Are you ready to unlock the full potential of your 3D laser cutting machine?

Imagine a precision tool that can effortlessly transform your designs into stunning reality. With just a few expert tips, you can optimize your machine’s performance and achieve the best results possible.

In this article, we will delve into the world of 3D laser cutting and provide you with five essential tips to enhance your cutting experience. From understanding the fundamentals to fine-tuning your settings, we will guide you through every step of the process.

By following these techniques, you will maximize efficiency, maintain your machine’s longevity, and stay up-to-date with the latest advancements. Get ready to elevate your craftsmanship and produce impeccable results with your 3D laser cutting machine.

Let’s dive in!

Key Takeaways

- Understanding laser technology and CAD software is crucial for optimizing machine performance and achieving accurate and detailed designs.

- Ensuring compatibility between design files and the laser cutting machine is essential for a smooth workflow.

- Regular calibration and maintenance of the machine, including adjusting laser power and focus, cleaning, and inspecting for debris buildup, are necessary for precise cutting and avoiding errors.

- Testing, fine-tuning settings, and staying updated with new techniques and technologies are important for enhancing the performance of the 3D laser cutting machine.

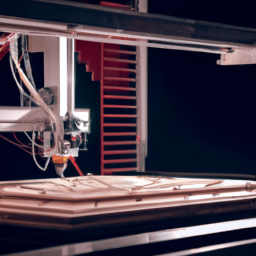

Understand the Basics of 3D Laser Cutting

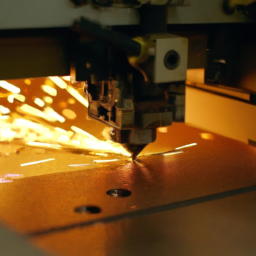

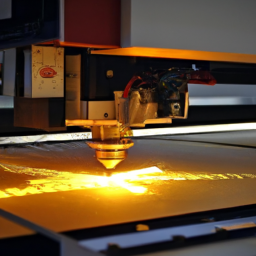

To get the best results from your 3D laser cutting machine, you need to understand the basics of laser technology and how it can benefit your cutting process. Laser cutting uses a high-powered laser beam to melt, burn, or vaporize materials, resulting in precise and intricate designs. The laser beam is controlled by computer software, allowing for accurate cuts and shapes.

The benefits of 3D laser cutting include increased speed, versatility, and the ability to cut a wide range of materials. By understanding the basics of laser technology, you can make informed decisions about the settings and parameters to use for your specific project.

Now that you have a grasp on the basics, it’s time to prepare your design and files properly for optimal results.

Prepare Your Design and Files Properly

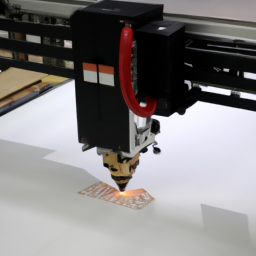

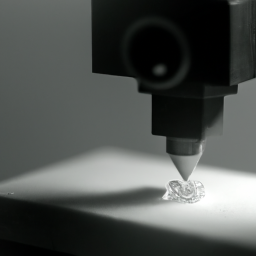

To prepare your design and files properly for 3D laser cutting, you need to use CAD software to create accurate and detailed designs. This will ensure that your design is precisely translated into the final product.

Additionally, it’s crucial to ensure that your files are compatible with your laser cutting machine. Compatibility issues can lead to errors or inefficiencies in the cutting process.

Use CAD software to create accurate and detailed designs

When using your 3D laser cutting machine, make sure to utilize CAD software for creating precise and intricate designs. CAD software is essential for achieving the highest level of accuracy and detail in your designs. It allows you to create complex geometries and precise measurements, ensuring that your final product meets your exact specifications.

To ensure precision, it is crucial to perform thorough testing and validation of your designs using design software. This will help you identify any potential issues or errors before sending your design to the laser cutting machine. By conducting precision testing, you can make necessary adjustments and corrections, resulting in a flawless final product.

Incorporating CAD software into your design process also allows for efficient collaboration and sharing of files. You can easily communicate your design intent to others involved in the manufacturing process, ensuring everyone is on the same page.

To ensure that your files are compatible with your laser cutting machine, it is important to follow specific file format requirements and guidelines. This will help prevent any compatibility issues and ensure a smooth workflow.

Ensure that your files are compatible with your laser cutting machine

Make sure your files are compatible with the laser cutting machine to avoid any frustrating technical difficulties. File compatibility is crucial for seamless operation and accurate results.

Before sending your files to the machine, ensure that they are in a format that is supported by the machine’s software. Different laser cutting machines have different file requirements, such as DXF or AI formats.

Additionally, it’s essential to consider machine calibration. The laser cutting machine must be properly calibrated to ensure precise cutting and avoid any errors or misalignments. Regularly check and calibrate the machine to maintain optimal performance.

Once you’ve ensured file compatibility and machine calibration, you can move on to optimizing cutting parameters for efficiency. This will further enhance the performance and productivity of your 3D laser cutting machine.

