Did you know that improper ventilation in a laser cutting workspace can release harmful fumes and particles into the air? These byproducts can pose serious health risks and damage the environment.

To ensure the safety of your engraving projects and protect your health, it is crucial to follow proper ventilation practices. In this article, we will share five essential tips to help you achieve effective laser cutter ventilation. Whether you are a beginner or an experienced engraver, these tips will help you create a safe and clean working environment.

We will guide you through assessing your workspace, choosing the right ventilation system, positioning it properly, and maintaining regular cleaning and maintenance. Additionally, we will discuss implementing additional safety measures and the importance of regularly monitoring and testing your ventilation system.

By following these tips, you can engrave with confidence, knowing that you are prioritizing safety and protecting yourself and those around you.

Key Takeaways

- Assess workspace for optimal ventilation.

- Clear clutter and remove flammable materials.

- Choose the right ventilation system for laser cutter and workspace.

- Maintain regular cleaning and maintenance for laser cutter and ventilation system.

Assess Your Workspace

Now, let’s take a moment to evaluate your workspace and see if it’s set up for optimal laser cutter ventilation. A proper workspace assessment is essential to ensure a safe and efficient engraving project.

Start by looking at your workspace organization. Is it cluttered or disorganized? Clear any unnecessary items from the area to create a clean and spacious workspace. Make sure there aren’t any flammable materials nearby that could pose a risk.

Additionally, consider the ventilation in the room. Is there adequate airflow? Open windows or use fans to promote air circulation. By having a well-organized and properly ventilated workspace, you’re setting the stage for a successful engraving project.

Now, let’s move on to choosing the right ventilation system for your needs.

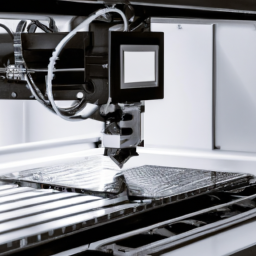

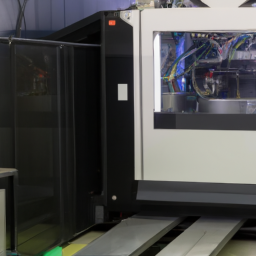

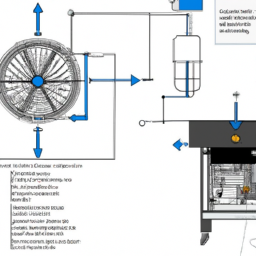

Choose the Right Ventilation System

When choosing the right ventilation system for your laser cutter, it’s important to research different options available. This will ensure you find the best fit for your needs. Consider the specific needs of your laser cutter and workspace. Think about the size of the machine and the materials you’ll be working with. By taking the time to find the right ventilation system, you can ensure a safe and efficient working environment for your engraving projects.

Research different ventilation options available

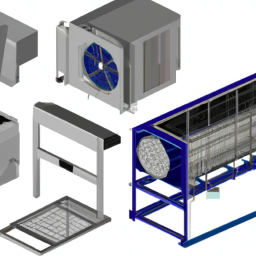

To explore the various ventilation options, it’s crucial to consider the potential impact on the safety and quality of your engraving projects. Start by comparing costs and evaluating the effectiveness of different systems.

One option is a fume extraction system that uses filters to remove harmful particles and gases from the air. This can be a more affordable choice, but it may not be as effective as other options.

Another possibility is a direct outdoor venting system, which expels fumes directly outside. While this can be highly effective, it may require more upfront costs for installation.

It’s important to research and weigh the pros and cons of each option to ensure you choose the right ventilation system for your needs. Consider the specific needs of your laser cutter and workspace to make an informed decision.

Consider the specific needs of your laser cutter and workspace

Take into account the unique requirements of your laser machine and work area in order to make an informed decision. When considering ventilation options for your engraving projects, it’s crucial to consider your workspace organization and laser cutter maintenance.

Ensure that your work area is well-organized, with enough space around the laser cutter for proper ventilation. Additionally, regularly maintain your laser cutter to keep it in optimal condition and prevent any potential hazards. This includes cleaning the machine, replacing filters, and checking for any leaks or malfunctions.

By keeping your laser cutter well-maintained and your workspace organized, you can ensure a safer and more efficient engraving process.

Now, let’s talk about how to position your ventilation system properly for maximum effectiveness.

