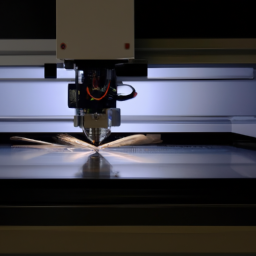

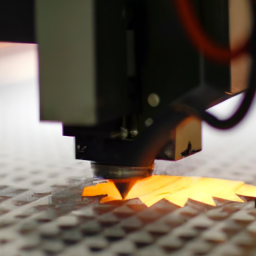

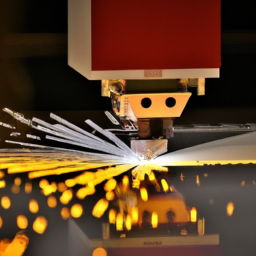

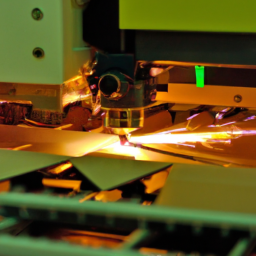

Safely slicing, dicing, and designing with your Nd:YAG laser cutter requires more than just skill and precision. Protection and precaution are paramount when harnessing the power of this cutting-edge technology.

To ensure your safety and that of your team, here are 5 safety tips to keep in mind.

-

First and foremost, don the appropriate Personal Protective Equipment (PPE) to shield yourself from potential hazards.

-

Next, familiarize yourself with the laser cutter’s Operation Manual, understanding its intricacies and protocols.

-

Furthermore, proper ventilation in your workspace is crucial to maintain a safe environment, so ensure adequate airflow.

-

Regularly inspect and maintain your laser cutter to prevent any unforeseen malfunctions.

-

Lastly, implement safe material handling practices, exercising caution when loading and unloading materials.

By following these guidelines, you can confidently navigate the world of laser cutting, knowing that you are prioritizing safety every step of the way.

Key Takeaways

- Wear appropriate personal protective equipment (PPE) such as safety glasses with side shields, a well-fitting face shield, and appropriate gloves.

- Familiarize yourself with the operation manual of the Nd:YAG laser cutter for safe and efficient use.

- Ensure proper ventilation in the workspace to remove fumes and smoke, regulate temperature and humidity, and reduce airborne particles and odors.

- Regularly inspect and maintain the laser cutter, checking for loose or damaged parts, proper alignment of mirrors and lenses, and the condition of coolant and filters.

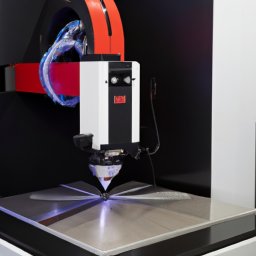

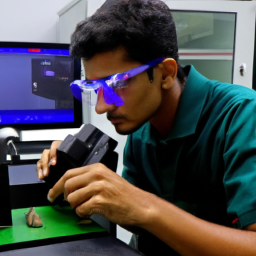

Wear Appropriate Personal Protective Equipment (PPE)

Make sure you’re wearing the right PPE to protect yourself when using your nd:yag laser cutter. Following PPE guidelines is crucial for your safety.

Start by wearing safety glasses with side shields to shield your eyes from laser radiation. Make sure the glasses have a sufficient optical density for the laser wavelength.

Additionally, wear a well-fitting face shield to protect your face and neck from potential hazards such as flying debris.

Don’t forget to wear appropriate gloves to shield your hands from laser beam exposure and potential burns.

Regularly inspect and maintain your PPE to ensure it’s in good condition and provides adequate protection.

Once you have your PPE in place, it’s time to familiarize yourself with the laser cutter’s operation manual, which’ll provide you with important instructions and safety guidelines.

Familiarize Yourself with the Laser Cutter’s Operation Manual

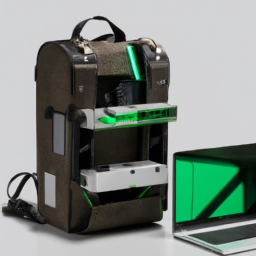

Get to know the laser cutter’s operation manual as your trusted guide to unlocking the secrets of this powerful tool. Acquiring knowledge about the laser cutter’s operation is crucial for ensuring safe and efficient use.

The operation manual provides a comprehensive overview of the machine’s functionalities, safety precautions, and maintenance procedures. It guides you through each step of the laser cutting process, explaining how to set up the machine, adjust the power settings, and troubleshoot any issues that may arise.

