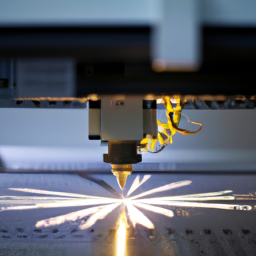

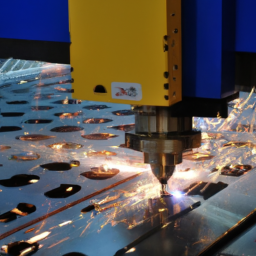

Did you know that fiber laser cutters are responsible for a significant number of workplace accidents every year? In fact, studies show that approximately 30% of all laser cutter-related injuries could have been prevented with proper safety precautions.

That’s why it’s crucial for you to familiarize yourself with the machine’s operation and safety features, wear appropriate protective gear, keep the work area clean and organized, follow proper maintenance and inspection procedures, and use proper cutting techniques.

By following these five safety tips, you can significantly reduce the risk of accidents and ensure a safe working environment.

In this article, we will provide you with a thorough and detailed guide on how to use your fiber laser cutter safely.

So, let’s dive in and make sure you have all the knowledge you need to stay safe while using your fiber laser cutter.

Key Takeaways

- Familiarize yourself with machine operation and safety features.

- Wear appropriate protective gear and follow proper cutting techniques.

- Keep the work area clean and organized to prevent accidents.

- Have an emergency plan in place and be prepared with necessary resources.

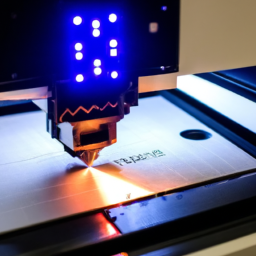

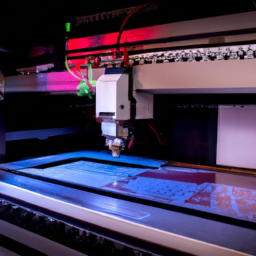

Familiarize Yourself with the Machine’s Operation and Safety Features

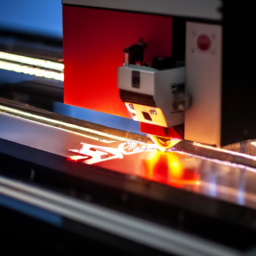

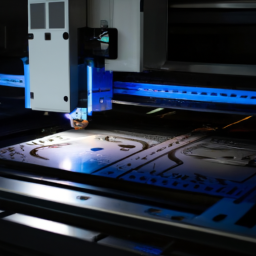

Before you start using your fiber laser cutter, make sure you’re familiar with its operation and safety features, so you can confidently navigate its buttons and switches like a seasoned captain on their ship.

Begin by thoroughly understanding the machine setup, including the location of emergency stops, power switches, and control panels.

Familiarize yourself with the laser safety precautions, such as wearing appropriate protective eyewear and ensuring the machine is properly ventilated.

Take the time to read the user manual and attend any training sessions provided by the manufacturer. This will give you a comprehensive understanding of the machine’s capabilities and potential hazards.

Remember, safety should always be your top priority when operating a fiber laser cutter.

Wear Appropriate Protective Gear

Always ensure you’re properly geared up to protect yourself when operating a fiber laser cutter. Wearing appropriate protective gear is of utmost importance to safeguard against potential hazards.

The intense laser beam emitted by the cutter can cause severe eye damage. To protect your eyes, wear safety goggles that are specifically designed for laser use.

In addition, wear a face shield to shield your face from any sparks, debris, or flying particles that may be generated during the cutting process.

It is also crucial to wear flame-resistant gloves to protect your hands from burns and cuts.

Failure to wear the necessary protective gear can result in serious injuries, such as burns, eye damage, and lacerations.

Don’t compromise your safety – always prioritize wearing the right equipment when using a fiber laser cutter.

Keep the Work Area Clean and Organized

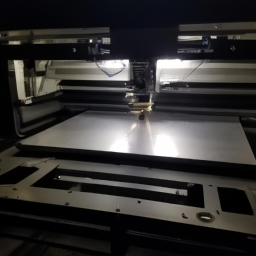

Make sure to maintain a clean and organized work area to prevent any potential accidents or hazards. Work area hygiene is essential when using a fiber laser cutter. Keeping your work area clean and clutter-free is crucial for both your safety and the efficiency of your work. A cluttered work area increases the risk of tripping or falling, which can lead to serious injuries.

Additionally, a messy work area can obstruct your vision and make it difficult to navigate around the machine safely. To ensure a clean and organized work area, make it a habit to clean up any debris, scraps, or waste materials immediately after each use. Store all tools and equipment in designated areas to avoid clutter. Regularly inspect your work area for any potential hazards and address them promptly.

By maintaining a clutter-free environment, you can significantly reduce the risk of accidents and create a safer working environment.

Follow Proper Maintenance and Inspection Procedures

Don’t neglect the importance of following proper maintenance and inspection procedures to ensure the longevity and optimal performance of your machine. Regular maintenance procedures are essential for keeping your fiber laser cutter running smoothly.

This includes cleaning and lubricating the machine components, checking for any loose or worn out parts, and replacing them if necessary. It’s also important to follow the manufacturer’s recommended inspection protocols to identify any potential issues early on. Regular inspections can help prevent major breakdowns and ensure the safety of the operator.

Additionally, make sure to keep a record of all maintenance and inspection activities, including dates and any repairs or replacements made. By following these procedures, you can extend the lifespan of your fiber laser cutter and avoid any unnecessary downtime or accidents.

