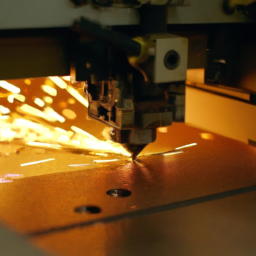

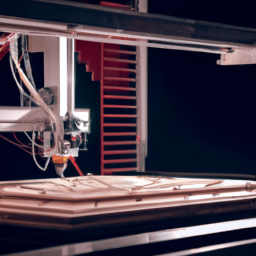

Imagine a master craftsman skillfully sculpting a masterpiece from a block of marble, chiseling away with unwavering precision and artistry. Now, imagine that same level of skill and precision applied to the world of metal cutting. That is the power of 3D laser cutting.

In the realm of metal cutting, 3D laser cutting is the virtuoso, seamlessly melding the art of design with the science of technology. With its ability to precisely cut through metal with unparalleled accuracy, this technique has revolutionized the manufacturing industry.

But what makes 3D laser cutting the perfect choice for metal cutting? Well, let me enlighten you. With its precision and accuracy, it ensures that every cut is flawless, resulting in a finished product of impeccable quality. Its versatility allows for the creation of complex designs that were once thought to be impossible. And with its cost-effectiveness and efficiency, it not only saves time but also minimizes material waste.

So, if you’re looking for a metal cutting technique that combines artistry with efficiency, look no further than 3D laser cutting. It’s time to elevate your metal fabrication to a whole new level.

Key Takeaways

- Flawless cuts with impeccable quality

- Creation of complex designs

- Cost-effective and minimizes material waste

- Unmatched precision and accuracy

Precision and Accuracy

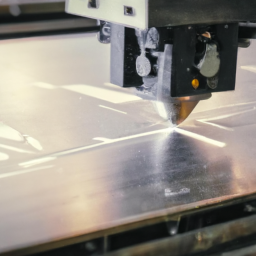

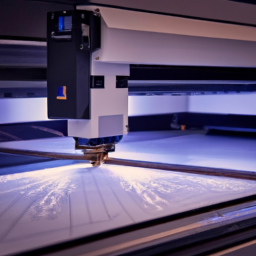

You’ll be amazed at how 3D laser cutting can ensure every intricate detail of your metal cutting project is executed with utmost precision and accuracy, leaving no room for errors or imperfections. The precision and repeatability offered by this cutting-edge technology is unparalleled.

With advanced cutting techniques, the laser can create intricate and complex designs with ease, ensuring that each cut is made exactly where it needs to be. This level of precision allows for the creation of intricate metal components that are essential for various industries, including aerospace and automotive.

But precision is not the only benefit of 3D laser cutting. Its versatility for complex designs is equally impressive, making it the ideal choice for projects that require intricate and detailed metal fabrication.

Versatility for Complex Designs

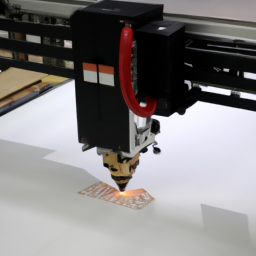

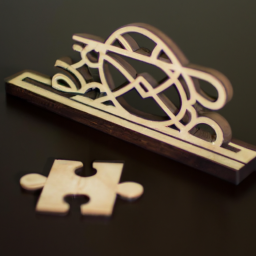

With 3D laser cutting, you can easily tackle intricate designs, thanks to its versatility for handling complex shapes and patterns. Did you know that 3D laser cutting can achieve precision levels as high as 0.1mm? This level of precision combined with its design capabilities makes it perfect for creating even the most intricate patterns. Whether it’s a complex geometric shape or a delicate filigree design, 3D laser cutting can handle it with ease.

The laser beam can follow intricate paths and curves, allowing for the creation of highly detailed and precise cuts. This level of versatility opens up a world of possibilities for designers and engineers, enabling them to bring their most complex and imaginative creations to life.

In addition to its design capabilities, 3D laser cutting also offers cost-effectiveness and efficiency, making it a preferred choice for metal cutting projects.

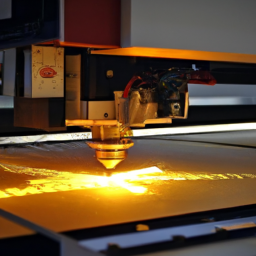

Cost-Effectiveness and Efficiency

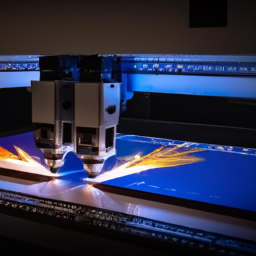

Incorporating 3D laser cutting into manufacturing processes can significantly boost cost-efficiency and streamline operations. This advanced technology offers numerous cost-saving benefits and improved production speed. By utilizing a high-powered laser beam, 3D laser cutting allows for precise and accurate cuts, resulting in minimal material waste. This eliminates the need for additional machining processes and reduces material costs. Furthermore, the speed and accuracy of 3D laser cutting enable manufacturers to complete complex designs in a fraction of the time compared to traditional cutting methods. This not only saves time but also increases overall productivity. With its ability to optimize material usage and enhance production speed, 3D laser cutting is the ideal solution for cost-effective and efficient metal cutting. Transitioning to the next section, the minimal material waste achieved through 3D laser cutting further enhances its appeal.

Minimal Material Waste

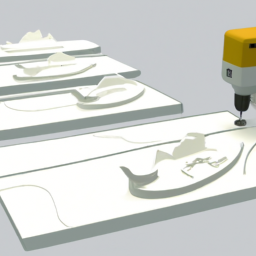

Maximizing material usage is essential in any manufacturing process, and 3D laser cutting ensures minimal waste, allowing you to optimize your resources effectively.