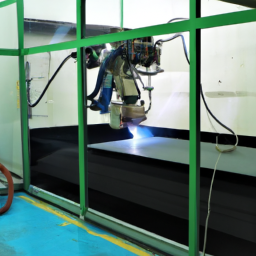

Position Your Ventilation System Properly

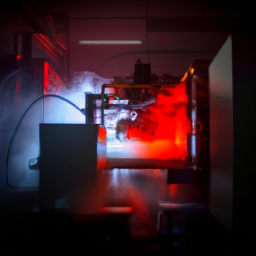

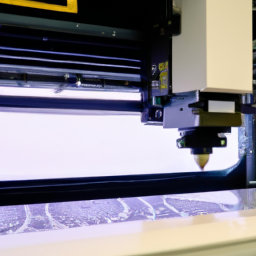

Properly positioning your ventilation system is crucial for proper ventilation and effective removal of fumes and smoke generated during your engraving projects. By ensuring the correct placement of your ventilation system, you can create a clean and safe working environment.

Firstly, it’s important to locate your laser cutter near a window or an exterior wall to allow for easy exhaust discharge. This will help in directing the fumes and smoke out of the workspace. Additionally, positioning the ventilation system close to the laser cutter, with the exhaust hose securely connected, will optimize the extraction of contaminants. Remember to avoid placing obstacles or barriers that could obstruct the airflow.

By following these guidelines for proper ventilation system placement, you can maintain a healthy and efficient workspace.

Now, let’s move on to the next section and discuss how to maintain regular cleaning and maintenance for your laser cutter.

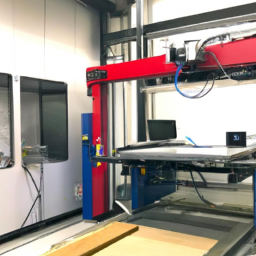

Maintain Regular Cleaning and Maintenance

To ensure the proper functioning of your ventilation system, it’s crucial to clean and replace the filters regularly. This will help prevent any buildup of dust and debris that can hinder the airflow and reduce the effectiveness of the system.

Additionally, it’s important to regularly check for any blockages or buildup in the ventilation system. This will ensure that the air can flow freely and efficiently, minimizing the risk of overheating or damage to the laser cutter.

By staying on top of cleaning and maintenance, you can ensure the safety and longevity of your equipment.

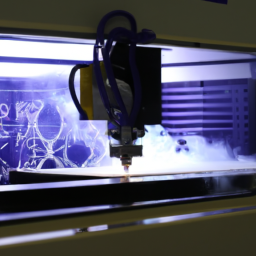

Clean and replace filters regularly

Regularly cleaning and replacing filters is crucial for maintaining proper ventilation in laser cutter engraving projects. A well-maintained cleaning schedule is essential to ensure that the filters are working efficiently.

Over time, the filters can become clogged with debris and dust particles, reducing their effectiveness and potentially causing harmful fumes to accumulate in the workspace. By regularly cleaning and replacing filters, you can ensure that the ventilation system is functioning optimally, providing a safe and clean environment for your laser engraving projects.

Additionally, clean filters can help extend the lifespan of your laser cutter by preventing dust buildup on internal components. Moving forward, it’s important to check for any blockages or buildup in the ventilation system, as this can also impact its efficiency and overall performance.

Check for any blockages or buildup in the ventilation system

Make sure you take a moment to check for any blockages or buildup in your ventilation system to ensure it’s working effectively and keeping your workspace clean and safe.

Regularly inspecting your ventilation system is crucial for maintaining its efficiency and preventing any potential hazards. Start by examining the air intake and exhaust vents, as well as any ductwork or filters. Clear any obstructions such as dust, debris, or residue that may have accumulated over time. This will help maintain proper airflow and prevent any potential damage to the laser cutter or health risks from poor ventilation.

Once you’ve cleared any obstructions, you can implement additional safety measures to further enhance the effectiveness of your ventilation system.

Implement Additional Safety Measures

Consider installing a smoke detector near the laser cutter to ensure prompt detection of any potential fire hazards during engraving projects. This additional safety measure is crucial when implementing safety protocols for laser cutter ventilation. By having a smoke detector in place, you can quickly respond to any signs of smoke or fire, minimizing the risk of accidents and potential damage.

