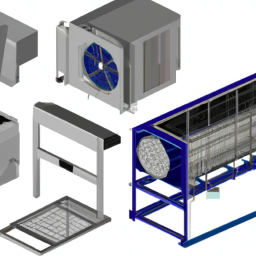

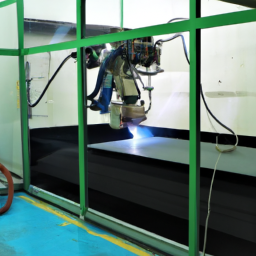

Exhaust Fan

An exhaust fan is a crucial component of a ventilation system in your workshop. It effectively extracts contaminants from the workspace, ensuring the air remains clean and safe for you to breathe.

Additionally, the exhaust fan plays a vital role in reducing heat build-up by expelling hot air and creating a comfortable working environment.

Extracts Contaminants from the Workspace

Clearing the air in your workshop, a laser cutter ventilation system extracts harmful contaminants from your workspace. To ensure optimal workplace air quality, it’s crucial to have an efficient system that effectively removes these contaminants. Here are four key components of a laser cutter ventilation system:

-

Exhaust Fan: The exhaust fan is responsible for drawing in and extracting the contaminated air from the workspace.

-

Ducting: Ducting connects the exhaust fan to the laser cutter, allowing the extraction of contaminants directly from the source.

-

Filters: Filters play a crucial role in removing particulate matter and VOCs from the extracted air, ensuring cleaner air is released back into the environment.

-

Ventilation Hood: The ventilation hood is positioned above the laser cutter, capturing the contaminants emitted during the cutting process.

By incorporating these components into your workshop, you can effectively improve workplace air quality and protect yourself from harmful contaminants. This extraction system also reduces heat build-up, ensuring a safe and comfortable working environment.

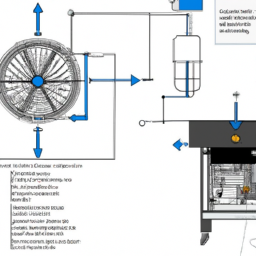

Reduces Heat Build-up

Reducing heat build-up in your workspace is crucial for creating a safe and comfortable environment, and studies have shown that excessive heat can decrease productivity by up to 20%. Proper thermal management is essential when using a laser cutter, as the machine generates a significant amount of heat during operation. To effectively manage the heat, cooling solutions are necessary to maintain optimal conditions. One option is to use a cooling fan system that circulates air and dissipates heat. Another solution is a heat sink, which absorbs and disperses heat away from the laser cutter. Additionally, installing a temperature control system can help regulate the heat levels in the workspace. By implementing these cooling solutions, you can ensure a cooler and more efficient working environment. Transitioning to the next section on ducting and hoses, it is important to consider the proper airflow and ventilation system to complement the heat reduction measures.

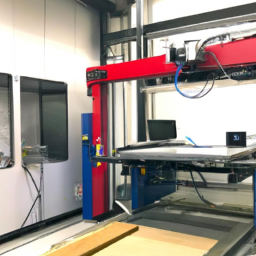

Ducting and Hoses

When it comes to laser cutter ventilation, one of the key elements you’ll need in your workshop is proper ducting and hoses.

Flexible tubing is essential for creating a well-designed ventilation system that efficiently removes fumes and heat generated by the laser cutter. The flexible nature of the tubing allows for easy installation and adjustment to fit the specific layout of your workshop. It also ensures that the fumes are effectively directed outside, preventing any potential health hazards.

In addition to the flexible tubing, you’ll need sturdy hoses to connect the tubing to the ventilation system. These hoses should be made of high-quality materials that can withstand the heat and chemical exposure from the fumes.

With the right ducting and hoses in place, you can ensure a safe and efficient ventilation system for your laser cutter.

Now let’s move on to the next section about personal protective equipment (PPE).

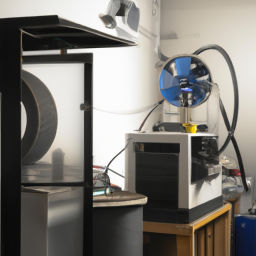

Personal Protective Equipment (PPE)

Equipping oneself with the proper personal protective equipment (PPE) is like donning a suit of armor, ensuring that potential hazards are kept at bay during laser cutting operations. When it comes to laser cutter ventilation safety, respiratory protection is of utmost importance.