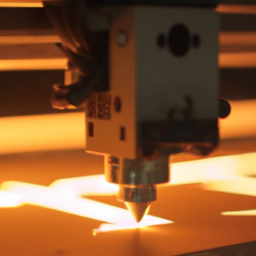

Use Proper Cutting Techniques

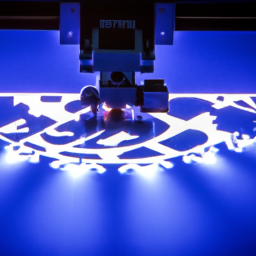

Ensure you’re getting the most out of your machine by mastering proper cutting techniques. When using your fiber laser cutter, it’s essential to follow safety precautions to protect yourself and others.

Firstly, always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a face shield, to shield yourself from flying debris and potential laser beam hazards.

Secondly, make sure to secure the material being cut properly to prevent it from moving during the cutting process. This will help avoid accidents and ensure precise cuts.

Additionally, keep a safe distance from the machine while it’s in operation, as the laser beam can cause serious injuries if not handled correctly.

Lastly, regularly inspect the cutting area for any potential hazards or obstructions and keep the workspace clean and organized.

By following these proper cutting techniques and safety precautions, you can maximize the efficiency and safety of your fiber laser cutter.

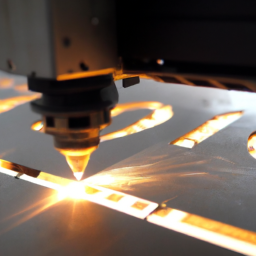

Have an Emergency Plan in Place

It’s important to have an emergency plan in place when operating a fiber laser cutter, so you can respond quickly and effectively in case of any unexpected incidents. Did you know that having an emergency plan can reduce response time by up to 30% and potentially save lives? When working with a fiber laser cutter, it’s crucial to know the location of emergency exits and have a clear evacuation route in mind. In the event of a fire or any other emergency, being able to quickly and safely exit the area is essential. Additionally, having a well-stocked first aid kit nearby is vital in case of any injuries that may occur during operation. The first aid kit should include basic supplies such as bandages, antiseptic solution, and gloves. By having an emergency plan in place and being prepared with the necessary resources, you can ensure the safety of yourself and others when using a fiber laser cutter.

| Emergency Exits | Evacuation Routes | First Aid Kits |

|---|---|---|

| Clearly marked | Planned and practiced | Fully stocked |

| Easily accessible | Unobstructed | Easily accessible |

| Regularly checked | Clearly communicated | Updated regularly |

Frequently Asked Questions

How long does it typically take to familiarize yourself with the operation and safety features of a fiber laser cutter?

It typically takes a few hours to familiarize yourself with the operation and safety features of a fiber laser cutter. To ensure your safety, it’s important to wear the appropriate safety gear, including safety glasses, gloves, and closed-toe shoes.

Familiarization time may vary depending on your prior experience with similar machinery, but it’s crucial to thoroughly understand the machine’s functions and safety protocols before operating it.

What types of protective gear are recommended when using a fiber laser cutter?

When using a fiber laser cutter, it’s crucial to wear the appropriate protective gear to ensure your safety. The recommended safety equipment includes safety glasses or goggles with side shields to protect your eyes from potential laser radiation. It’s also important to wear gloves made of materials that are resistant to heat and sparks. Additionally, wearing a long-sleeved shirt, long pants, and closed-toe shoes will provide further protection against any potential hazards. Always prioritize your safety by wearing the necessary protective gear.

How often should the work area be cleaned and organized to maintain safety?

To maintain safety, it’s crucial to regularly clean and organize your work area. Think of it like tidying up your workspace, as neatness breeds efficiency and safety.

Clean up any debris, remove any potential hazards, and ensure all tools and materials are properly stored. By maintaining work area cleanliness, you reduce the risk of accidents, improve visibility, and create a more organized and efficient work environment.

Remember, safety measures should always be a top priority.

What are some common maintenance and inspection procedures that should be followed for a fiber laser cutter?

To ensure the smooth operation of your fiber laser cutter, it’s crucial to follow proper maintenance procedures and inspection protocols. Regularly inspect the machine for any signs of wear or damage. Pay particular attention to the laser source, lens, and mirrors. Clean and lubricate the moving parts as recommended by the manufacturer.

Additionally, regularly inspect the electrical connections and cooling system. By following these maintenance and inspection procedures diligently, you can minimize the risk of accidents and prolong the lifespan of your fiber laser cutter.

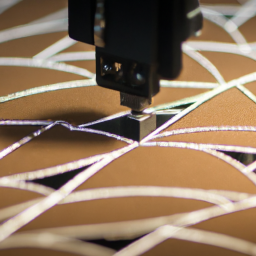

Are there any specific cutting techniques that should be used when operating a fiber laser cutter?

To unleash the full potential of your fiber laser cutter, it’s crucial to master specific cutting techniques. Firstly, make sure the material is securely positioned to prevent any unwanted movement during the cutting process.

Secondly, adjust the focus of the laser beam to achieve precise and clean cuts.

Additionally, use a low power setting for initial test runs before gradually increasing it.

Lastly, regularly perform laser cutter maintenance, including cleaning the lens and checking for any signs of wear or damage, to ensure optimal performance and longevity.

Conclusion

In conclusion, using your fiber laser cutter can be a safe and efficient way to cut materials. By familiarizing yourself with the machine’s operation and safety features, wearing appropriate protective gear, and keeping the work area clean and organized, you can ensure a safe working environment.

Additionally, following proper maintenance and inspection procedures and using proper cutting techniques are essential for preventing accidents and injuries. While it’s true that taking these precautions may require some extra time, they are essential and ultimately save you time and money in the long run.

Remember, safety should always be your top priority when operating a fiber laser cutter.