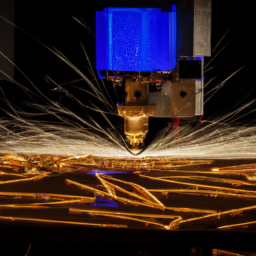

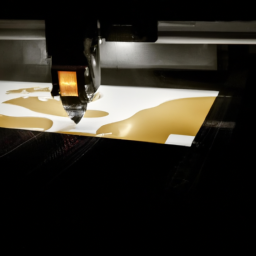

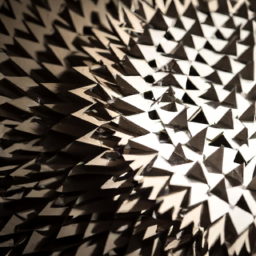

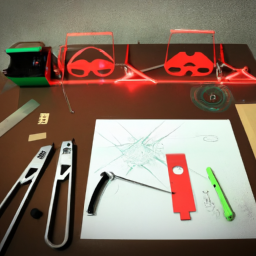

Imagine stepping into your home workshop, surrounded by the hum of machinery and the smell of burning metal. You’re about to embark on a creative journey, using laser cutting to bring your ideas to life. But amidst the excitement, it’s crucial to prioritize safety.

Laser cutting can be a powerful tool, but without proper precautions, it can also pose serious risks. That’s why we’ve compiled 5 essential tips to ensure a safer home workshop experience. From wearing the right safety gear to understanding machine features and following correct operating procedures, these tips will help you navigate the world of laser cutting with confidence.

By implementing these measures, you can protect yourself, your workspace, and those around you, allowing you to focus on what truly matters: unleashing your creativity and craftsmanship. Let’s dive in and make your home workshop a haven of safety.

Key Takeaways

- Wear appropriate safety gear: safety glasses, face shield, gloves, and long-sleeved shirt.

- Set up a well-ventilated workspace to remove fumes and smoke.

- Understand laser cutting machine safety features: emergency stop button, protective enclosure, laser power control, laser beam alignment indicator.

- Follow correct operating procedures: read manufacturer’s instructions, wear appropriate protective equipment, keep work area clean and organized, regularly inspect and maintain the machine.

Wear Appropriate Safety Gear

You should always wear the appropriate safety gear, such as safety glasses and a face shield, to protect your eyes and face from any potential flying debris or sparks while operating a laser cutter in your home workshop. Safety precautions should be your top priority when using any power tools, and laser cutters are no exception. The intense heat generated by the laser can cause materials to melt or emit harmful fumes, so it’s crucial to have proper protective equipment.

Safety glasses with side shields will shield your eyes from direct contact with the laser beam, while a face shield will provide full-face protection. Additionally, wearing gloves and a long-sleeved shirt can help protect your skin from accidental burns.

Now that you’re equipped with the right safety gear, let’s move on to setting up a well-ventilated workspace.

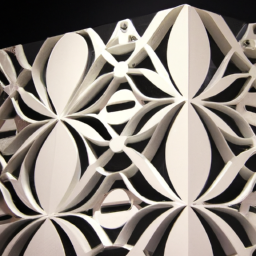

Set Up a Well-Ventilated Workspace

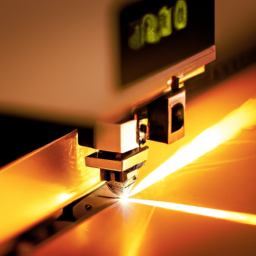

To ensure a breezy and comfortable environment in your DIY zone, it’s crucial to have a well-ventilated workspace. Proper ventilation is essential when working with a laser cutting machine as it helps to remove any fumes or smoke produced during the cutting process.

Make sure your workspace has good airflow by opening windows or using fans. Additionally, consider installing an exhaust system or using a portable fume extractor to efficiently remove the pollutants.

Along with proper ventilation, workspace organization is important for safety. Keep your work area clean and clutter-free to prevent accidents and ensure easy access to your tools and materials.

Now that you’ve set up a well-ventilated workspace, it’s time to understand laser cutting machine safety features.