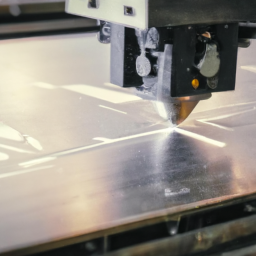

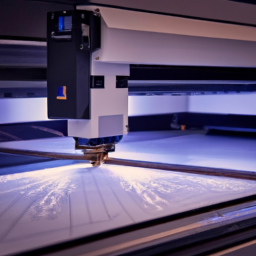

Optimize Cutting Parameters for Efficiency

Getting the most bang for your buck with your 3D laser cutting machine? Optimize those cutting parameters for maximum efficiency and watch the magic happen!

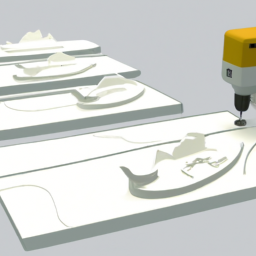

To improve cutting speed, consider increasing the laser power and reducing the cutting speed. This will allow the laser to cut through the material faster, saving you valuable time. Additionally, adjusting the focus of the laser beam can help improve the quality of the cut.

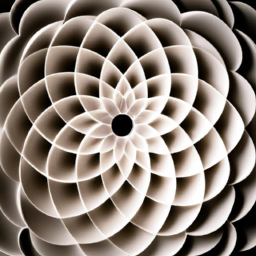

To reduce material waste, make sure to optimize the nesting of your parts. By arranging the parts efficiently on the material, you can minimize the amount of wasted material.

Lastly, consider using compressed air or gas assist to blow away debris during the cutting process, as this can help prevent material from sticking to the laser. Maintaining and cleaning your machine regularly is crucial for optimal performance.

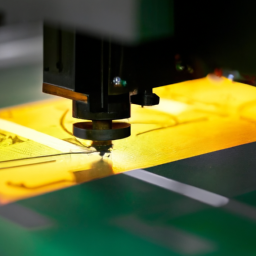

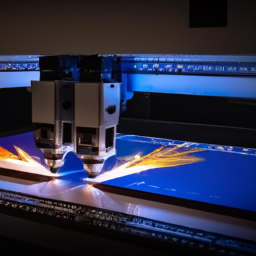

Maintain and Clean Your Machine Regularly

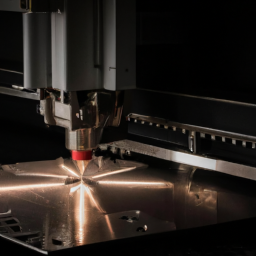

To keep your machine running smoothly and maintain cutting precision, it’s crucial to keep it clean and free from debris.

Regularly inspect and clean the machine to prevent any damage that may occur due to the accumulation of dirt and debris.

Additionally, make sure to regularly check and replace any worn-out parts to ensure optimal performance and avoid any potential issues that may arise during the cutting process.

Keep the machine clean and free from debris to prevent damage and maintain cutting precision

Ensuring a clean and debris-free environment for your 3D laser cutting machine is crucial in preserving its cutting precision and preventing any potential damage. To achieve this, regularly clean your machine to remove any accumulated debris or dust that may affect the cutting process. Additionally, keep the machine free from any loose materials or objects that could interfere with its operation.

To illustrate the importance of maintaining a clean machine, consider the following table:

| Potential Damage | Impact on Cutting Precision |

|---|---|

| Debris buildup | Reduced accuracy and quality of cuts |

| Loose materials | Interference with the cutting process |

By keeping your machine clean and free from debris, you can prevent these potential issues and ensure optimal performance. However, it is also important to regularly check and replace worn-out parts to maintain cutting precision. This will be discussed in the subsequent section.

Regularly check and replace worn-out parts to ensure optimal performance

To maintain the efficiency and precision of your 3D laser cutting machine, it’s crucial to regularly check and replace worn-out parts. Over time, the constant use and high temperatures can cause components to wear down, leading to decreased performance and potential damage to the machine.

By inspecting the machine and identifying any worn-out parts, you can ensure optimal performance and prevent costly repairs or downtime. Additionally, it’s essential to check the machine calibration to guarantee accurate cutting. Periodically troubleshoot common issues such as misalignment or improper focusing, as these can significantly affect the quality of the cuts.

By addressing these concerns promptly, you can maximize the capabilities of your machine.

Now, let’s delve into the next section and explore how to test and fine-tune your settings for ideal results.

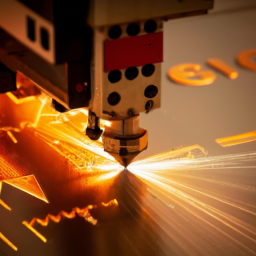

Test and Fine-tune Your Settings

Get ready to see your 3D laser cutting machine reach its full potential by testing and fine-tuning your settings for optimal results. Here are four testing techniques and troubleshooting methods to help you achieve the best outcomes:

-

Start with small test cuts to determine the ideal speed and power settings for different materials. This will minimize wasted time and resources.

-

Use a variety of test patterns to assess the accuracy and precision of your machine. Adjust the settings accordingly to achieve the desired level of detail.