In addition to ensuring proper ventilation, this step adds an extra layer of protection to your workspace. Regularly monitoring and testing your ventilation system is essential to maintain a safe working environment. By doing so, you can identify any issues or blockages that may hinder the effectiveness of the ventilation system. This proactive approach enables you to address any problems promptly, ensuring the continued safety and efficiency of your engraving projects.

Regularly Monitor and Test Your Ventilation System

To ensure a safe working environment, it’s important for you to regularly monitor and test the effectiveness of your ventilation system to address any potential issues promptly. By regularly monitoring and testing your ventilation system, you can ensure that it is functioning properly and effectively removing harmful fumes and particles from the air. This will help prevent any health hazards and maintain a clean and safe workspace.

To monitor the effectiveness of your ventilation system, you can use various methods such as visual inspection, air quality testing, and airflow measurement. Visual inspection involves checking for any blockages or damage to the ventilation system. Air quality testing can be done using portable air monitors to check for any harmful substances in the air. Airflow measurement can be done using an anemometer to ensure that the ventilation system is providing sufficient air circulation.

If any issues are identified during the monitoring process, it’s important to troubleshoot and address them promptly. This can involve cleaning or replacing filters, checking for any leaks or obstructions, and ensuring that the ventilation system is properly maintained. Regular monitoring and troubleshooting will help ensure that your ventilation system is working effectively and providing a safe working environment for your laser engraving projects.

| Monitoring Effectiveness | Troubleshooting Issues | |||

|---|---|---|---|---|

| Visual inspection | Cleaning or replacing filters | |||

| Air quality testing | Checking for leaks or obstructions | |||

| Airflow measurement | Proper maintenance | Airflow measurement | Proper maintenance and regular servicing of HVAC systems |

Frequently Asked Questions

Can I use a laser cutter without a ventilation system?

Using a laser cutter without a ventilation system isn’t recommended due to the potential health and safety risks involved. However, if you can’t install a traditional ventilation system, there are alternative options available. These include using a fume extractor or positioning the laser cutter near an open window or doorway. It’s important to remember that a proper ventilation system provides numerous benefits, such as removing harmful fumes and preventing debris accumulation, ensuring a safer and cleaner working environment.

How often should I clean and maintain my ventilation system?

How often should you clean and maintain your ventilation system?

Keeping your ventilation system clean is crucial for the safety and efficiency of your laser cutter. Regular cleaning and maintenance will prevent the build-up of dust and debris, ensuring proper airflow and preventing potential fire hazards.

Aim to clean your ventilation system at least once a month, or more frequently if you notice reduced airflow. Additionally, perform routine maintenance procedures such as checking for leaks, replacing filters, and inspecting the exhaust fan.

What safety measures should I implement to ensure proper ventilation?

To ensure proper ventilation for laser cutting and maintain the importance of air quality in laser engraving, there are several safety measures you should implement.

Firstly, make sure your ventilation system is in good working condition and regularly clean and maintain it.

Secondly, use a high-quality air filtration system to remove harmful particles and fumes.

Additionally, wear appropriate personal protective equipment such as goggles and masks.

Lastly, ensure proper airflow in your workspace by keeping doors and windows open or using fans.

How can I test the effectiveness of my ventilation system?

To test the effectiveness of your ventilation system, you need to perform ventilation system troubleshooting. Start by checking for signs of inadequate ventilation, such as strong odors or smoke lingering in the air.

Use a smoke test to see if the smoke is being properly extracted. Additionally, monitor the temperature and humidity levels in the area.

If you notice any issues, it’s crucial to address them immediately to ensure the safety of your engraving projects.

What are the consequences of not positioning the ventilation system properly?

Not positioning your ventilation system properly can have serious consequences. Without proper positioning, the ventilation system may not effectively remove harmful fumes and particles from the air. This can result in poor air quality, which can be hazardous to your health.

Additionally, improper ventilation positioning can lead to the accumulation of flammable materials, increasing the risk of fire. Regular ventilation system maintenance and proper positioning are crucial for ensuring a safe and healthy working environment.

Conclusion

So there you have it, fellow laser engravers! You’ve now reached the end of this informative guide, and I hope you’ve gained valuable insights into laser cutter ventilation.

By following these five tips, you can ensure a safe and efficient workspace for all your engraving projects. Remember, like a skilled conductor guiding their orchestra, you must assess, choose, position, maintain, and implement to create a harmonious and secure environment.

So, take these precautions seriously, and let your creativity engrave wonders while keeping safety center stage. Happy engraving!