Laser cutting involves the release of harmful fumes and particles, which can be inhaled and cause serious health issues. Therefore, wearing a respirator that’s specifically designed for laser cutting is essential. Additionally, safety goggles are crucial for protecting the eyes from laser radiation and potential flying debris. These goggles should have the appropriate lens shade to block the specific wavelength of the laser being used.

By wearing the right respiratory protection and safety goggles, you can safeguard yourself from the harmful effects of laser cutting.

Moving on to the next section, let’s discuss the importance of a fire suppression system in your workshop.

Fire Suppression System

Installing a fire suppression system is crucial to ensure the safety and protection of your workspace during laser cutting operations. Here are four reasons why you need a fire suppression system in your workshop:

-

Rapid Response: A fire suppression system, such as a sprinkler system, can quickly detect and extinguish fires, minimizing potential damage and reducing the risk of injury.

-

Automatic Activation: The system is designed to activate automatically when it detects fire, ensuring that immediate action is taken even if no one is present in the workshop.

-

Effective Suppression: Fire suppression systems utilize various methods, such as water, foam, or gas, to effectively suppress and extinguish fires, depending on the type of fire and materials involved.

-

Compliance with Safety Protocols: Having a fire suppression system in place not only enhances the safety of your workshop but also ensures compliance with safety regulations and guidelines.

Remember to regularly inspect and maintain your fire suppression system, and keep a fire extinguisher nearby as an additional safety measure.

Frequently Asked Questions

What is the recommended maintenance schedule for an air purifier in a laser cutter workshop?

To ensure optimal performance of your air purifier in a laser cutter workshop, it’s crucial to follow a recommended maintenance schedule. Regularly clean or replace the filters according to the manufacturer’s guidelines, typically every 3-6 months.

Inspect the unit for any signs of wear or damage and address them promptly. Additionally, consider using recommended ventilation products, such as exhaust fans and ducting systems, to enhance the air purification process in your workshop.

Can a ventilation system be installed in a small workshop with limited space?

In a small workshop with limited space, installing a ventilation system may seem like an impossible task. However, fear not! There are alternative ventilation options that can effectively address the limitations.

Consider utilizing compact and powerful exhaust fans strategically placed to ensure proper air circulation. Additionally, investing in a portable air purifier with high filtration efficiency can greatly improve the air quality.

While the space may be small, the possibilities for ventilation are endless!

How often should an exhaust fan be cleaned to ensure optimal performance?

To ensure optimal performance, it’s recommended to clean your exhaust fan regularly. The exhaust fan maintenance frequency depends on the level of usage and the environment in which it operates. Generally, it’s advised to clean the fan at least once every three to six months.

Regular cleaning of the exhaust fan offers several benefits. It improves air circulation, increases efficiency, reduces the risk of overheating, and prevents dust buildup. Neglecting regular cleaning can lead to decreased performance and potential damage to the fan.

Are there any specific types of ducting and hoses that are recommended for laser cutter ventilation?

When it comes to laser cutter ventilation, using the right types of ducting and hoses is crucial for proper airflow. Opt for high-quality, durable materials that can withstand the heat and chemicals associated with laser cutting.

There are various types of ventilation systems available, such as flexible ducting and PVC hoses, each with its own benefits. Implementing proper ventilation techniques ensures efficient removal of fumes, protecting both your health and the performance of your laser cutter.

What are the different types of personal protective equipment (PPE) that should be worn while operating a laser cutter, aside from the basic safety goggles and gloves?

When operating a laser cutter, it’s crucial to wear additional personal protective equipment (PPE) to ensure your safety. This includes a respirator or mask to protect against harmful fumes and particles. You should also wear ear protection to prevent hearing damage from the machine’s noise. Additionally, a full-body protective suit is necessary to shield yourself from any potential hazards.

Furthermore, regular maintenance of the ventilation system, optimal exhaust fan cleaning, and the use of recommended ducting and hoses are essential for a safe working environment.

Conclusion

In conclusion, as you wrap up your workshop setup, it’s imperative to prioritize laser cutter ventilation safety. By incorporating essential products such as an air purifier, ventilation system, exhaust fan, ducting, and hoses, as well as personal protective equipment (PPE), you can ensure a secure and healthy working environment.

Remember, safety should never be compromised, and investing in a fire suppression system will provide an extra layer of protection. So, equip yourself with these indispensable tools and breathe easy knowing that you’ve taken every precaution to safeguard yourself and your workshop.