-

Regularly check and calibrate the focus of your laser beam to ensure consistent cutting depth and clean edges.

-

Experiment with different nozzle sizes and gas pressures to optimize the cutting quality and speed for specific materials.

By employing these testing techniques and troubleshooting methods, you can fine-tune your settings and achieve the best results with your 3D laser cutting machine. As you continue to refine your techniques, make sure to stay updated with new techniques and technologies to further enhance your machine’s performance.

Stay Updated with New Techniques and Technologies

To achieve optimal results from your 3D laser cutting machine, it is crucial to continuously update your knowledge and skills. As the field of laser cutting evolves rapidly, staying updated with new techniques and technologies is essential. By doing so, you can take advantage of the latest advancements to enhance the precision and efficiency of your cutting processes.

New laser cutting techniques are constantly emerging, enabling you to explore innovative ways to achieve intricate designs and complex shapes. Additionally, futuristic laser cutting technologies are being developed, promising even greater speed, accuracy, and versatility. By keeping abreast of these advancements, you can stay ahead of the competition and offer cutting-edge solutions to your clients.

To assist you in visualizing the advancements in laser cutting technologies, here is a table showcasing the evolution of laser cutting techniques:

| Laser Cutting Techniques | Description | Benefits |

|---|---|---|

| Traditional Laser Cutting | Utilizes high-powered lasers to cut through materials | Precise and clean cuts |

| Fiber Laser Cutting | Utilizes fiber-optic technology for increased power and efficiency | Faster cutting speeds, reduced maintenance costs |

| CO2 Laser Cutting | Utilizes a carbon dioxide laser for versatile cutting capabilities | Suitable for a wide range of materials |

| Ultrafast Laser Cutting | Utilizes ultrafast laser pulses for minimal heat-affected zones | Ideal for delicate materials and intricate designs |

| Hybrid Laser Cutting | Combines multiple laser sources for enhanced cutting capabilities | Increased flexibility and versatility |

By staying updated with new laser cutting techniques and embracing futuristic laser cutting technologies, you can unlock the full potential of your 3D laser cutting machine and achieve exceptional results.

Frequently Asked Questions

Can I use a 3D laser cutting machine for materials other than metal?

Yes, you can use a 3D laser cutting machine for materials other than metal. These machines are also compatible with a wide range of non-metal materials such as wood, acrylic, plastic, and even certain types of fabric.

The advantages of using a 3D laser cutting machine for non-metal materials include high precision, clean and smooth cuts, minimal material wastage, and the ability to create intricate designs. This makes it an excellent choice for various applications in industries such as signage, prototyping, and crafts.

How do I ensure that my design is compatible with the 3D laser cutting machine?

To ensure compatibility between your design and the 3D laser cutting machine, it’s crucial to avoid common mistakes and follow troubleshooting tips.

Common mistakes include using unsupported file formats or insufficiently detailed designs. Troubleshooting tips involve double-checking the design’s dimensions and ensuring it doesn’t exceed the machine’s capabilities.

Additionally, optimizing the design for the specific material being cut can prevent issues during the laser cutting process and result in the best possible results.

What are the common issues that can arise when cutting with a 3D laser cutting machine?

Common troubleshooting issues that can arise when cutting with a 3D laser cutting machine include material warping, excessive heat generation, misalignment, inconsistent cutting depths, and nozzle clogging.

To maximize efficiency, ensure that the material is properly secured and supported. Optimize the cutting parameters for each material type. Regularly clean and inspect the machine, and use high-quality cutting nozzles.

These tips will help you overcome common challenges and achieve the best results with your 3D laser cutting machine.

How often should I clean and maintain my 3D laser cutting machine?

To ensure optimal performance, it’s crucial to clean and maintain your 3D laser cutting machine regularly. Best practices for cleaning include removing debris and dust from the machine’s components using compressed air or a soft brush.

Additionally, lubricate moving parts with appropriate lubricants to prevent friction and wear. To troubleshoot common problems, consult the machine’s manual or contact technical support for guidance.

Regular cleaning and maintenance will help prolong the lifespan of your machine and maximize its cutting capabilities.

Are there any safety precautions I should take when operating a 3D laser cutting machine?

To ensure operator safety while using a 3D laser cutting machine, it’s crucial to take appropriate safety precautions.

Prioritize wearing safety goggles and gloves to protect your eyes and hands from potential hazards.

Additionally, always operate the machine in a well-ventilated area to minimize exposure to fumes.

Regularly inspect the machine for any damaged parts and maintain a safe distance from the laser beam during operation.

Following these safety measures will greatly reduce the risk of accidents and ensure a secure working environment.

Conclusion

To achieve the best results from your 3D laser cutting machine, it’s crucial to understand the basics. Prepare your designs meticulously and optimize cutting parameters. Maintain and clean your machine regularly. Test and fine-tune your settings. By following these five tips, you’ll unlock the true potential of your machine and unleash your creativity.

Just like a skilled conductor leading an orchestra, you’ll harness the power of precision and efficiency to create masterpieces that’ll leave everyone in awe. Embrace these techniques and stay updated with new advancements to elevate your laser cutting game to new heights.