By familiarizing yourself with the operation manual, you’ll gain a thorough understanding of the laser cutter’s capabilities and limitations, allowing you to operate it with confidence and precision. This knowledge acquisition will enable you to utilize the machine to its full potential while ensuring your safety and the safety of those around you.

As you delve into the subsequent section about ensuring proper ventilation in your workspace, you’ll be equipped with the operational understanding necessary to create a safe and efficient working environment.

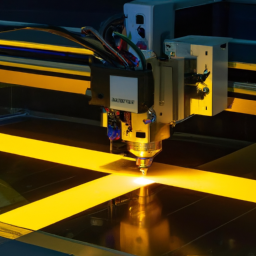

Ensure Proper Ventilation in Your Workspace

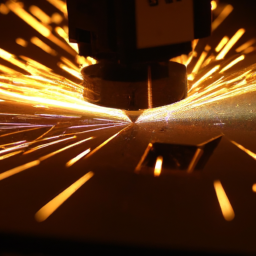

Create a well-ventilated workspace by installing an exhaust system and opening windows to ensure that fumes and smoke are properly ventilated. Proper ventilation is crucial for maintaining a safe working environment and ensuring good air quality in your workspace.

Here are five important reasons why ventilation is important for your safety when using a laser cutter:

- It helps remove harmful fumes and smoke generated during laser cutting.

- It prevents the accumulation of flammable gases, reducing the risk of fire.

- It helps regulate temperature and humidity levels in the workspace, preventing overheating and discomfort.

- It reduces the concentration of airborne particles, protecting your respiratory health.

- It minimizes the odor associated with laser cutting, creating a more pleasant working environment.

Remember, ensuring proper ventilation is just one aspect of maintaining a safe workspace. Next, we’ll discuss the importance of regularly inspecting and maintaining your laser cutter.

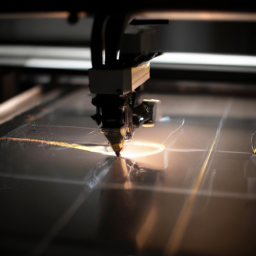

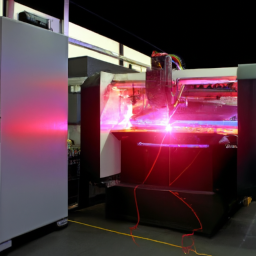

Regularly Inspect and Maintain Your Laser Cutter

Take a moment to ensure the longevity and efficiency of your laser cutter by regularly inspecting and maintaining it, like a car that needs regular tune-ups to keep running smoothly.

To help you stay on top of this, create an inspection checklist and a maintenance schedule.

Inspecting your laser cutter should include checking for any loose or damaged parts, ensuring proper alignment of the mirrors and lenses, and examining the condition of the coolant and filters.

Additionally, cleaning the machine regularly and lubricating moving parts will help prevent any buildup or friction.

By following a regular maintenance schedule, you can catch any potential issues before they become major problems and keep your laser cutter operating at its best.

With a well-maintained machine, you can now move on to implementing safe material handling practices.

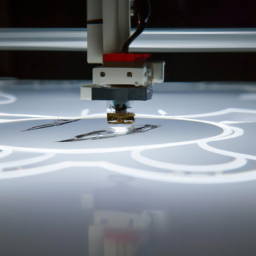

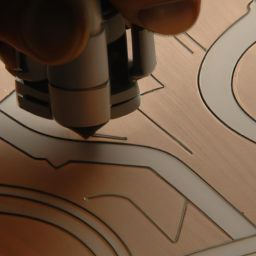

Implement Safe Material Handling Practices

To ensure the wellbeing of both yourself and the materials you work with, it’s crucial to establish responsible practices for handling materials when operating a laser cutter. Creating a safe work environment begins with proper training on safe material handling practices. Here are five important guidelines to keep in mind:

-

Always wear appropriate personal protective equipment (PPE) such as gloves and safety glasses.

-

Use lifting tools or equipment to handle heavy or awkward materials.

-

Keep the work area clean and free from clutter to prevent accidents.

-

Avoid using materials that aren’t recommended for laser cutting, as they may produce harmful fumes or damage the machine.

-

Dispose of waste materials properly to prevent fire hazards and maintain a clean workspace.

By following these guidelines, you can minimize the risk of accidents and create a safe work environment.