By utilizing precise laser beams, 3D laser cutting minimizes material waste by accurately cutting the desired shape without any excess. This reduced waste not only saves cost but also has a reduced environmental impact, as less material is being discarded.

Furthermore, minimal material waste also contributes to improved safety in the manufacturing process. With less scrap material, there is a lower risk of accidents and injuries caused by handling and disposing of excess metal.

Thus, 3D laser cutting not only enhances cost-effectiveness and efficiency but also promotes environmentally-friendly practices and ensures a safer working environment.

Transitioning into the subsequent section about ‘speed and productivity’, the efficiency of 3D laser cutting also translates into enhanced speed and productivity.

Speed and Productivity

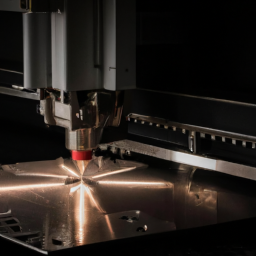

Boost your productivity and get your projects done faster with 3D laser cutting technology. This advanced method of metal cutting offers improved cutting quality and reduced production time, making it perfect for any manufacturing process.

With 3D laser cutting, you can achieve precise and accurate cuts, resulting in a higher quality end product. The speed of the laser cutting process allows for quick turnaround times, increasing your overall productivity. You can complete more projects in less time, giving you a competitive edge in the market.

Additionally, the reduced production time means that you can meet tight deadlines and satisfy customer demands promptly. With 3D laser cutting, you can save time and effort, ultimately boosting your business’s efficiency.

This leads us to the next section about the reduced need for post-processing.

Reduced Need for Post-Processing

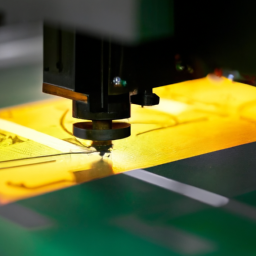

Save time and effort by utilizing 3D laser cutting technology, which significantly reduces the need for extensive post-processing, allowing you to focus on delivering exceptional results.

With traditional cutting methods, extensive post-processing is often required to remove burrs and smooth rough edges. However, 3D laser cutting provides clean and precise cuts, minimizing the need for additional finishing processes.

This not only saves time but also reduces costs associated with labor and materials. Moreover, the accuracy of 3D laser cutting ensures improved quality control, as it eliminates human error and produces consistent results.

By reducing the need for post-processing, 3D laser cutting technology streamlines the production process, enabling you to meet deadlines more efficiently while maintaining the highest standards of quality.

Frequently Asked Questions

How does 3D laser cutting compare to traditional metal cutting methods in terms of precision and accuracy?

In terms of precision and accuracy, 3D laser cutting has significant advantages over traditional metal cutting methods. The laser beam used in 3D laser cutting is highly focused, allowing for precise and fine cuts with minimal material wastage. Additionally, the computer-controlled system ensures consistent and accurate cutting throughout the entire process.

These advantages make 3D laser cutting ideal for various applications, including intricate designs and complex shapes, where precision and accuracy are crucial.

Can 3D laser cutting be used for cutting other materials besides metal?

3D laser cutting is not limited to metal cutting—it has a wide range of applications. In the automotive industry, it is used for precision cutting of various materials, like plastics and composites, to create intricate car parts.

Moreover, the aerospace field benefits from 3D laser cutting due to its ability to produce lightweight components with high precision. With its versatility and accuracy, 3D laser cutting proves to be an invaluable tool across industries.

What are the factors that contribute to the cost-effectiveness and efficiency of 3D laser cutting?

To understand the cost-effectiveness and efficiency of 3D laser cutting, several factors must be considered.

The precision and accuracy of the laser cutting process greatly minimize material waste, resulting in cost savings.

The high cutting speeds and ability to handle complex designs lead to increased efficiency, reducing production time.

Additionally, the automated nature of 3D laser cutting reduces labor costs and human error.

Overall, these factors contribute to the cost-effectiveness and efficiency of 3D laser cutting processes.

How does 3D laser cutting minimize material waste compared to other cutting techniques?

With 3D laser cutting, you can dramatically reduce material waste compared to other cutting techniques. This cutting-edge technology allows for precise and accurate cuts, minimizing errors and maximizing material utilization.

By using a focused laser beam, 3D laser cutting achieves clean and smooth edges, reducing the need for additional finishing processes. This not only increases production speed but also reduces environmental impact by minimizing scrap material, making it an ideal choice for metal cutting.

Does 3D laser cutting significantly reduce the need for post-processing compared to other methods?

Yes, 3D laser cutting significantly reduces the need for post-processing compared to other methods. This reduction in post-processing is due to the precise and accurate nature of laser cutting, which minimizes the need for additional finishing touches.

Additionally, the high energy density of the laser beam results in clean and precise cuts, eliminating the need for extensive deburring or smoothing processes. These time-saving benefits make 3D laser cutting an efficient choice for metal cutting.

Conclusion

In conclusion, 3D laser cutting is the ideal method for metal cutting due to its unmatched precision and accuracy. Its versatility allows for the creation of complex designs with ease, while also being cost-effective and efficient.

Additionally, it minimizes material waste and increases speed and productivity. Although some may argue that the initial investment is high, the long-term benefits and increased productivity outweigh the cost.

Embracing this advanced technology will undoubtedly elevate your metal cutting capabilities to new heights.