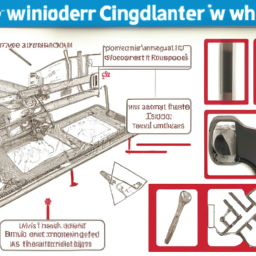

Understand Laser Cutting Machine Safety Features

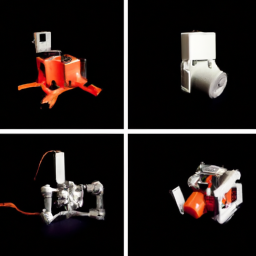

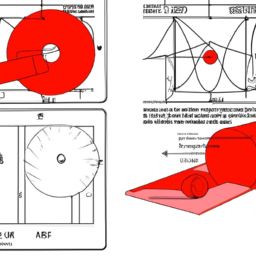

Understanding the safety features of a laser cutting machine is like having a knowledgeable guide by your side, ensuring a smooth and secure DIY experience. Laser cutting machines come equipped with various safety features to protect you and your workshop from potential hazards. Take a look at the table below to familiarize yourself with some common safety features and their functions.

| Safety Feature | Function |

|---|---|

| Emergency Stop Button | Immediately stops the machine in case of an emergency |

| Protective Enclosure | Shields the laser beam and prevents accidental exposure |

| Laser Power Control | Adjusts the laser power to match the material being cut |

| Laser Beam Alignment Indicator | Helps ensure accurate cutting by aligning the laser beam |

To ensure a safe environment, it is crucial to abide by laser cutting safety regulations and properly maintain and clean your laser cutting machine. This will be discussed in the next section.

Properly Maintain and Clean Your Laser Cutting Machine

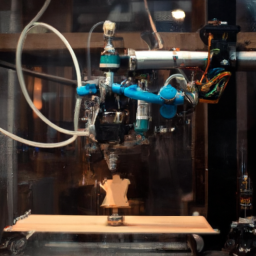

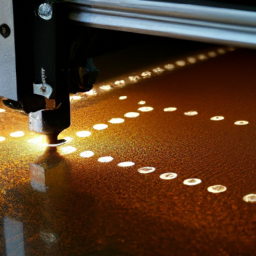

Ensure that your laser cutting machine stays in optimal condition and operates smoothly by properly maintaining and cleaning it. Regular maintenance is essential to prolong the lifespan of your machine and prevent any potential issues. Here are some tips to help you maintain and clean your laser cutting machine:

-

Clean the lens regularly using a microfiber cloth and lens cleaning solution to remove any dust or debris that may affect the laser beam’s quality.

-

Check and clean the exhaust system to ensure proper ventilation and prevent any buildup of fumes or particles.

-

Inspect and clean the mirrors to maintain their reflectivity and prevent any loss of laser power.

-

Lubricate the moving parts of the machine according to the manufacturer’s instructions to reduce friction and ensure smooth operation.

-

Keep the workspace clean and organized to prevent any potential hazards and ensure the machine’s safety.

By following these maintenance and cleaning practices, you can ensure the longevity and efficient operation of your laser cutting machine.

Next, let’s discuss how to follow correct operating procedures to further enhance safety and productivity.

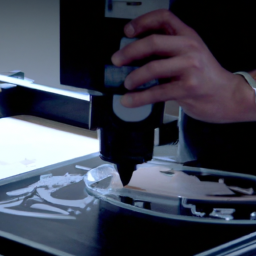

Follow Correct Operating Procedures

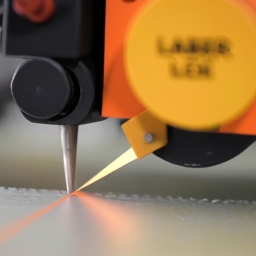

Make sure you take the time to familiarize yourself with the proper operating procedures for your machine, ensuring a smooth and efficient workflow that will leave you feeling confident and in control. By following the correct operating procedures, you can avoid accidents and minimize risks in your home workshop.

Start by reading the manufacturer’s instructions thoroughly and understanding the machine’s limitations and capabilities. Always wear the appropriate personal protective equipment, such as safety glasses and gloves, to protect yourself from potential hazards.

Keep your work area clean and organized, ensuring there are no obstructions that could cause accidents. Regularly inspect and maintain your machine to identify any potential issues before they escalate.