Transitioning into the next section, it’s equally important to educate yourself and your team on laser safety guidelines to further enhance workplace safety.

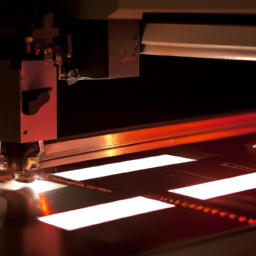

Educate Yourself and Your Team on Laser Safety Guidelines

Familiarize yourself and your team with essential laser safety guidelines to ensure a secure and protected work environment, where the brilliant glow of the laser beams illuminates the path to success. Laser hazard awareness is crucial for everyone involved in laser cutting operations. By understanding the potential risks associated with laser use, you can take necessary precautions to prevent accidents and injuries. Conduct a thorough risk assessment for laser cutting operations, evaluating factors such as the power of the laser, material properties, and ventilation in the workspace. This assessment will help identify potential hazards and determine appropriate safety measures. It is important to continuously educate yourself and your team on laser safety guidelines, staying updated with advancements in technology and best practices. By following these guidelines, you can ensure the safe and efficient use of your ND:YAG laser cutter.

| Laser Hazard Awareness | Risk Assessment for Laser Cutting Operations | |

|---|---|---|

| Understand the potential risks associated with laser use | Evaluate factors such as laser power and material properties | |

| Identify potential hazards | Determine appropriate safety measures | |

| Stay updated with advancements in technology and best practices | Continuously educate yourself and your team on laser safety guidelines | …to ensure a safe and effective use of lasers in different applications and environments. |

Frequently Asked Questions

What are some common injuries that can occur when using a Nd:YAG laser cutter?

Common laser accidents that can occur when using an Nd:YAG laser cutter include eye injuries from direct exposure to the laser beam, burns from contact with the hot materials, and electrical shocks from improper handling of the equipment.

To prevent these injuries, it’s crucial to wear appropriate safety goggles, use protective gloves, and ensure proper grounding of the machine.

Additionally, regular maintenance and training on safe operating procedures are essential to minimize the risk of accidents.

Are there any specific regulations or certifications needed to operate a Nd:YAG laser cutter?

To operate a nd:yag laser cutter, you must adhere to specific regulations and obtain necessary certifications. These measures are crucial to ensure the safe and effective use of the equipment. Compliance with regulations guarantees that you’re following industry standards and guidelines, minimizing risks and maintaining a secure environment. Obtaining certifications demonstrates your proficiency in operating the laser cutter, validating your competence and understanding of the necessary precautions. By adhering to these regulations and certifications, you can ensure the safe operation of your nd:yag laser cutter.

How often should I inspect and maintain my laser cutter?

To ensure optimal performance and safety, it’s crucial to adhere to a recommended inspection schedule and maintenance frequency for your nd:yag laser cutter.

Regular inspections should be conducted to check for any signs of wear and tear, loose components, or potential hazards.

Maintenance tasks, such as cleaning, lubricating moving parts, and calibrating the laser, should be performed according to the manufacturer’s guidelines.

By following these procedures diligently, you can minimize the risk of malfunctions and maintain the longevity of your laser cutter.

What are some safe material handling practices to follow when using a Nd:YAG laser cutter?

When operating a nd:yag laser cutter, it’s crucial to practice safe material handling. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself from potential hazards.

Always ensure that the work area is clear of any flammable materials and that the laser cutter is properly grounded.

Additionally, handle materials with care, avoiding any sharp or jagged edges that could cause injury.

Following these safe material handling practices is essential for a successful and accident-free laser cutter operation.

Where can I find additional resources or training on laser safety guidelines?

To ensure laser safety, seek additional resources and training on laser safety guidelines. Expand your knowledge and expertise with comprehensive training programs offered by reputable organizations.

Access online resources, such as laser safety websites and publications, to stay up-to-date with the latest guidelines and best practices.

Remember, "Better safe than sorry." Equip yourself with the necessary knowledge and skills to handle your nd:yag laser cutter safely and responsibly.

Conclusion

In conclusion, it’s crucial that you prioritize safety when operating your nd:yag laser cutter. By wearing the appropriate PPE and familiarizing yourself with the operation manual, you can minimize the risk of accidents and injuries.

Ensure proper ventilation and regularly inspect and maintain the machine. Implement safe material handling practices to keep yourself and your team safe.

Remember, safety isn’t an option, it’s a must! So don’t be a ‘laser-loser,’ follow these tips and stay safe.