By following these procedures, you can ensure a safe working environment and minimize the risks associated with laser cutting. Remember to educate yourself on laser cutting safety guidelines for further protection.

Educate Yourself on Laser Cutting Safety Guidelines

Take the time to educate yourself on laser cutting safety guidelines so you can confidently create in a secure and protected environment. By understanding the potential laser cutting hazards and implementing the necessary safety precautions, you can ensure a safer home workshop experience.

Here are some key guidelines to keep in mind:

-

Wear appropriate protective gear, such as safety glasses and gloves, to shield yourself from potential laser beam reflections and heat.

-

Maintain a clean and organized workspace to prevent accidents and minimize fire hazards.

-

Familiarize yourself with the laser cutting machine’s manual and operating instructions to ensure proper usage and avoid any mishaps.

By following these safety guidelines, you can minimize the risks associated with laser cutting and create a safer working environment for yourself and those around you. Remember, safety should always be a top priority in your home workshop.

Frequently Asked Questions

What are the essential safety gear items that should be worn while operating a laser cutting machine?

When operating a laser cutting machine, it’s crucial to prioritize your safety. One essential safety gear item that you must wear is protective eyewear. Think of it as your ‘shield’ against potential hazards. By wearing it, you protect your eyes from flying debris and harmful laser radiation.

The importance of wearing protective eyewear cannot be overstated. It not only prevents eye injuries but also ensures the long-term health and well-being of your vision. The benefits of using this gear are invaluable, providing you with peace of mind and a safer working environment.

How can I ensure that my workspace is well-ventilated for laser cutting?

To ensure a well-ventilated workspace for laser cutting, prioritize the importance of ventilation for safety. Install proper ventilation systems, like exhaust fans or air purifiers, to remove harmful fumes and particles produced during the cutting process. Position the equipment near a window or door to allow fresh air circulation. Regularly check and clean ventilation systems to maintain their efficiency.

Remember, proper ventilation is crucial for a safe and healthy laser cutting environment.

What are some common safety features found in laser cutting machines and how do they contribute to a safer working environment?

Laser cutting machine safety features are paramount for a secure workspace. They include interlocks, emergency stop buttons, and enclosure systems.

Interlocks ensure that the laser beam cannot be emitted when the doors are open, preventing accidents.

Emergency stop buttons immediately halt the machine in case of an emergency.

Enclosure systems enclose the cutting area, containing fumes and minimizing the risk of fire.

Wearing safety gear such as goggles, gloves, and aprons is equally important to protect yourself from potential hazards.

Are there any specific maintenance and cleaning procedures that should be followed regularly for a laser cutting machine?

To ensure the optimal performance and longevity of your laser cutting machine, it’s crucial to follow regular maintenance procedures and cleaning routines.

Start by checking and cleaning the lenses and mirrors to remove any dirt or debris that may affect the laser beam’s quality.

Additionally, inspect and clean the exhaust system, ensuring it’s clear of any obstructions.

Regularly lubricate the machine’s moving parts and check for loose connections.

By maintaining these routines, you can ensure a safe and efficient working environment.

Where can I find comprehensive guidelines on laser cutting safety to further educate myself on the topic?

You can find comprehensive guidelines on laser cutting safety to further educate yourself on the topic from various sources.

One option is to check the Occupational Safety and Health Administration (OSHA) website, which provides detailed information on laser safety standards and practices.

Additionally, laser manufacturers often provide their own safety guidelines and recommendations for operating their specific machines.

It’s essential to thoroughly review these guidelines to ensure a safe laser cutting environment.

Conclusion

In conclusion, by following these laser cutting tips, you can create a safer and more enjoyable home workshop experience.

Remember to gear up with safety glasses and gloves, protecting yourself from potential hazards.

Ensure your workspace is well-ventilated, allowing fresh air to circulate and keep you comfortable.

Familiarize yourself with the safety features of your laser cutting machine and maintain it regularly to prevent any mishaps.

Lastly, always adhere to proper operating procedures and educate yourself on laser cutting safety guidelines.

With these precautions in place, your home workshop will be a haven of creativity and safety.